Process method for printing thermal dye sublimation ribbon soft label

A process method, thermal sublimation technology, applied in the direction of copying/marking method, printing, temperature recording method, etc., can solve the problems of limiting the use range of thermal sublimation ribbon, and achieve the effect of wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment provides a process method for dye-sublimation ribbon soft label printing, including the following steps:

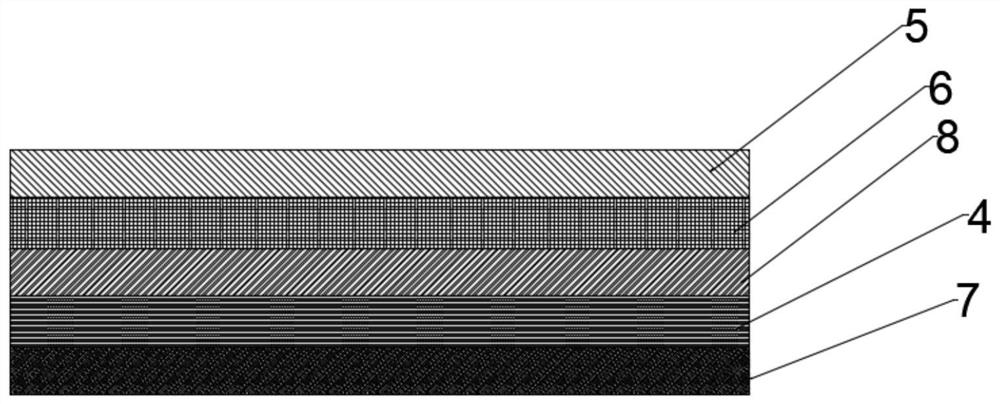

[0034] S1: Pre-transfer the next layer of carbon tape to the required soft label substrate 7 to obtain the next layer of substrate;

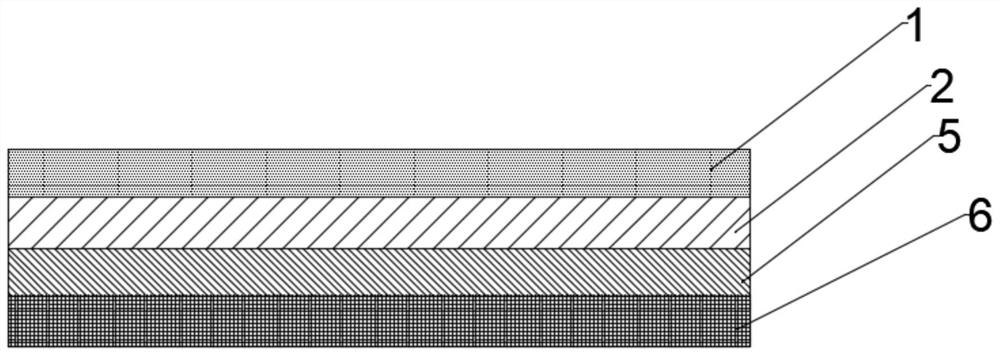

[0035] S2: Mirror printing the required pattern 8 onto the dye-receiving layer ribbon to obtain the dye-receiving layer ribbon with the pattern 8;

[0036] S3: Thermal lamination transfer of the dye-receiving layer carbon tape with the pattern 8 in S2 to the adhesive layer substrate in S1.

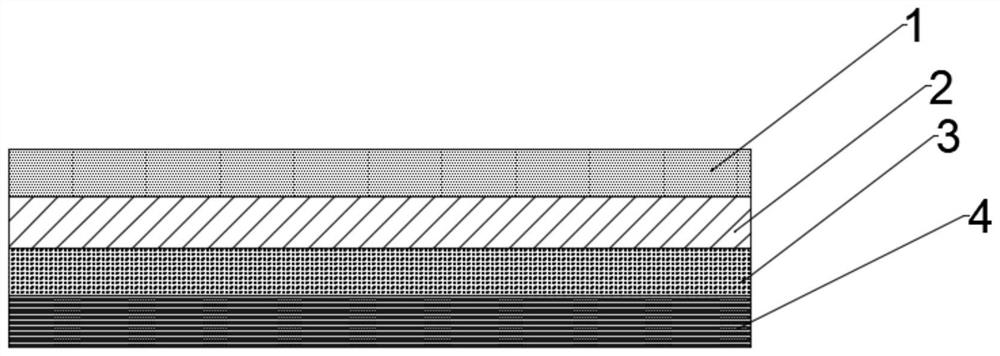

[0037] Specifically, in step S1, the adhesive layer carbon tape includes a back coat 1, a PET base material 2, a release layer 3 and an adhesive layer 4, and the top of the PET base material 2 is coated with the back coat layer 1. The bottom is sequentially coated with the release layer 3 and the adhesive layer 4 from top to bottom;

[0038] Described release layer 3 is made by following steps:

[0039] Weigh 1 part of EVA wax,...

Embodiment 2

[0050]This embodiment provides a process method for dye-sublimation ribbon soft label printing, including the following steps:

[0051] S1: Pre-transfer the next layer of carbon tape to the required soft label substrate 7 to obtain the next layer of substrate;

[0052] S2: Mirror printing the required pattern 8 onto the dye-receiving layer ribbon to obtain the dye-receiving layer ribbon with the pattern 8;

[0053] S3: Thermal lamination transfer of the dye-receiving layer carbon tape with the pattern 8 in S2 to the adhesive layer substrate in S1.

[0054] Specifically, in step S1, the adhesive layer carbon tape includes a back coat 1, a PET base material 2, a release layer 3 and an adhesive layer 4, and the top of the PET base material 2 is coated with the back coat layer 1. The bottom is sequentially coated with the release layer 3 and the adhesive layer 4 from top to bottom;

[0055] Described release layer 3 is made by following steps:

[0056] Weigh 5 parts of Brazilia...

Embodiment 3

[0067] This embodiment provides a process method for dye-sublimation ribbon soft label printing, including the following steps:

[0068] S1: Pre-transfer the next layer of carbon tape to the required soft label substrate 7 to obtain the next layer of substrate;

[0069] S2: Mirror printing the required pattern 8 onto the dye-receiving layer ribbon to obtain the dye-receiving layer ribbon with the pattern 8;

[0070] S3: Thermal lamination transfer of the dye-receiving layer carbon tape with the pattern 8 in S2 to the adhesive layer substrate in S1.

[0071] Specifically, in step S1, the adhesive layer carbon tape includes a back coat 1, a PET base material 2, a release layer 3 and an adhesive layer 4, and the top of the PET base material 2 is coated with the back coat layer 1. The bottom is sequentially coated with the release layer 3 and the adhesive layer 4 from top to bottom;

[0072] Described release layer 3 is made by following steps:

[0073] Weigh 7 parts of Brazili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com