A kind of fluorine-containing organosilicon polymer modified epoxy resin mastic and preparation method thereof

A technology of epoxy resin mastic and fluorosilicon polymer, which is applied in the field of building materials, can solve the problems of insufficient toughness of epoxy resin mastic, high linear expansion coefficient, poor anti-corrosion and pollution resistance, etc., and achieve good stress dispersion and chain flexibility Good, small steric hindrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

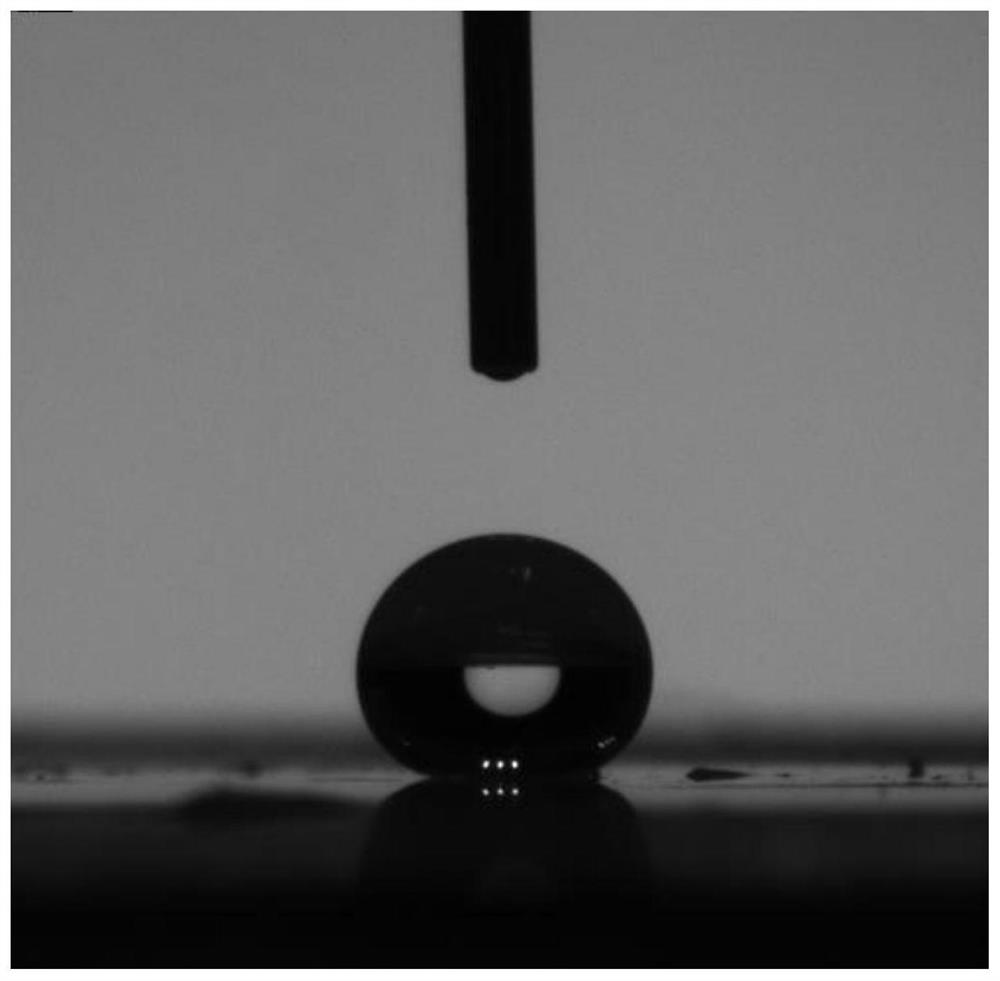

Image

Examples

preparation example Construction

[0045] The preparation method of this fluorine-containing organosilicon polymer modified epoxy resin mastic comprises the following steps:

[0046] Prepare A component according to the following steps: (1) Pre-react epoxy-based fluorosilicon polymer and amino POSS in toluene solution at 90±5°C for 10h-24h, and then vacuum remove it at 80°C-100°C Toluene solvent to obtain viscous fluorosilicon polymer grafted POSS.

[0047] (2) Mix epoxy resin, diluent, fluorosilicon polymer grafted POSS, and thixotropic agent according to a predetermined mass ratio, and use a planetary mixer with a vacuum system for high-speed dispersion, and the dispersion speed is 800r / min~2000r / min, the dispersion temperature is controlled at 20°C to 50°C, and the dispersion time is 30min to 60min to obtain a resin premix.

[0048] (3) Add the predetermined mass fraction of quartz powder into the resin premix prepared in step (2), heat the material to 40°C~60°C, and turn on the vacuum system to carry out ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com