Assembling equipment for USB connector joint processing and production

A technology for assembling equipment and connectors, which is applied in the direction of assembly/disassembly of contacts, which can solve problems such as inability to limit the housing and terminals, and achieve the effect of avoiding falling apart

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

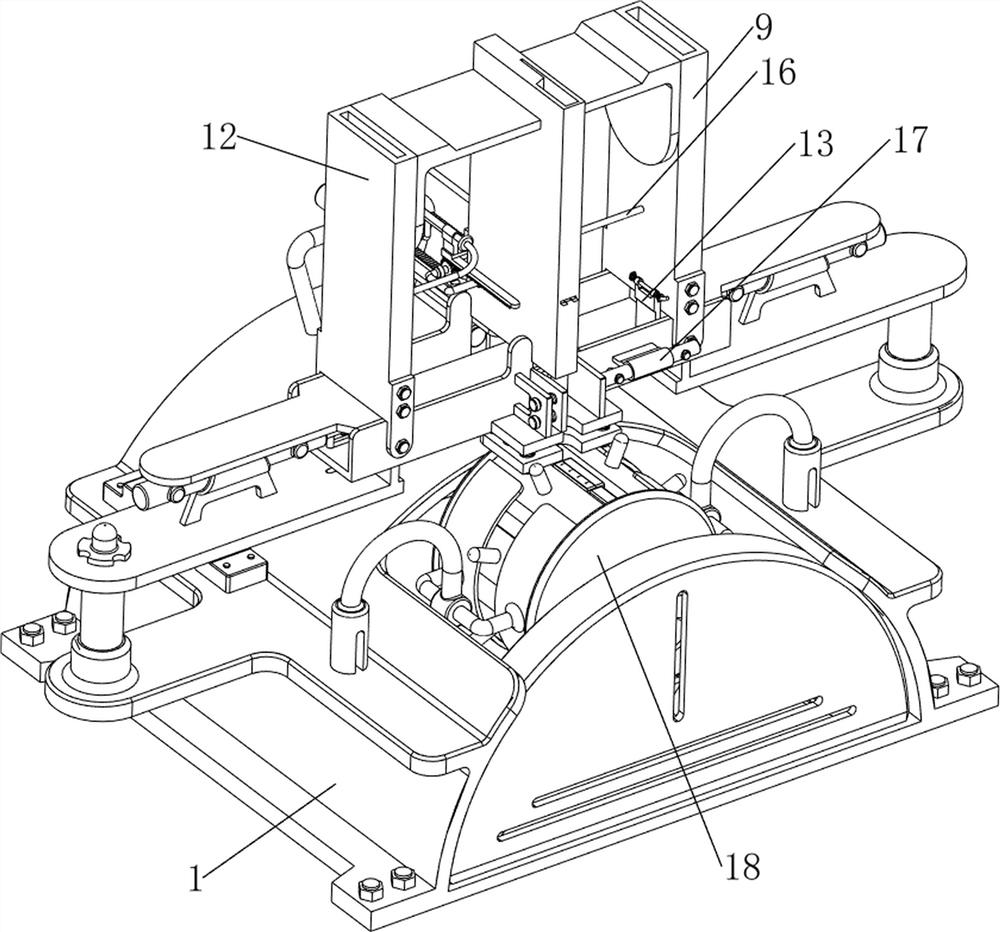

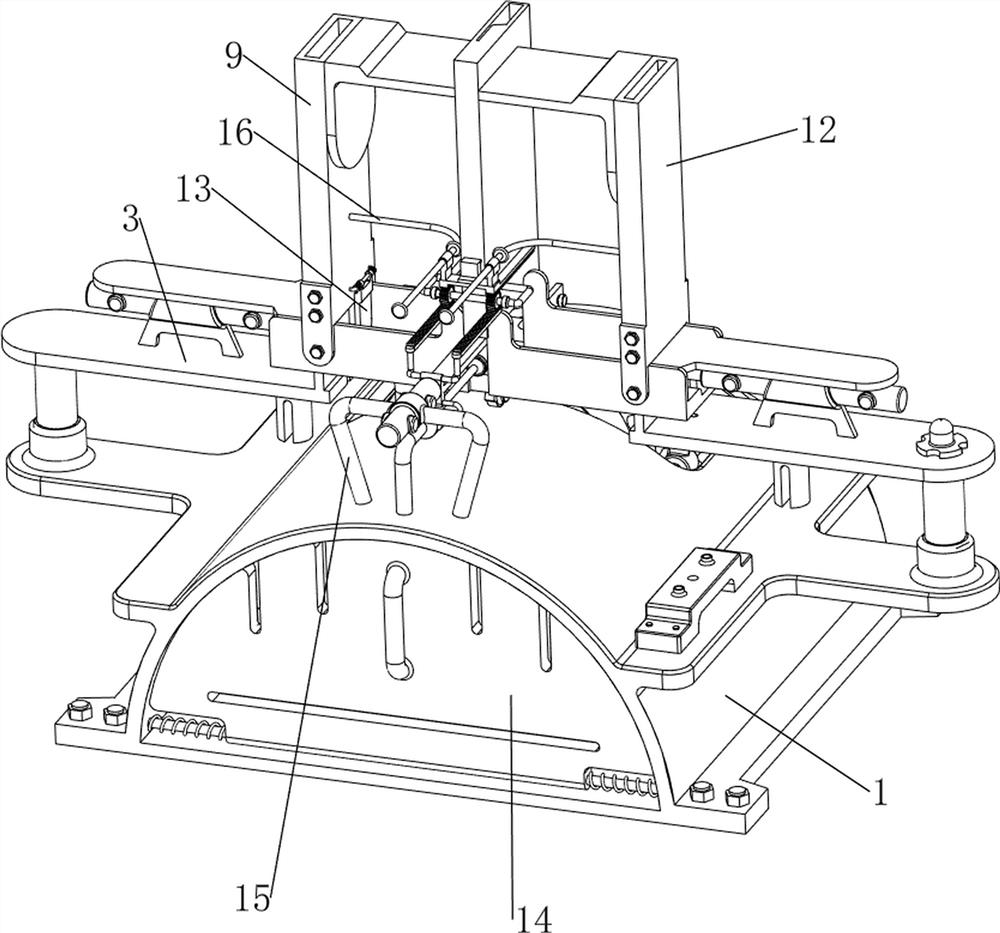

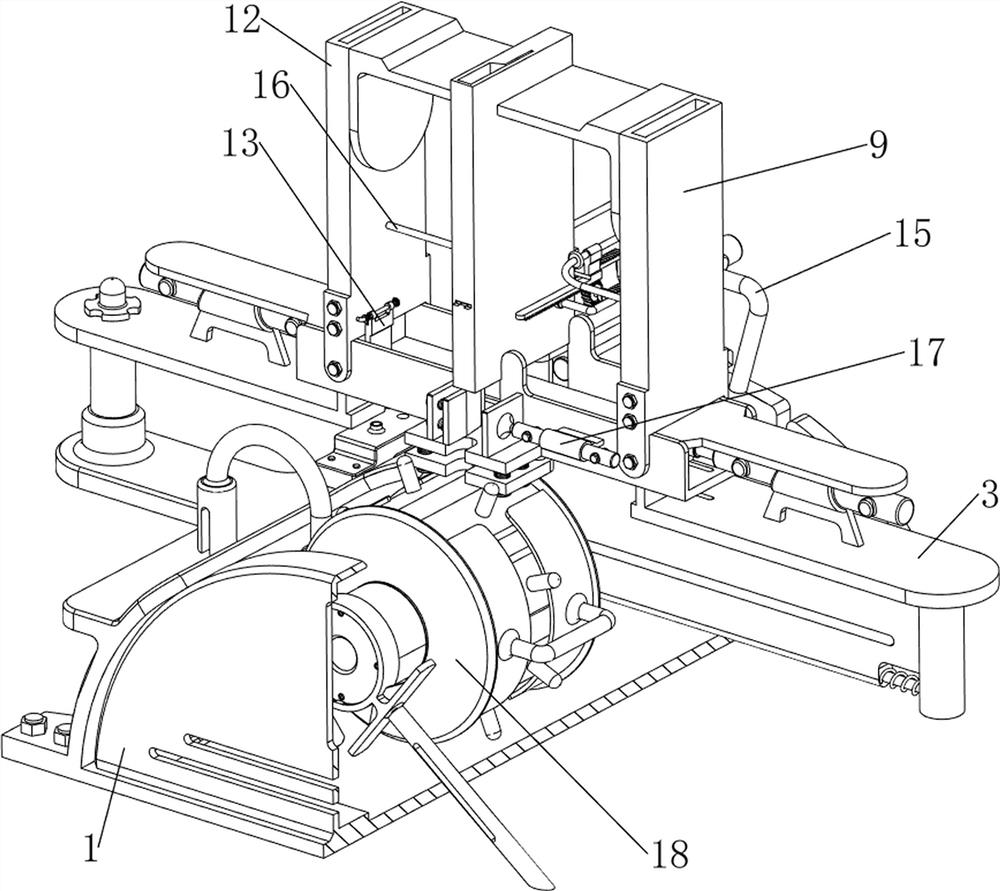

[0093] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 The shown assembly equipment for processing and producing USB connector joints includes a collection frame 1, a first fixing plate 3, a contact switch 4, a first fixing column 5, a first electric push rod 6, a first push plate 7, The limit frame 8, the first shell blanking frame 9, the second fixed plate 10, the terminal blanking frame 11, the second shell blanking frame 12, the limit mechanism 13 and the collection mechanism 14, and the top of the collection frame 1 is welded with two The first fixed plate 3, the first fixed plate 3 is symmetrically arranged left and right, the left side of the first fixed plate 3 top left side is provided with a contact switch 4, and the first fixed column 5 is welded on the top of the two first fixed plates 3, The first electric push rods 6 are installed inside the two first fixed columns 5 through bolts, and the first push pl...

Embodiment 2

[0098] On the basis of Example 1, such as figure 1 , figure 2 , image 3 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 with Figure 18 As shown, a pusher mechanism 15 is also included, and the pusher mechanism 15 includes a second fixed column 151, a second electric push rod 152, a second limit plate 153, a push column 154, a pressure sensor 155 and a pressure rod 156, collecting The frame 1 top rear side is welded with the second fixed column 151, and the second fixed column 151 top is provided with the second electric push rod 152, and the second electric push rod 152 telescoping rod front side is provided with the second limit plate 153, and the second limit plate 153 is arranged on the second limit plate. The top of the positioning plate 153 is in contact with the bottom of the terminal blanking frame 11, and the lower side of the rear part of the second limiting plate 153 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com