Zero material tobacco blending method

A technology of mixing and formulating, which is applied in the fields of tobacco, tobacco preparation, application, etc., and can solve problems such as the lack of an implementation plan for the mixing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

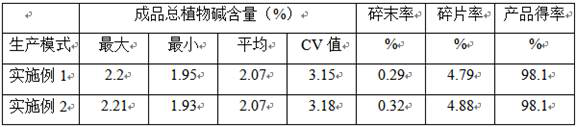

Embodiment 1

[0029] Firstly, the number of premixed zero-material smoke formula grades is 54, and they are sorted according to the order of each grade from small to large; set the capacity of the mixing cabinet to 12000kg, and the number is 6; take the first 28 grades of zero-material Tobacco, the total amount of 28 grades is 53700kg, which meets the condition that the total amount of 28 grades is ≤12000 kg, which is called small-grade formula module smoke material, and the remaining 26 grades are called large-grade formula module smoke material; the small-grade formula module The tobacco material is manually divided into 5 equal parts, and each equal part is 10740kg, and the splitting process is completed.

[0030] Then, the disassembled small-grade formula module smoke materials are initially mixed and re-mixed according to the mixing device provided by the present invention.

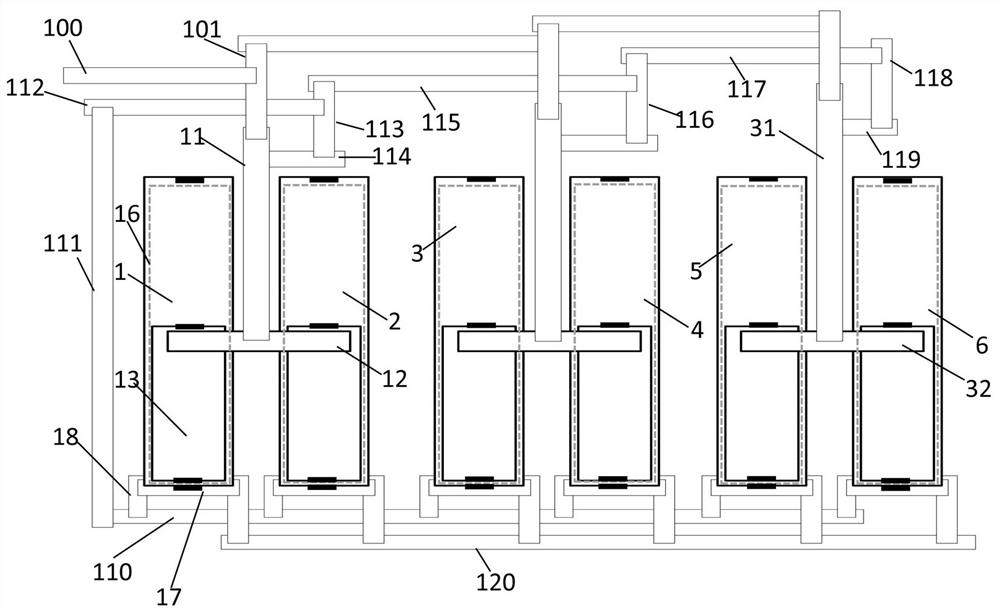

[0031] Such as figure 1 As shown, the device for primary mixing of small-grade zero-material smoke in this emb...

Embodiment 2

[0040]There are 54 grades of zero-material smoke formula to be premixed, sorted according to each grade from small to large, set the capacity of the mixing cabinet to 12000kg, and the number is 6; take the first 28 grades, the total amount is 53700kg, If the total amount of 28 grades is less than or equal to 60000kg, it is called small-grade formula module smoke material, and the remaining 26 grades are called large-grade formula module smoke material. Randomly combine the smoke materials of 28 small-grade modules, take the total amount of zero material smoke of grade number 1-19 as 10600kg, split the grades of number 23 and 26 into two halves, and the total amount of grade number 20-23.5 is 11700kg , the total grade of serial number 23.5-26.5 is 11700kg, the total grade of serial number 26.5-27 is 11700kg, and the total grade of serial number 28 is 8000kg, which is divided into 5 parts to complete the splitting process.

[0041] The disassembled 5 small-grade formula module s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com