Six-degree-of-freedom low-stress assembly method for spacecraft

An assembly method and a technology with a degree of freedom, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., to achieve low-stress assembly and realize the effect of stress assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

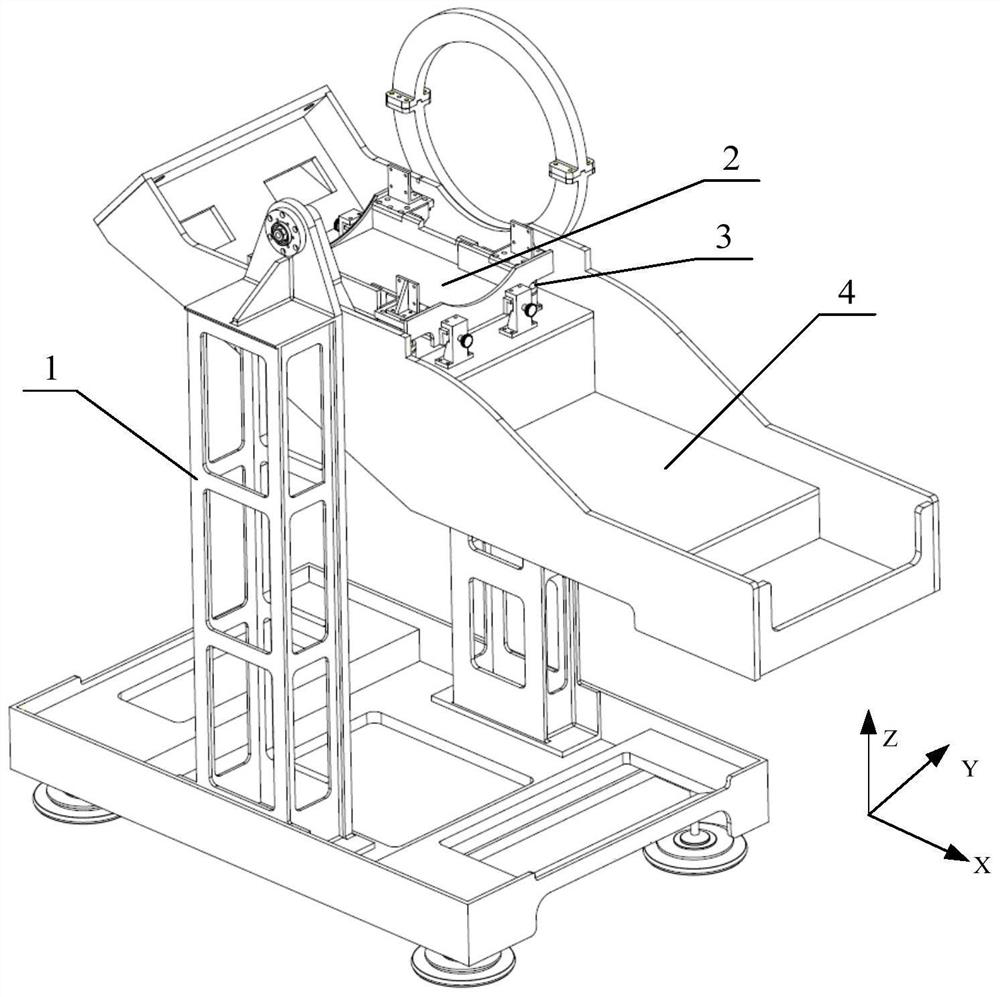

[0075] Embodiment: This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is given, but the protection scope of the present invention is not limited to the following embodiments.

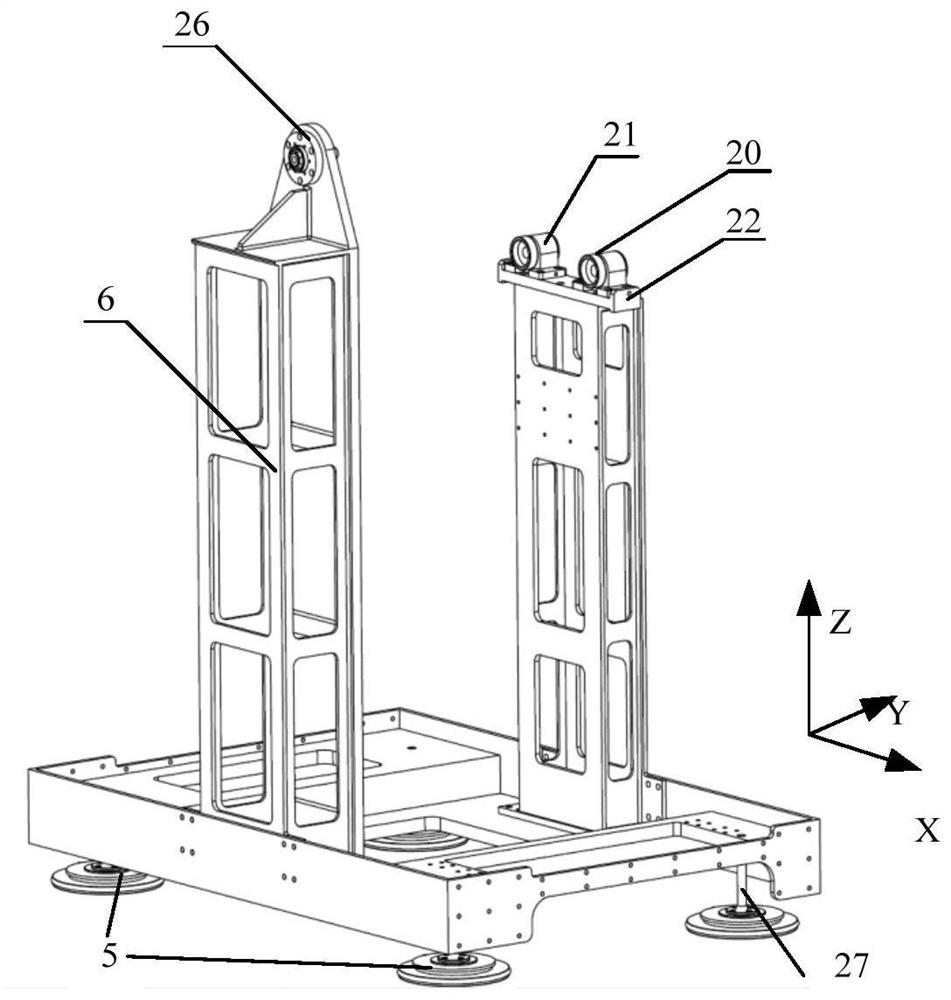

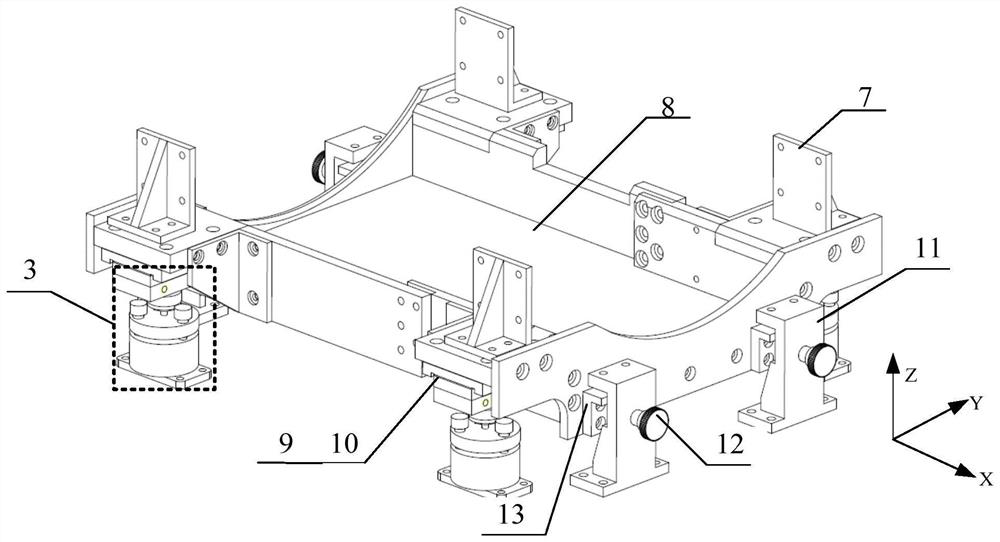

[0076] Figure 6 Among them, the part to be installed is the joint 23, the part to be assembled is the joint 24, the total weight of the joint 24 is 80kg, and the total mass of the assembled parts is 155kg after the assembly is completed. According to the load capacity of 200kg on a single plane air foot, the frame car 6 is designed Four flat air feet 5 are installed on the bottom surface, and they are arranged at the corners of a rectangle in the range of 1040×650 to increase the span as much as possible and improve the anti-overturning ability of the trolley 6 during assembly.

[0077] Step 1. Before use, it is necessary to supply air to the foot, the air pressure is 0.5Mpa, and the joint 24 is moved to the vicinity of the join...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap