Primary equipment defect prediction model prediction method based on data mining

A technology of data mining and primary equipment, applied in prediction, data processing applications, character and pattern recognition, etc., can solve problems such as insufficient research depth and accuracy to be improved, and achieve the effect of ensuring safe and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: A data mining-based prediction method for a primary equipment defect prediction model. The equipment defect prediction model is applicable to the defect prediction of primary power transmission equipment in the main network under the jurisdiction of the power grid company. The prediction model of the present invention is based on transformer expansion, and the specific content includes the overall prediction of defect quantity, the group prediction of defect quantity and the defect characteristic curve model of single equipment. The prediction of defects is helpful for maintenance personnel to focus on the parts and components with high defect occurrence in advance, prevent defects in time, and ensure the safe and stable operation of equipment; the method includes the following steps:

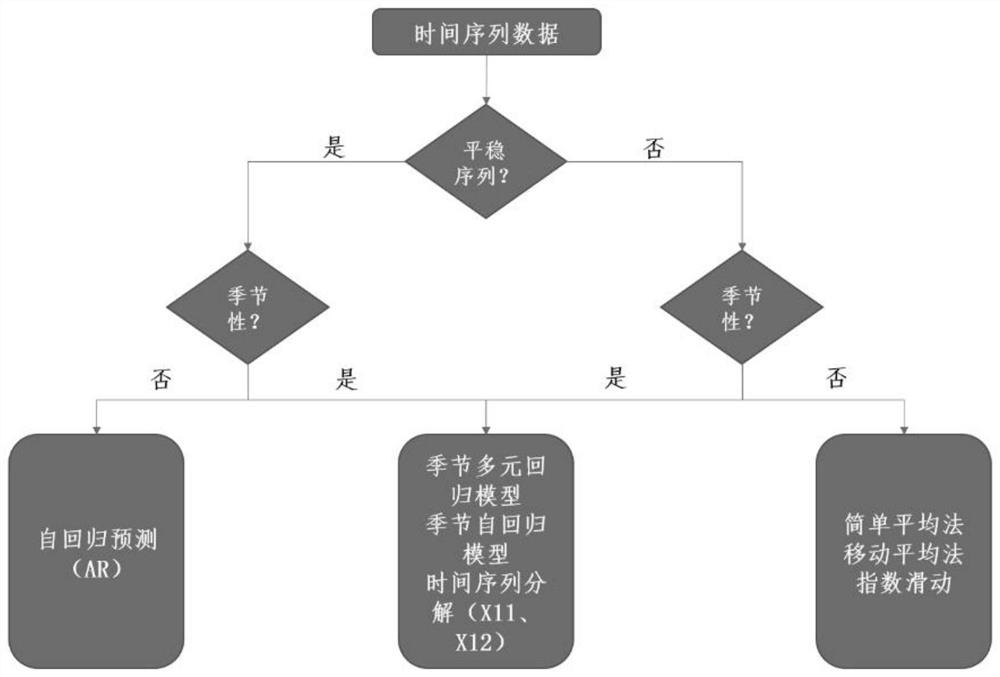

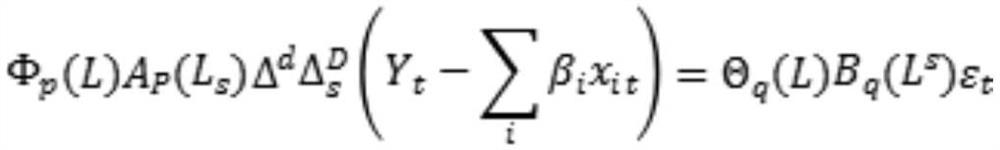

[0039] Step 1: Overall prediction of defect quantity: By obtaining historical defect data, use data mining algorithm to predict the development trend of defect data. The def...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap