Patents

Literature

43results about How to "Improve package stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A process for preparing a polymer product having a 2,5-furandicarboxylate moiety within the polymer backbone to be used in bottle, film or fibre applications

A process for preparing a polymer having a 2,5-furandicarboxylate moiety within the polymer backbone, and having a number average molecular weight of at least 25,000, includes a transesterification step, a polycondensation step, a drying and / or crystallizing step, and a step where the polymer is subjected to post condensation conditions, and to a polyester-containing bottle or film or fibre-containing woven or non-woven object made from melt-processing poly(ethylene-2,5-furandicarboxylate), where the poly(ethylene-2,5-furandicarboxylate) is obtainable by the process of the invention.

Owner:FURANIX TECH BV

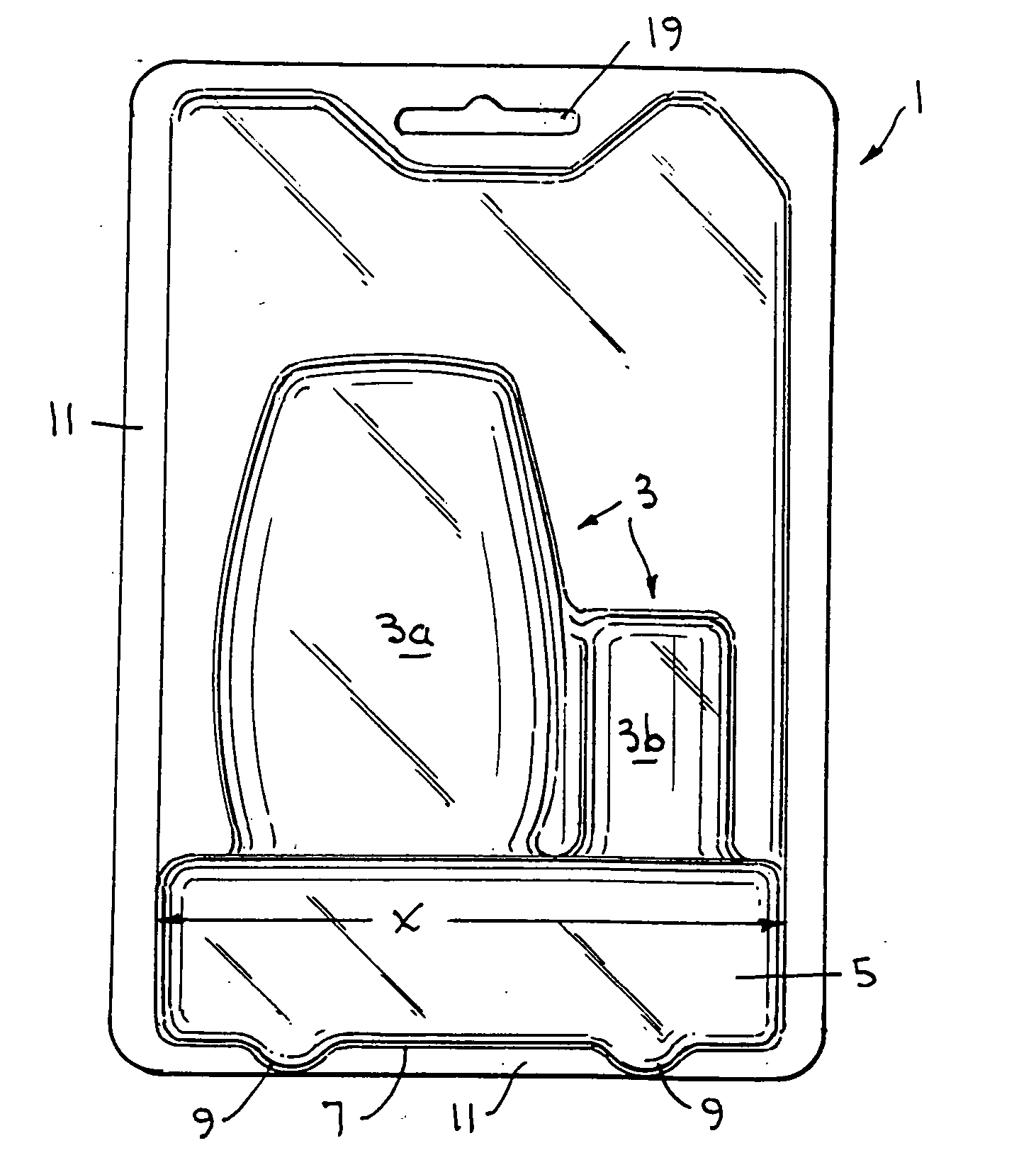

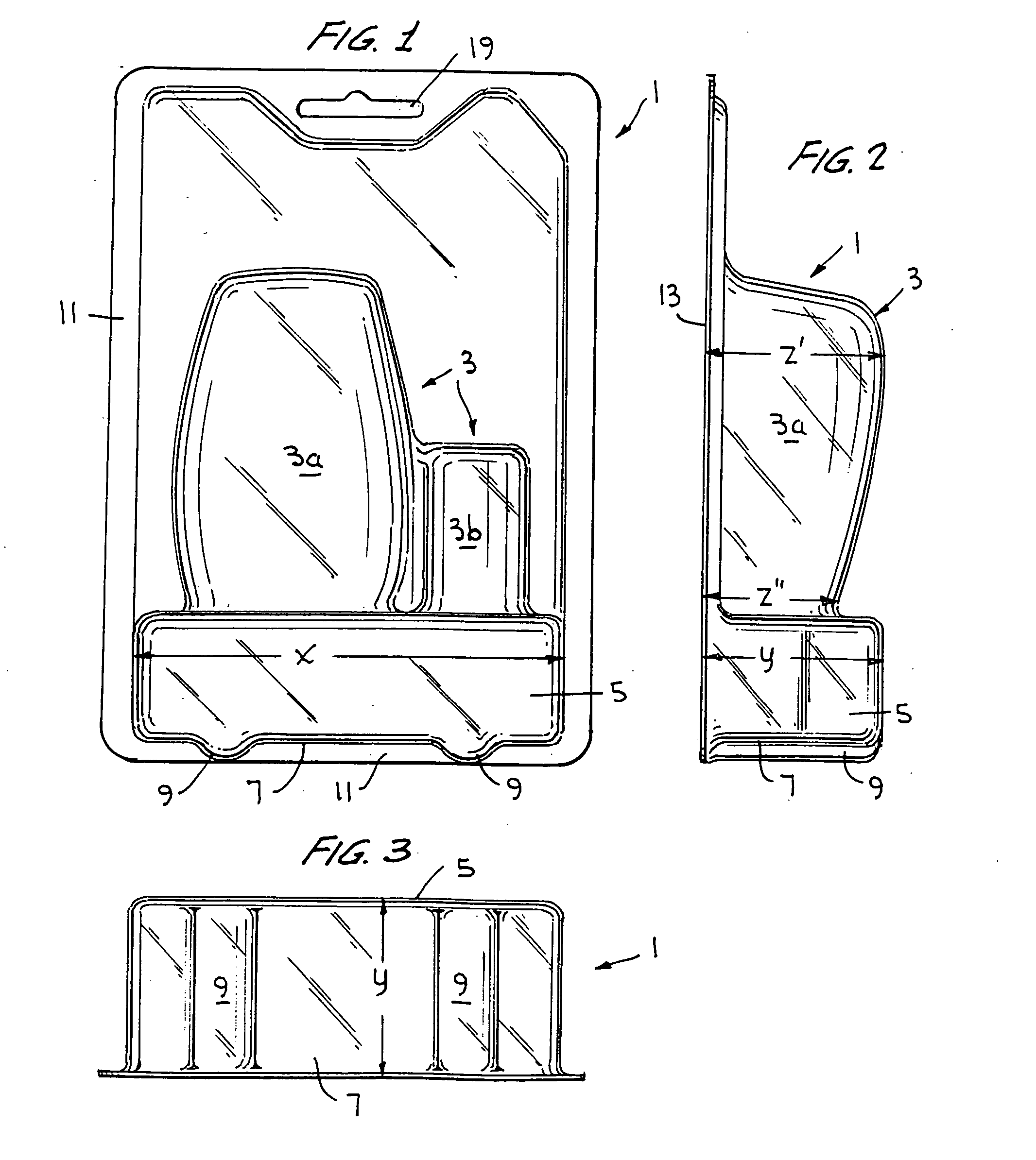

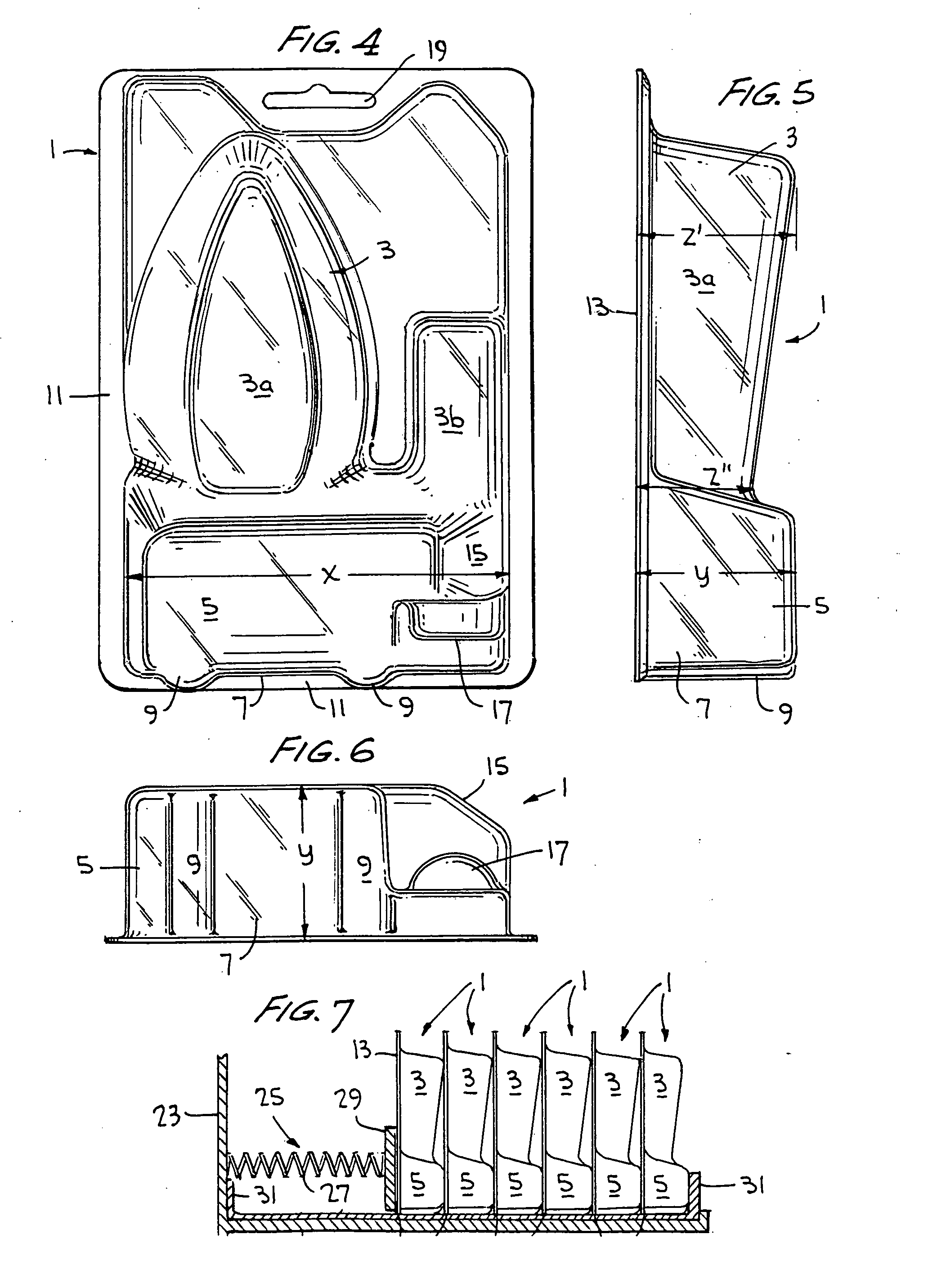

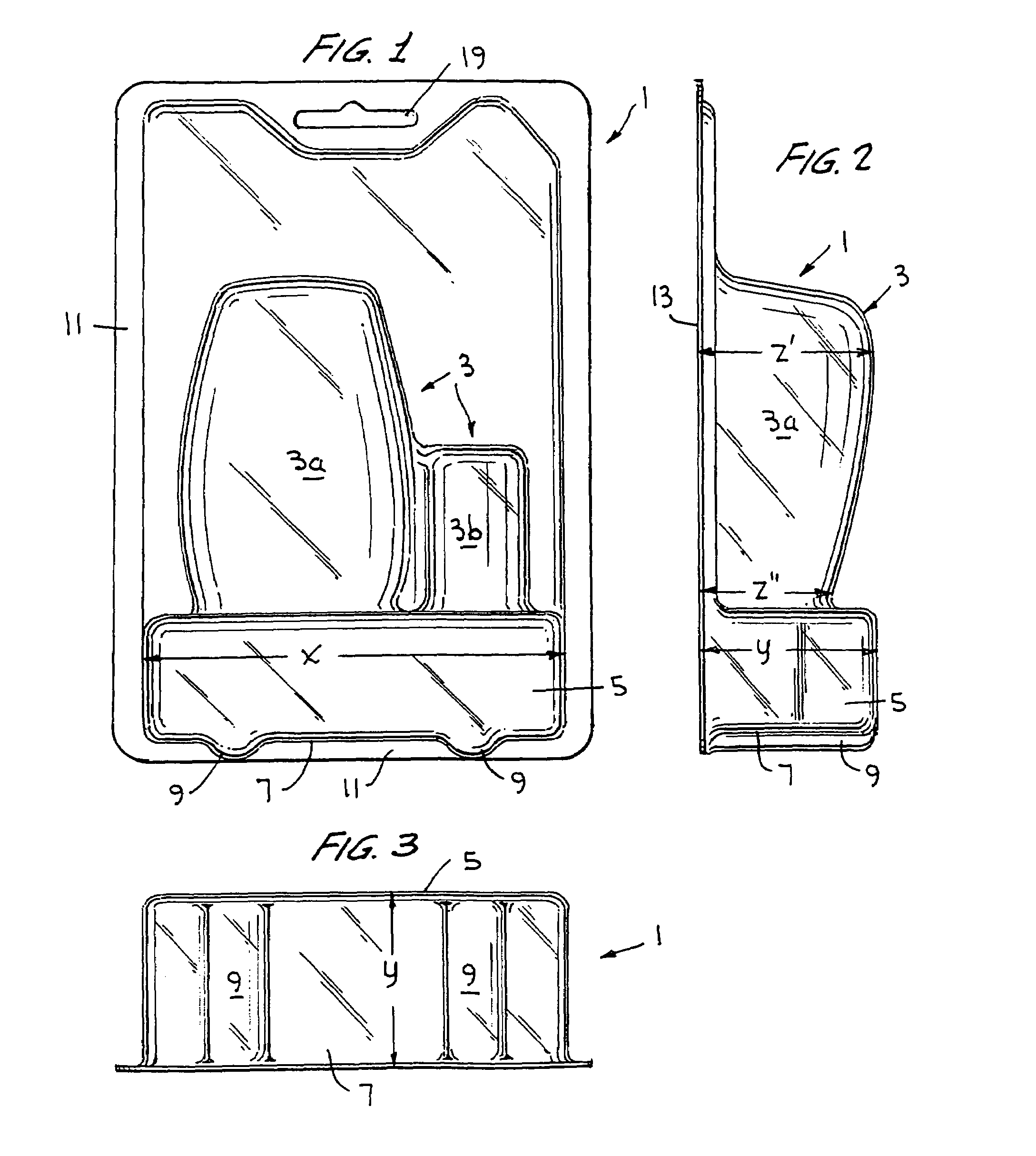

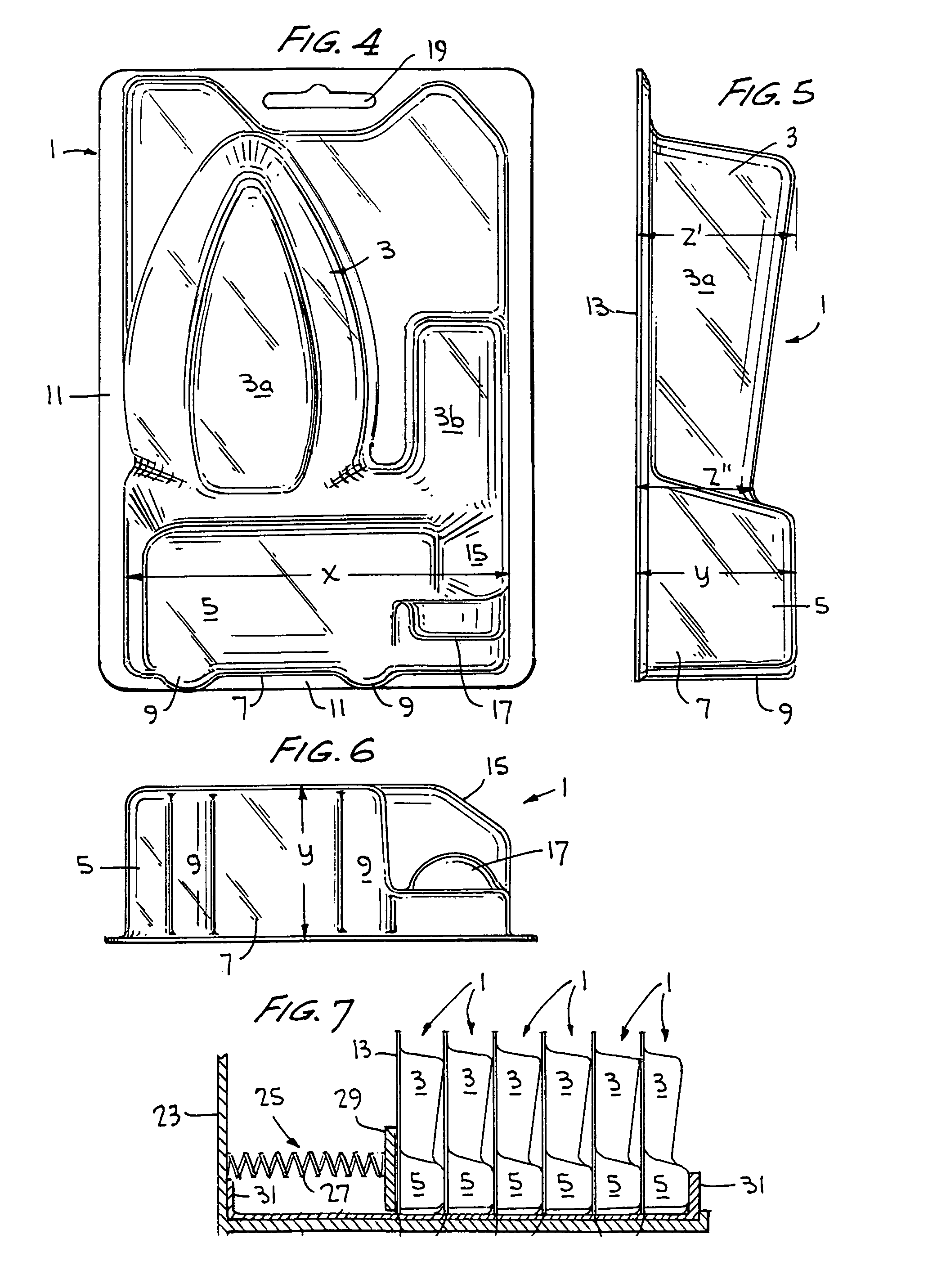

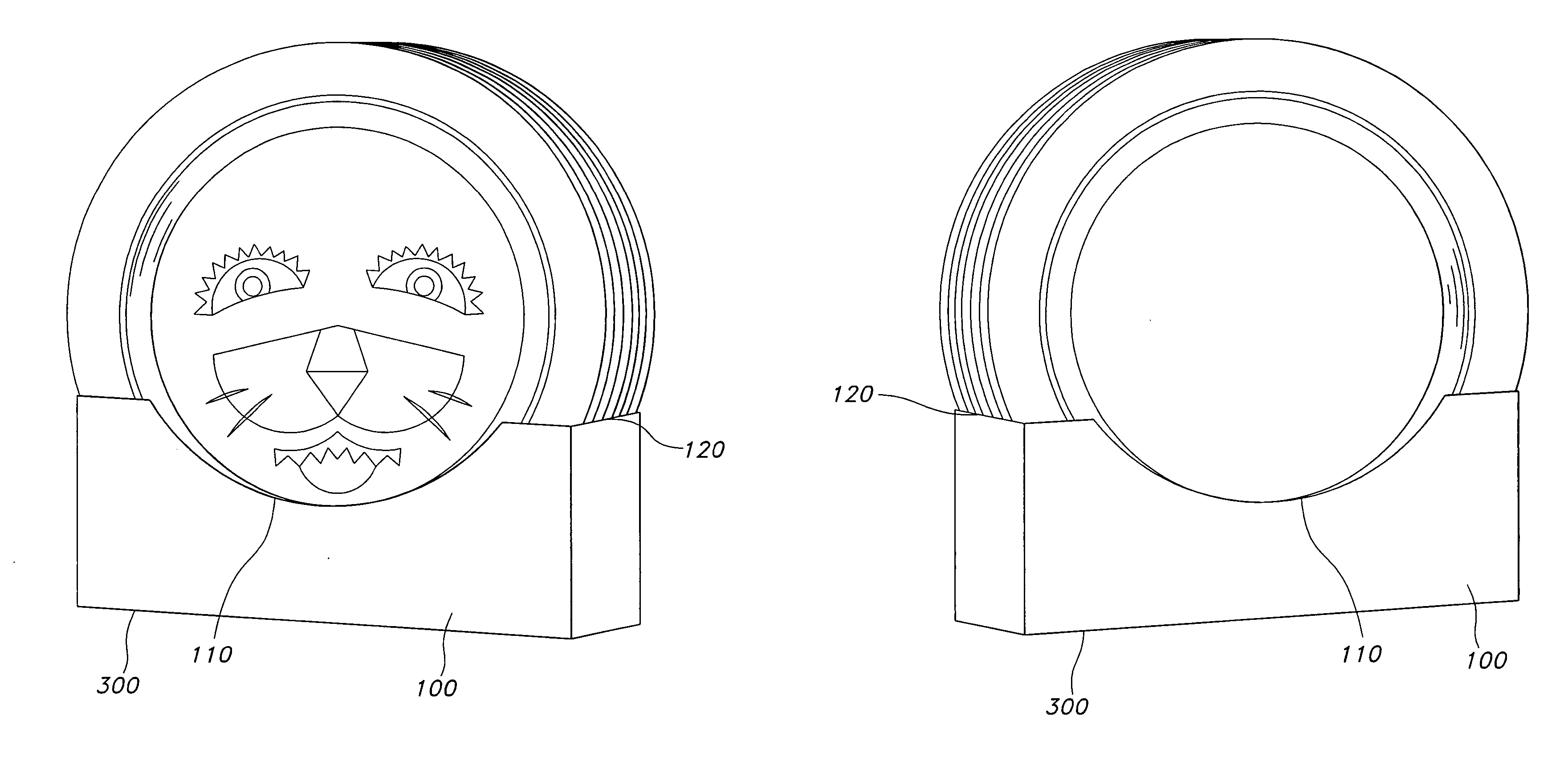

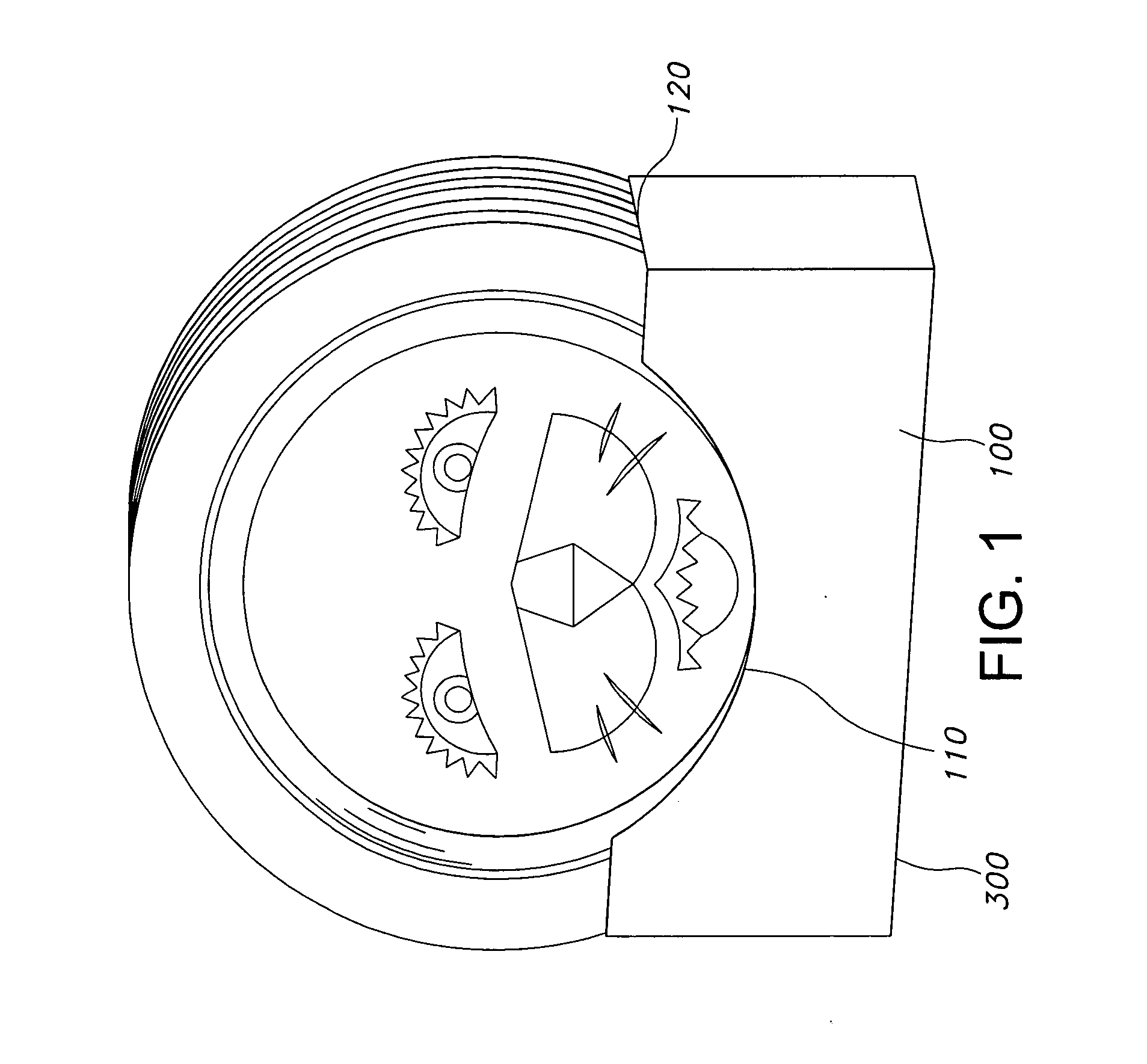

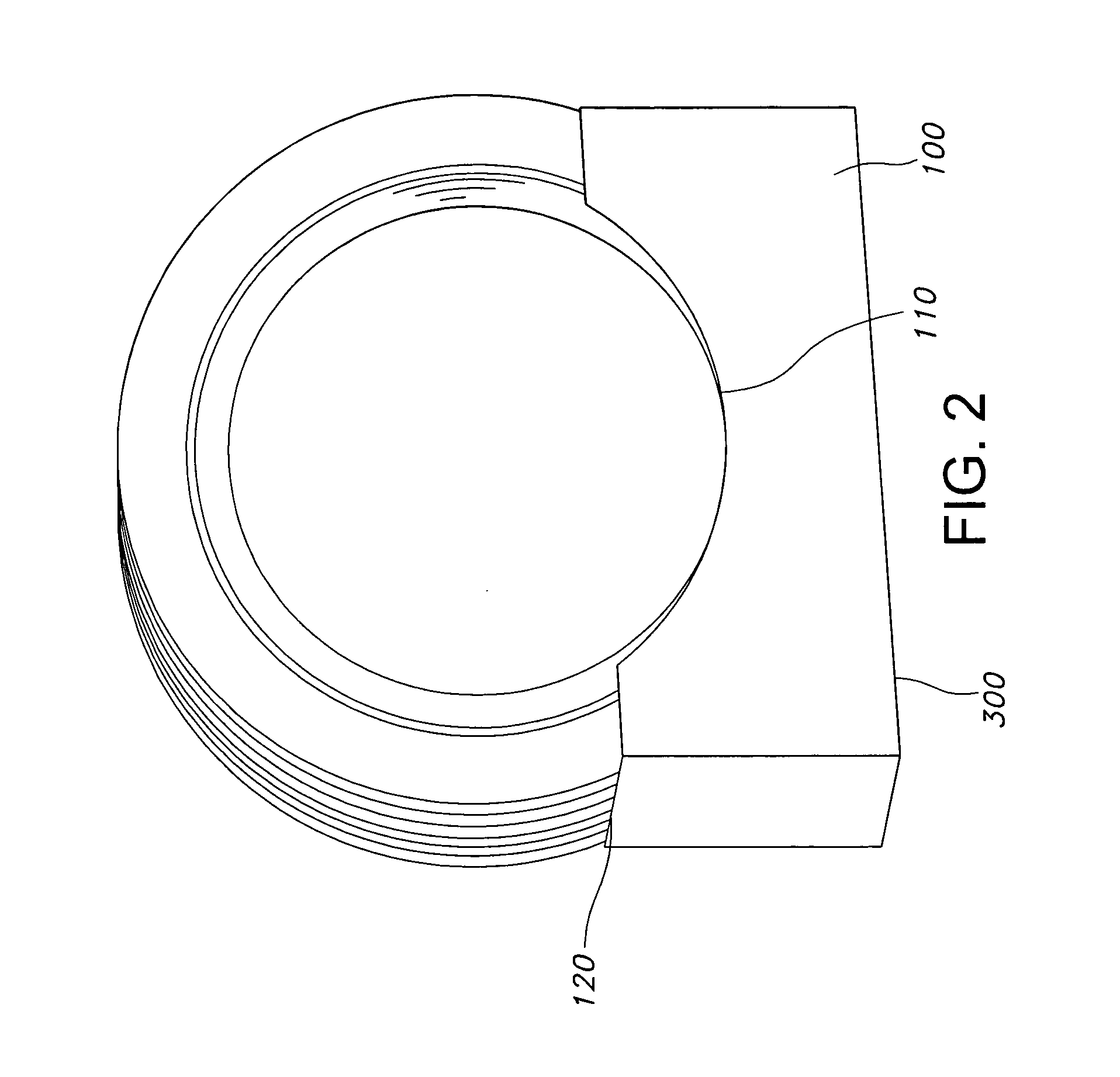

Display package with stabilizing and indexing means

ActiveUS20050092644A1Provide stabilityImprove package stabilityRacksOther accessoriesEngineeringBlister pack

A blister pack and package including such blister pack is described which provides for package stability and self-indexing in relation to adjacently aligned packages. The blister pack is configured to include at least one compartment for enclosing an article, and an outward projecting portion or foot in the bottom portion of the blister pack. The foot is configured to have a width, depth and height sufficient to allow the package to be freestanding and self-indexing. The package is especially suited for use in a merchandise point-of-sale display including a pressure applicator for maintaining displayed packages in a forwardmost position in the display when one or more packages are removed from the display. The foot provides for a predetermined stable spacing during packaging and while in storage and on display, and provides for self-indexing, i.e. maintenance of proper spacing, when a pressure applicator moves the aligned packages forward in a display.

