Micro-conveying unit for flexible conveying system and flexible conveying system applying micro-conveying unit

A conveying unit and conveying system technology, which is applied to conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of lack of coherence in the transportation of trolley materials, and achieve the effect of ensuring coherence, reducing labor costs, and improving transmission efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

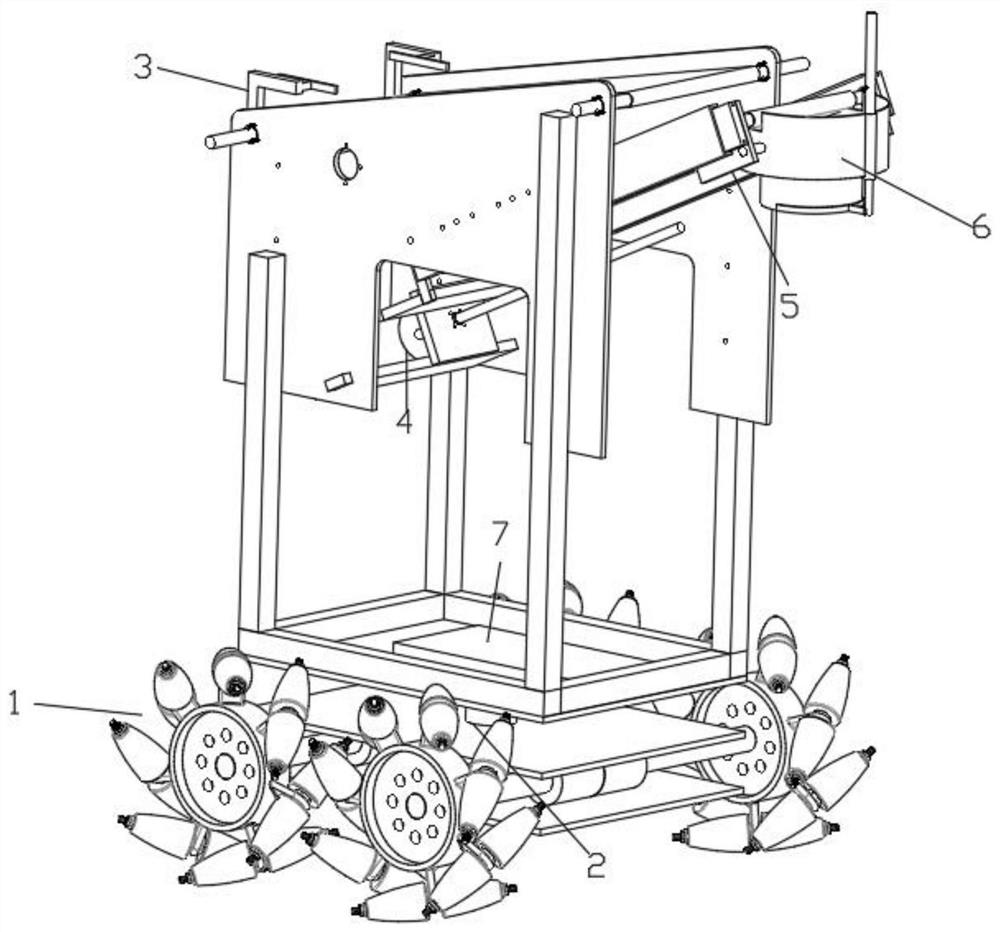

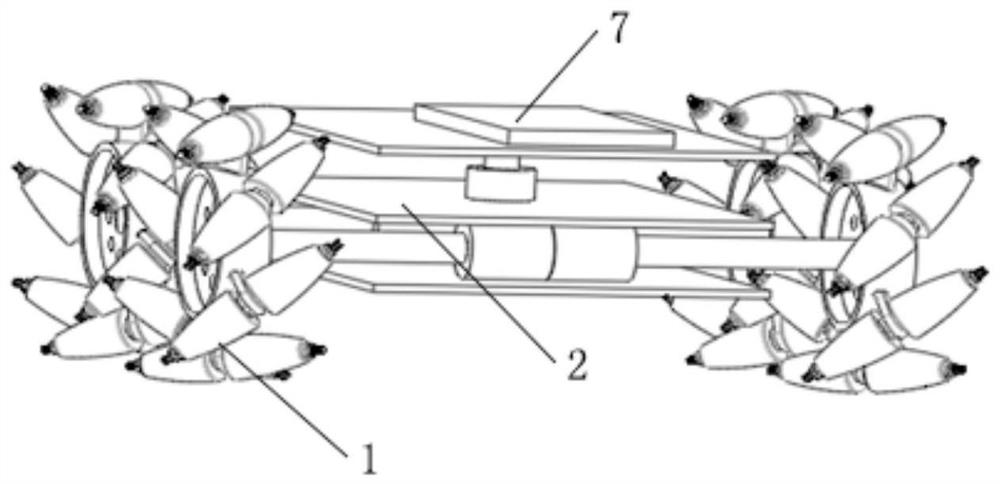

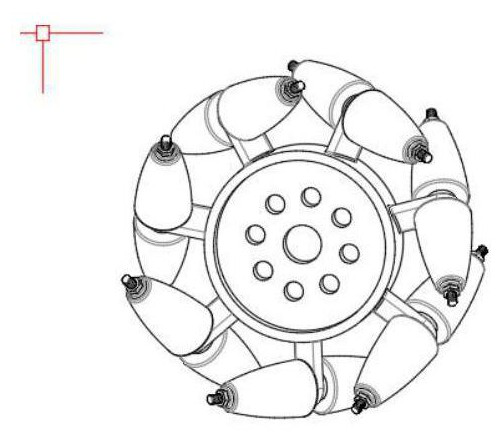

[0040] As an embodiment, the moving mechanism includes a mecanum wheel 1, which is installed on the base, and many small rollers are distributed obliquely on its rim, so the wheel can slide laterally. The generatrix of the small rollers is very special. When the wheel rotates around the fixed wheel mandrel, the envelope of each small roller is a cylindrical surface, so the wheel can roll forward continuously. Mecanum wheel 1 has a compact structure, It is flexible in movement and is a very successful all-round wheel. There are 4 new wheels of this type combined, which can realize all-round mobile functions more flexibly and conveniently.

[0041]As an embodiment, the rotating platform 2 includes a bottom plate 22 and a stepping motor 21 , and the stepping motor 21 is used to drive the bottom plate 22 to rotate, thereby adjusting the attitude of the double-layer telescopic device installed on the rotating platform 2 .

[0042] As an embodiment, the drive mechanism includes a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com