Cotton yarn winding device

A winding device and cotton yarn technology, which is applied in the directions of transportation and packaging, thin material handling, and delivery of filamentous materials, etc. It can solve the problems of irregular winding, poor winding effect, inconvenient installation and adjustment of winding drum, etc. , to achieve the effects of simple structure, neat and standardized curling, and improved efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

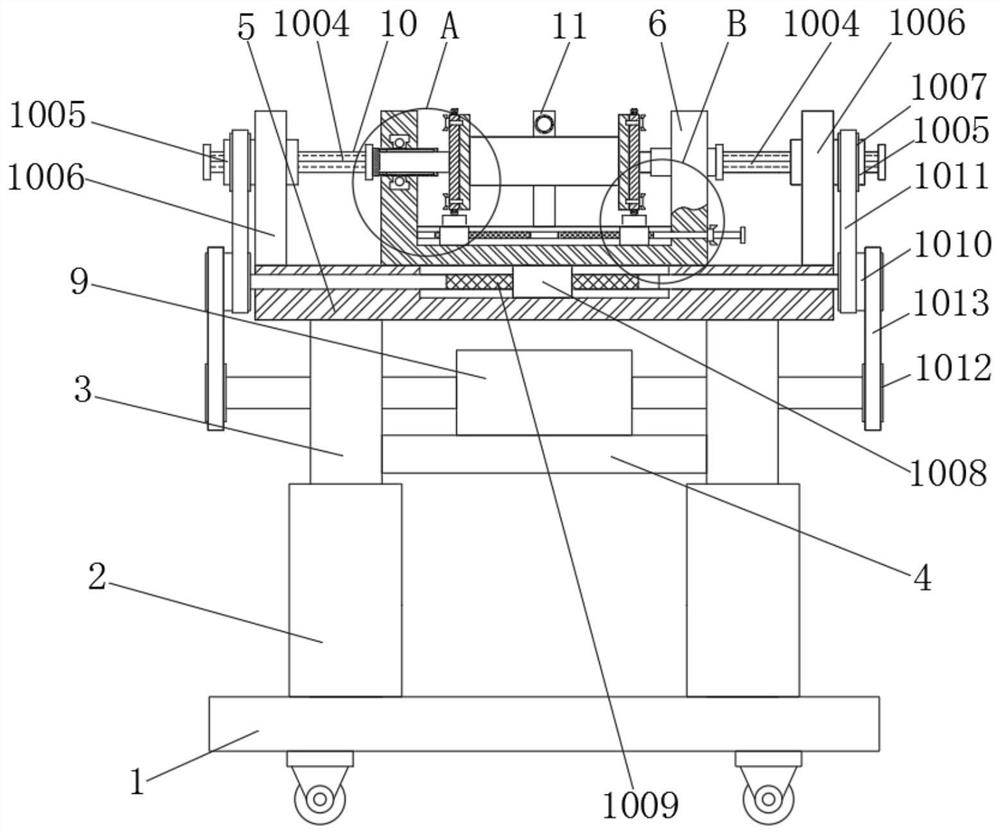

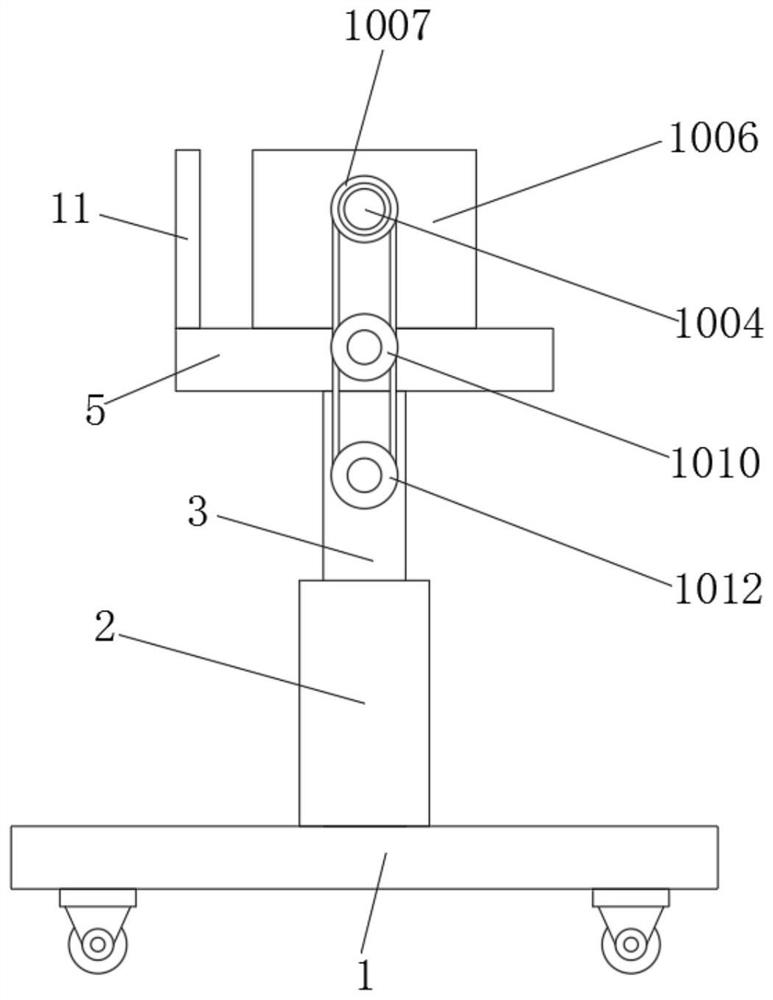

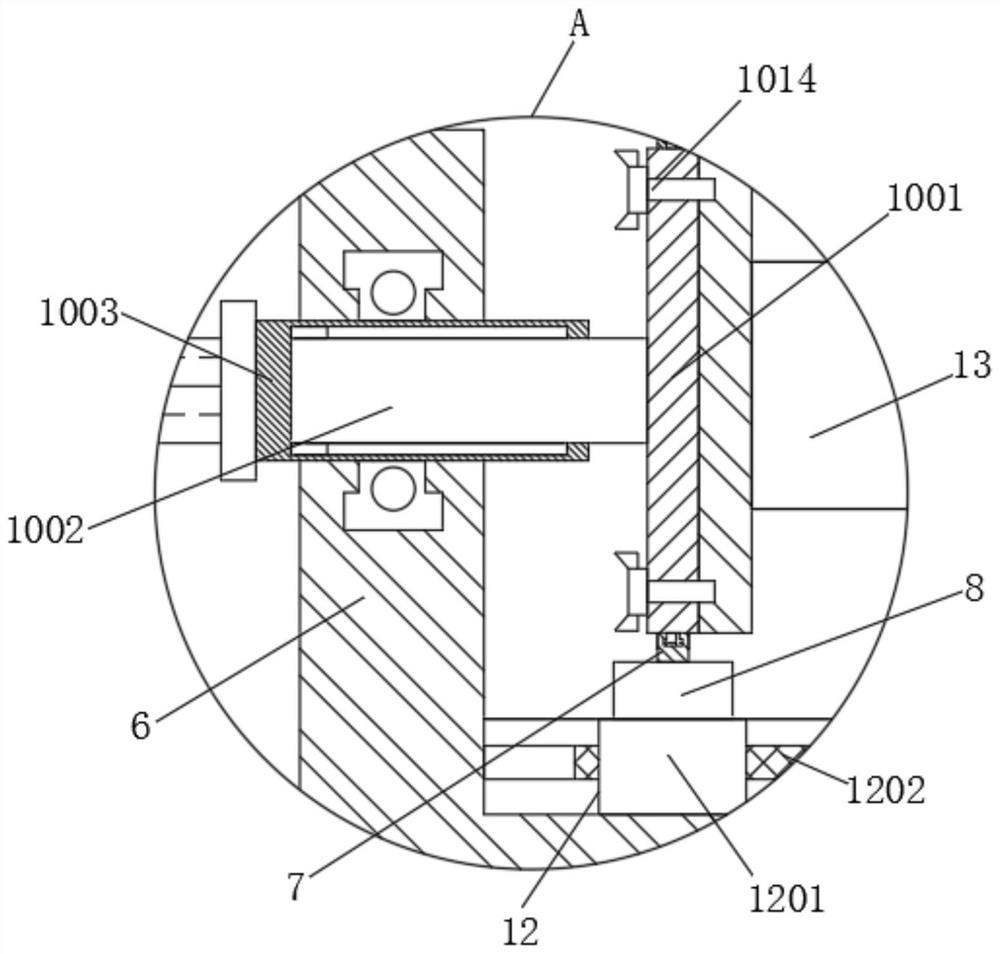

[0021] refer to Figure 1-4 , a cotton yarn winding and winding device, including a mobile base 1, a lower support column 2, an upper support column 3, a load plate 4, a top plate 5, a u-shaped mobile frame 6, a connecting ring 7, a connecting seat 8, a biaxial motor 9, Reciprocating rolling mechanism 10, rotating disc 1001, telescopic inner rod 1002, rotating outer rod 1003, spline shaft 1004, spline sleeve 1005, fixed frame 1006, pulley 1 1007, guide seat 1008, reciprocating screw rod 1009, pulley Two 1010, transmission belt one 1011, pulley three 1012, transmission belt two 1013, thumb screw 1014, threading frame 11, adjustment mechanism 12, sliding seat 1201, scr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap