Wood floor without pressing strip and construction method

A wooden floor and layering technology, which is applied in the processing of building materials, construction, floors, etc., can solve the problems of reducing the joint degree of wooden floor and ceramic tile installation, it is difficult to ensure the flatness of wooden floor installation, and it is easy to leave gaps, etc., to achieve Improve installation flatness and support stability, improve wedging aesthetics, and improve the effect of connection flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The implementation of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

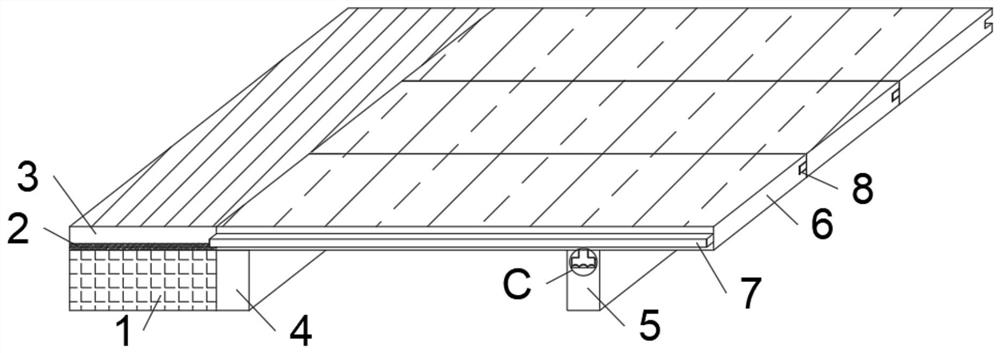

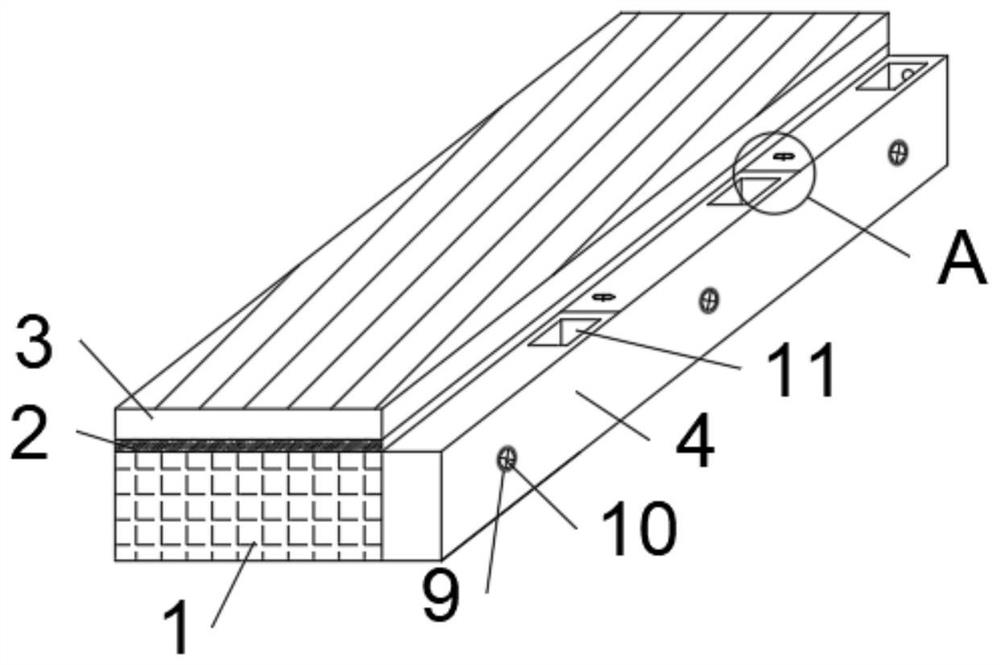

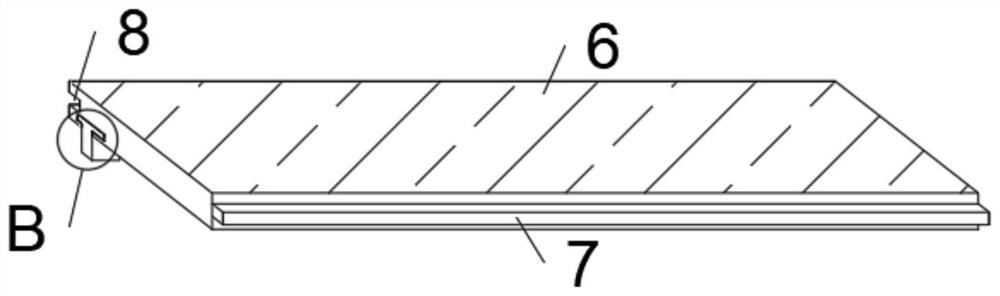

[0045] like Figure 1-Figure 9 As shown, the non-layer wooden floor provided by this embodiment includes a concrete threshold stone 1 and a wooden floor body 6, the upper end surface of the concrete threshold stone 1 is provided with a door brick 3 through the cement bonding surface 2, and the outer side of the concrete threshold stone 1 is The side is connected with a first keel 4, and the first keel 4 is provided with evenly distributed first threaded holes 9, and the first threaded holes 9 are provided with first fastening bolts 10, and the concrete threshold stone 1 and the first keel 4 pass through the first A fastening bolt 10 is fixedly connected, thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com