Internal and external parameter calibration method based on known camera position

A technology of camera position and calibration method, which is applied in image data processing, instruments, calculations, etc., can solve the problems of many marking points, high cost of acquiring accurate marking points, and multiple solutions, and achieves the effect of fewer marking points.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

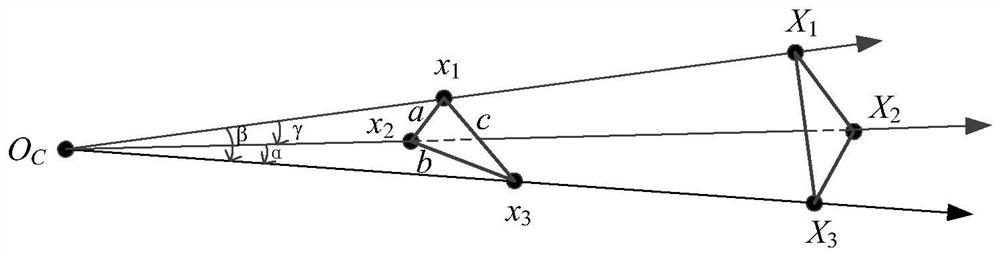

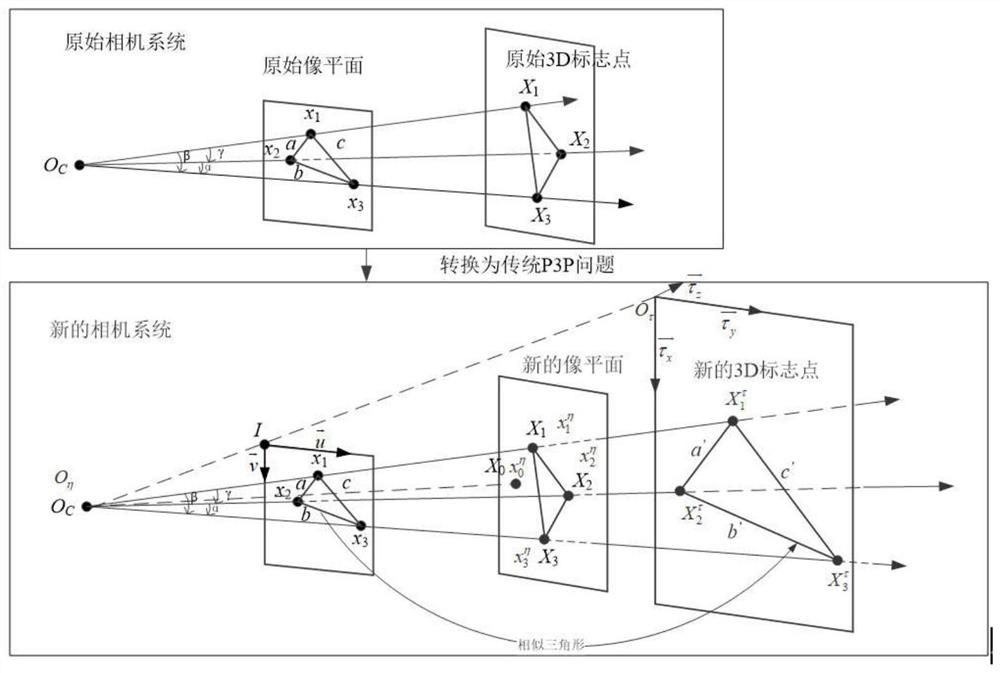

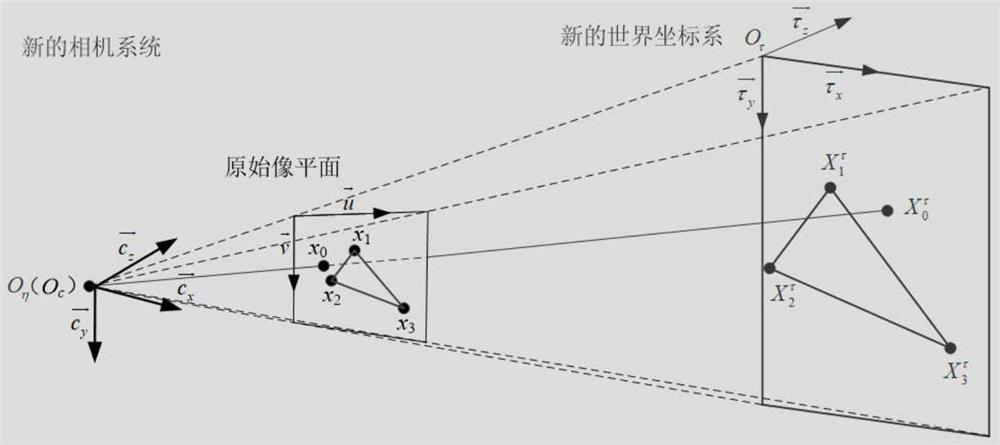

Method used

Image

Examples

Embodiment 1

[0100] The present invention is illustrated with a case by using a simulation method. Suppose the world coordinate system S w with the camera coordinate system S c Parallel, that is, the theoretical value of the rotation matrix in the external parameters is

[0101]

[0102] During the simulation, set the three marker points as

[0103] x 1 =(-20 -10 200)

[0104] x 2 =(20 -10 200)

[0105] x 3 =(20 -5 200)

[0106] The camera position coordinates are

[0107] o c =(0 0 0)

[0108] The focal length of the lens is 50mm, the resolution is 1280×800, and the pixel size is 14μm. According to the pinhole imaging model, the pixel coordinates after imaging are obtained as

[0109] x 1 =(282.8571 221.4286)

[0110] x 2 =(997.1429 221.4286)

[0111] x 3 =(997.1429 310.7143)

[0112] According to the internal and external parameter calibration method proposed by the present invention, it is obtained

[0113]

[0114]

[0115]

[0116] After the focal length...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com