Hoisting equipment for fabricated building construction

A technology for building construction and hoisting equipment, applied in hoisting devices, transportation and packaging, load hoisting elements, etc., can solve problems such as reduced stability, four steel bars cannot be aligned at the same time, and reduced structural stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

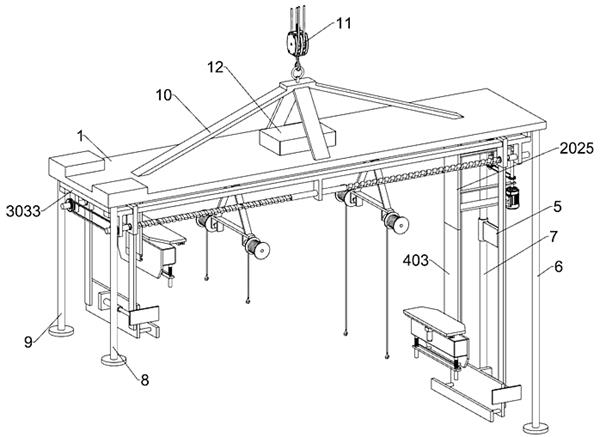

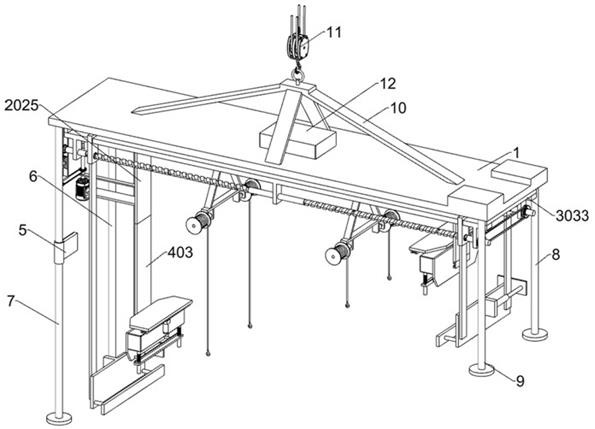

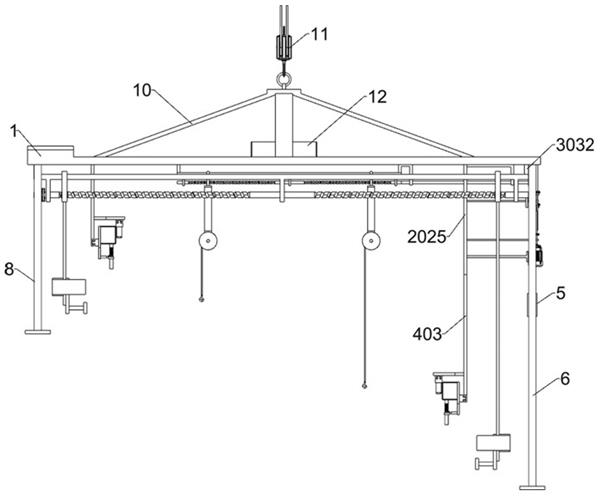

[0031] A hoisting device for prefabricated building construction, such as Figure 1-3 As shown, it includes a support plate 1, a hoisting assembly, a hole assembly, a grouting assembly, a control panel 5, a first support rod 6, a second support rod 7, a third support rod 8, a fourth support rod 9, a first balance The frame 10, the first hook 11 and the first storage battery 12; the lower surface of the support plate 1 is fixedly connected with the hoisting assembly; the lower surface of the support plate 1 is fixedly connected with the hole assembly; A grouting component is fixedly connected to the surface; the lower surface of the right rear part of the support plate 1 is fixedly connected with the first support rod 6; the lower surface of the front right part of the support plate 1 is fixedly connected with the second support rod 7; Three support rods 8; the fourth support rod 9 is fixedly connected to the lower surface of the left front part of the support plate 1; the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com