Automatic boxing equipment

An automatic boxing and equipment technology, applied in the direction of packaging, transportation and packaging, single objects, etc., can solve the problems that do not meet the needs of efficient and intelligent development, troublesome processing process, complicated adjustment process, etc., to improve the success rate of opening the box, high Cartoning efficiency and the effect of improving the overall running speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

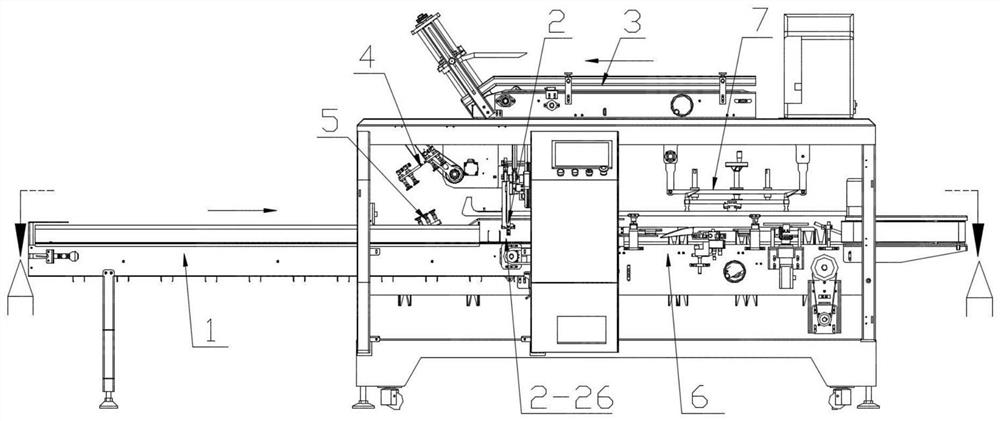

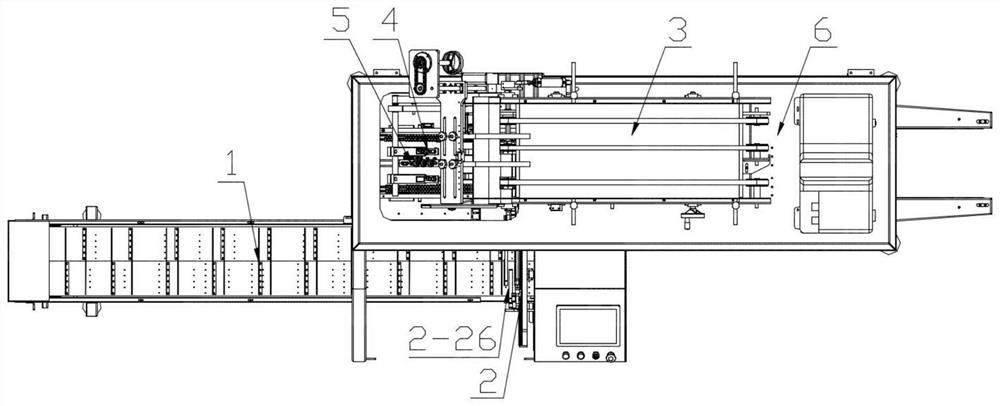

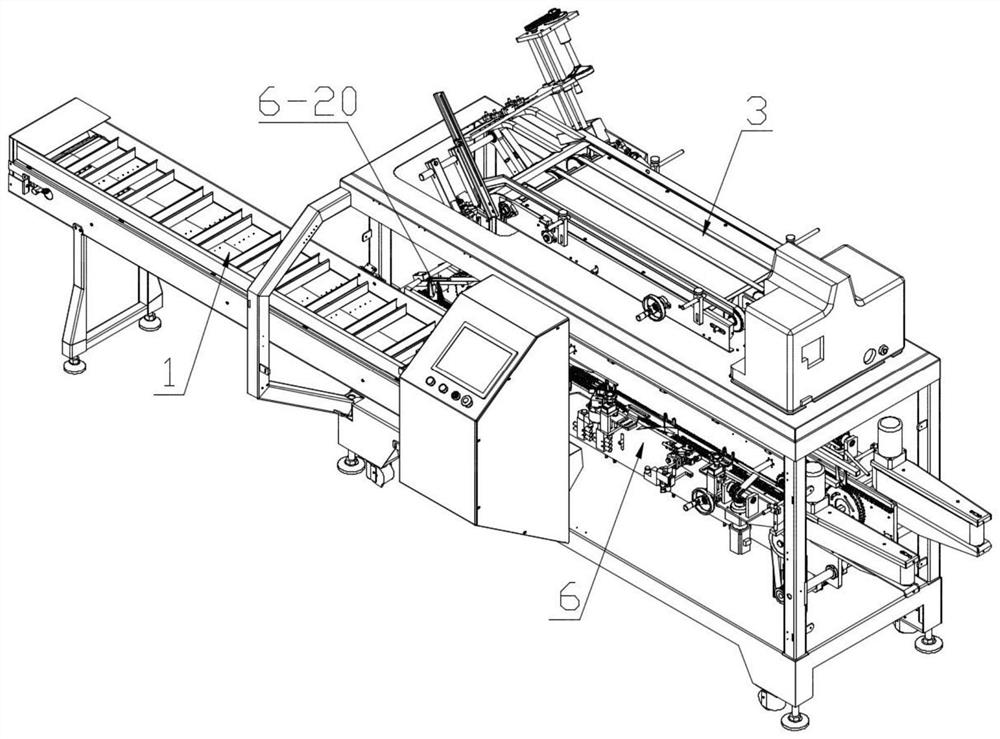

[0097] As a preferred embodiment of the present invention, this embodiment discloses an automatic boxing equipment, which can automatically send materials 8 into the packaging boxes quickly and accurately, so as to better realize the packaging of materials 8. boxing. like Figure 1-4 As shown, the automatic box packing equipment includes a feeding device 1, a material pushing device 2, a packaging box conveying device 3, a box opening device, an output device 6 and a box pressing device 7, and the output device 6 is used to realize the loading of materials 8 The transportation of the packaging box, and the earring and sealing of the packaging box are realized during the transportation process. Specifically, it includes a box-entry end and a box-exit end. The box-entry end is provided with a box receiving station 6-20 and a box-input station 6-21 in sequence. During the station 6-21, the material 8 can be pushed into the packing box. Both the packing box conveying device 3 a...

Embodiment 2

