Concave center flat car reinforcing device

A reinforcement device, flat car technology, applied in transportation and packaging, railway car body parts, cargo support/secured parts, etc., can solve problems such as poor adaptability, non-reusable, easy to interfere with goods, etc.

Active Publication Date: 2021-12-17

CRRC HARBIN VEHICLES CO LTD

View PDF7 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

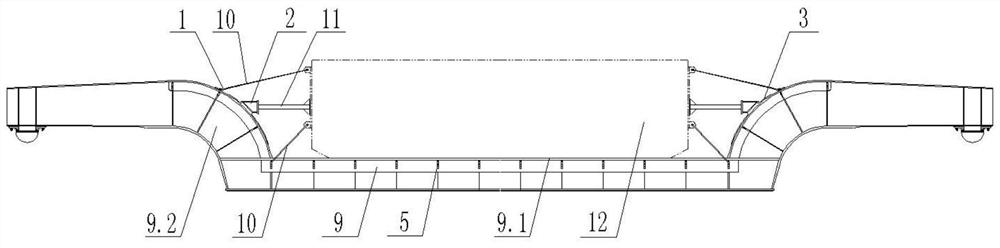

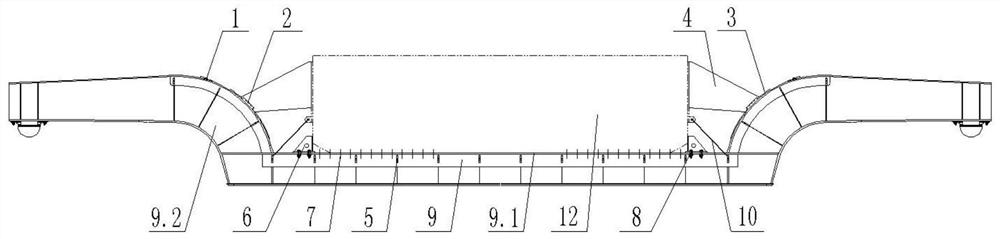

[0004] In order to solve the technical problems of the existing reinforcements on the concave bottom frame of long railway freight cars, such as poor adaptability, non-reusable use, high reinforcement cost and easy interference with cargo, the present invention provides a reinforcement device for flat wagons with concave bottoms , including a turn-over reinforcement ring assembly symmetrically installed at the corners at both longitudinal ends of the concave chassis, the turn-over reinforcement ring assembly includes a ring seat and a reinforcement ring, the ring seat and the reinforcement ring are hinged, the The ring seat is installed on the concave bottom frame, and the reinforcement ring is used to cooperate with the flexible reinforcement to pull and reinforce the longitudinal ends of the cargo

[0005] The flip-type reinforcement

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

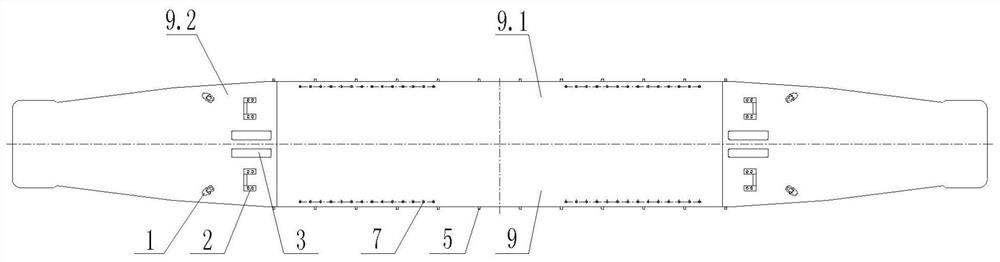

The invention relates to a concave center flat car reinforcing device which comprises turnover type reinforcing ring assemblies and detachable reinforcing assemblies which are symmetrically installed at the bent corner portions of the two longitudinal ends of a concave center frame respectively, the turnover type reinforcing ring assembly comprises a ring base and a reinforcing ring, the ring base and the reinforcing ring are connected through a hinge, the ring base is installed on the concave center frame, the reinforcing rings and flexible reinforcing pieces are matched to longitudinally pull and reinforce the two ends of goods together without disassembly. The detachable reinforcing assembly comprises a reinforcing base and an upper backstop, the reinforcing base is connected with the upper backstop through a first fastener, and the detachable reinforcing assembly is used for reinforcing the upper portion of goods and can be disassembled and assembled according to loading requirements. The turnover type reinforcing ring assembly and the detachable reinforcing assembly can effectively solve the technical problem that an existing fixed type reinforcing ring and an existing fixed type reinforcing block which are arranged on the surfaces of the bent corner parts at the two longitudinal ends of the concave underframe in a protruding mode are prone to interference with long and large goods in the loading process, repeated use can be achieved, and the reinforcing cost is reduced.

Description

technical field [0001] The invention relates to the technical field of flat cars with concave bottoms, in particular to a reinforcing device for flat cars with concave bottoms. Background technique [0002] The railway concave-bottomed flat car is the vehicle with the widest application range and the largest proportion of quantity and variety for transporting large goods. It is usually used to transport goods with moderate length, moderate height and wide width, such as transformers, generator stators, rolls, large machinery etc. During the transportation of these grown goods, they need to be reinforced longitudinally and transversely in accordance with the railway loading reinforcement requirements. The existing reinforcement method is to weld stoppers at the end and side of the cargo or use wire ropes to pull them. The existing reinforcements include reinforcement blocks, reinforcement plates and rope hooks welded on the concave bottom frame. There are many varieties and ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B61D45/00

CPCB61D45/001

Inventor 孙晓东郑景龙栗明柱王雷焦海旭徐长胜葛忠孝曲峰利徐涛岳娜

Owner CRRC HARBIN VEHICLES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com