Clamp capable of fixing and adjusting multiple optical lenses

A technology of optical lenses and fixtures, which is applied in the direction of optics, optical components, optical surface grinders, etc., can solve the problems of low work efficiency, inability to adjust angles from multiple angles, and inconvenient processing by operators, so as to improve work efficiency and stability , Improve the effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

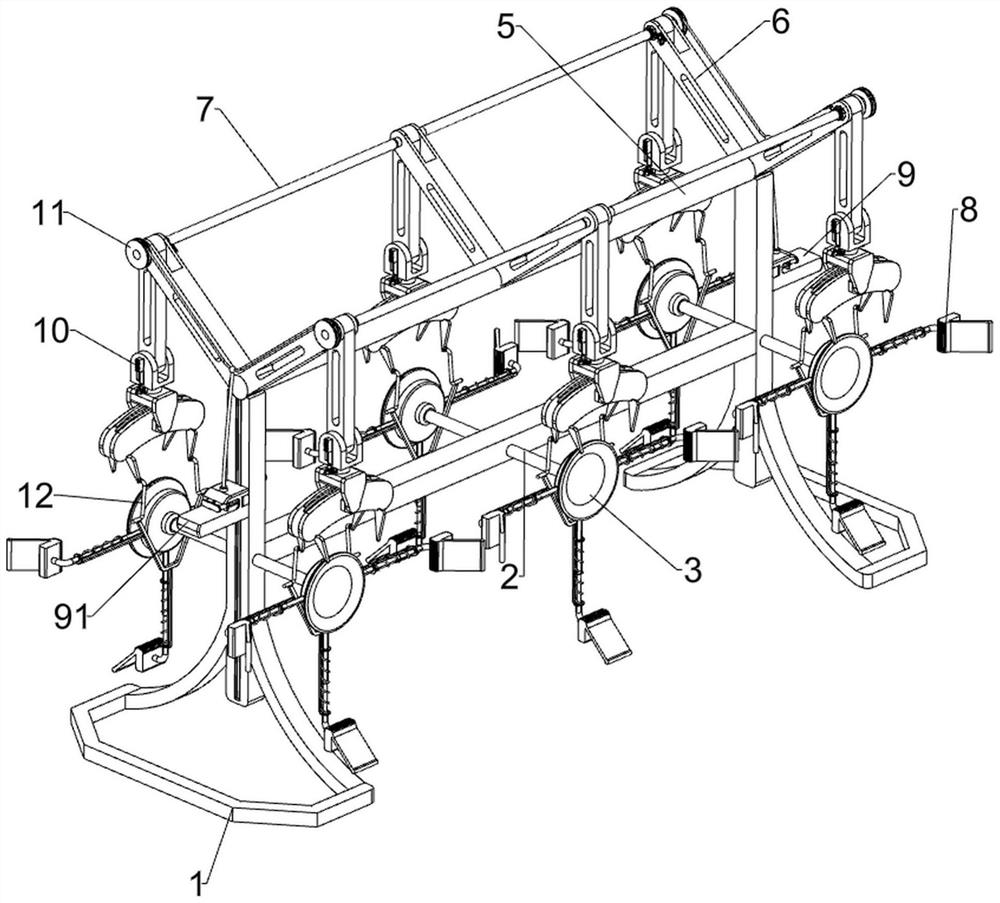

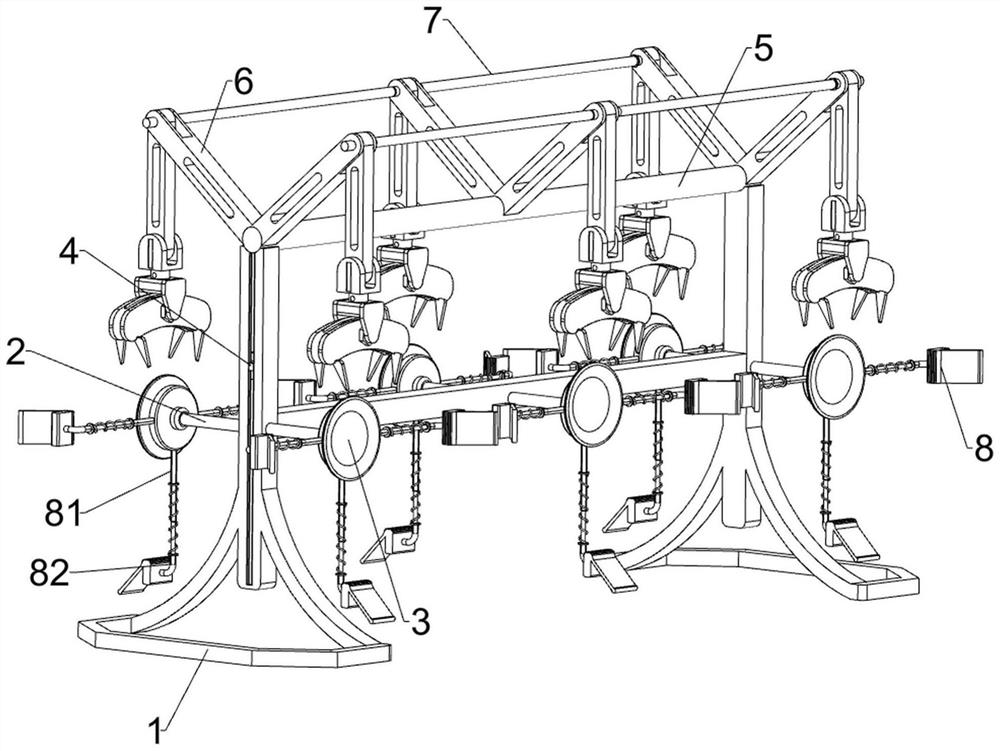

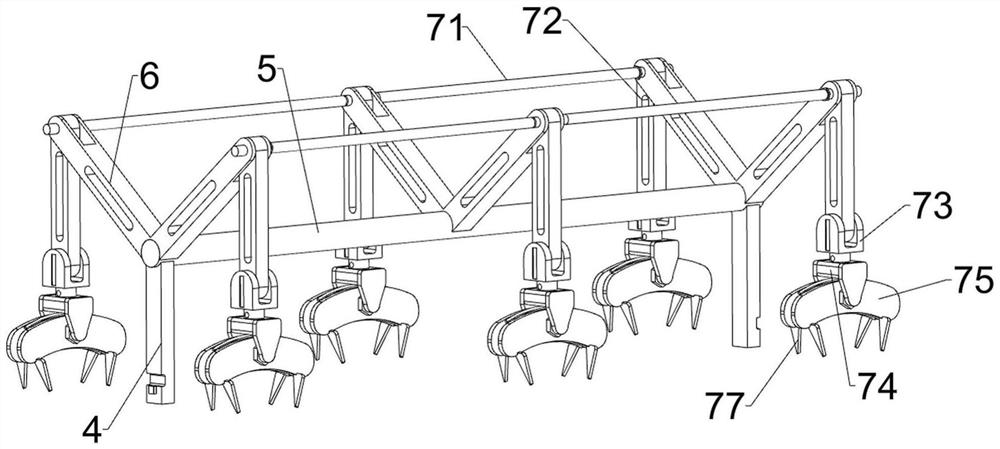

[0035] A fixture that can fix and adjust a large number of optical lenses, such as Figure 1-5 As shown, it includes a mounting frame 1, a fixed rod 2 and a suction cup 3. The middle part of the mounting frame 1 is connected with three fixed rods 2 evenly spaced from left to right, and the fixed rods 2 run through the mounting frame 1. Both ends are connected with a suction cup 3 for fixing the lens through a threaded connection, and also include a lifting rod 4, a cross bar 5, a V-shaped frame 6, a clamping component 7 and a positioning component 8, and the left and right sides of the mounting frame 1 are There is a chute, and the lifting rod 4 is slidably connected in the chute, and the tops of the lifting rods 4 on both sides are connected with a cross bar 5 by welding, and three V-shaped joints are welded on the cross bar 5 evenly Frame 6, a clamping assembly 7 that can clamp the lens is installed between the three V-shaped frames 6, and a positioning assembly 8 for positi...

Embodiment 2

[0040] On the basis of Example 1, such as figure 1 , Figure 6 , Figure 7 , Figure 8 and Figure 9 As shown, it also includes a limit mechanism 9, the limit mechanism 9 includes a lifting block 91, a guide frame 92, a limit block 93, a return spring 94 and a guide block 96, and the left and right sides of the mounting frame 1 are all slidably connected with Two guide blocks 96, the two guide blocks 96 are symmetrical up and down, the guide block 96 on the top is connected with the elevating rod 4 by welding, the left and right sides of the installation frame 1 have openings, the guide blocks 96 run through the opening, and the bottom The guide block 96 of the guide block 96 is connected with a lifting block 91 by welding, and the upper part of the lifting block 91 is slidably connected with a guide frame 92. The position block 93, the stop block 93 and the lift block 91 are connected with a return spring 94, the return spring 94 is sleeved on the outside of the guide fra...

Embodiment 3

[0045] On the basis of Example 2, such as figure 1 , Figure 10 , Figure 11 and Figure 12 As shown, a pulling mechanism 11 is also included, and the pulling mechanism 11 includes a winding wheel 111, a first backguy 112, a second backguy 113, a ratchet 114, a guide sleeve 115, a ratchet 116, a fourth spring 117 and a shifting block 118, Both left and right ends of the first connecting rod 71 are connected with reels 111, and there are second stay wires 113 wound between the two reels 111 on the left and between the two reels 111 on the right. The middle part of the second backguy 113 and the top of the lifting block 91 are connected with the first backguy 112 by means of lap connection, and the leftmost and rightmost V-shaped frames 6 are connected with guide sleeves 115, which slide on the guide sleeves 115. A ratchet 116 is connected in a conventional manner, and a fourth spring 117 is connected between the ratchet 116 and the guide sleeve 115. The fourth spring 117 is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap