Six-dimensional force sensor and calibration device

A six-dimensional force sensor and calibration device technology, which is applied in measuring devices, instruments, force/torque/work measuring instruments, etc., can solve the problems of increasing the weight of the sensor, being difficult to apply to small robot force control applications, and difficult to realize miniaturization and other problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0023] In order to facilitate the understanding of the six-dimensional force sensor provided by the embodiment of the present invention, its application scenario is firstly explained. The six-dimensional force sensor aims to reduce the weight and achieve lightweight so as to reduce the impact on application equipment such as intelligent robots.

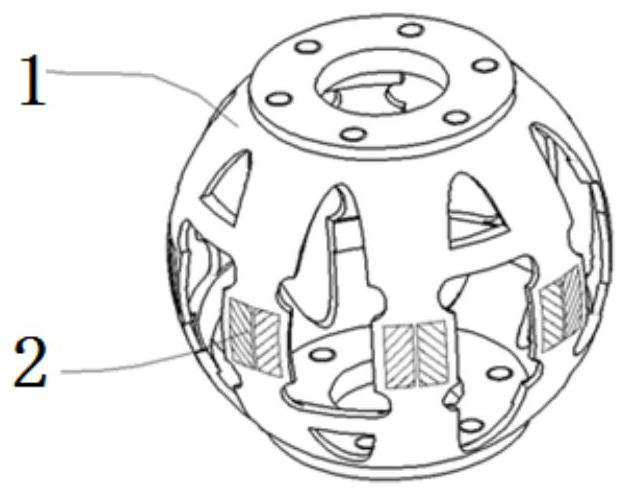

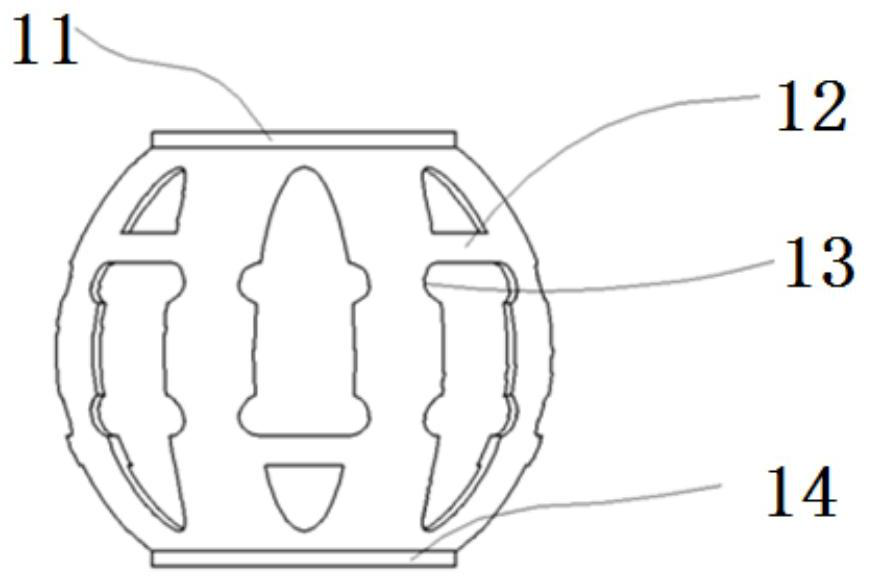

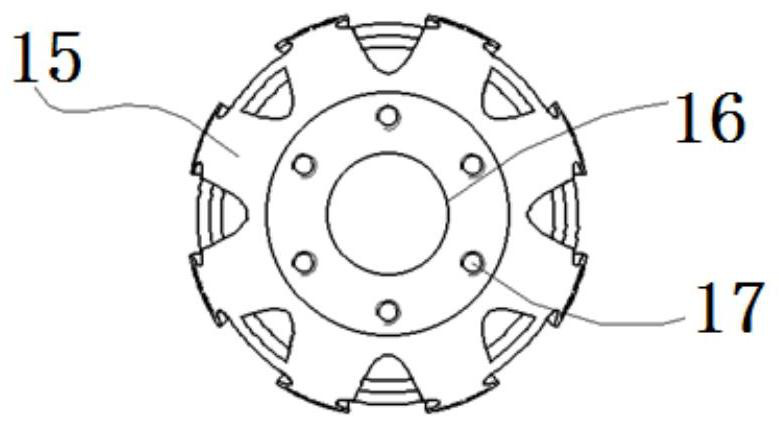

[0024] refer to figure 1 and combine image 3 , figure 1 A perspective view of a six-dimensional force sensor is shown, image 3 A bottom view of the elastic carrier is shown. The six-dimensional force sensor includes: an elastic carrier 1 and a strain gauge 2 . Wherein, the elastic carrier 1 is a spherical shell with a hollow interior and evenly distributed with a hollow structure, vertical beams 15 are formed betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com