[0118] As another preferred embodiment of the present invention, this embodiment further improves the pushing device 2 on the basis of Embodiment 1, such as Figure 9 As shown, when the material 8 reaches the pushing station 2-26, the pushing device 2 first presses the material 8 from the top of the material 8 through the pressing plate 2-15, and then pushes the material 8 into it through the pushing hand plate 2-14. packing box, and in the process of pushing in, the pressing plate 2-15 moves horizontally towards the packing box direction together with the push hand plate 2-14.

[0119] Further, the pushing device 2 includes a main body plate 2-1, a drive mechanism 2-2, a drive mechanism 2 2-3, a swing arm 2-4, a connecting rod 2-5, a connecting rod 2 2-6, Horizontal slider 1 2-7, horizontal slider 2 2-8, horizontal slide rail 2-9, connecting plate 2-10, up and down slider, up and down slide rail 2-13, up and down reciprocating mechanism, push hand plate 2- 14 and the pressin...

Embodiment 3

[0123] As the best implementation mode of the present invention, on the basis of embodiment 2, refer to the attached description Figure 9-14 , the first horizontal slider 2-7 and the second horizontal slider 2-8 are respectively equipped with an adapter plate 2-19, and the first connecting rod 2-5 and the second connecting rod 2-6 are respectively hinged on the adapter plate 2-19 , using the adapter plate 2-19 can make the installation more convenient and firm. The push hand plate 2-14 and the pressing plate 2-15 are also respectively installed on the adapter plate 2-19. The up and down sliders are divided into up and down slider one 2-11 and up and down slider two 2-12, correspondingly two up and down sliders 2-13 are installed on the other side of the main board 2-1. Pushing hand plate 2-14 is mainly made up of vertical adjusting plate one 2-20 and horizontal pushing plate 2-21, and pushing hand plate 2-14 is anti-" L " shape. Described pressing plate 2-15 is mainly made ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap