A kind of continuous furnace high temperature carburizing method and carburizing cr-mo steel parts

A high-temperature carburizing and continuous furnace technology, applied in solid-state diffusion coating, coating, metal material coating process, etc., can solve the problem that Cr-Mo carburizing steel cannot meet the high-temperature carburizing demand above 980 ℃, etc. Achieve the effect of improving efficiency and high-efficiency carburizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

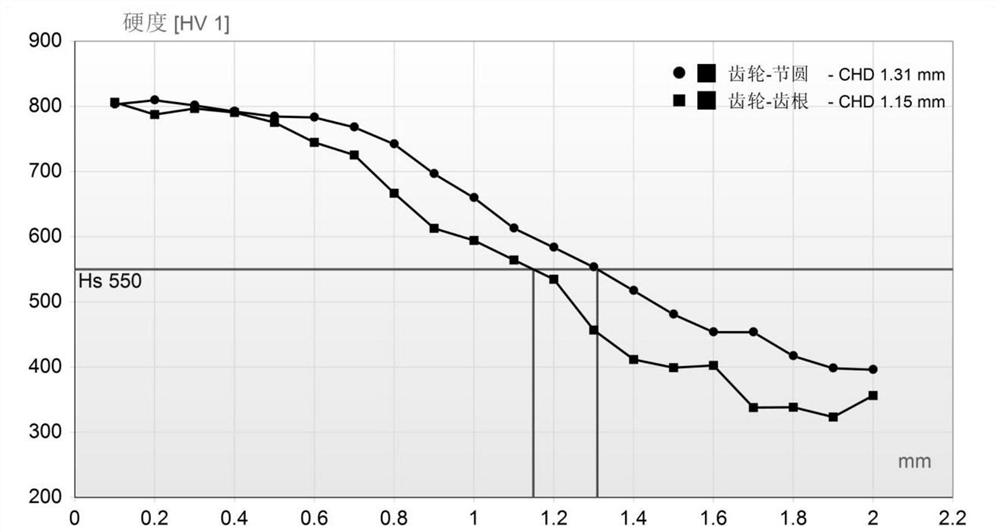

[0106] For a heavy-duty gearbox gear, the depth of carburized layer is required to be 1.1-1.6mm.

[0107] In this embodiment, high-temperature carburizing treatment is carried out on heavy-duty transmission gears with the following chemical composition by weight percentage: C0.15, Si0.13, Mn0.6, P0.016, S0.026, Cr0.90, Al0.020 , Ti0.010, Nb0.042, N120ppm, Ni0.020, Cu0.13, O≤15ppm, and the rest are Fe and unavoidable impurities.

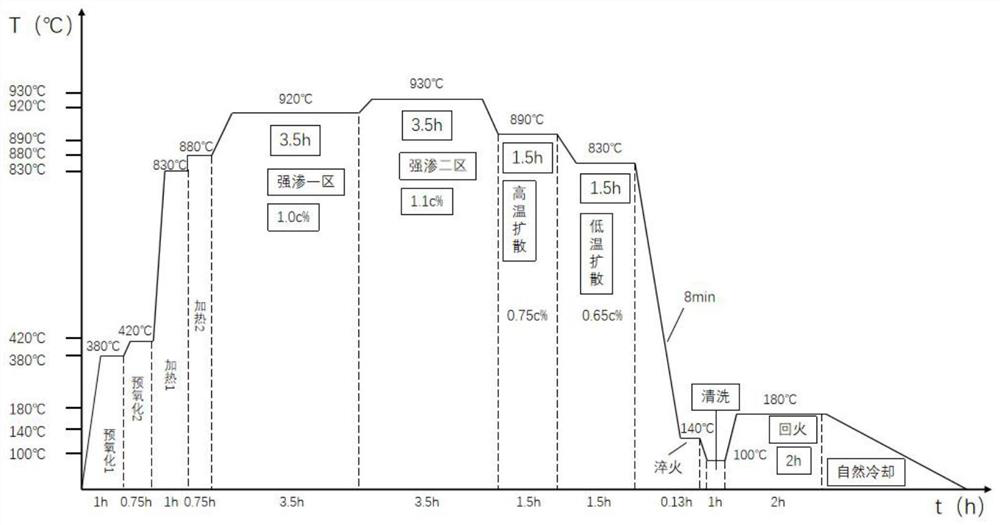

[0108] This embodiment provides a continuous furnace high-temperature carburizing method for the above-mentioned heavy-duty gearbox gear, and the steps are as follows:

[0109] S1. Heating step: put the heavy-duty gearbox gear into the continuous furnace, raise the temperature to 380°C, perform constant temperature pre-oxidation treatment for 60 minutes; raise the temperature to 580°C, perform constant temperature pre-oxidation treatment for 60 minutes; raise the temperature to 860°C, and preheat and keep it for 60 minutes.

[0110] S2. High-temperat...

Embodiment 2

[0115] For a heavy-duty gearbox gear, the depth of carburized layer is required to be 1.1-1.6mm.

[0116] In this embodiment, high-temperature carburizing treatment is performed on heavy-duty transmission gears with the following chemical composition by weight percentage: C0.23, Si0.20, Mn0.9, P0.020, S0.04, Cr0.115, Al0.035 , Ti0.014, Nb0.058, N165ppm, Ni0.022, Cu0.13, O≤15ppm, and the rest are Fe and unavoidable impurities.

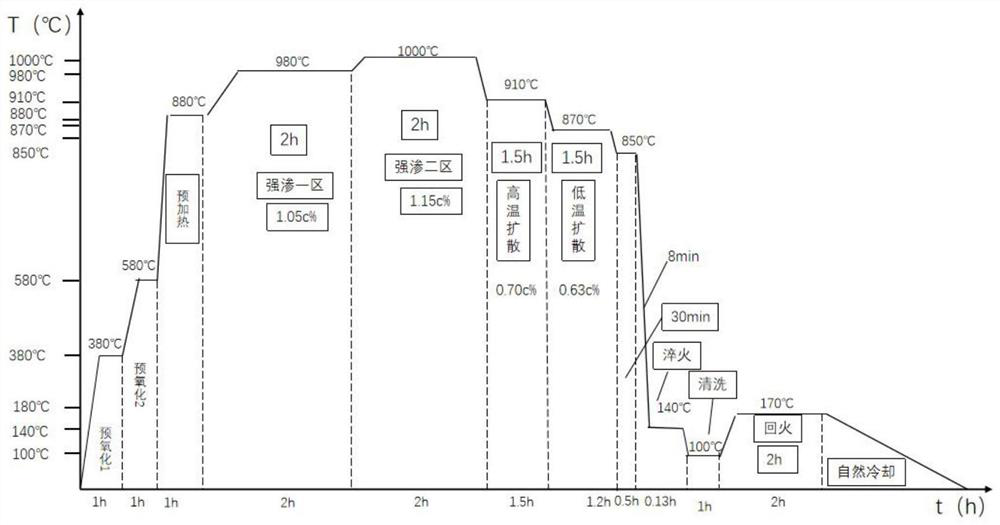

[0117] This embodiment provides a continuous furnace high-temperature carburizing method for the above-mentioned heavy-duty gearbox gear, and the steps are as follows:

[0118] S1. Heating step: put the heavy-duty gearbox gear into the continuous furnace, raise the temperature to 430°C, perform constant temperature pre-oxidation treatment for 60 minutes; raise the temperature to 640°C, perform constant temperature pre-oxidation treatment for 60 minutes; raise the temperature to 870°C, and perform preheating and heat preservation for 60 minutes.

[01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com