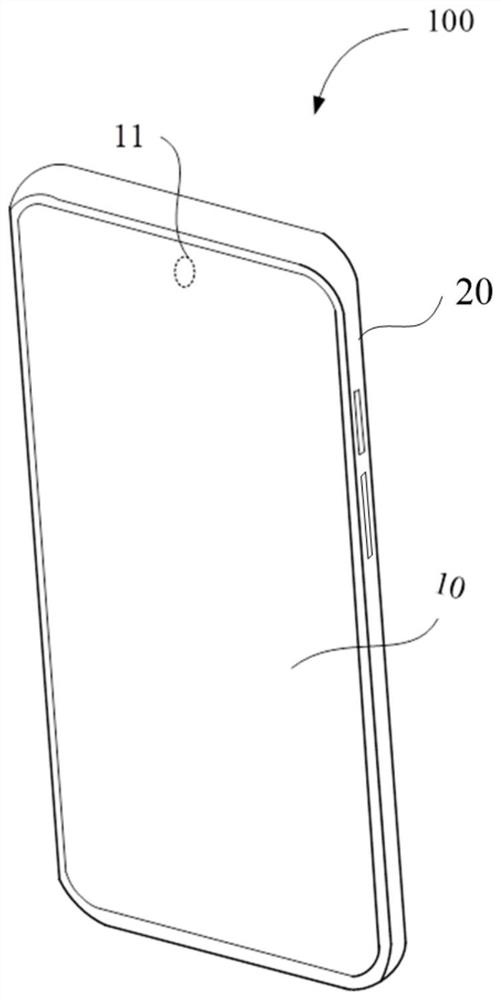

Camera module and electronic device

A camera module and wearing technology, applied in the direction of TV, electrical components, image communication, etc., can solve the problems of large friction force of the camera module, affecting the speed and accuracy of zooming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

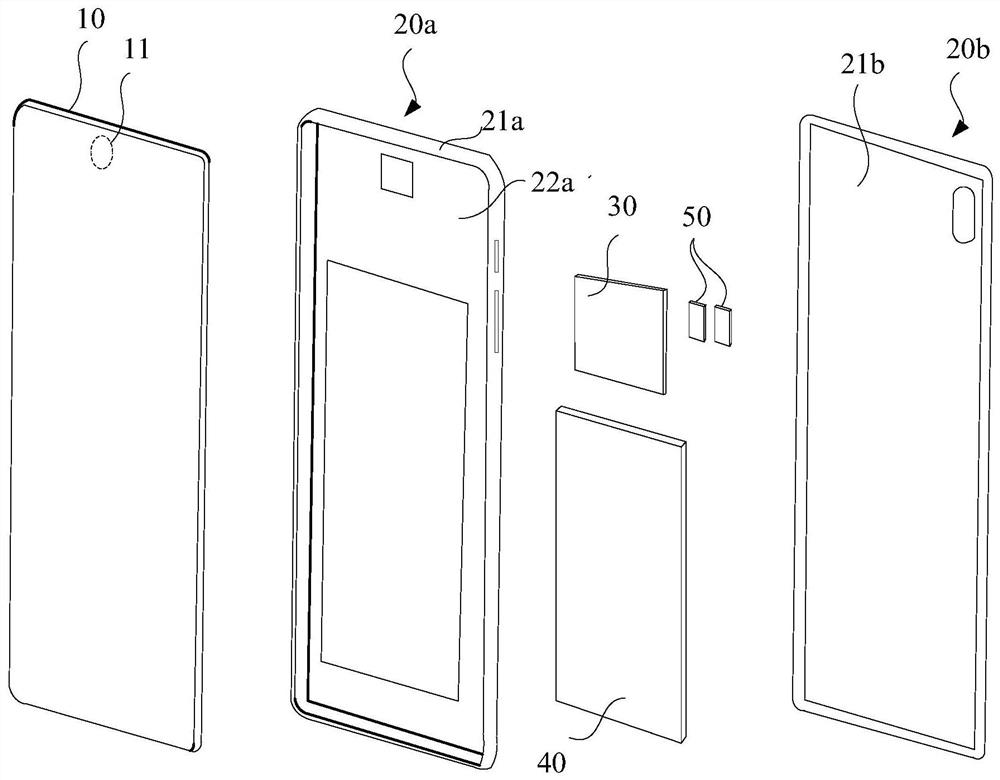

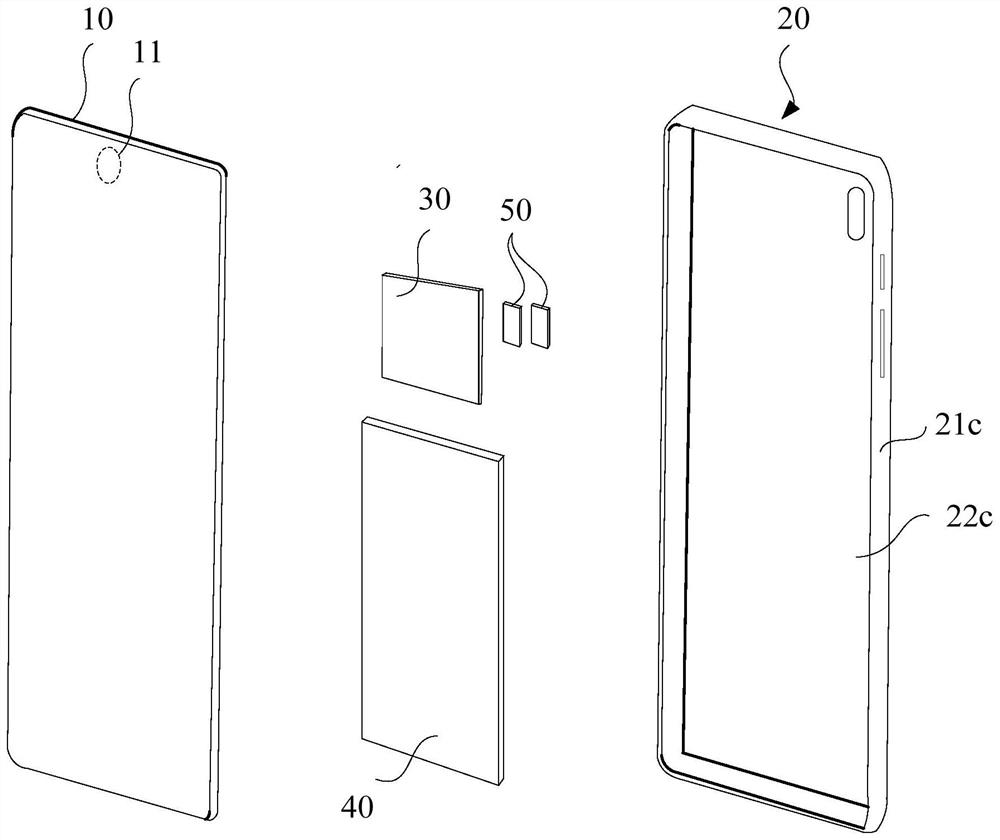

[0077] The terms used in the embodiments of the application are only used to explain the specific embodiments of the application, and are not intended to limit the application. The implementation of the embodiments of the application will be described in detail below with reference to the accompanying drawings.

[0078] In the camera module and electronic equipment provided in the embodiments of the present application, an adsorption device is provided on the carrier in the camera module, so that when the lens is decoupled from the carrier, the carrier is adsorbed on the first slide rail by the adsorption device and driven by the driving device Sliding along the first sliding rail, after the lens is coupled to the carrier, the carrier is separated from the first sliding rail, and the carrier and the lens form an integral structure, so that during the zooming process, when the driving device drives the carrier to move, there is a gap between the carrier and the first sliding rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com