A kind of denture colorimetric mold forming mold

A molding and colorimetric technology, applied in the field of denture colorimetry, can solve problems such as differences in optical properties of the surface of colorimetric molds, and achieve the effect of improving colorimetric accuracy, ensuring colorimetric accuracy, and improving colorimetric effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

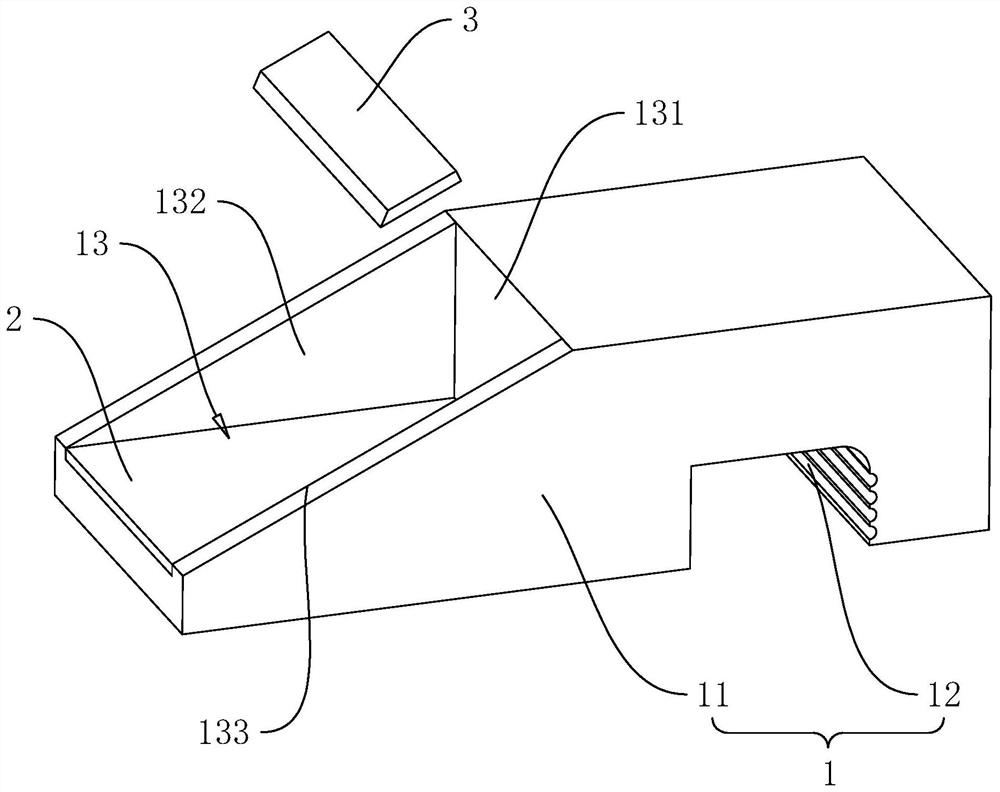

[0036] The embodiment of the present application discloses a colorimetric mold forming mold for a denture. refer to figure 1 , including the box body 1, the bottom plate 2 and the scraper 3. The box body 1 includes a molding part 11 and a hand-held part 12. The molding part 11 is used to fill the ceramic powder for forming the denture colorimetric mold.

[0037] The upper surface of the molding part 11 is inclined, and the lower end of the inclined surface is located on the side of the box body 1 away from the hand-held part 12 .

[0038] A forming groove 13 for filling ceramic powder is opened in the forming part 11 . The upper end of the forming groove 13 communicates with the inclined surface. The three side walls of the molding groove 13 are respectively set as a first side wall 131 , a second side wall 132 and a third side wall 133 , wherein the first side wall 131 is close to the handle portion 12 , the second side wall 132 and the third side The walls 133 are arrange...

Embodiment 2

[0053] The embodiment of the present application discloses a denture colorimetric mold forming mold, which is different from the first embodiment in that refer to Figure 4 , and also includes a side panel assembly 4 .

[0054] refer to Figure 5 , the side panel assembly 4 includes a first side panel 41 , a second side panel 42 and a third side panel 43 . The bottoms of the first side plate 41 , the second side plate 42 and the third side plate 43 are all connected to the bottom plate 2 , wherein the first side plate 41 is in close contact with the first side wall 131 of the molding groove 13 , and the second side plate 42 The upper end surfaces of the third side plate 43 and the second side plate 43 are inclined, and the second side plate 42 and the third side plate 43 are in close contact with the second side wall 132 and the third side wall 133 of the molding groove 13 respectively.

[0055] The upper end surface of the bottom plate 2 is provided with several mounting ho...

Embodiment 3

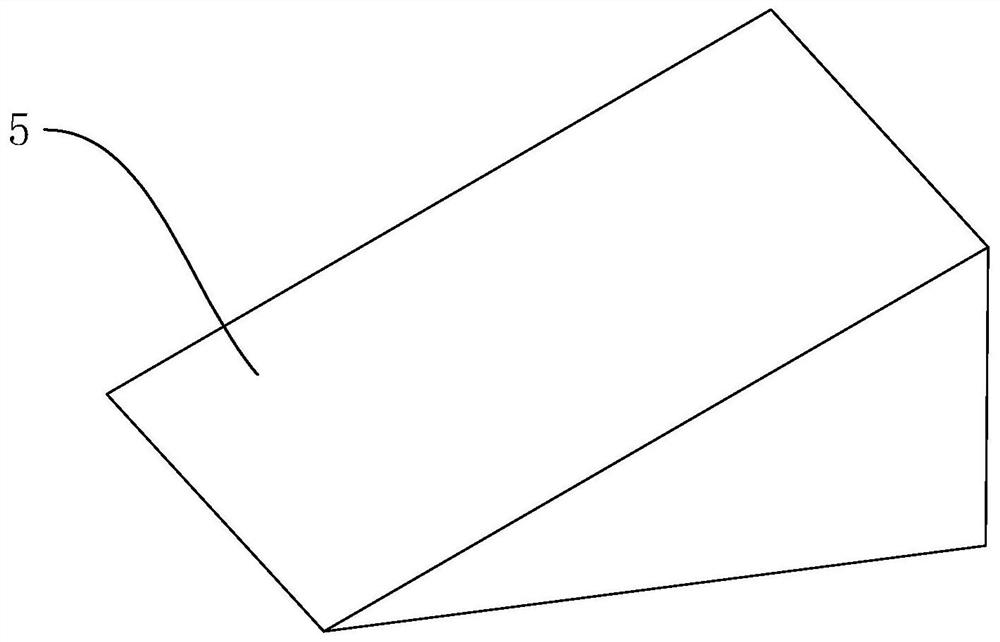

[0071] refer to Figure 7 , the embodiment of the present application discloses a denture colorimetric mold forming mold, which is different from the first embodiment in that the second side wall 132 and the third side wall 133 of the forming groove 13 are arranged in a stepped shape, that is, the denture colorimetric mold The color number of the mold is gradually increasing or decreasing, which is helpful for the measurement and determination of the thickness of the colorimetric mold of the denture.

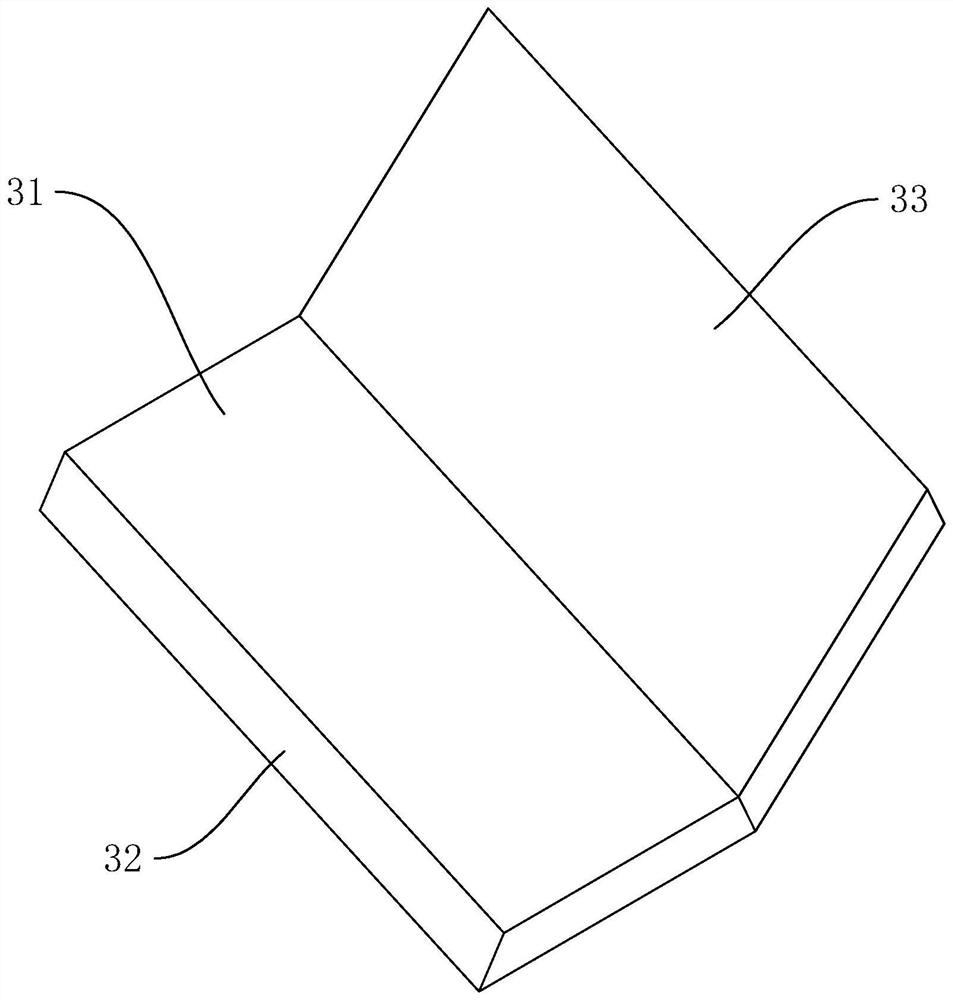

[0072] The scraping member 3 can be cut down along the stepped second side wall 132 and the third side wall 133 to scrape off excess ceramic powder from the forming groove 13 , and the scraping member 3 can be set as a scraper 31 at this time. or rope.

[0073] The scraper 31 can also be set in a stepped shape, and when cutting the excess ceramic powder, it moves from the stepped side wall on one side of the molding groove 13 to the stepped side wall on the other side, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com