Blanking stepping control method of blister packaging machine and blister packaging machine

A blister packaging machine, step control technology, applied to the blanking step control of the blister packaging machine, in the field of blister packaging machines, it can solve the problems of large blanking offset and length error of the material plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

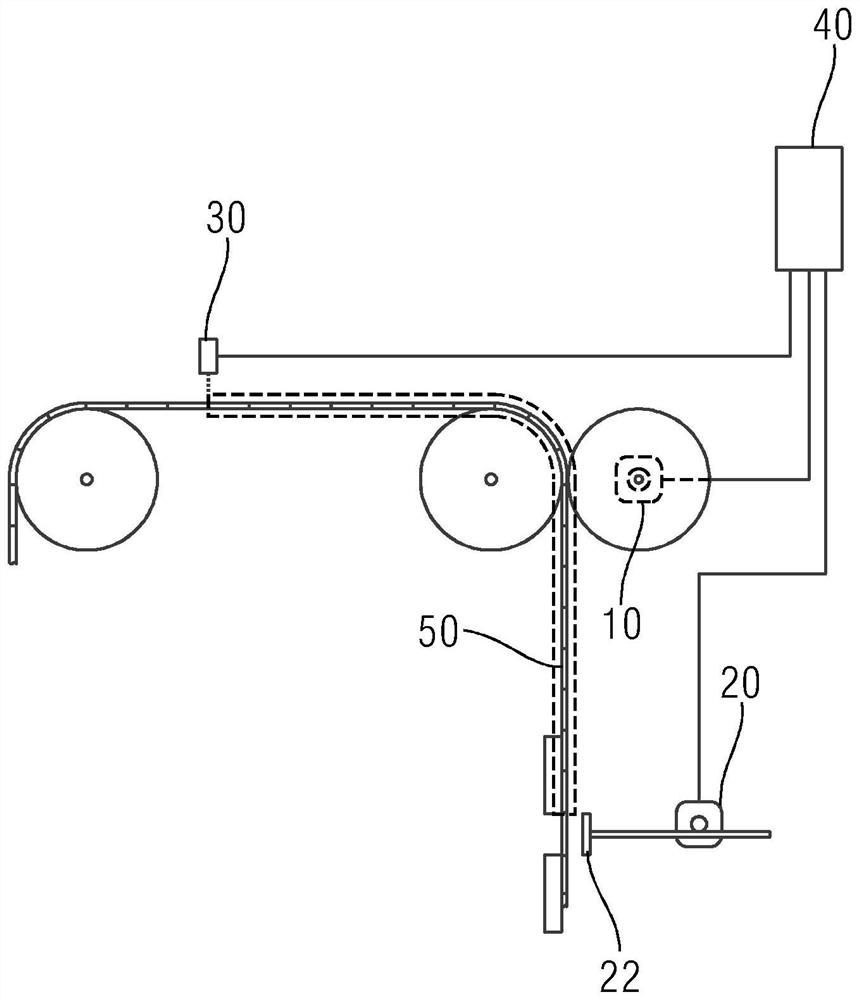

[0039] In order to have a clearer understanding of the technical features, purposes and effects of the invention, the specific embodiments of the present invention are now described with reference to the accompanying drawings, in which the same reference numerals represent components with the same or similar structures but the same functions.

[0040] In this article, "schematic" means "serving as an example, example or illustration", and any illustration or implementation described as "schematic" should not be interpreted as a more preferred or more advantageous Technical solutions.

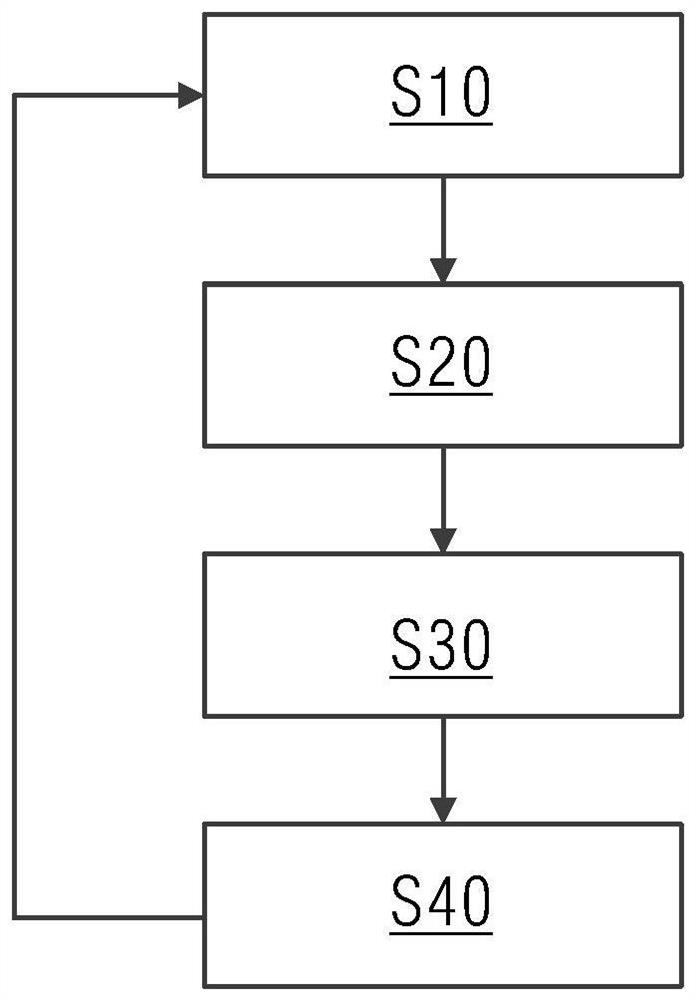

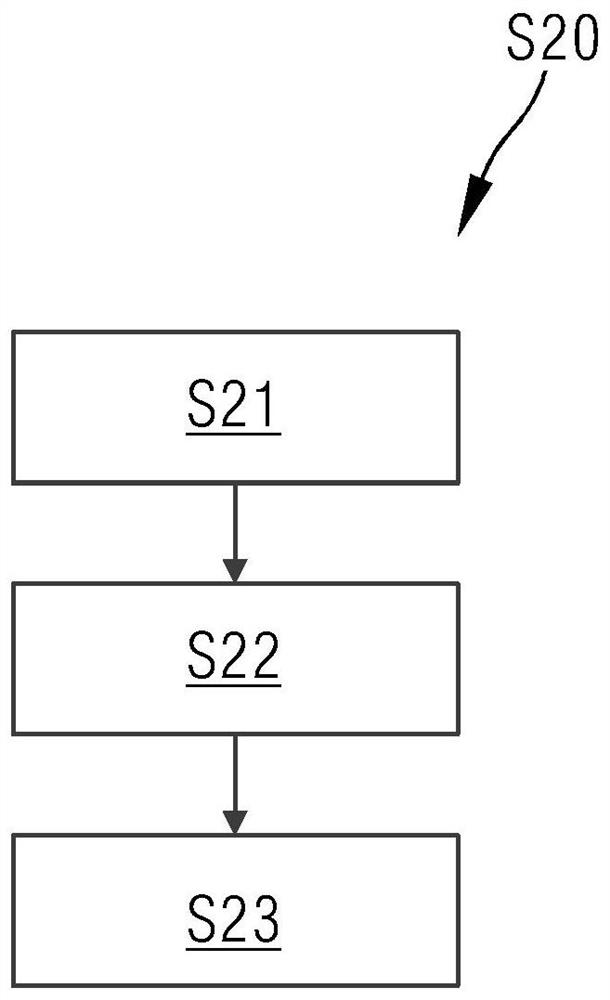

[0041] figure 1 It is a flow diagram of an exemplary embodiment of a punching step control method for a blister packaging machine. refer to figure 1 , the punching step control method of the blister packaging machine, comprising the following steps:

[0042] Step S10: setting a predictive pool before the punching position, the predictive pool includes several continuous material plates 50 clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com