Owner:SC JOHNSON & SON INC

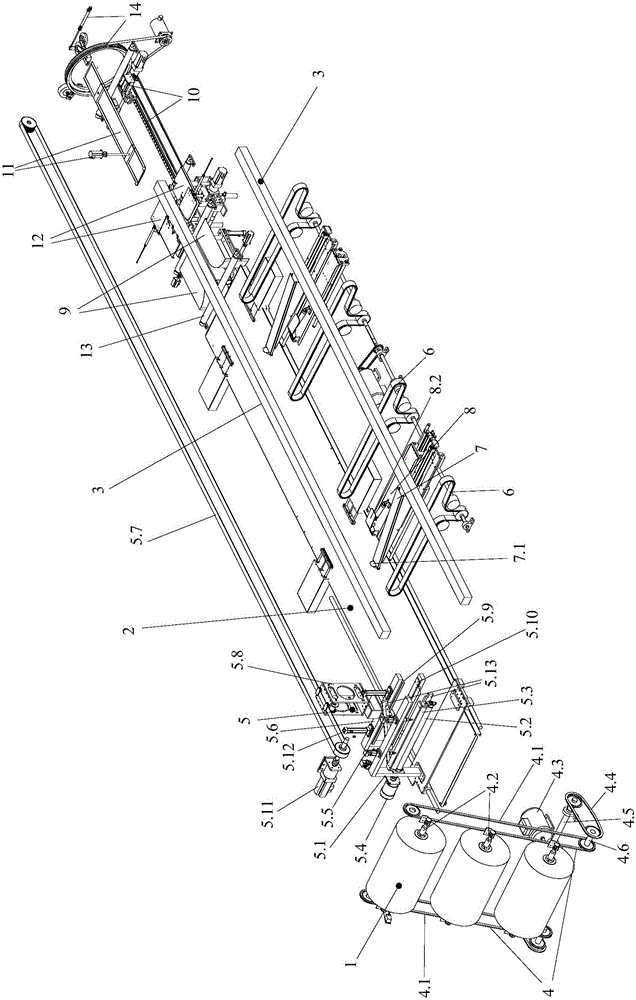

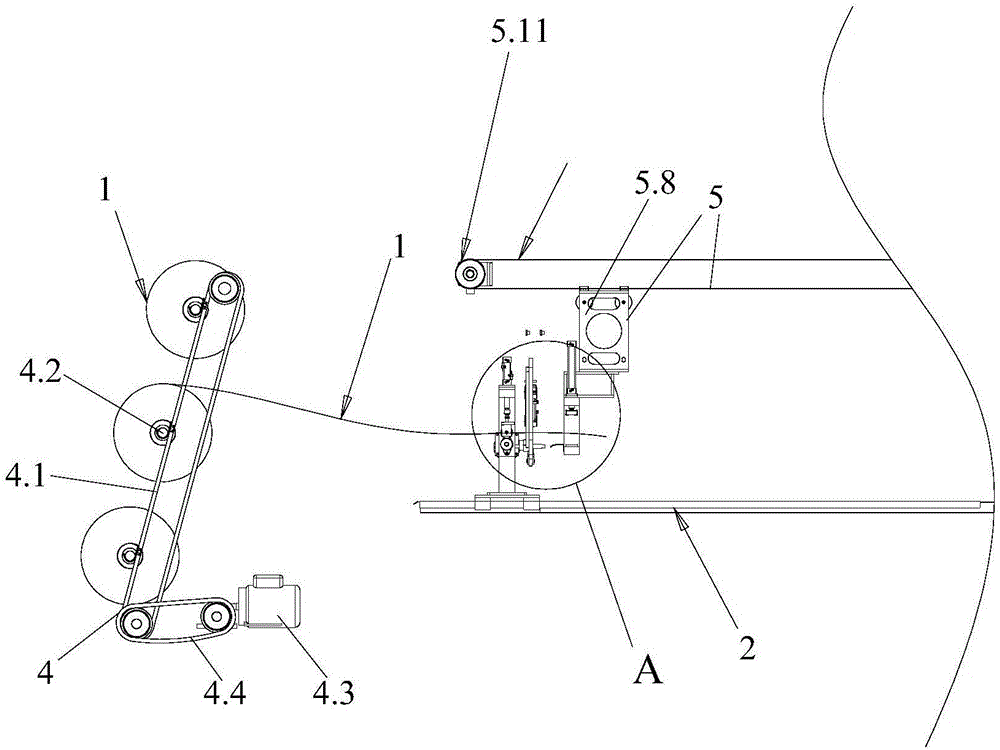

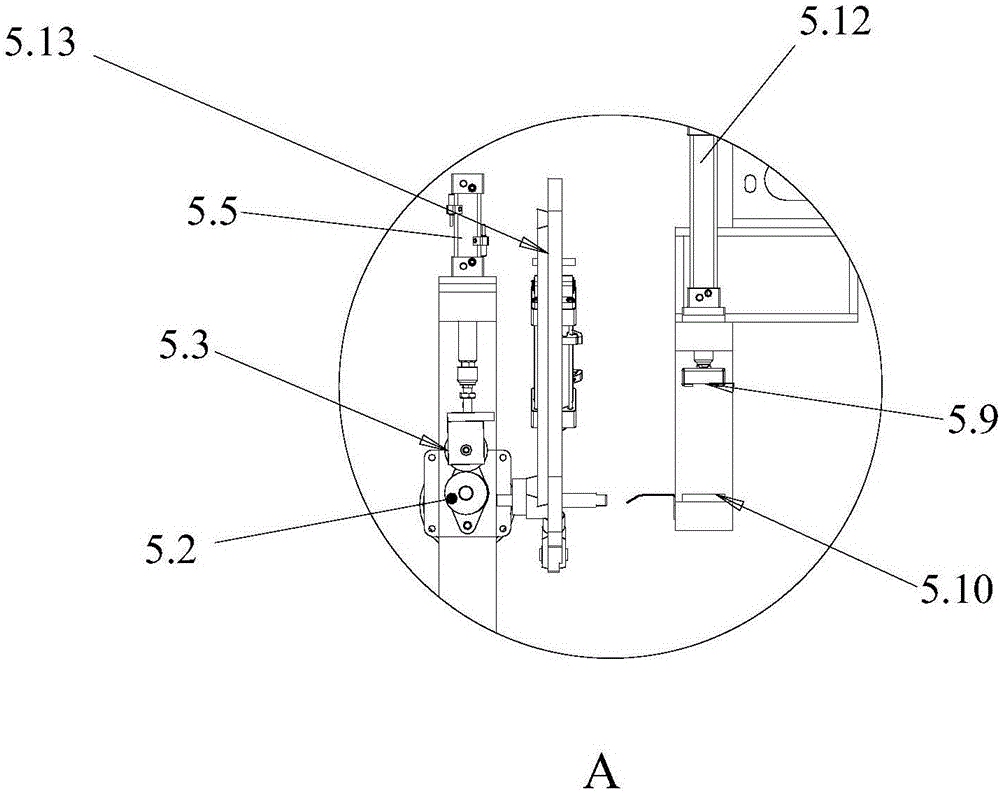

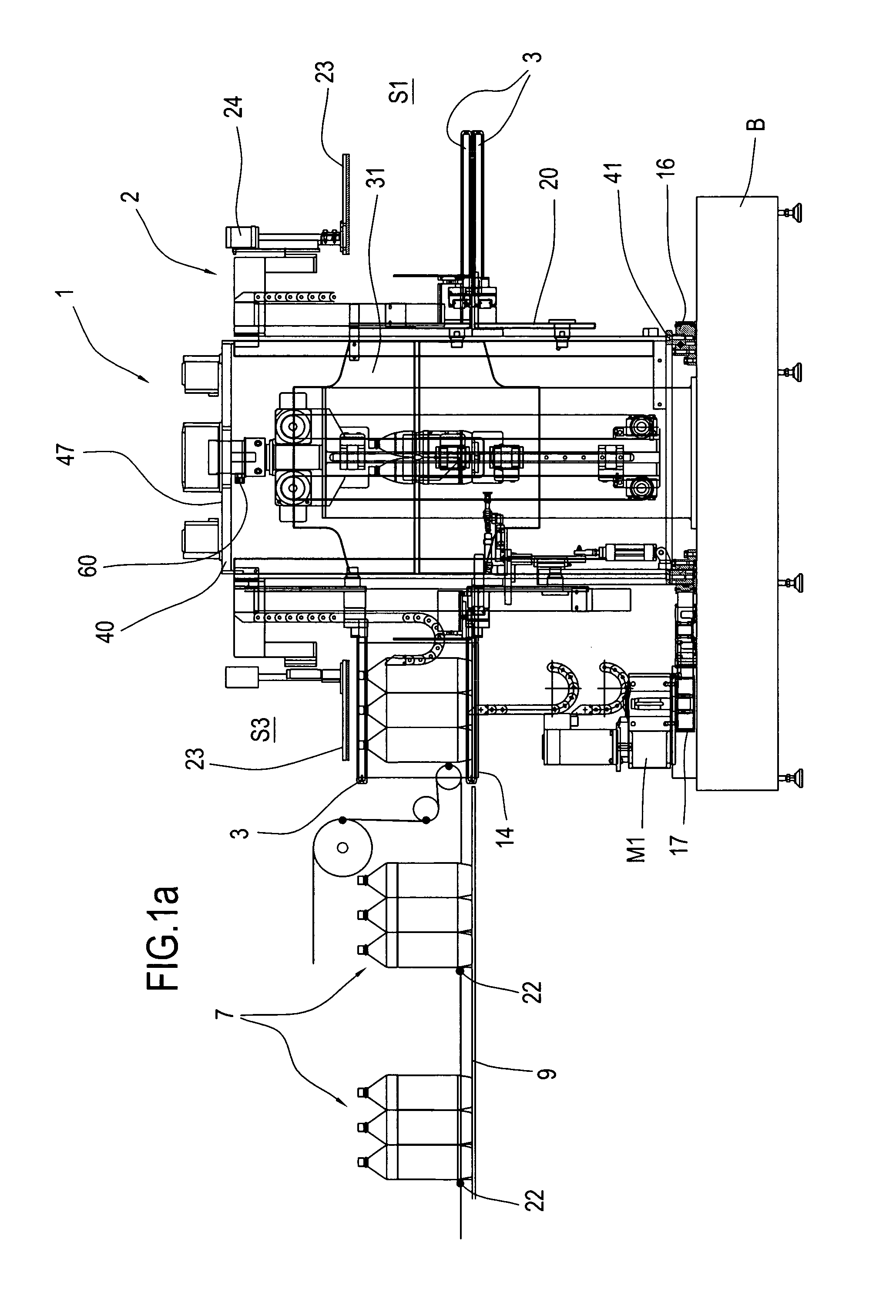

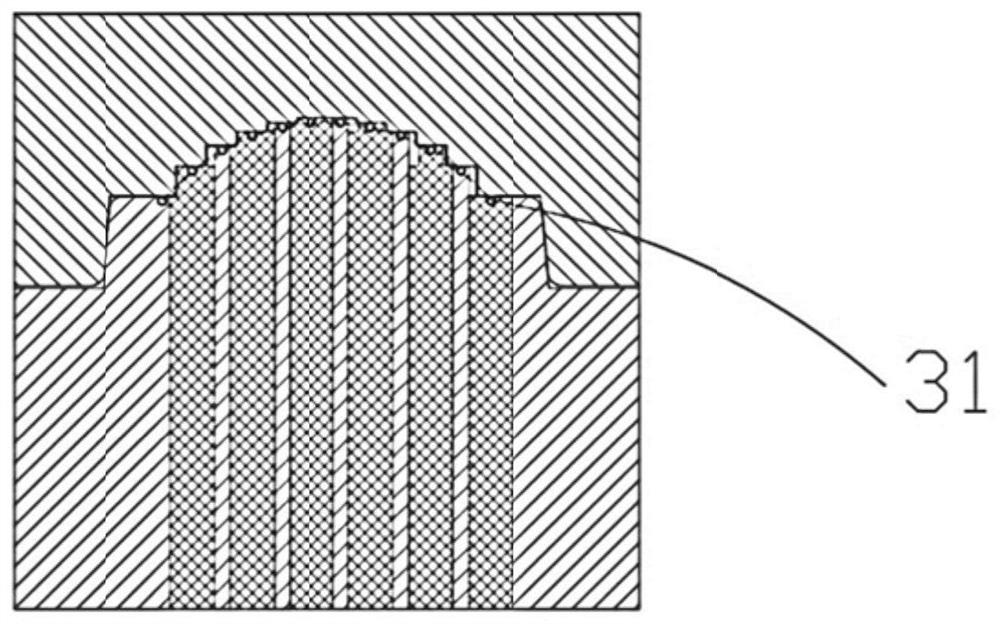

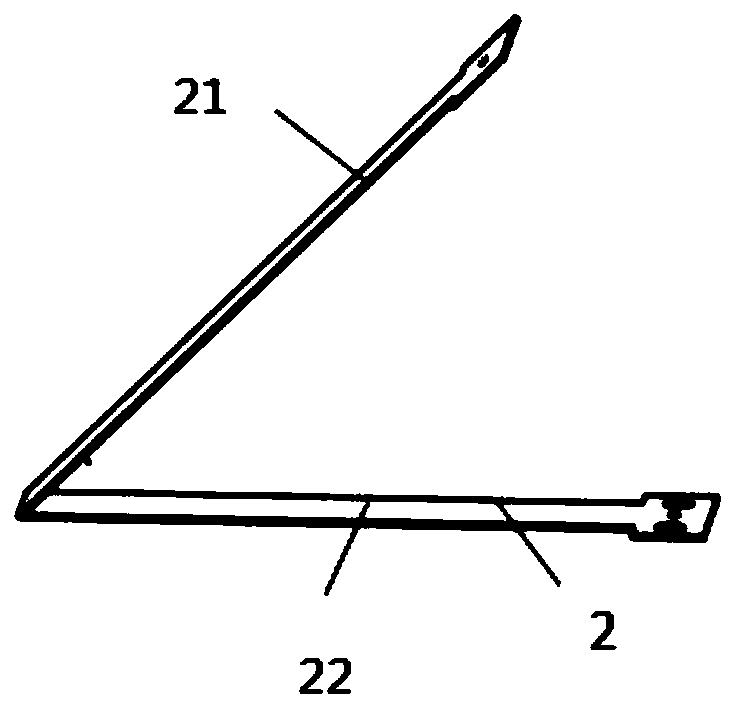

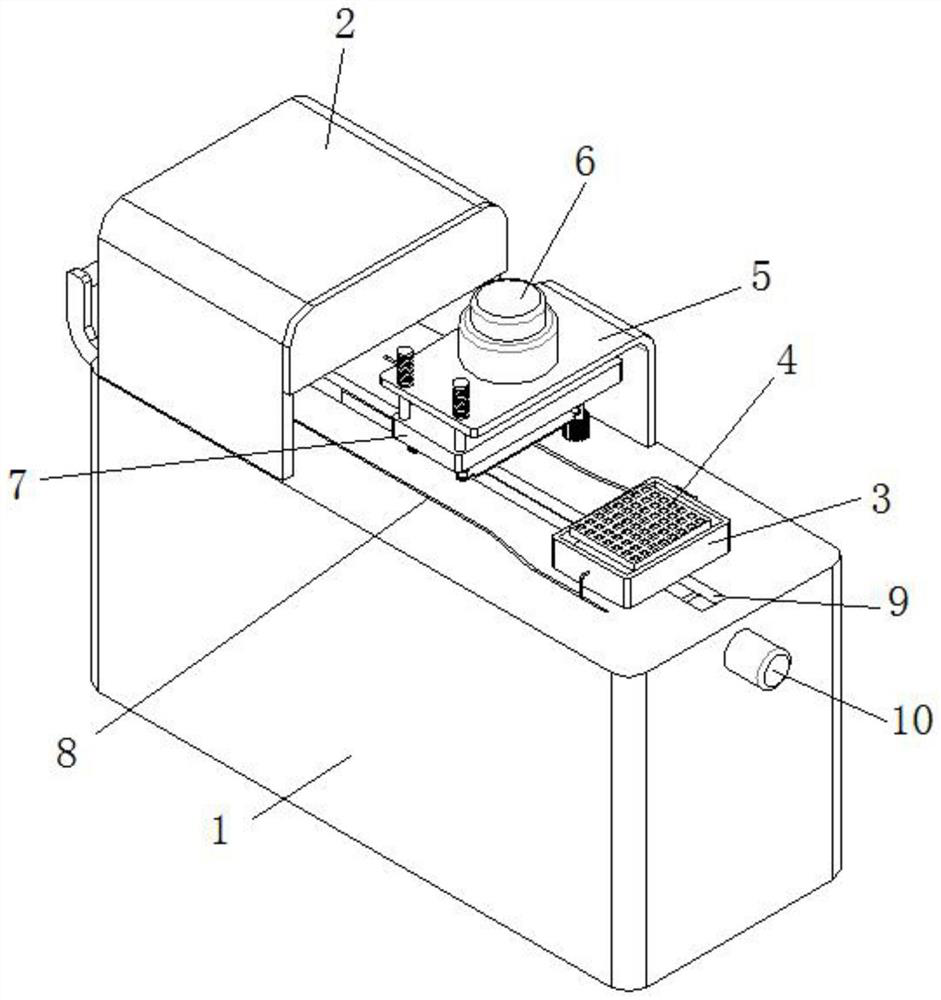

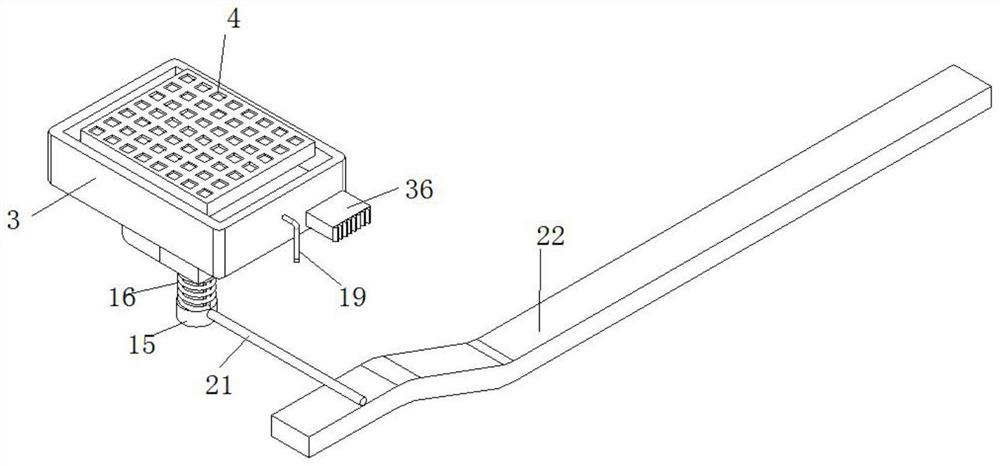

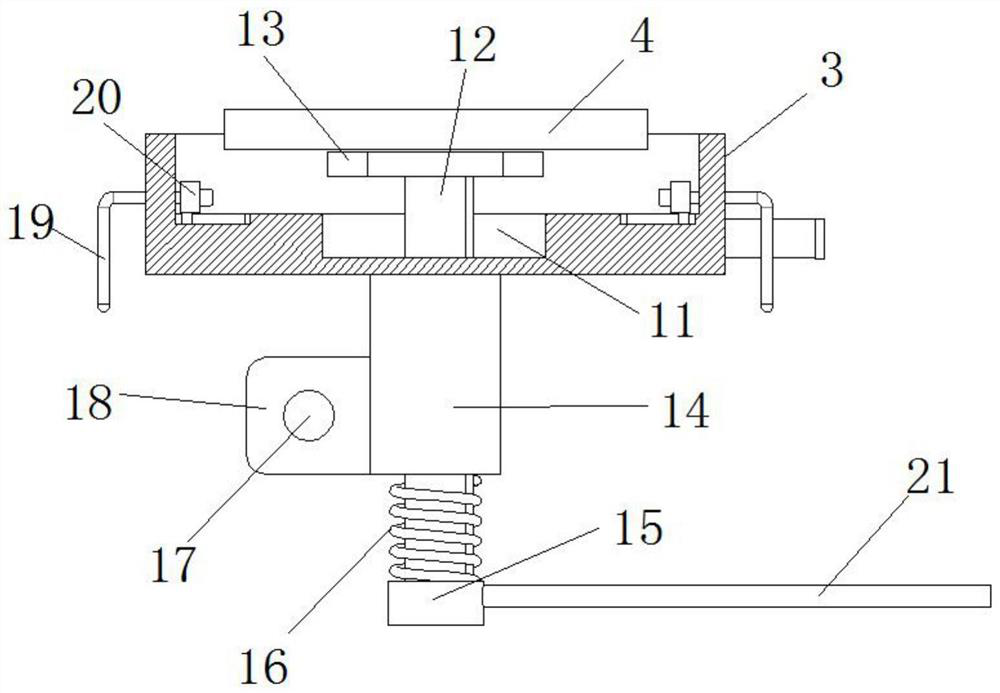

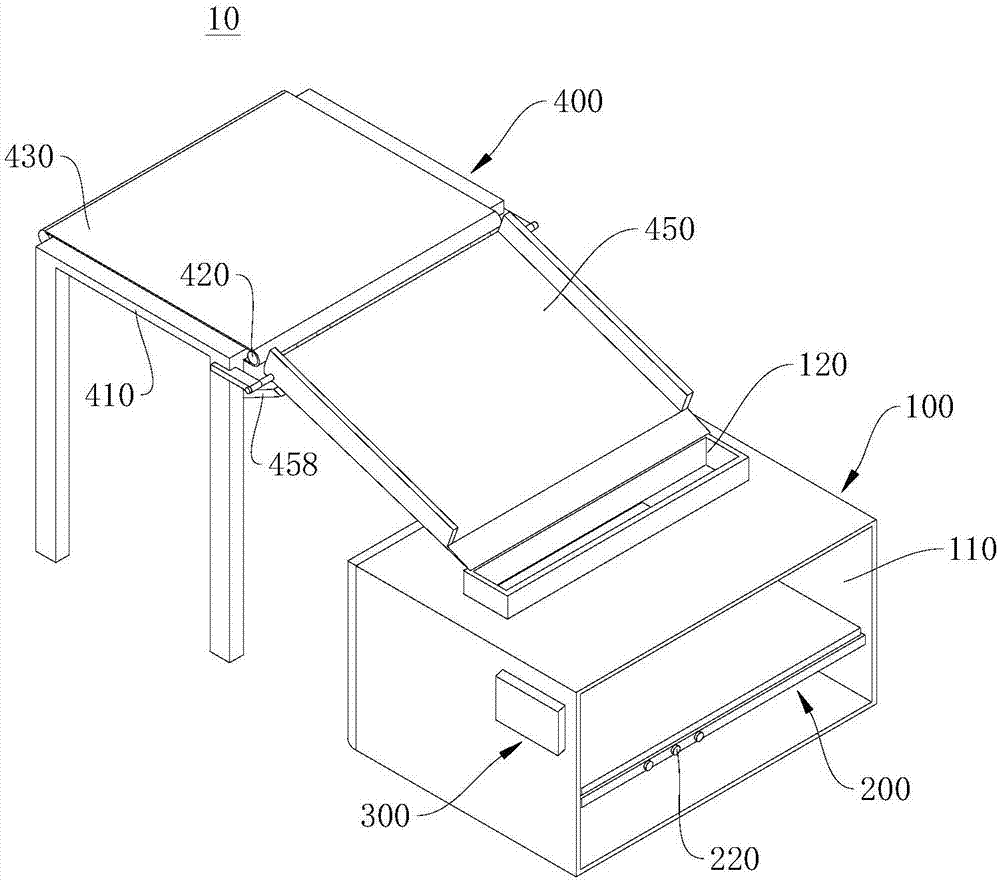

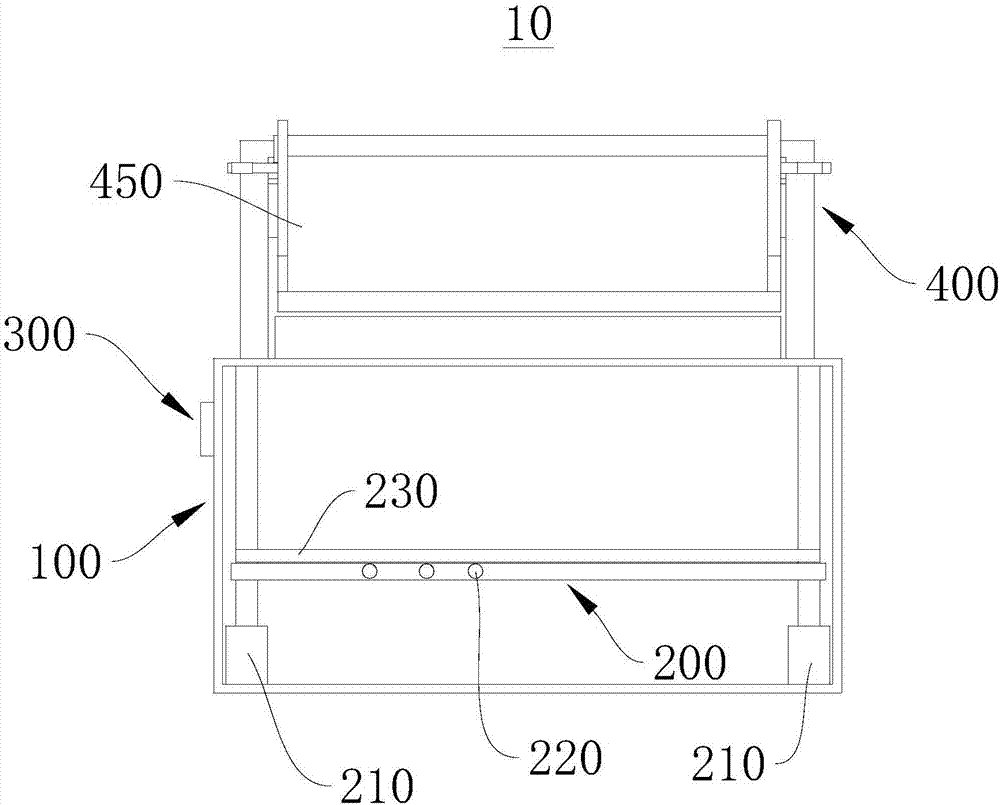

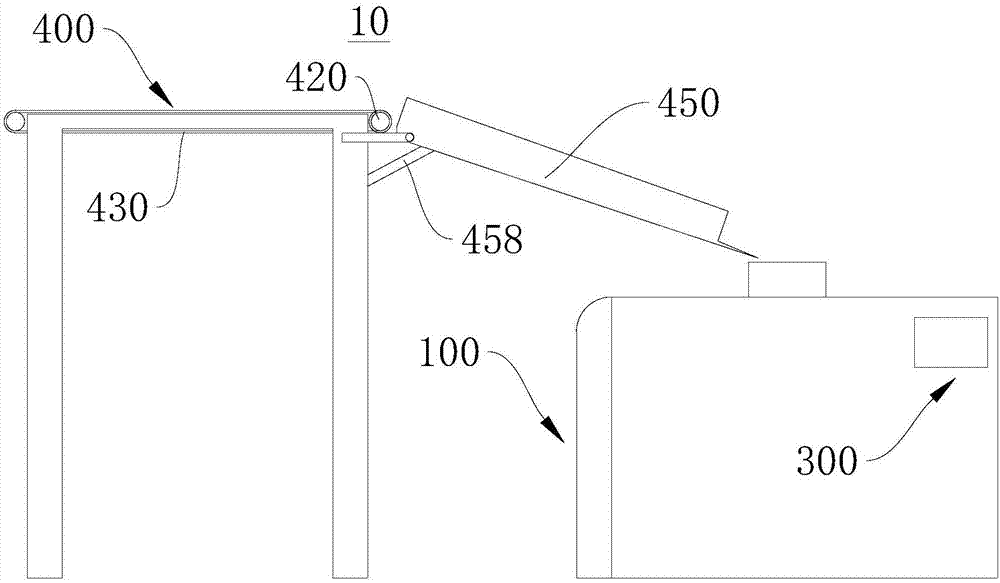

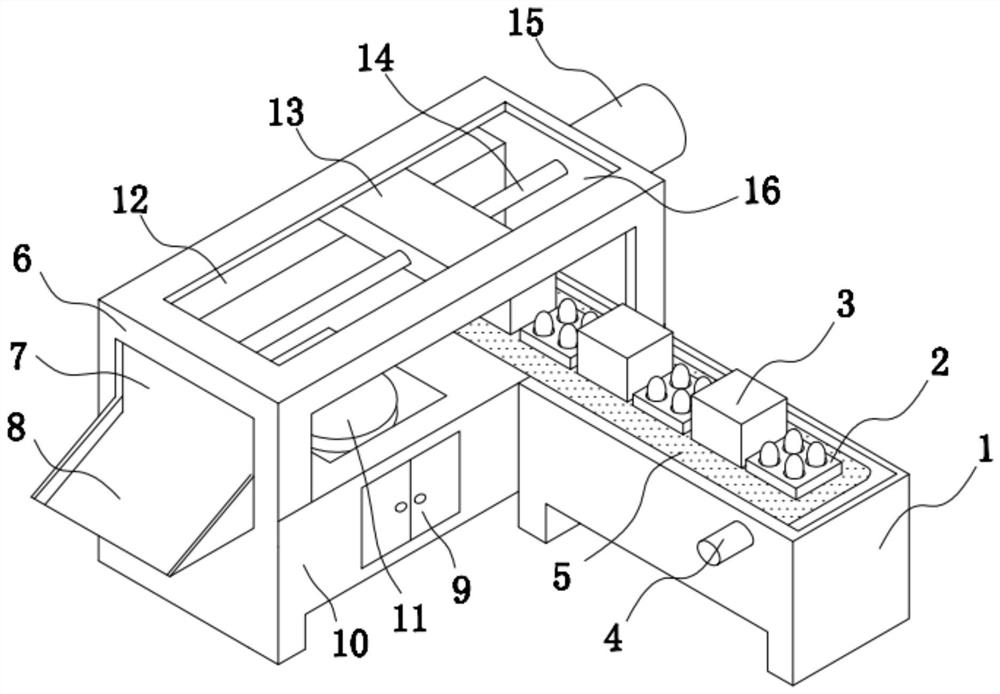

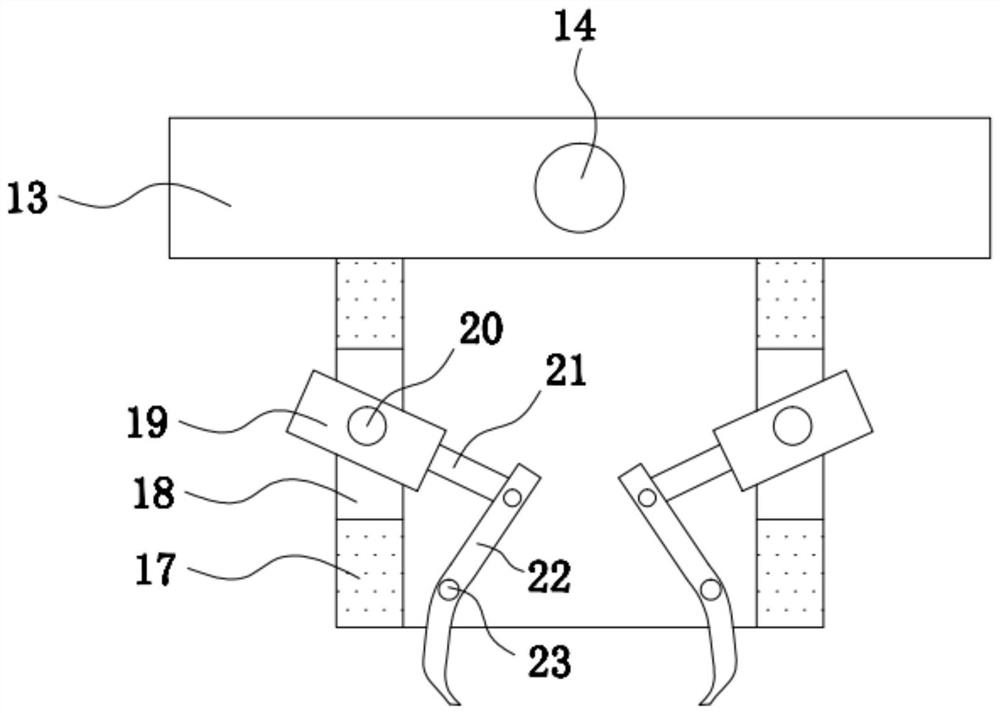

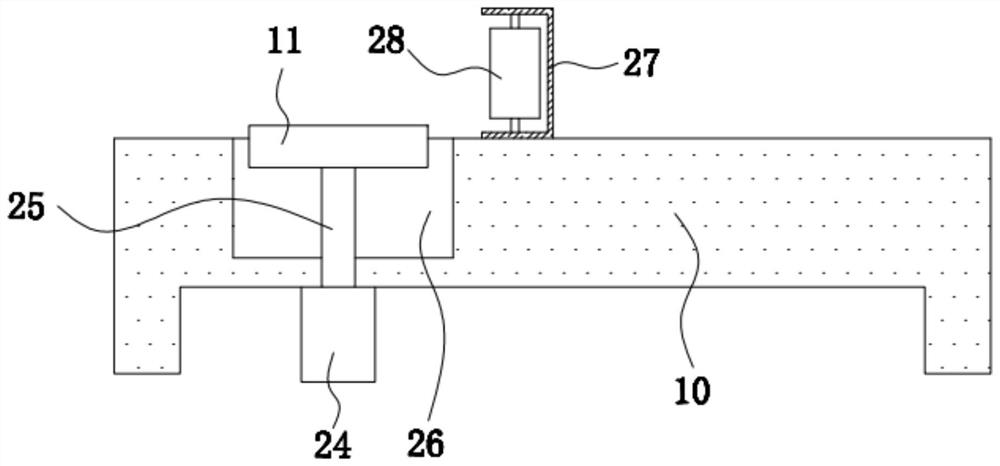

Section bar automatic packaging equipment

ActiveCN106218968AIncrease productivitySolve the low degree of automationWrapper folding/bending apparatusWrappingReciprocating motionUltimate tensile strength

The invention provides section bar automatic packaging equipment. The section bar automatic packaging equipment comprises a packaging paper feeding mechanism, a section feeding mechanism, a vertical folding mechanism, horizontal folding mechanisms, a packaging mechanism, a clamping and feeding mechanism, a pushing mechanism and a control mechanism, wherein the packaging paper feeding mechanism is used for lifting, pulling out and shearing and paving packaging paper on a platform; the section feeding mechanism is used for transferring and locating a section bar in the middle part of the platform where the packaging paper is paved; the vertical folding mechanism is used for adjusting the side edge separation distance of the packaging paper and bending the side edge of the packaging paper paved on the platform; the horizontal folding mechanisms are used for adjusting the side edge separation distance of the packaging paper and bending the side edge of the packaging paper paved on the platform and then horizontally folding the upper part of the side edge of the packaging paper, so that the packaging paper wrap the end surface of the section bar; the packaging mechanism is used for winding and sealing the packaging paper which wraps the section bar; the clamping and feeding mechanism is used for a reciprocating motion to transfer the section bar wrapped by the packaging paper to the packaging mechanism; and the pushing mechanism is used for compacting the opening of the packaging paper which wraps the end surface of the section bar. The section bar automatic packaging equipment provided by the invention can solve the problems that the efficiency is low and the labor intensity is great due to a manual operation, so that the packaging efficiency and quality of the section bar are improved.

Owner:佛山市嘉荣智能机械有限公司

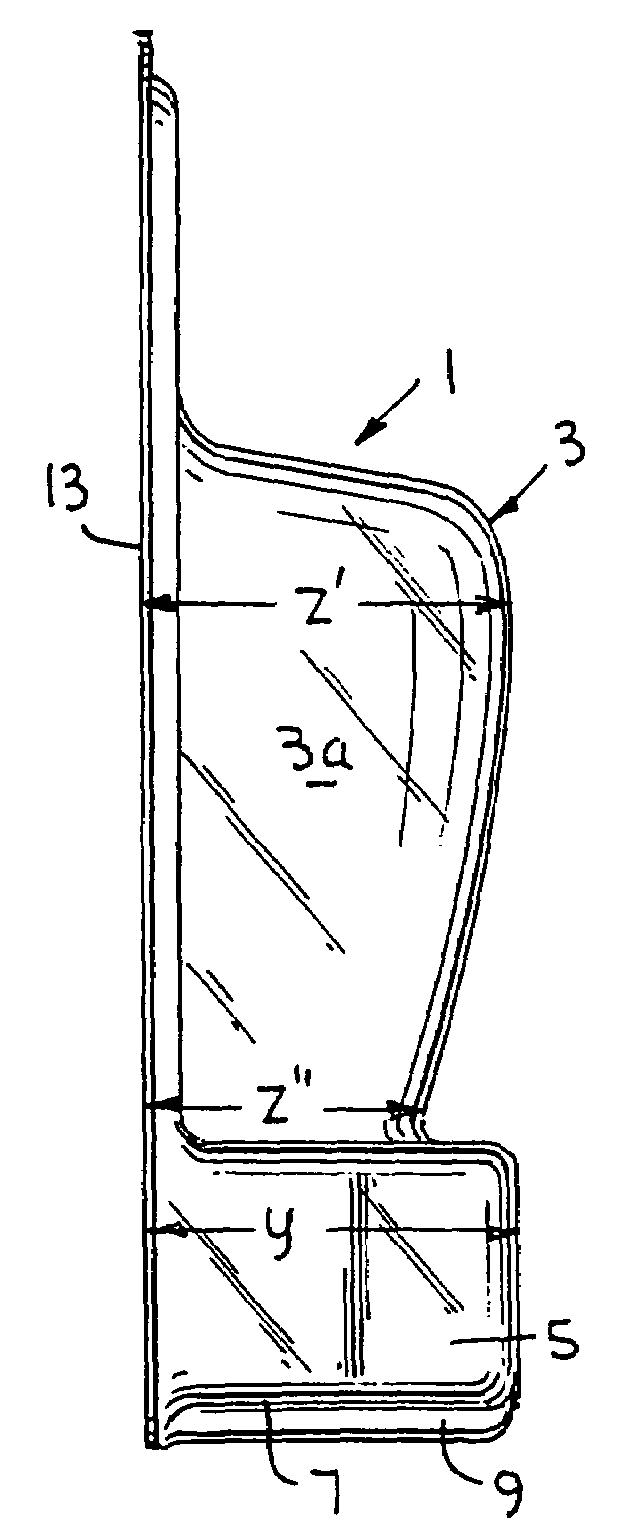

Display package with stabilizing and indexing means

ActiveUS7410056B2Provide stabilityImprove package stabilityRacksOther accessoriesDisplay deviceEngineering

A blister pack and package including such blister pack is described which provides for package stability and self-indexing in relation to adjacently aligned packages. The blister pack is configured to include at least one compartment for enclosing an article, and an outward projecting portion or foot in the bottom portion of the blister pack. The foot is configured to have a width, depth and height sufficient to allow the package to be freestanding and self-indexing. The package is especially suited for use in a merchandise point-of-sale display including a pressure applicator for maintaining displayed packages in a forwardmost position in the display when one or more packages are removed from the display. The foot provides for a predetermined stable spacing during packaging and while in storage and on display, and provides for self-indexing, i.e. maintenance of proper spacing, when a pressure applicator moves the aligned packages forward in a display.

Owner:SC JOHNSON & SON INC

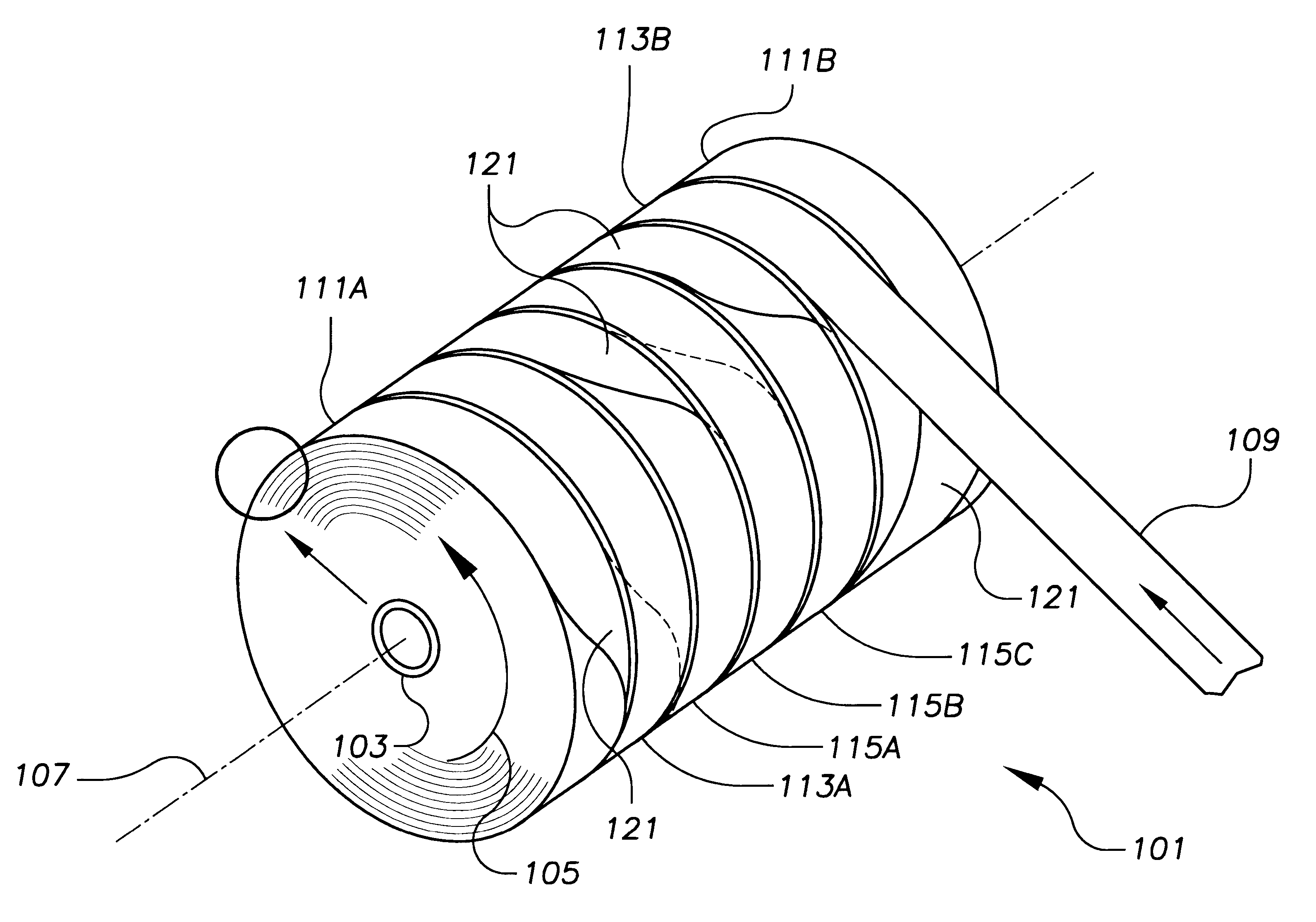

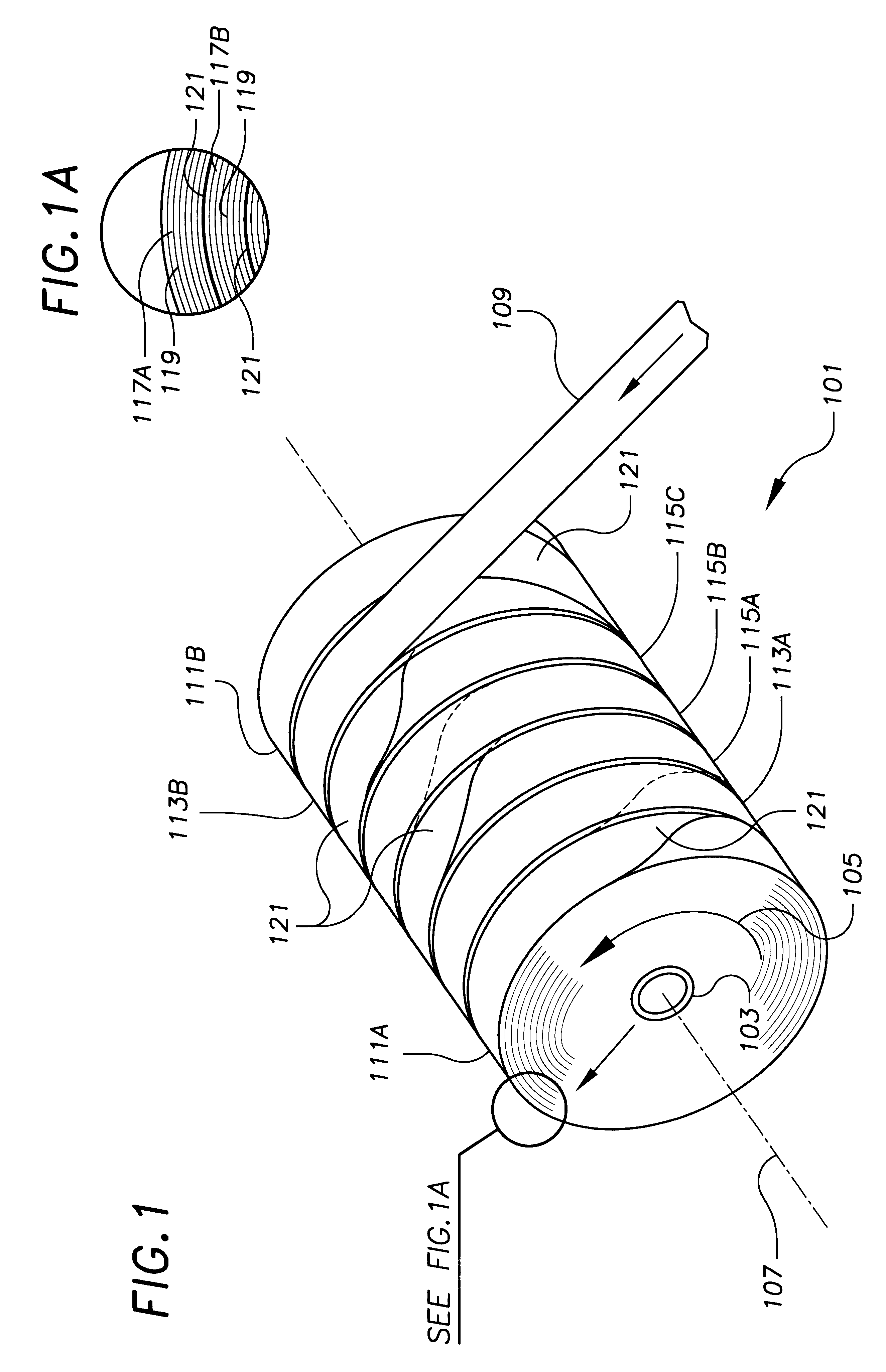

Multi-roll segment package for plastic tape

InactiveUS6209814B1Reduced transition stepReduce in quantityFilament handlingWebs handlingVolumetric Mass DensityConductor Coil

A multi-roll segment package (101) for plastic tape comprises a plurality of roll segments made up of concentrically disposed spiral winding groups (119) separated and defined by helical winding portions of tape (121) connecting the spiral winding groups on adjacent roll segments. The spiral winding groups of the end roll segments (111A), (111B) comprise at least 2.5 times the number of windings as the center roll segments (115A), (115B), (115C). The roll package features high wind density and good resistance from telescoping.

Owner:ISO POLY FILMS

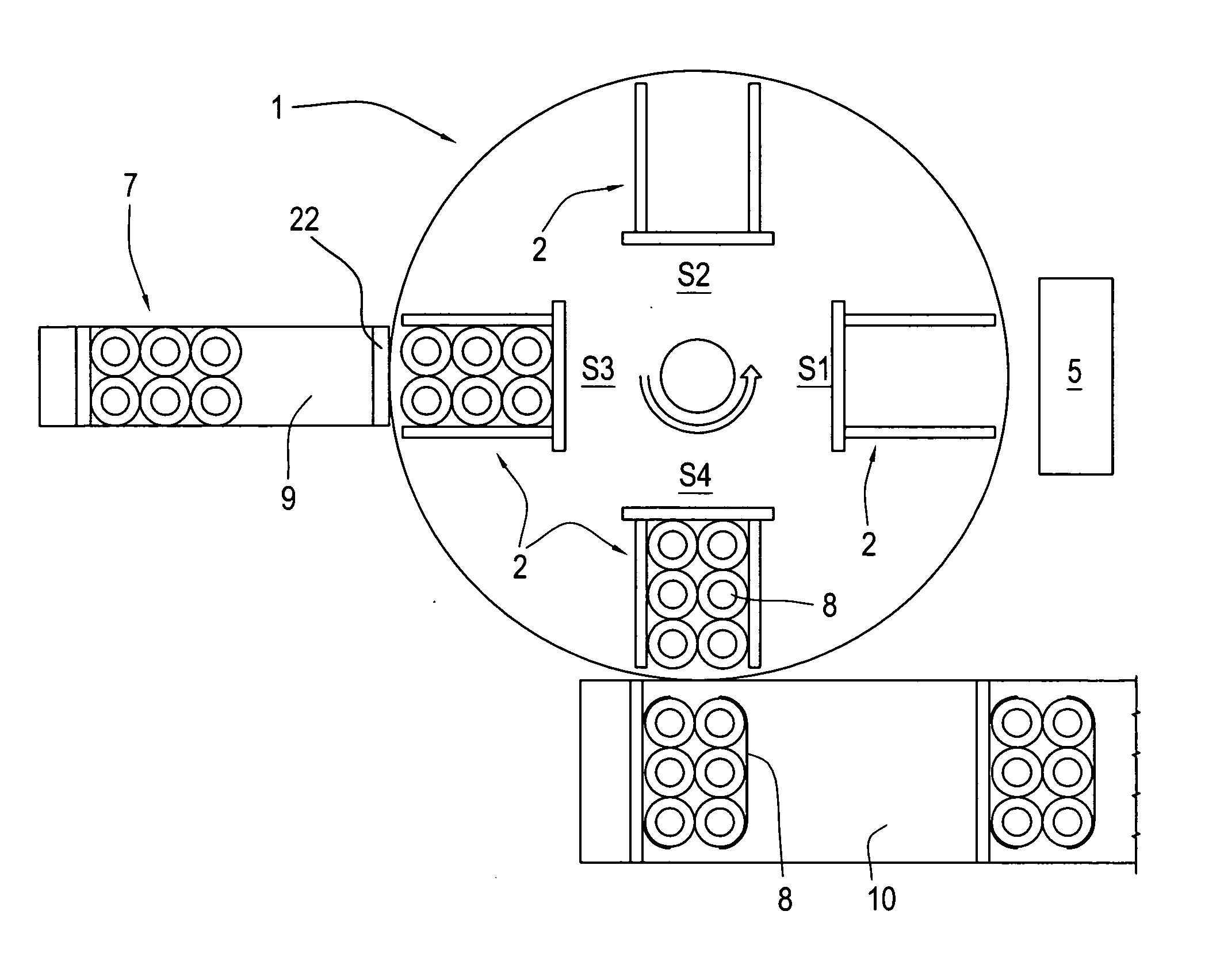

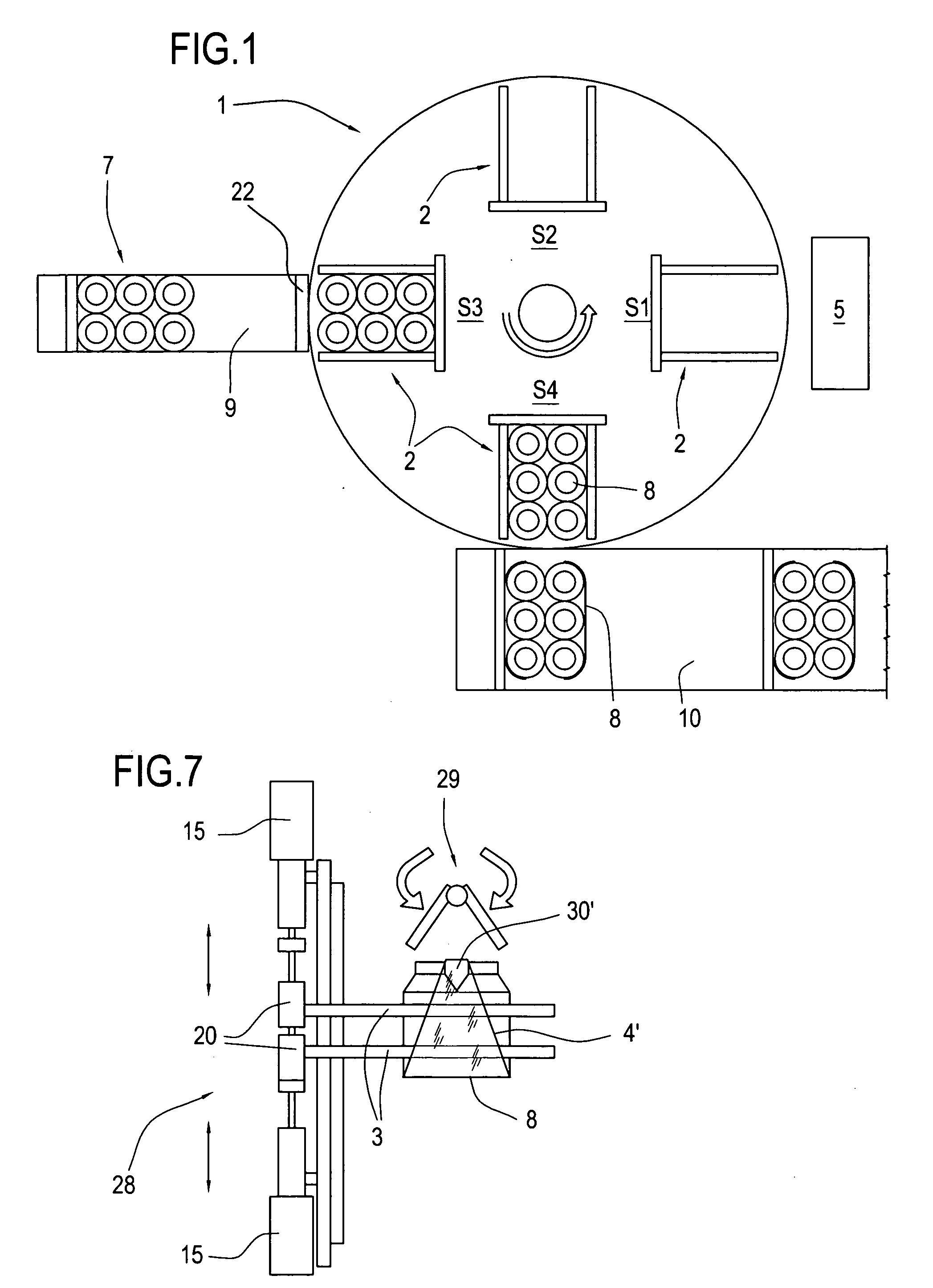

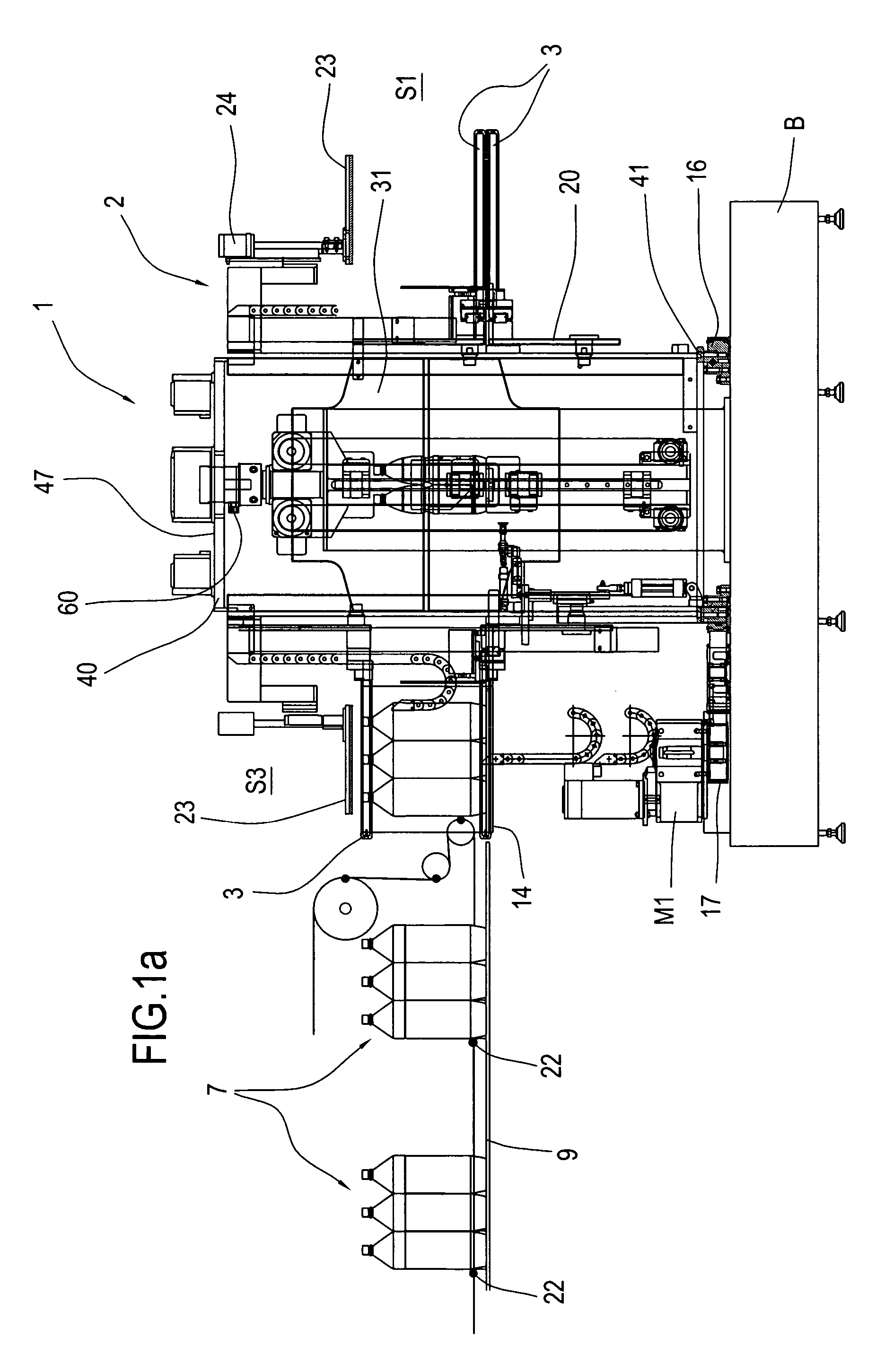

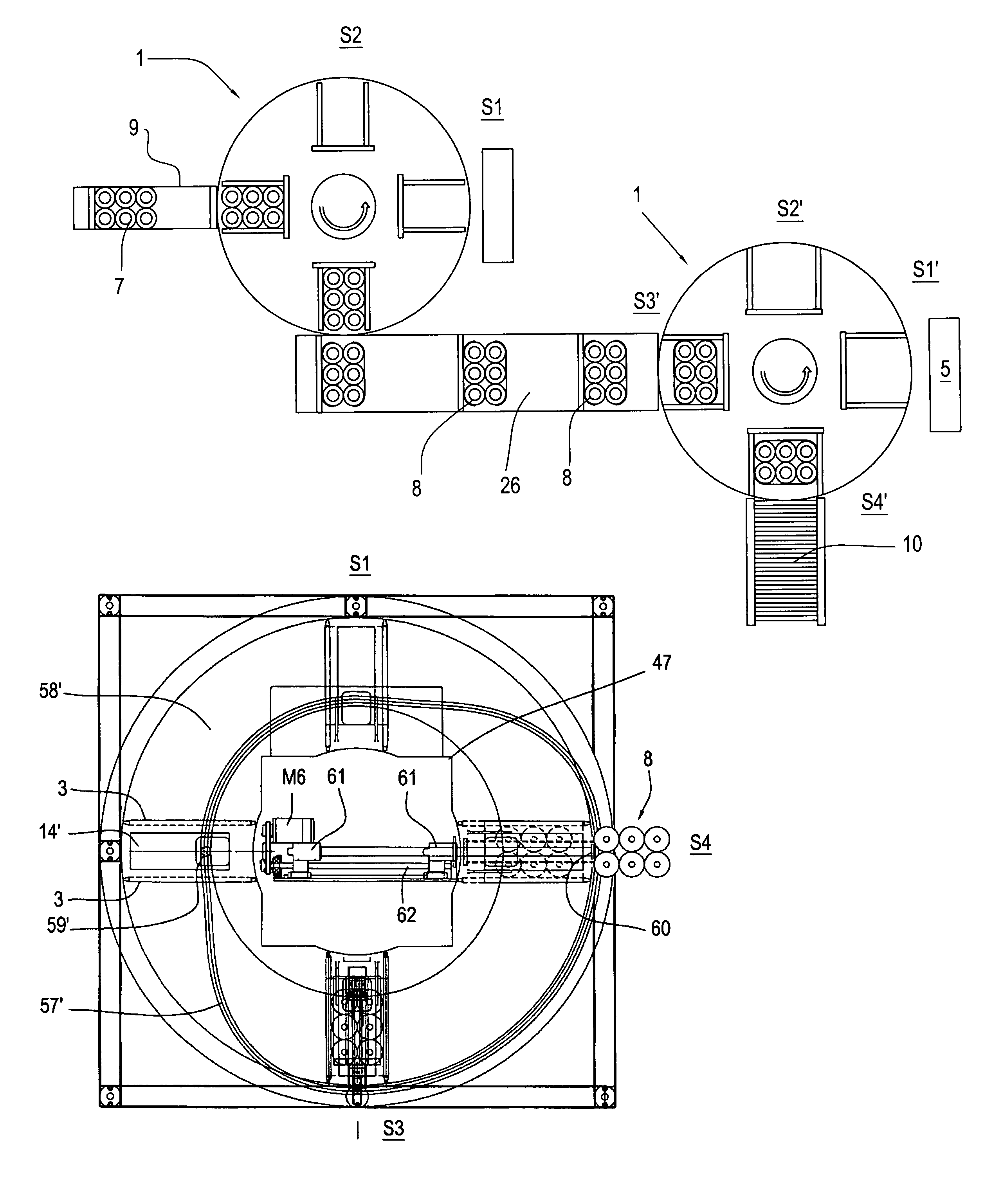

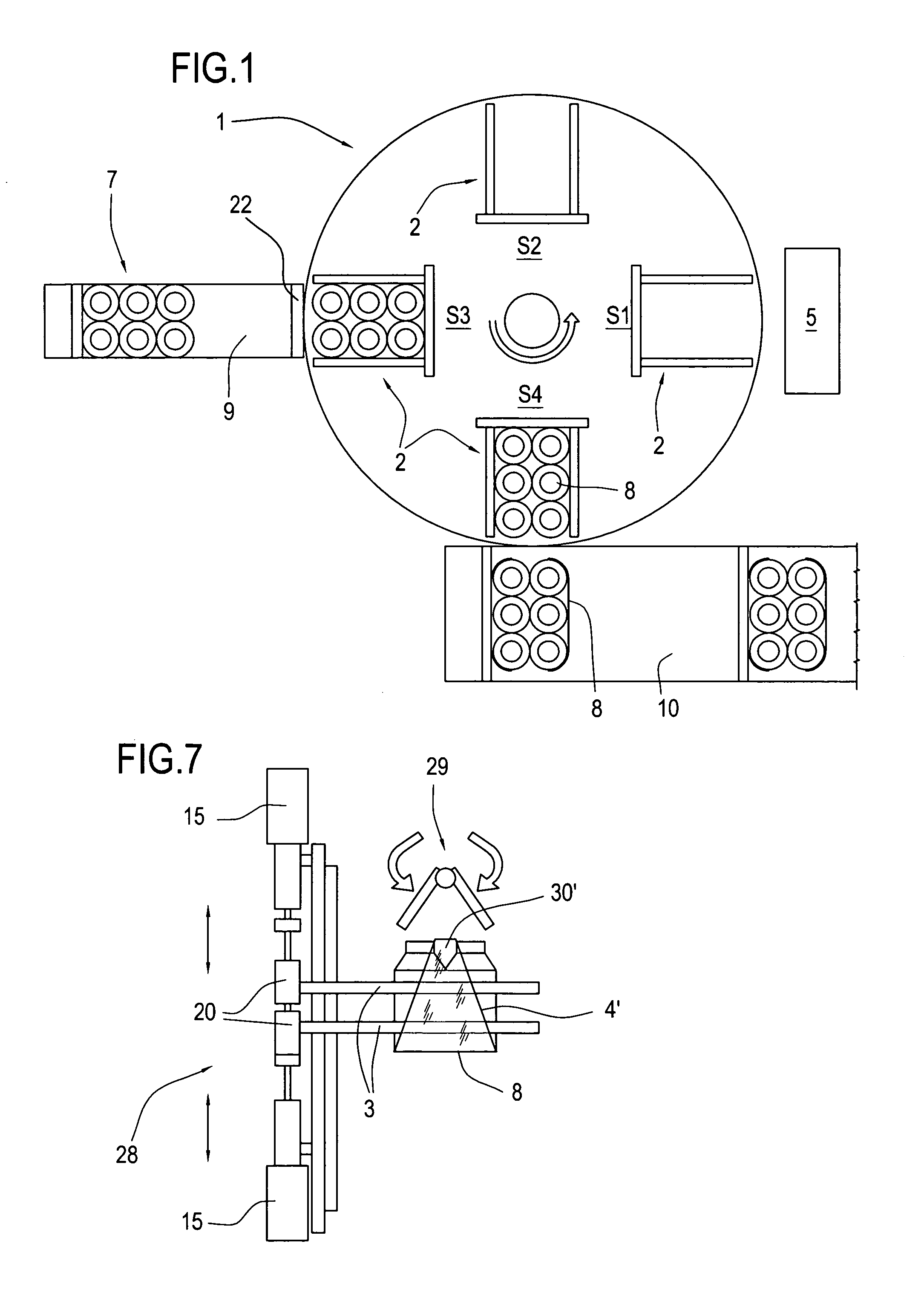

Machine for wrapping groups of products with tubular lenghts of stretch film

ActiveUS20050235613A1Reduce in quantityImprove positioning accuracyWrappers shrinkageWrapper folding/bending apparatusEngineering

A machine for wrapping groups of products (7) in tubular lengths of stretch film (4) comprises a rotating carousel (1) equipped with a plurality of wrapping units (2) having bars (3) for holding and stretching to size a succession of tubular film lengths (4) fed to a station (S1) and for placing the stretched tubular film lengths (4) around respective groups of products (7) to be wrapped fed one after the other.

Owner:AETNA GROUP

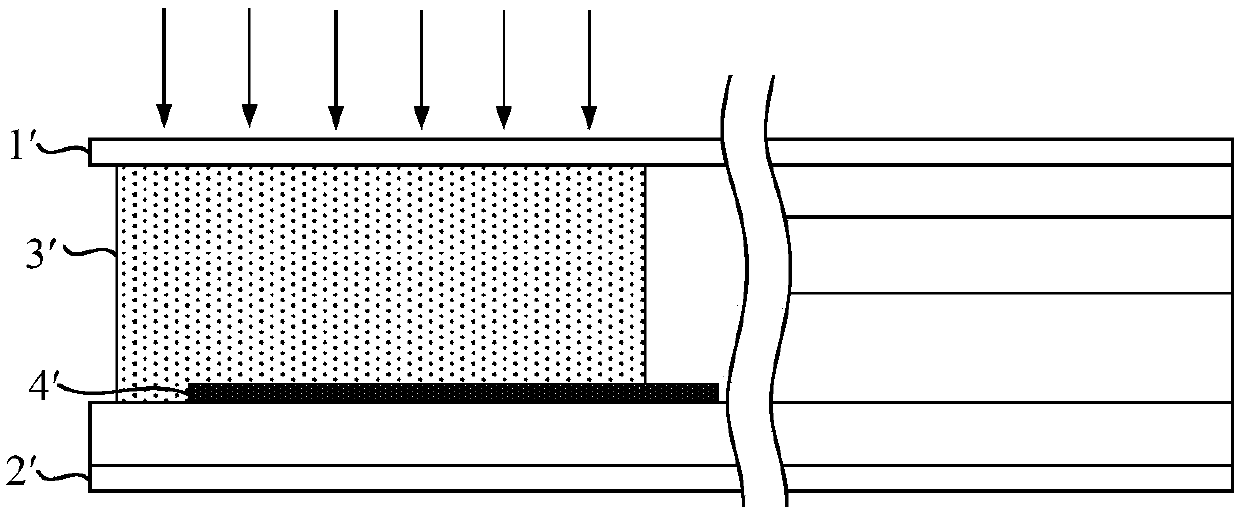

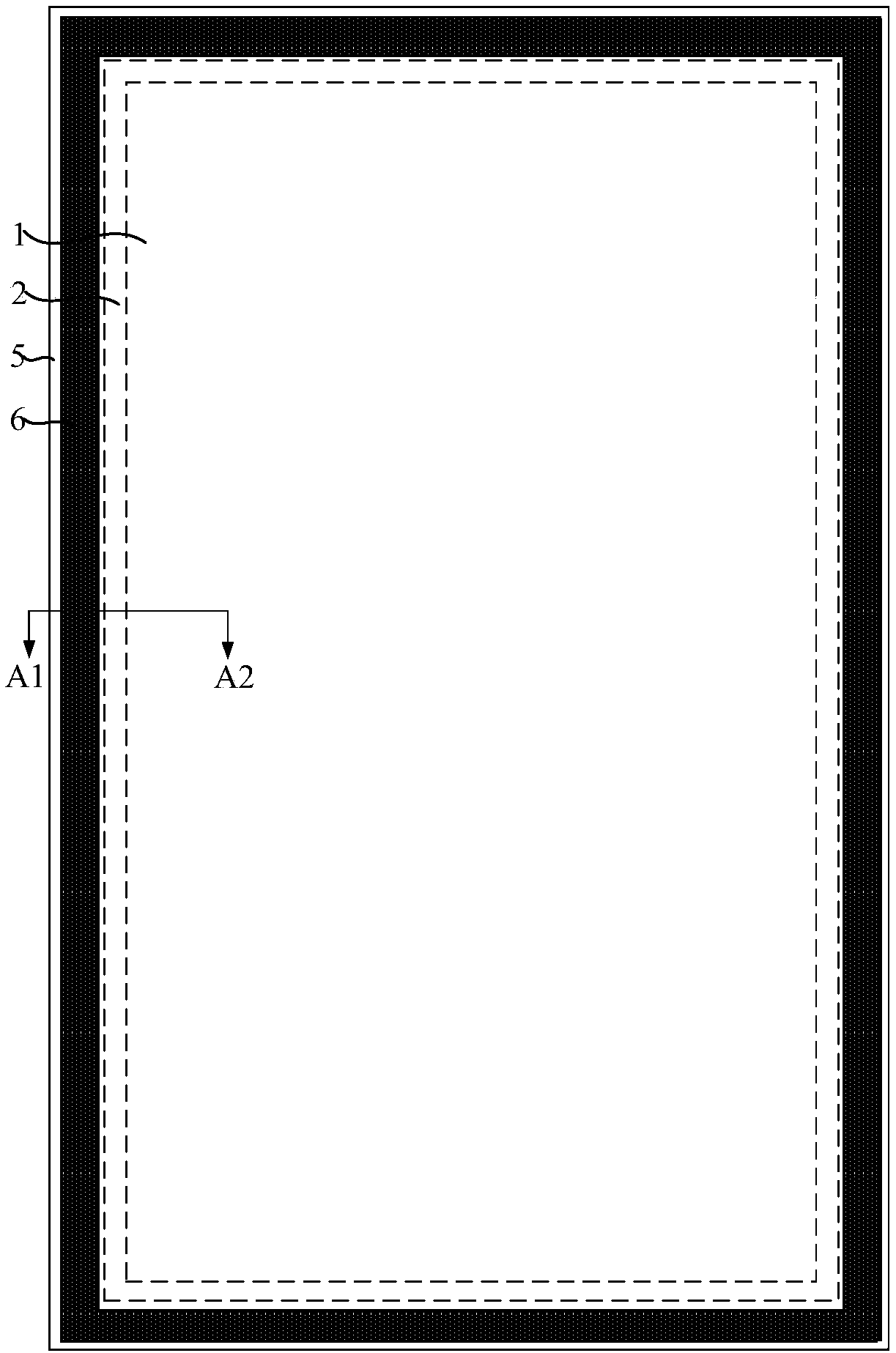

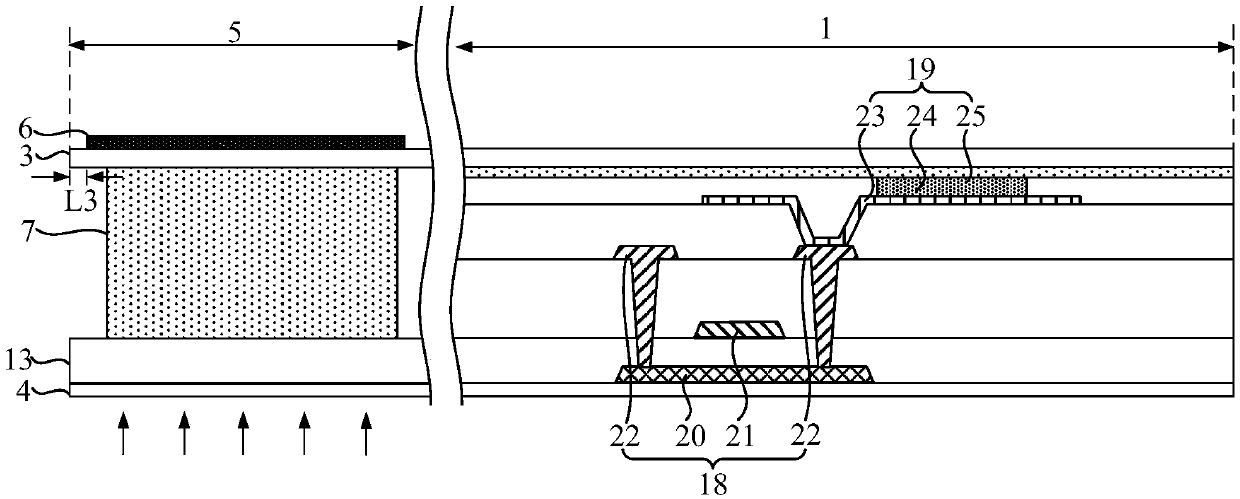

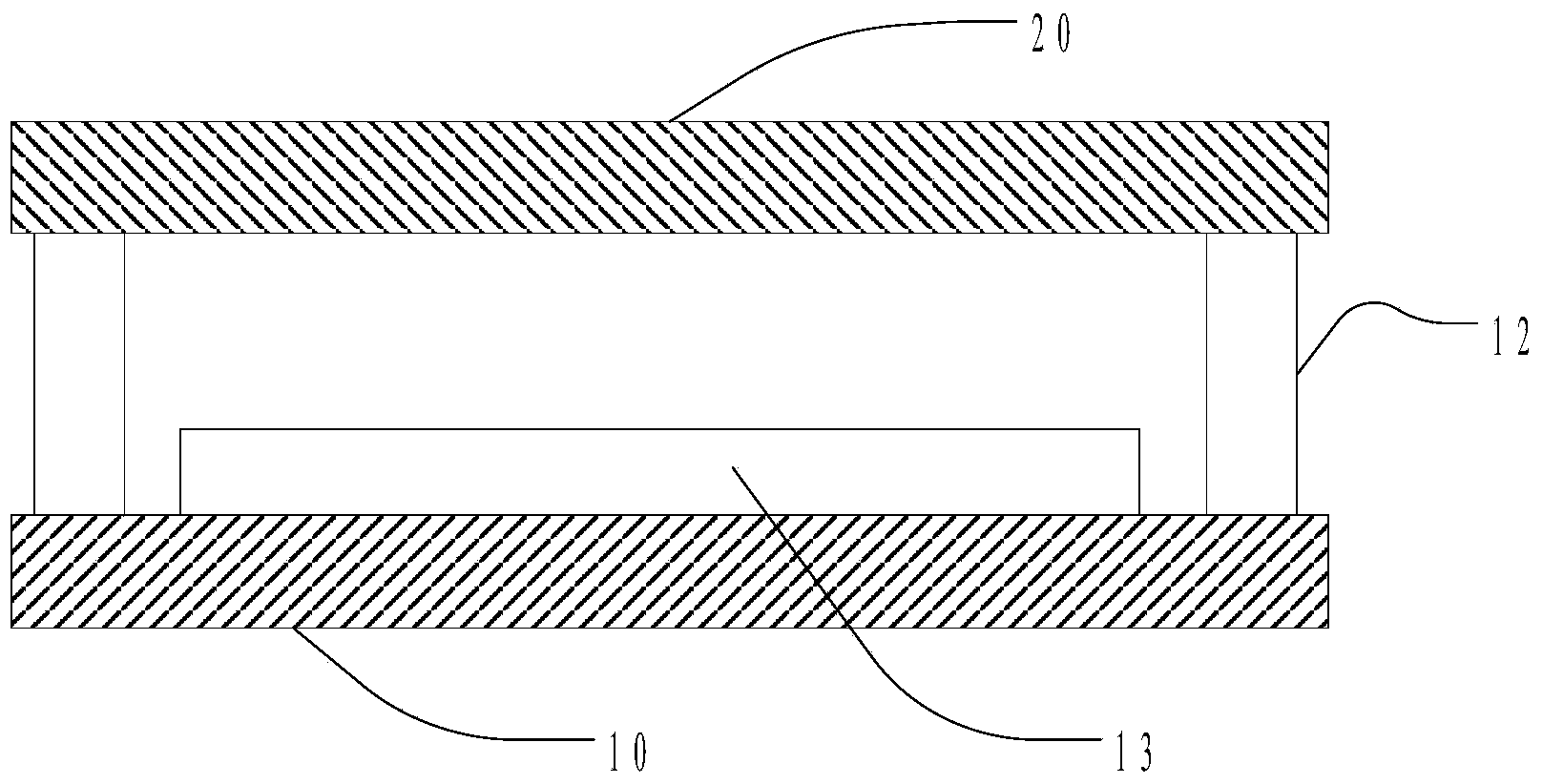

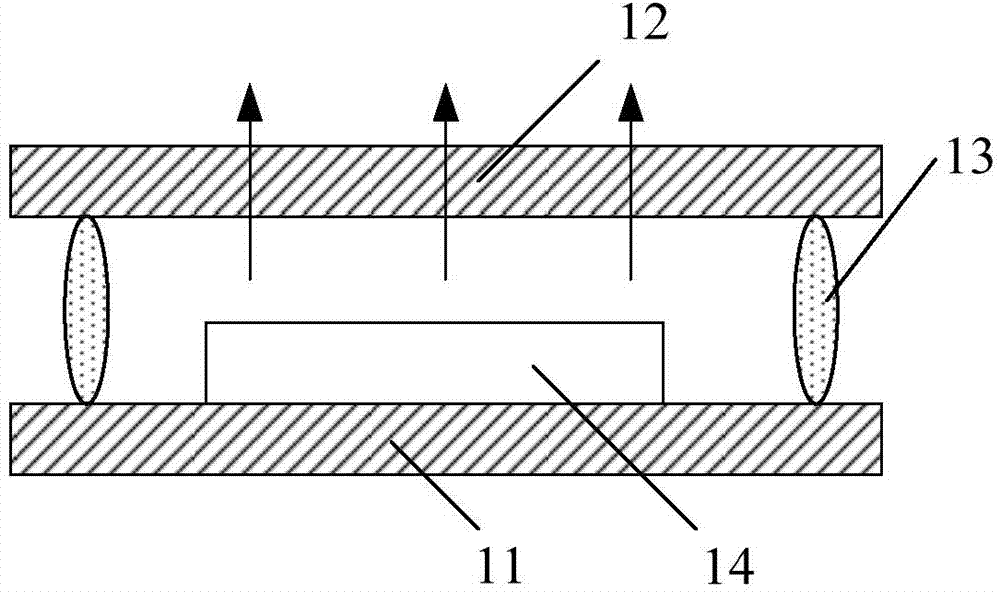

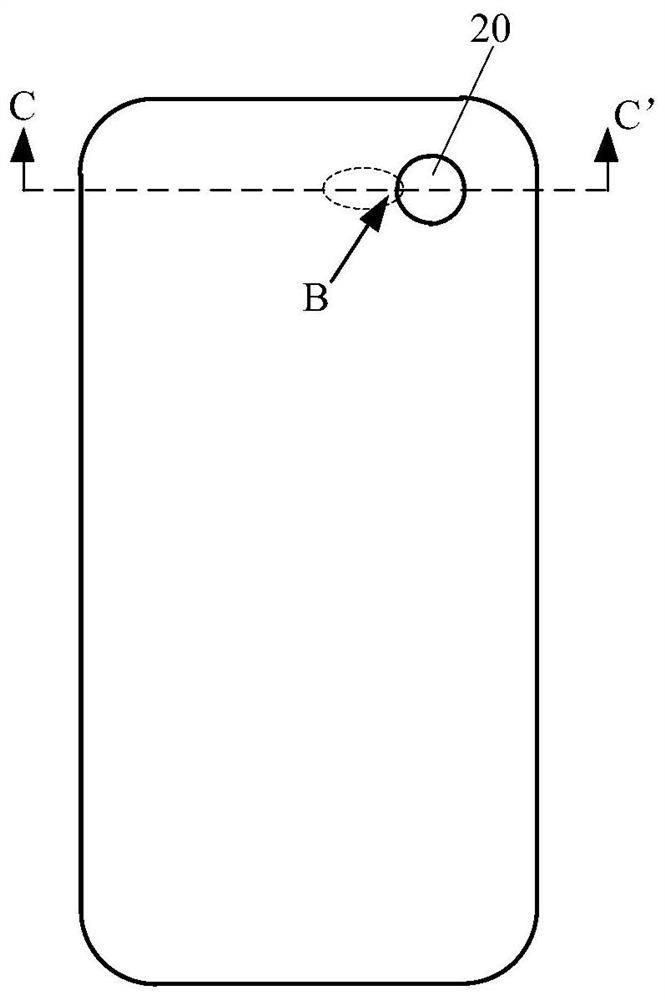

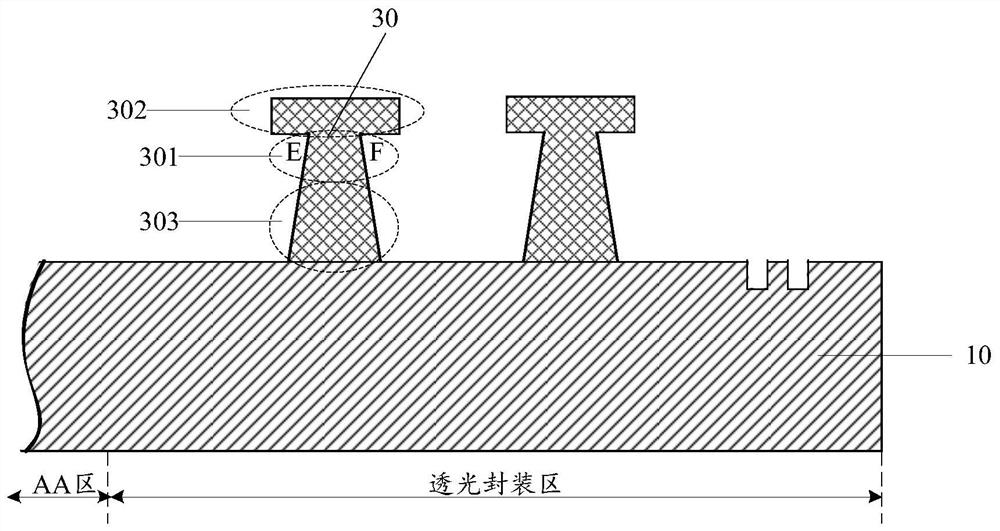

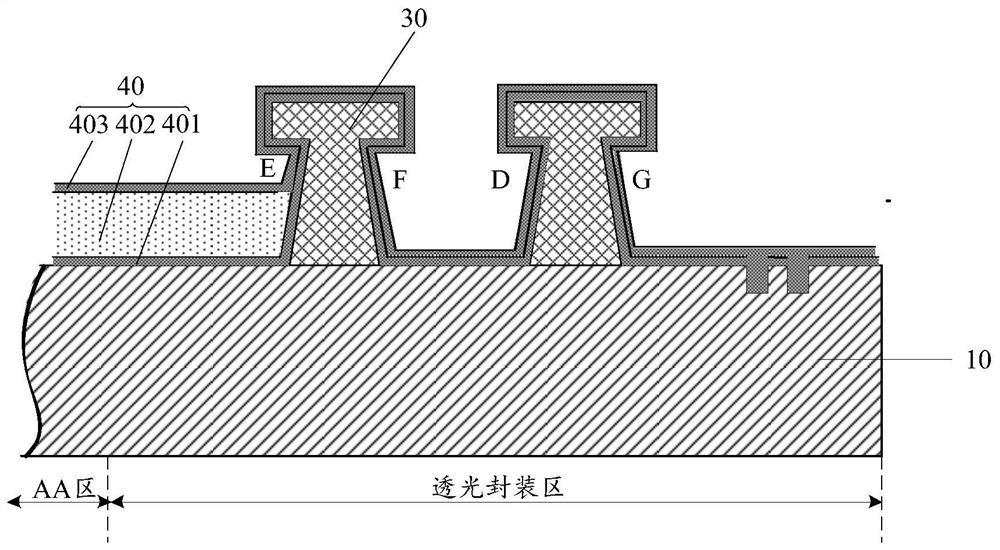

Display panel and display device

ActiveCN109671865APromote absorptionImprove package stabilitySolid-state devicesSemiconductor/solid-state device manufacturingAdhesiveDisplay device

The embodiment of the invention provides a display panel and a display device and relates to the technical field of display, aiming at preventing a packaging adhesive from being in contact with firstcushion layer metal and improving the packaging effect of the display panel. The display panel comprises a display region, a non-display region, a first substrate and a second substrate, wherein the non-display region is arranged around the display region; the first substrate and the second substrate are arranged oppositely; the non-display region comprises a glass material packaging region; the glass material packaging region comprises the first cushion layer metal; the first cushion layer metal is located at one side, back on to the second substrate, of the first substrate.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

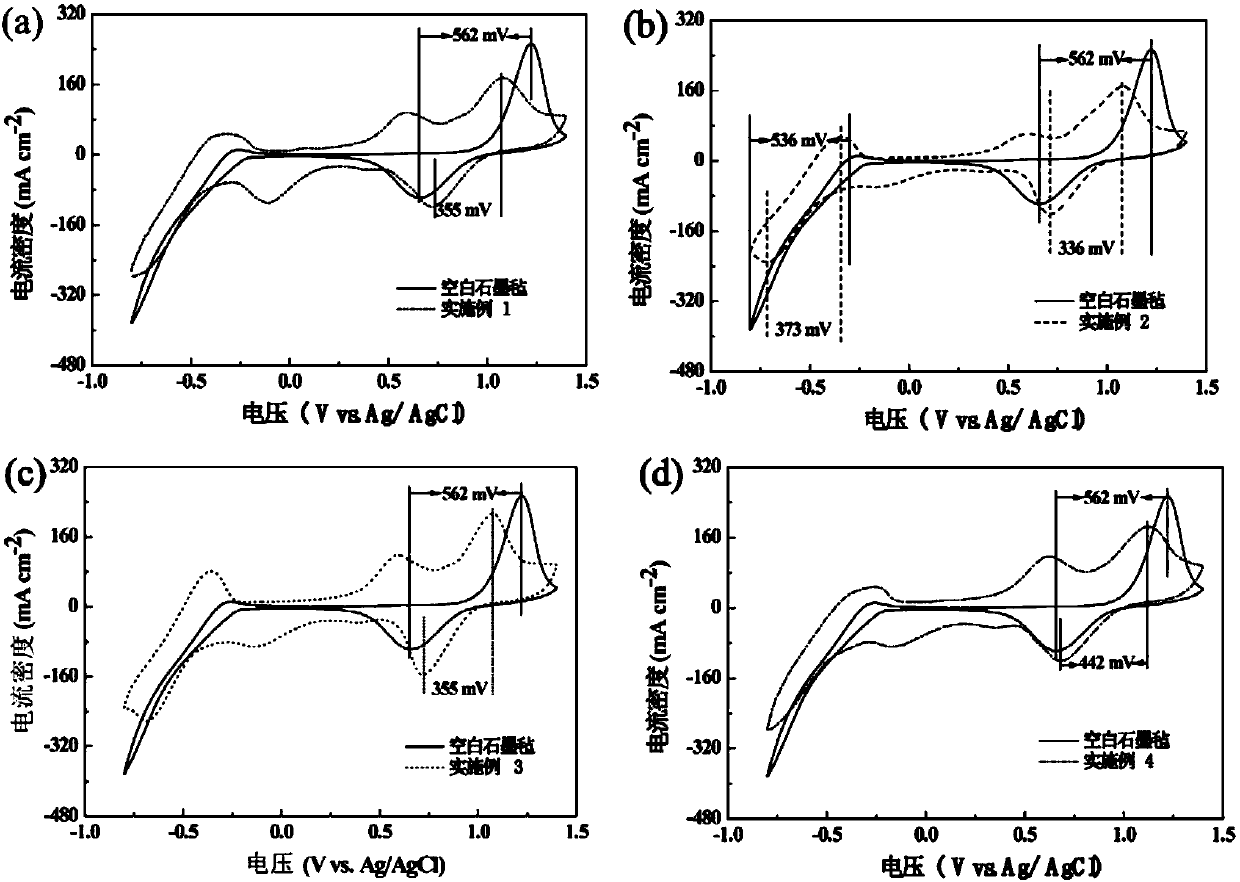

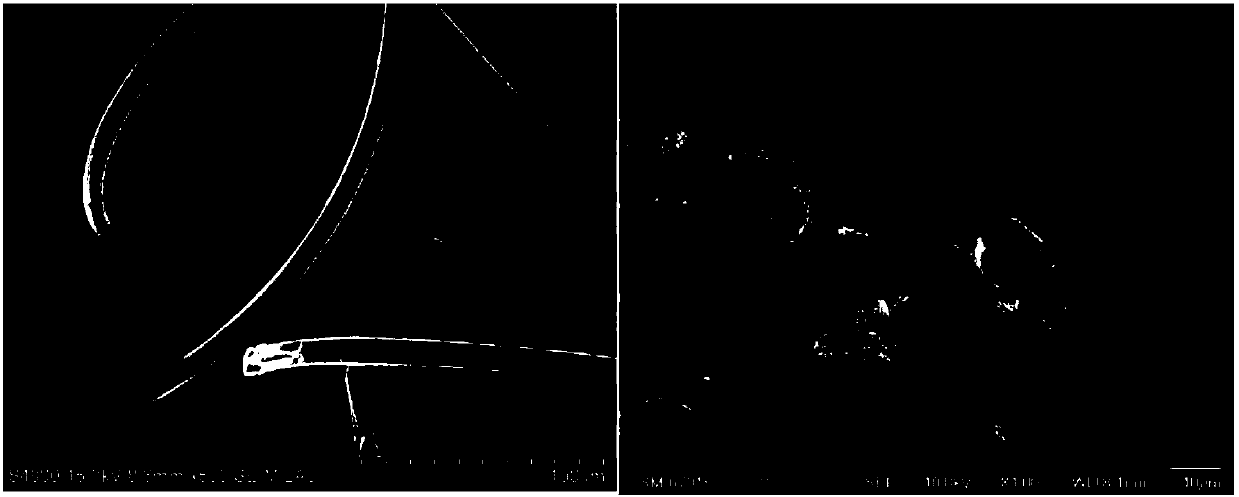

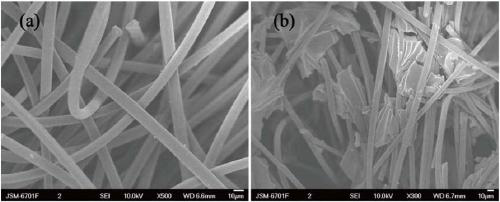

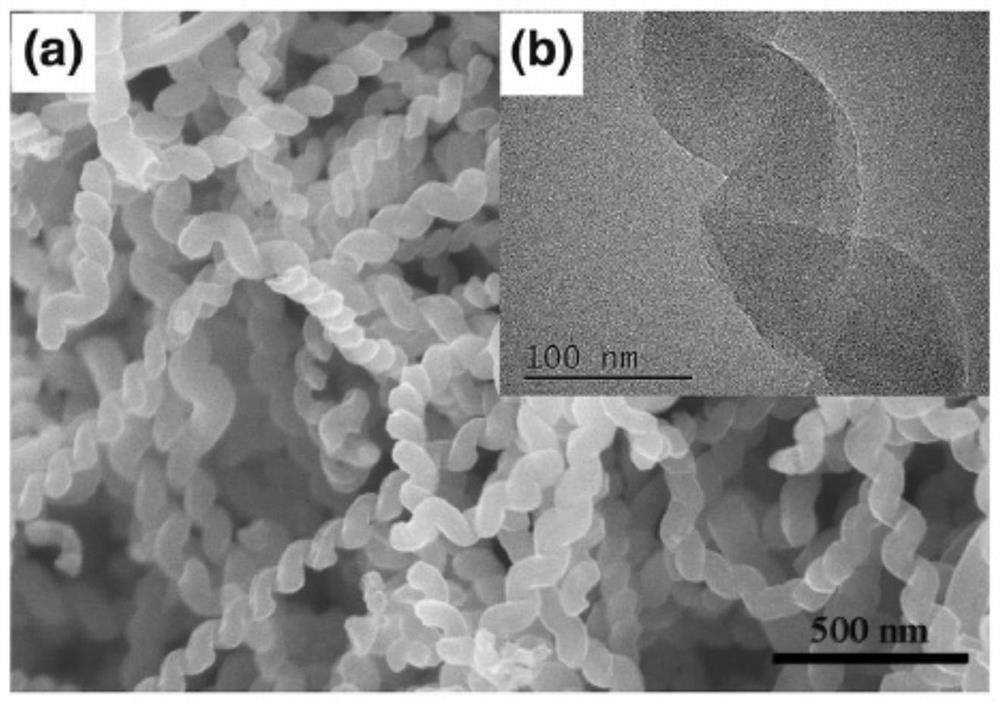

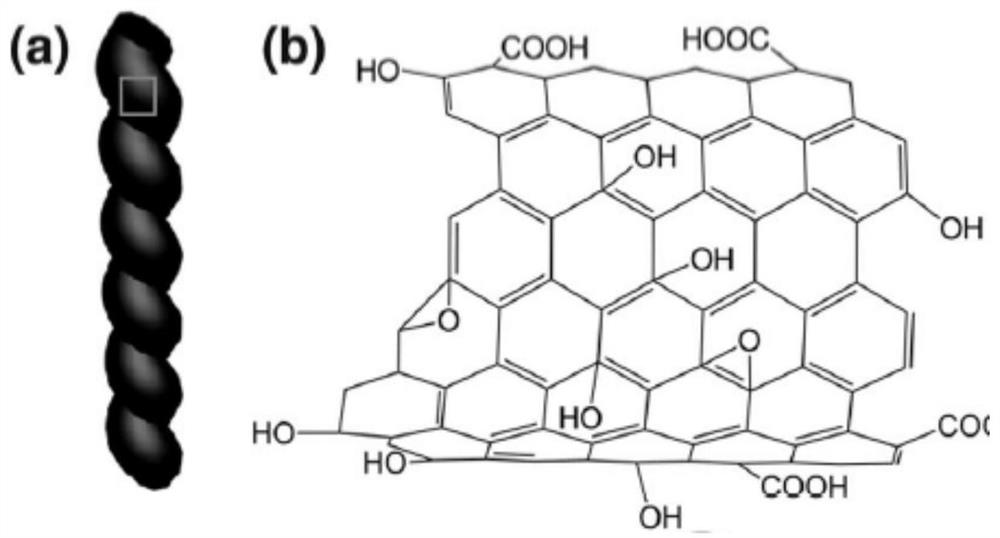

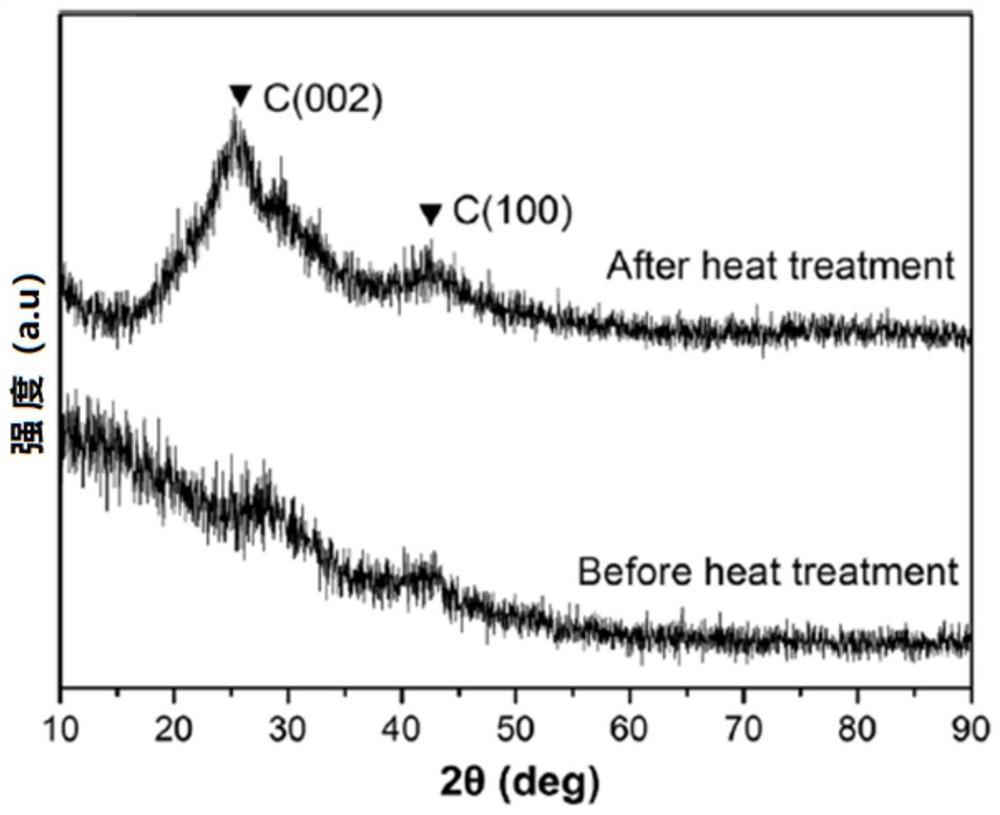

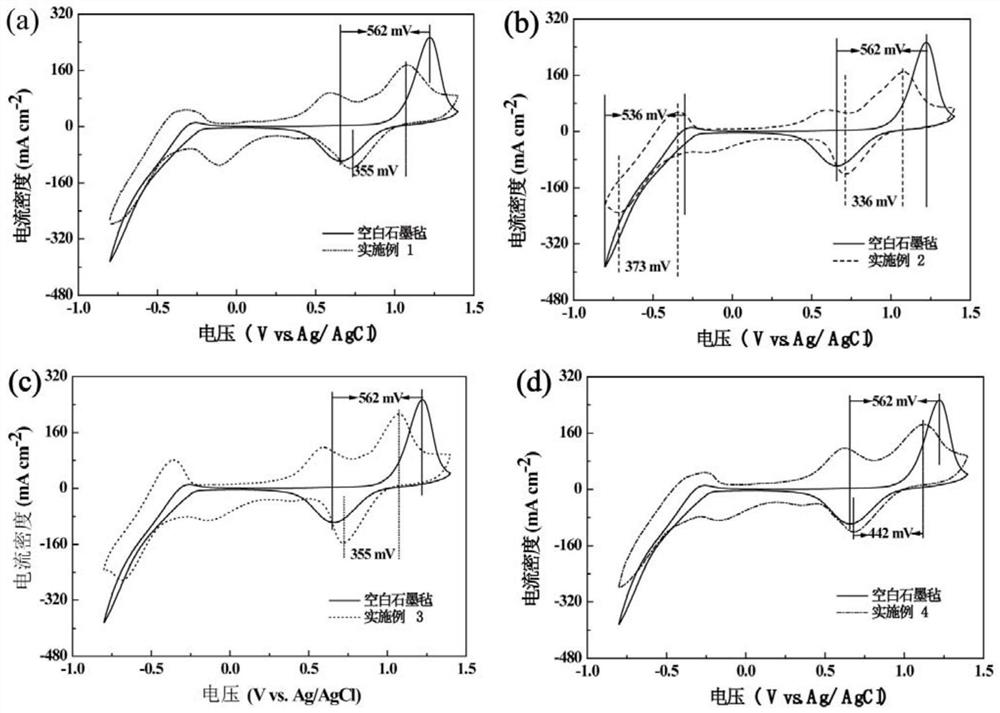

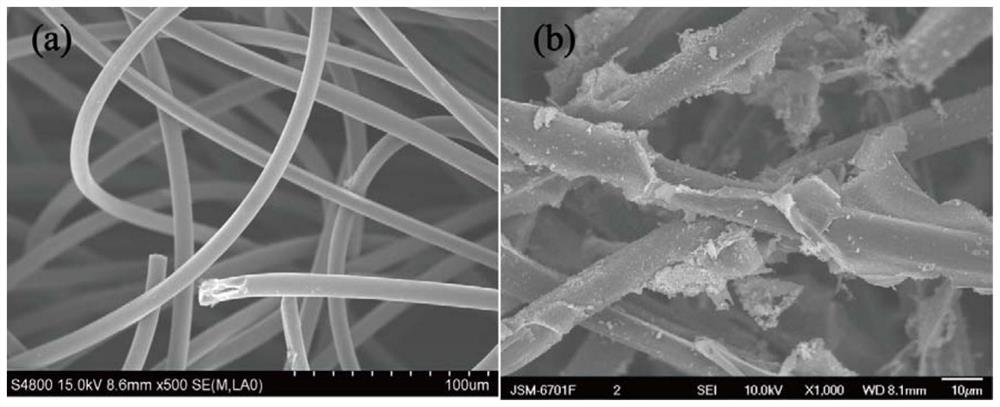

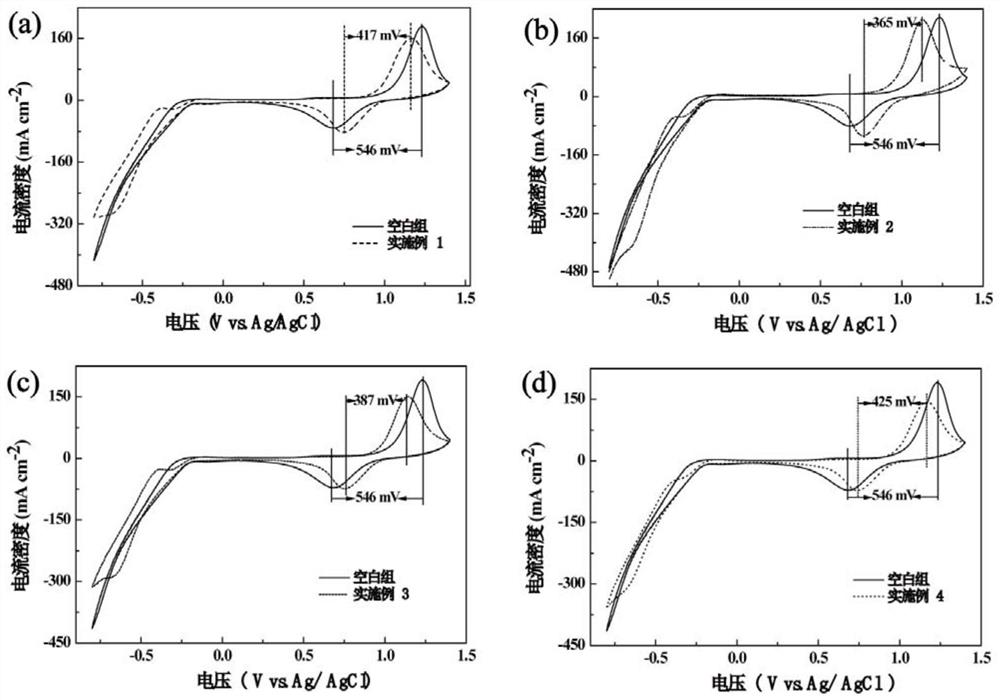

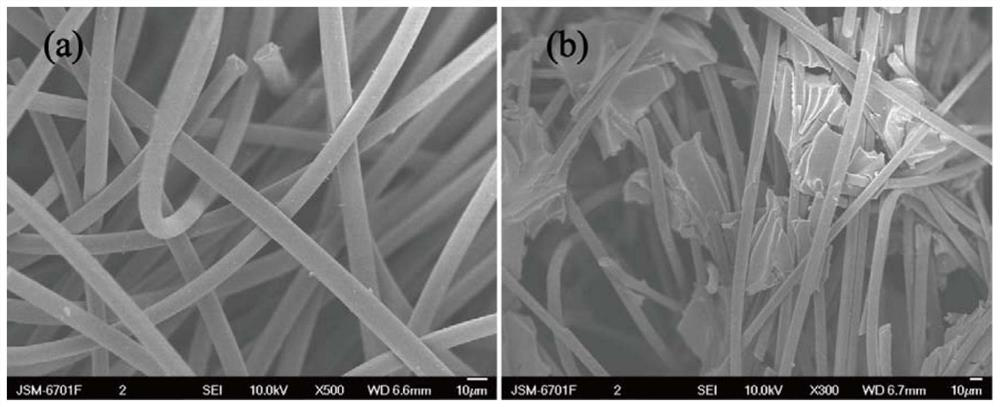

Modified carbon material and redox flow battery electrode modified by graphene-like nanosheet prepared from same

ActiveCN110197905ALarge specific surface areaIncrease the content of functional groupsCell electrodesModified carbonIn situ polymerization

The invention provides a modified carbon material, a preparation method thereof, and a redox flow battery electrode modified by a graphene-like nanosheet prepared from the same. The preparation methodcomprises the steps of: 1) subjecting phytic acid and an amino group-containing substance to in-situ polymerization on the surface of the carbon material; and 2) calcining the product at a high temperature. The carbon material treated by the method has rich oxygen-containing functional groups on its surface, and has greatly improved hydrophilic property, electrochemical activity and specific surface area. Moreover, the loading amount of hetero elements such as nitrogen and phosphorus can be controlled by adjusting the amount and molar ratio of phytic acid and urea. The electrode has high specific surface area and a high functional group content (for example, the oxygen-containing functional group), and exhibits good catalytic activity for both the positive and negative electrode pairs ofan all-vanadium redox flow battery, and the high catalytic activity of the electrode greatly reduces the polarization of the electrode.

Owner:HUNAN YINFENG NEW ENERGY

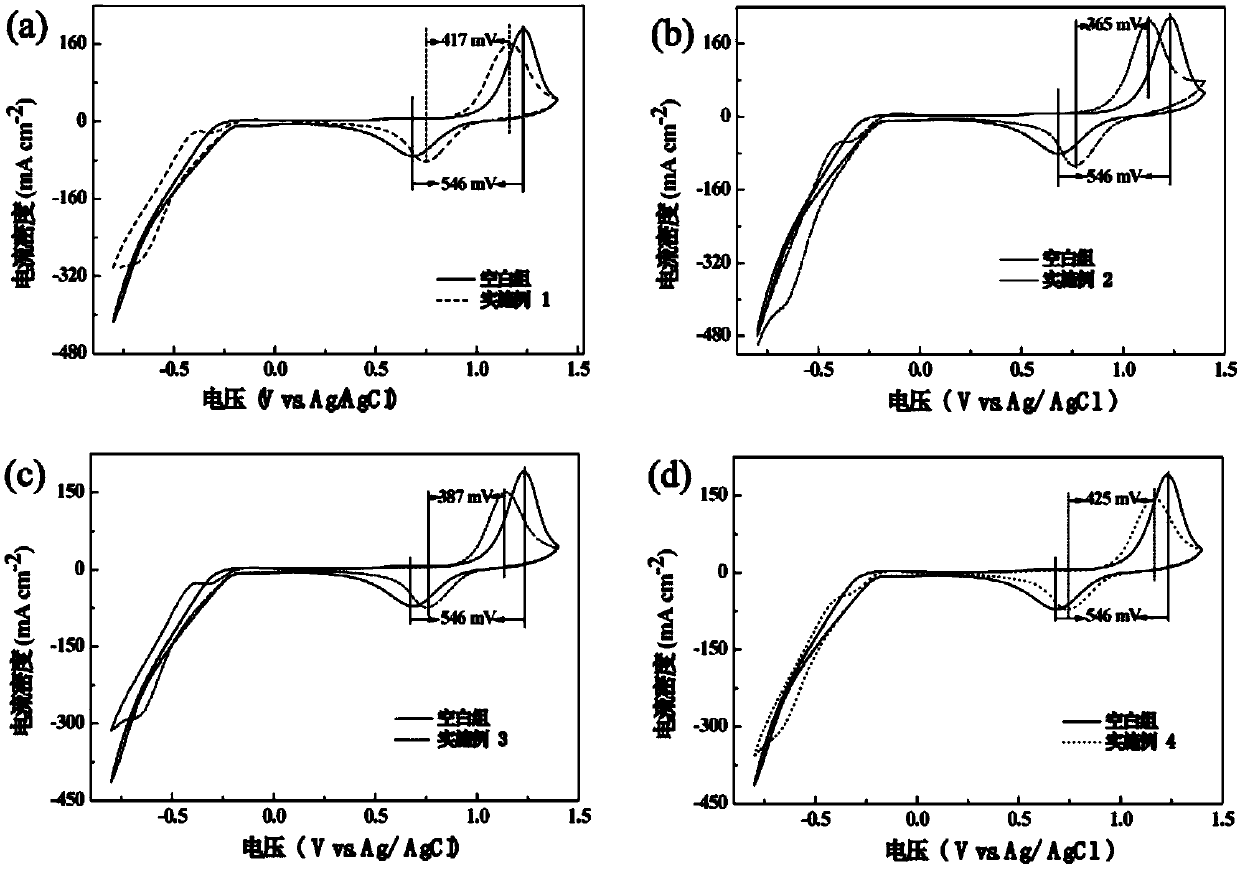

Modified carbon material and nitrogen-rich liquid flow battery electrode prepared from modified carbon material

ActiveCN110194453ALarge specific surface areaReduce polarizationGraphiteCell electrodesIn situ polymerizationModified carbon

The invention provides a modified carbon material and a preparation method thereof as well as a nitrogen-rich liquid flow battery electrode prepared from the material. The preparation method comprisesthe following steps: 1) carrying out in-situ polymerization reaction on an amino group-containing substance and a hydroxyl group-containing substance on the surface of a carbon material; and 2) calcining to obtain the modified carbon material. The surface of the carbon material treated by the method is rich in nitrogen-containing functional groups and oxygen-containing functional groups, and thehydrophilicity, electrochemical activity and specific surface area of the carbon material are greatly improved. In addition, the loading amount of nitrogen and oxygen elements can be controlled by adjusting the dosage of formaldehyde-urea-melamine. The electrode has high specific surface area and high functional group content (such as oxygen-containing functional groups), and especially shows goodcatalytic activity to main redox pairs of vanadium ions, and the higher catalytic activity greatly reduces the polarization of the electrode.

Owner:HUNAN YINFENG NEW ENERGY

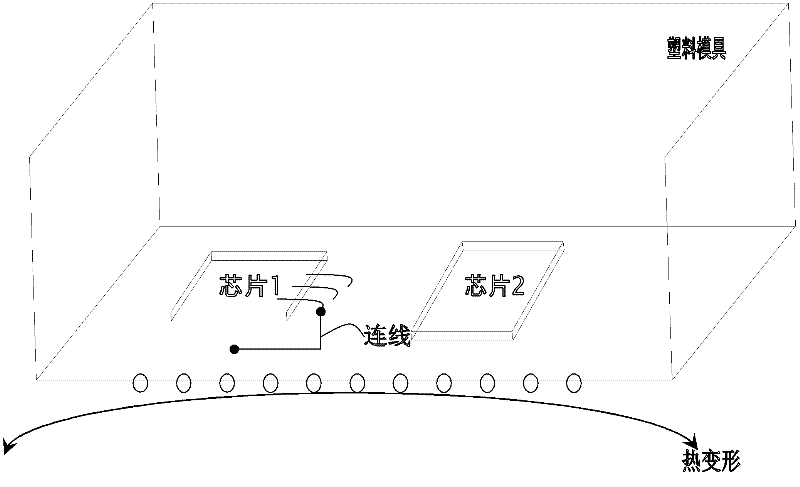

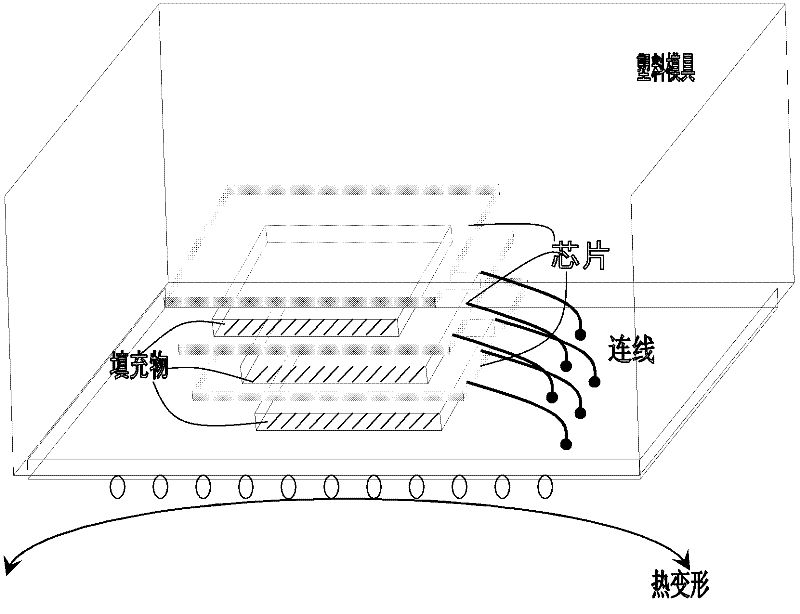

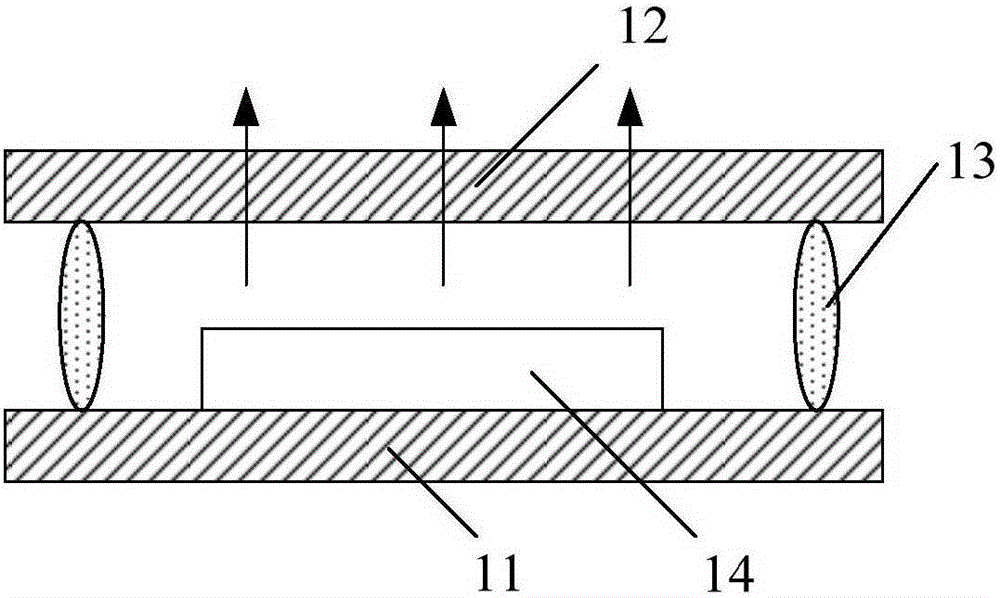

Packaging method and structure of chip

InactiveCN102332410AAvoid Package DistortionImprove package stabilitySemiconductor/solid-state device detailsSolid-state devicesElectric propertiesLead frame

The invention relates to a packaging method and structure of a chip. The method comprises the following steps of: 1, installing the chip in an independent chip lead frame or substrate; and 2, connecting one side of the obtained chip lead frame or substrate to an external packaging substrate. By using the packaging method and structure of the chip, the packaging deformation can be avoided, the packaging stability is high, the electric property is good, and the application scope is wide.

Owner:SHANDONG SINOCHIP SEMICON

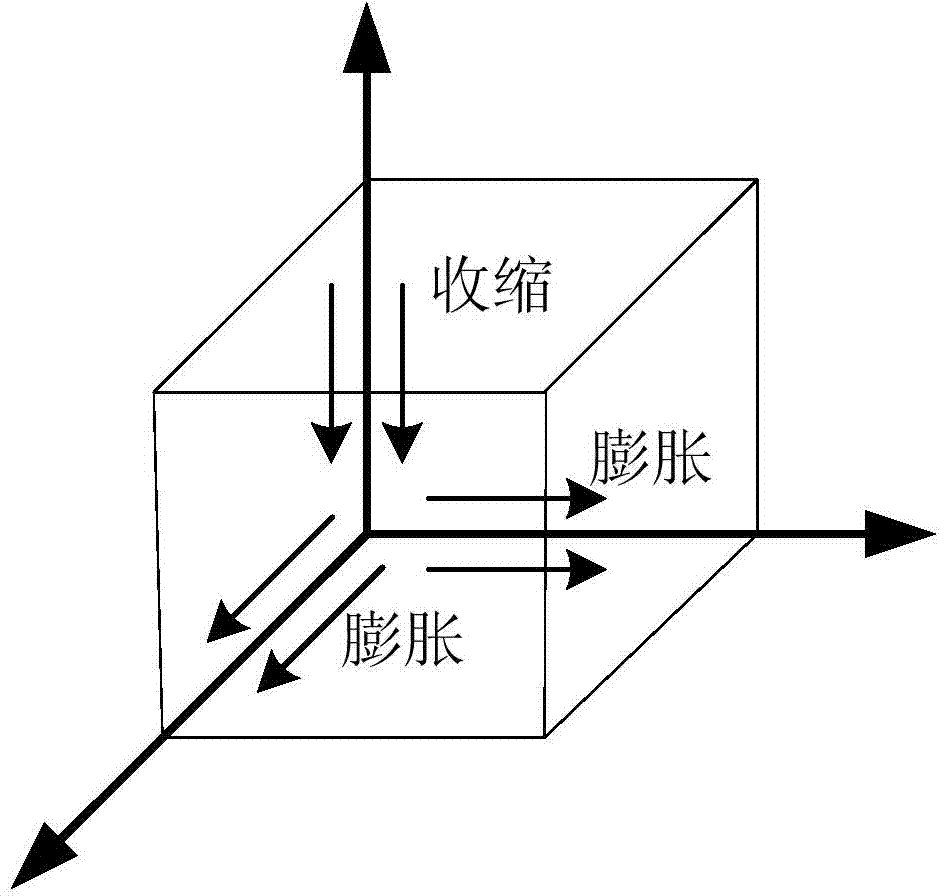

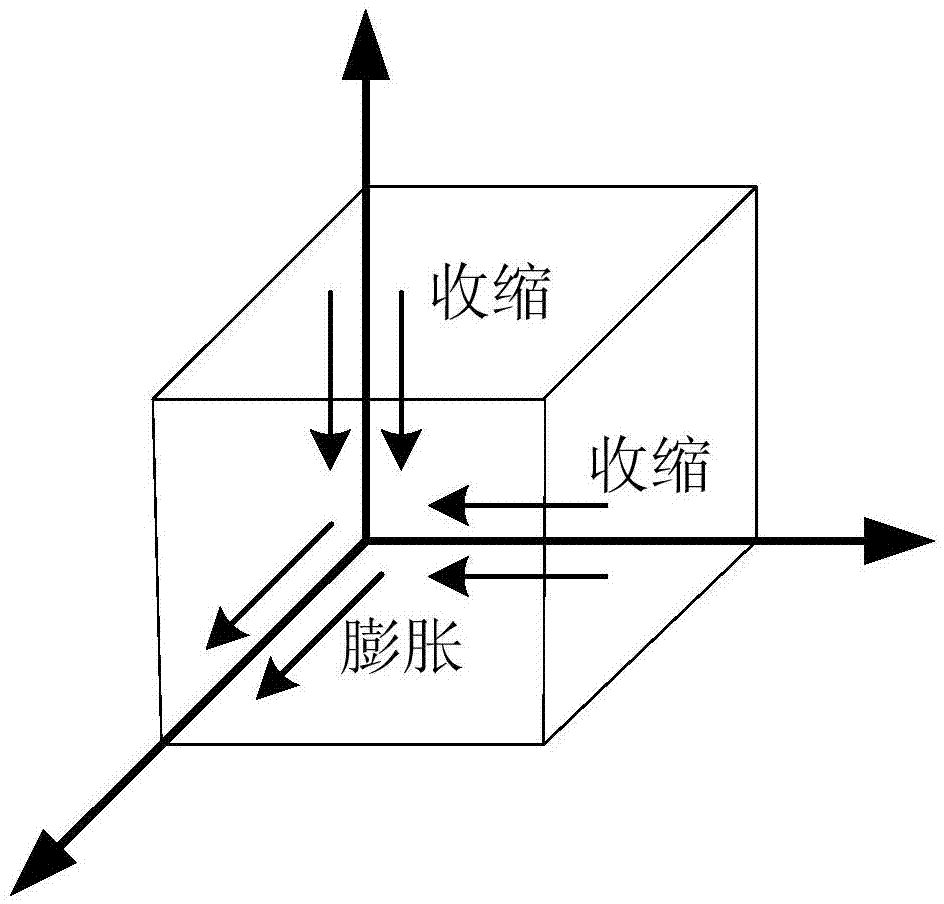

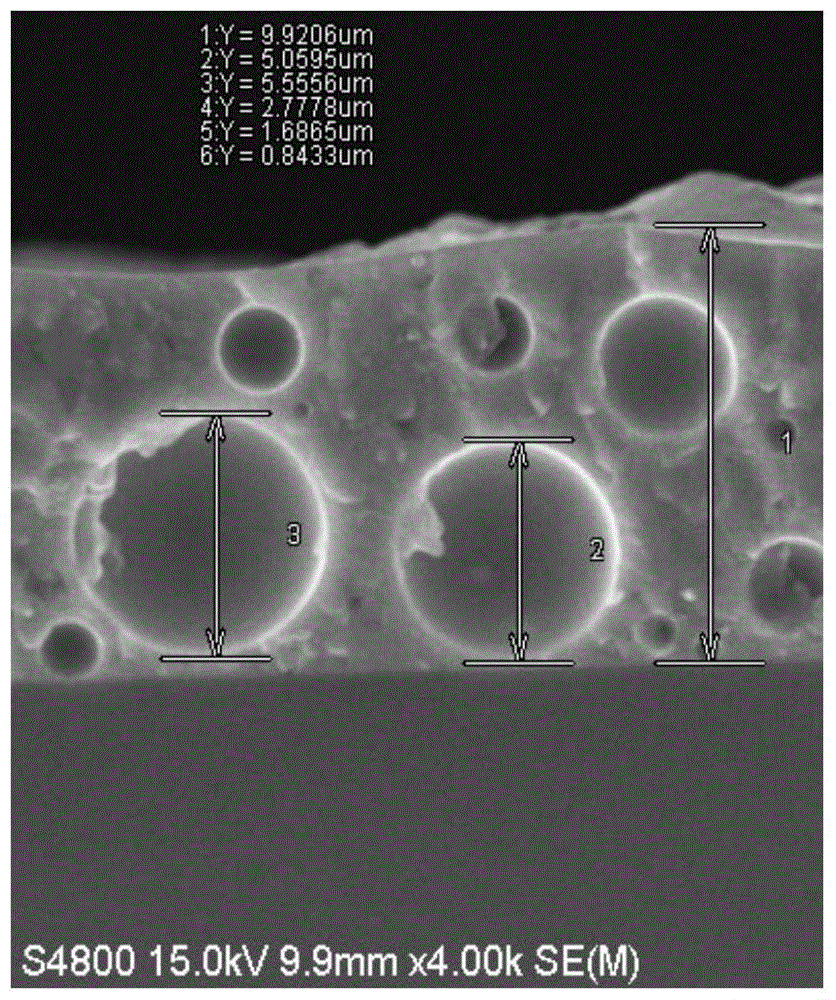

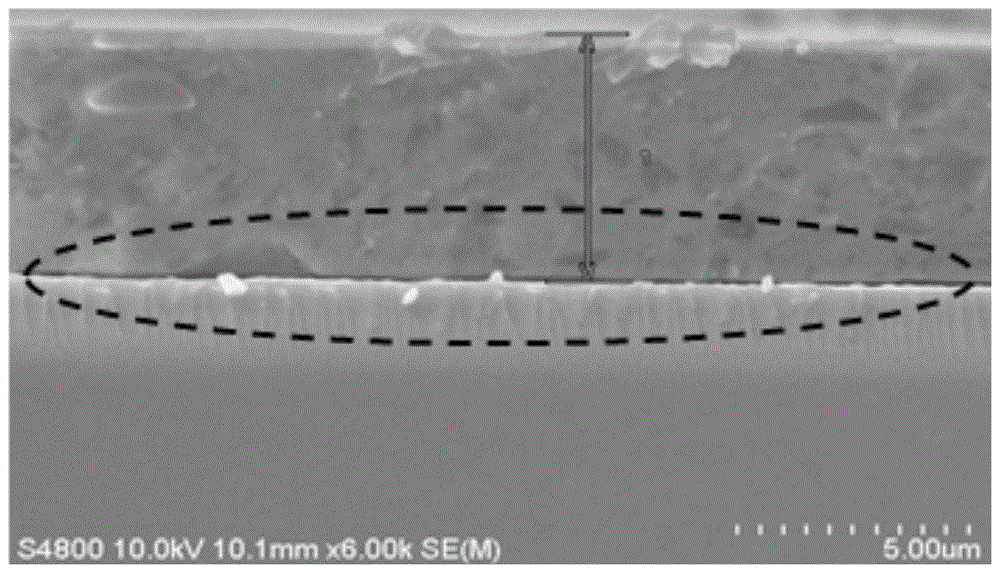

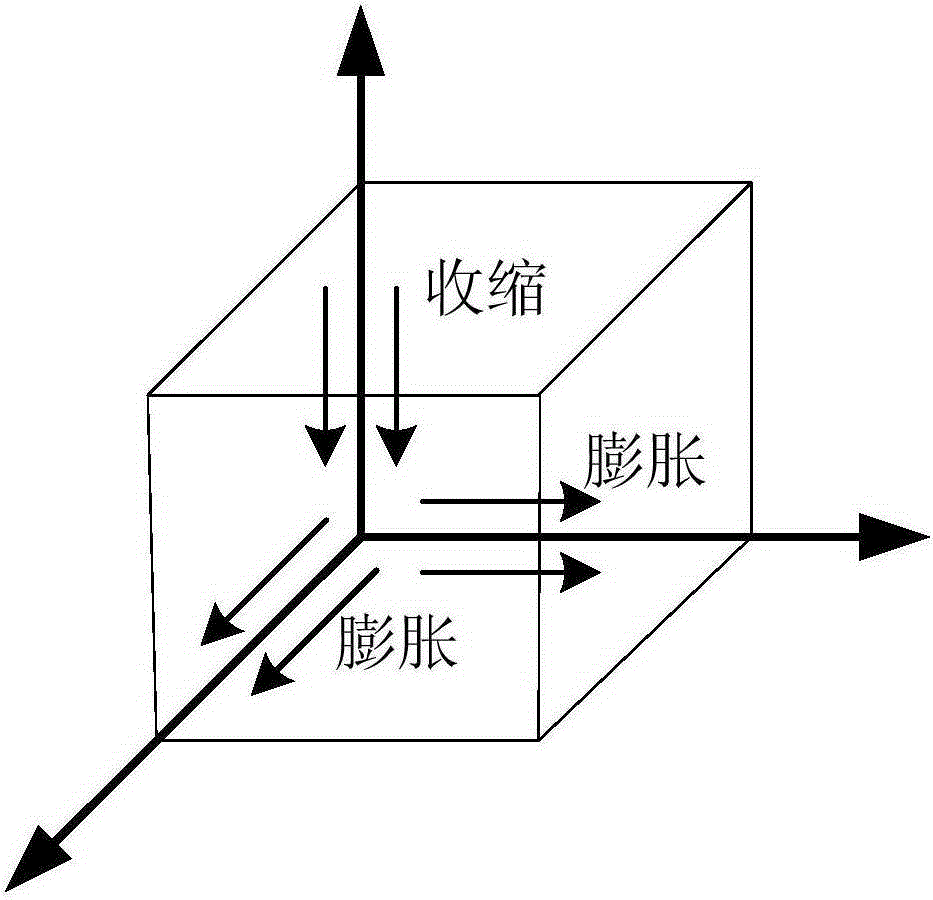

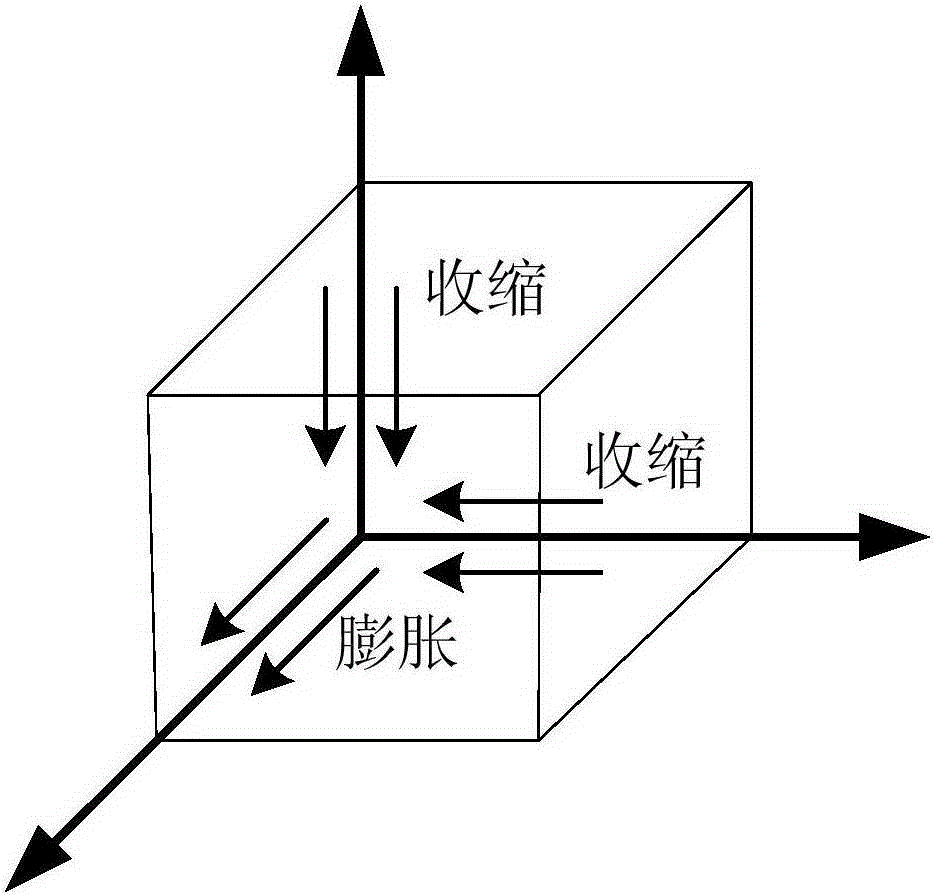

Frit composition, frit paste composition and sealing method and electric device

ActiveCN104045236AExpansion coefficient matchingAvoid crackingSolid-state devicesSemiconductor/solid-state device manufacturingFritLight-emitting diode

The invention discloses a frit composition which comprises a frit base material and filler, wherein the filler comprises a quasi-crystal material which accounts for 5-45wt% of the total weight of the filler. The frit composition, and the frit paste composition have negative thermal expansion coefficients, the thermal expansion coefficient of the frit can be reduced very well, so that the expansion coefficients of the frit and the base plate are further matched. Furthermore, a channel for discharging gross blow holes is provided and the compactness and adhesive strength of the frit composition are improved, so that the packaging yield is further improved and the OLED (Organic Light Emitting Diode) packaging stability is improved.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD +1

Process for preparing a polymer product having a 2,5-furandicarboxylate moiety within the polymer backbone to be used in bottle, film or fibre applications

A process for preparing a polymer having a 2,5-furandicarboxylate moiety within the polymer backbone, and having a number average molecular weight of at least 25,000, includes a transesterification step, a polycondensation step, a drying and / or crystallizing step, and a step where the polymer is subjected to post condensation conditions, and to a polyester-containing bottle or film or fiber-containing woven or non-woven object made from melt-processing poly(ethylene-2,5-furandicarboxylate), where the poly(ethylene-2,5-furandicarboxylate) is obtainable by the process of the invention.

Owner:FURANIX TECH BV

Frit composition, frit paste composition and electrical element

ActiveCN103936284ASmall coefficient of thermal expansionCoefficient of thermal expansion adjustmentFritElectrical element

The invention provides a frit composition. The frit composition comprises a frit base material and a filler, wherein the filler is an isotropic negative thermal expansion material, and the mass of the isotropic negative thermal expansion material accounts for 5-30% of the total mass of the frit composition. The frit composition can reduce the thermal expansion coefficient of frit in order to be matched with a glass substrate, can uniformly adjust the overall thermal expansion coefficient in all directions, avoids the cracks caused by the stress between the frit and the glass substrate, and improves the yield of products.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD +1

Machine for wrapping groups of products with tubular lengths of stretch film

ActiveUS7191574B2Reduce in quantityImprove package stabilityWrappers shrinkageWrapper folding/bending apparatusEngineering

A machine for wrapping groups of products (7) in tubular lengths of stretch film (4) comprises a rotating carousel (1) equipped with a plurality of wrapping units (2) having bars (3) for holding and stretching to size a succession of tubular film lengths (4) fed to a station (S1) and for placing the stretched tubular film lengths (4) around respective groups of products (7) to be wrapped fed one after the other.

Owner:AETNA GROUP

Packaging component

The present invention provides a packaging component. The packaging component includes: a light emitting diode and a packaging substrate; the light emitting diode includes first pads; the packaging substrate includes second pads; the light emitting diode and the packaging substrate are fixedly connected through the first pads and the second pads; the number of the first pads and the number of thesecond pads are identical; and the number of the first pads is at least three. The number of the first pads in the packaging component is at least three, and the number of the second pads is the sameas the number of the first pads. Then, the three or more pads generate tension in multiple directions, and in this way, a position of the light emitting diode can be aligned with a position of the packaging substrate are aligned, and an offset or skew can be prevented; and the packaging stability of the light emitting diode is improved.

Owner:XIAMEN CHANGELIGHT CO LTD

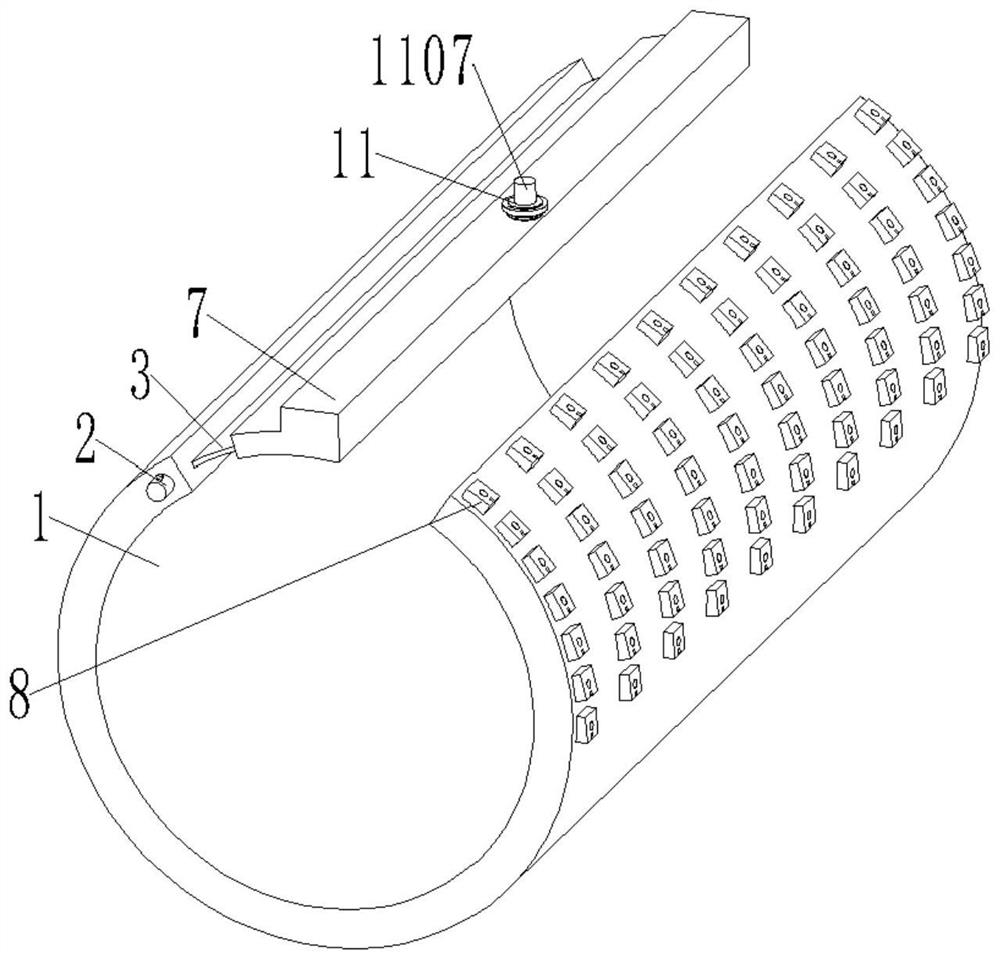

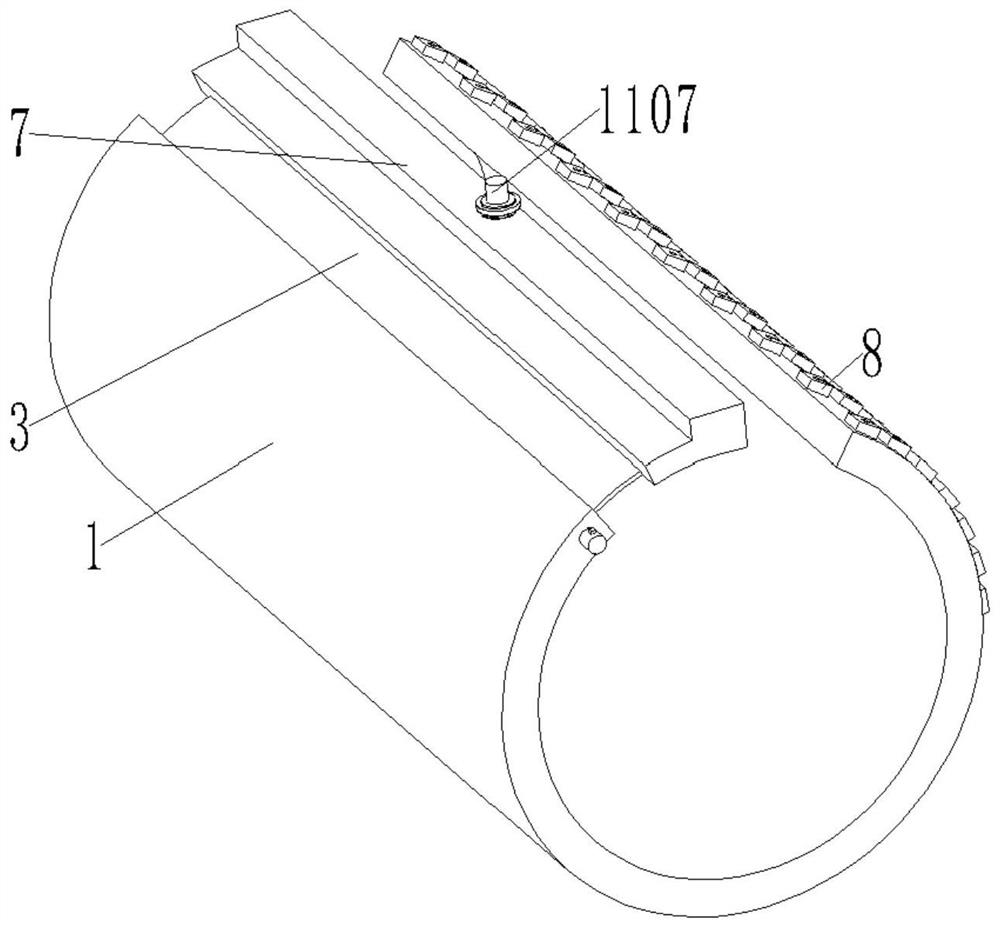

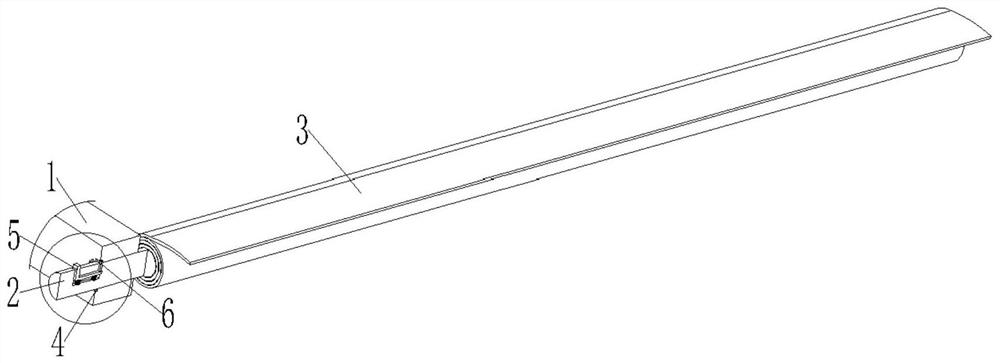

Leg wrapping device of external counterpulsation device

ActiveCN112704630AImprove package stabilityImprove stabilityPneumatic massagePhysical medicine and rehabilitationEngineering

The invention discloses a leg wrapping device of an external counterpulsation device. For the leg wrapping device of the external counterpulsation designed by the invention, an adjusting locking mechanism in an arranged arc-shaped connecting plate is connected and clamped with a fixed convex block on a wrapping device main body, so that corresponding adjustment can be performed according to the thickness degree of legs of different people, and the applicability is improved; the leg wrapping firmness and stability can be improved through the linkage effect of the adjusting locking mechanism and an auxiliary mechanism; through the cooperation effect of the adjusting locking mechanism and a connecting elastic cloth, certain comfort can be provided for a patient while the wrapping stability of the leg wrapping device is guaranteed; and through arrangement of a positioning clamping groove, an L-shaped movable strip and a positioning clamping strip, the connecting elastic cloth can be adjusted, therefore the actual requirement for leg wrapping can be met, and the working efficiency is improved.

Owner:CHONGQING PSK HEALTH SCI TECH DEV

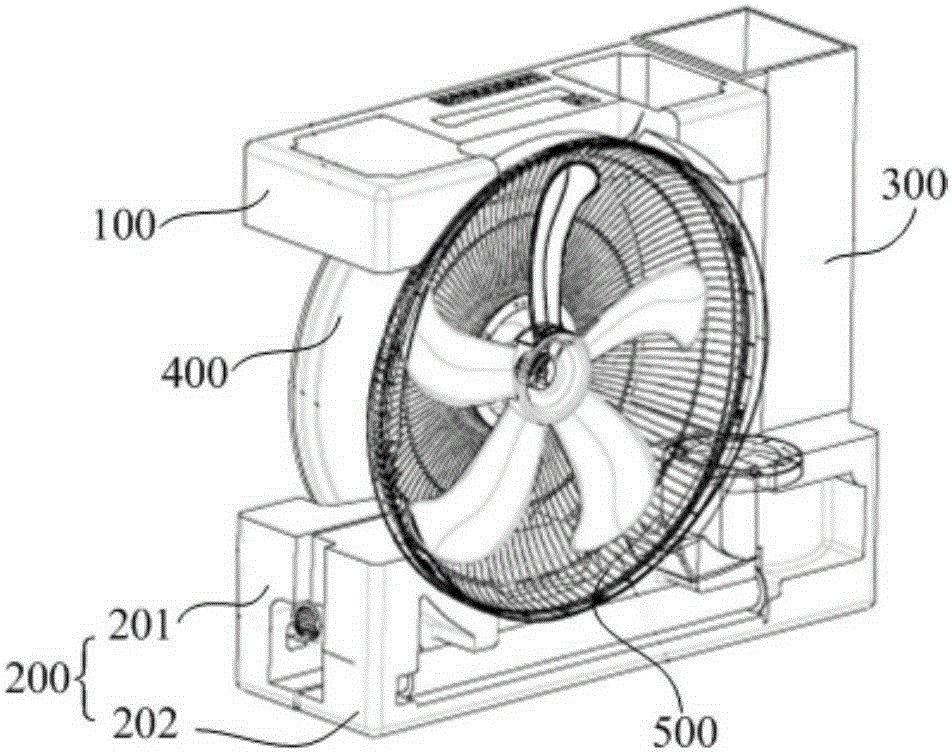

Packing component, packing method and packed object

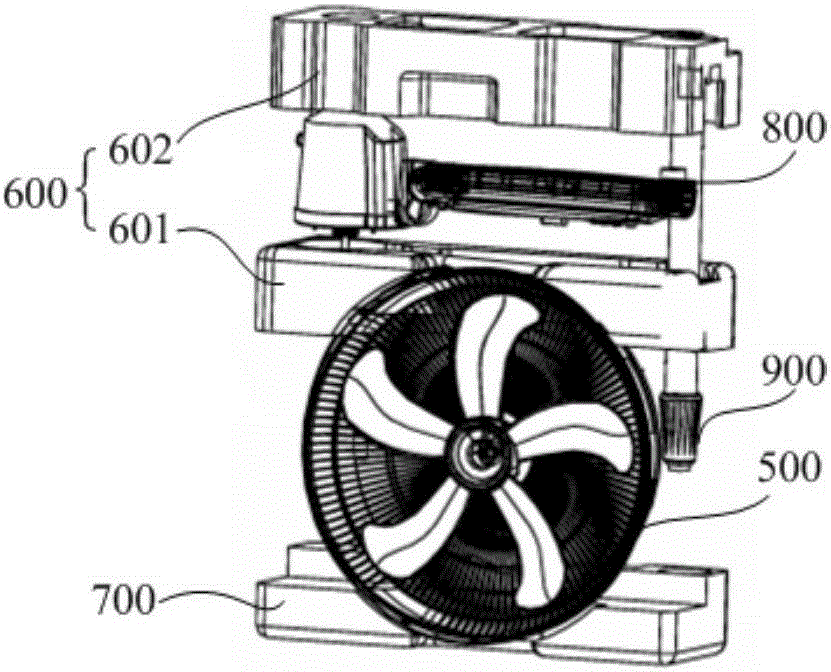

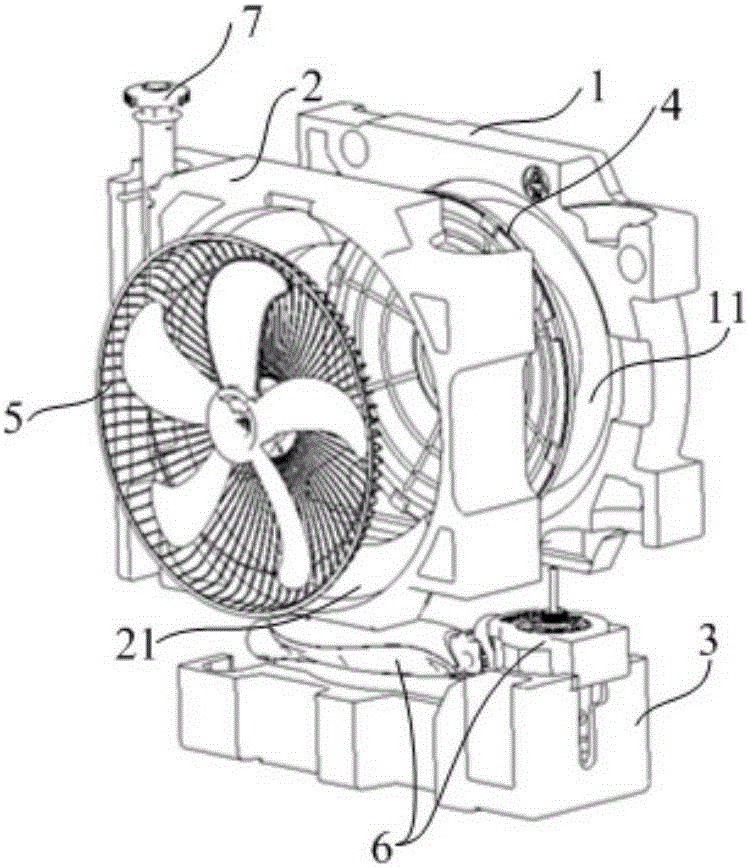

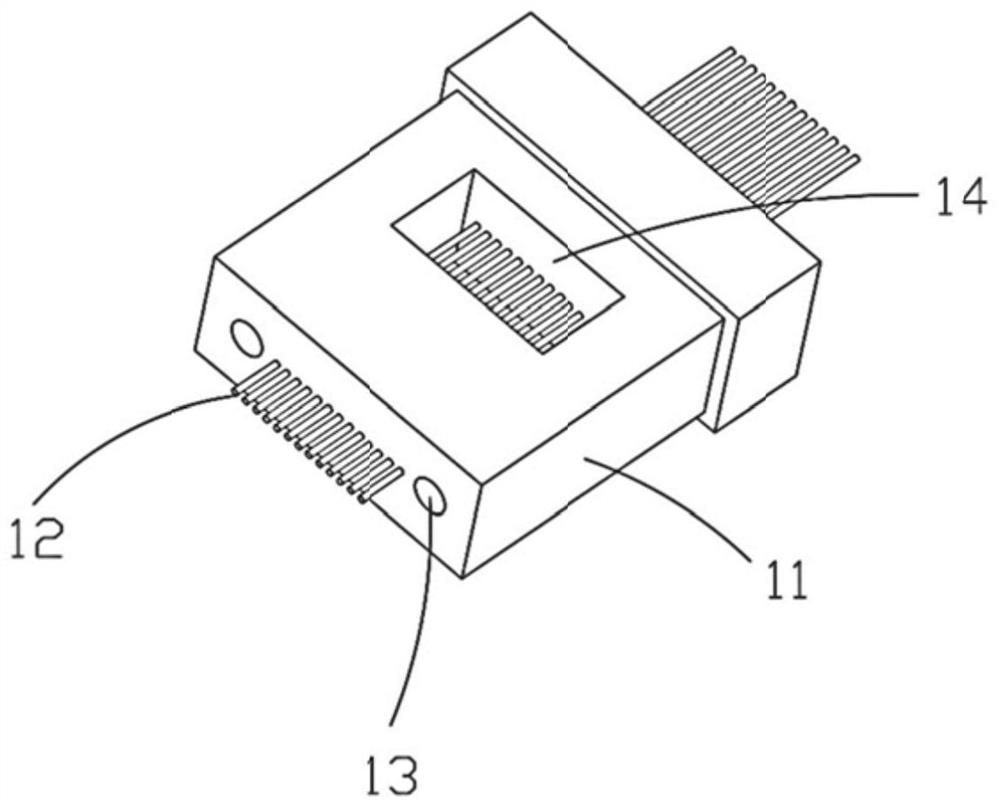

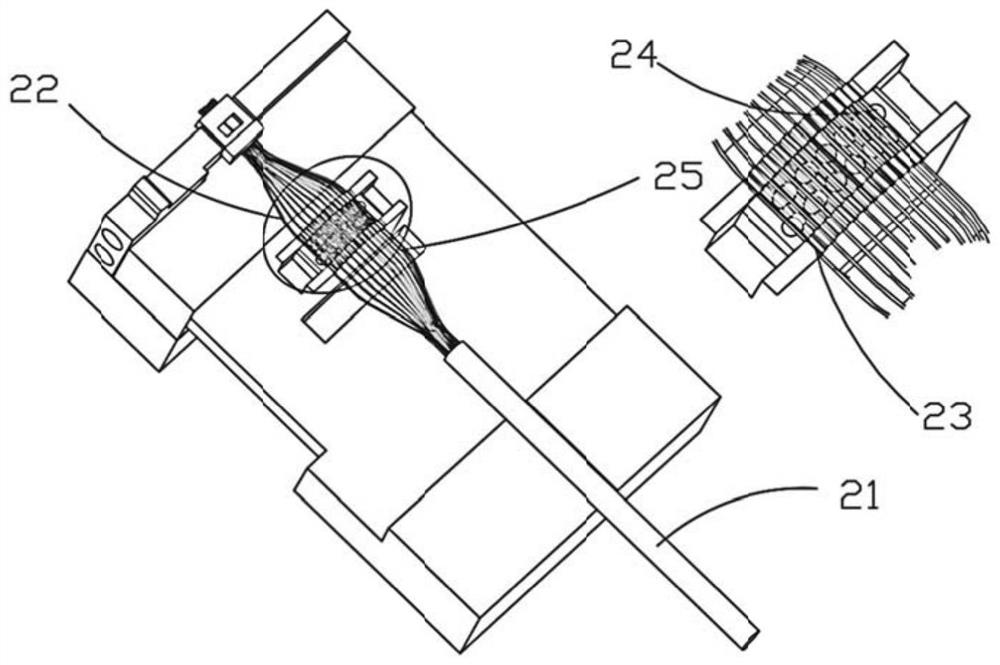

ActiveCN105197418AImproves packaging stabilityEasy and fast packagingContainers to prevent mechanical damageInternal fittingsMechanical engineeringPacking method

The invention discloses a packing component, a packing method and a packed object. The packing component is suitable for packing floor fans, and comprises a first packing piece and a second packing piece which are detachably connected with each other, wherein a first mounting position and a second mounting position, which are matched with the base plate and the fan cover blade component of a floor fan in shape, are formed in the first packing piece and the second packing piece respectively, and are used for mounting of the base plate and the fan cover blade component respectively. As the first mounting position and the second mounting position are matched with the base plate and the fan cover blade component in shape, the circumferences of the base plate and the fan cover blade component can be fixed integrally, and the packing stability of the packing method is higher as compared with that of the conventional local clamping manner. According to the packing method, the base plate and the fan cover blade component are packed integrally, and then transferred integrally to the next working procedure for complete fan packing, so that the packing is simpler and faster.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

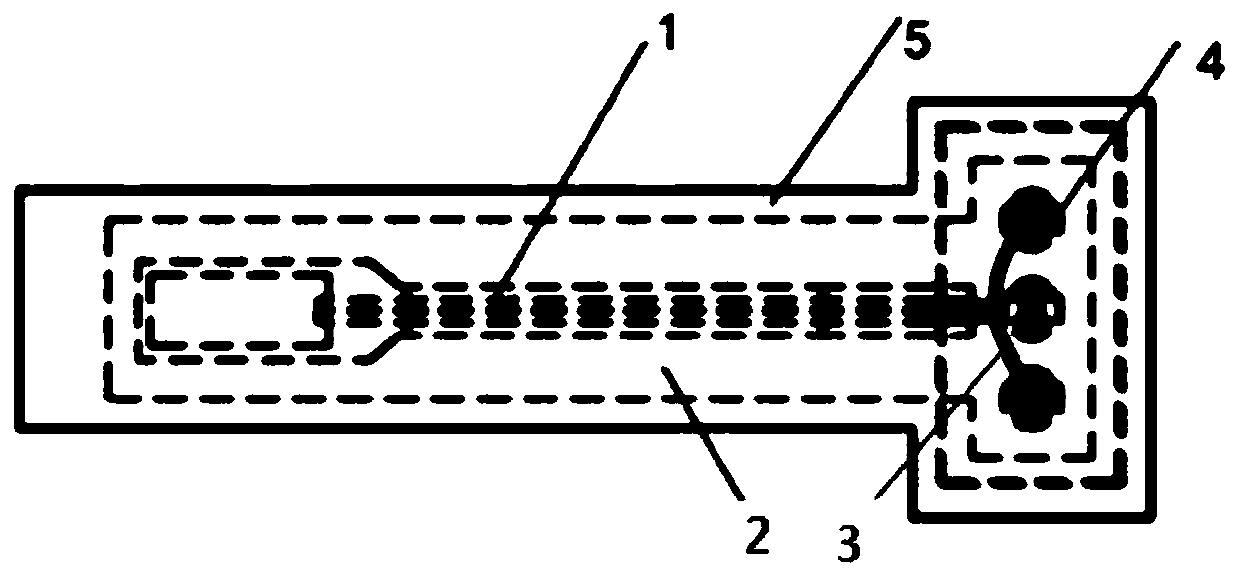

Multi-core optical fiber connector countershaft packaging system

ActiveCN112255739ACheap mass productionShorten the lengthCoupling light guidesMulticore optical fibreFace detectionPolymer adhesive

The invention discloses a multi-core optical fiber connector countershaft packaging system, which belongs to the field of optical fiber connectors. The system comprises a rotary countershaft mechanism, an optical fiber end face imaging detection module, and a dispensing and packaging module. The rotary countershaft mechanism is provided with a rotary countershaft clamp and an optical fiber lockingclamp, the rotary countershaft clamp is used for adjusting the angle of a multi-core optical fiber for countershaft, and the optical fiber locking clamp is used for fixing the optical fiber after theposition of the optical fiber is determined; the optical fiber end face imaging detection module has the functions of automatic focusing and multi-core optical fiber end face recognition so as to achieve optical fiber end face detection and output multi-core optical fiber rotation alignment angle information to be fed back to the rotation alignment mechanism; and the dispensing and packaging module is provided with a dispensing unit, an ultraviolet curing unit and a thermal curing unit, the dispensing unit provides a polymer adhesive injected into the porous ferrule, and the ultraviolet curing unit and the thermal curing unit realize permanent fixing and packaging of the multi-core optical fiber. According to the invention, accurate positioning of the multi-core optical fiber in the multi-hole insertion core can be realized, so that a novel high-density multi-core optical fiber connector with very low insertion loss can be manufactured.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

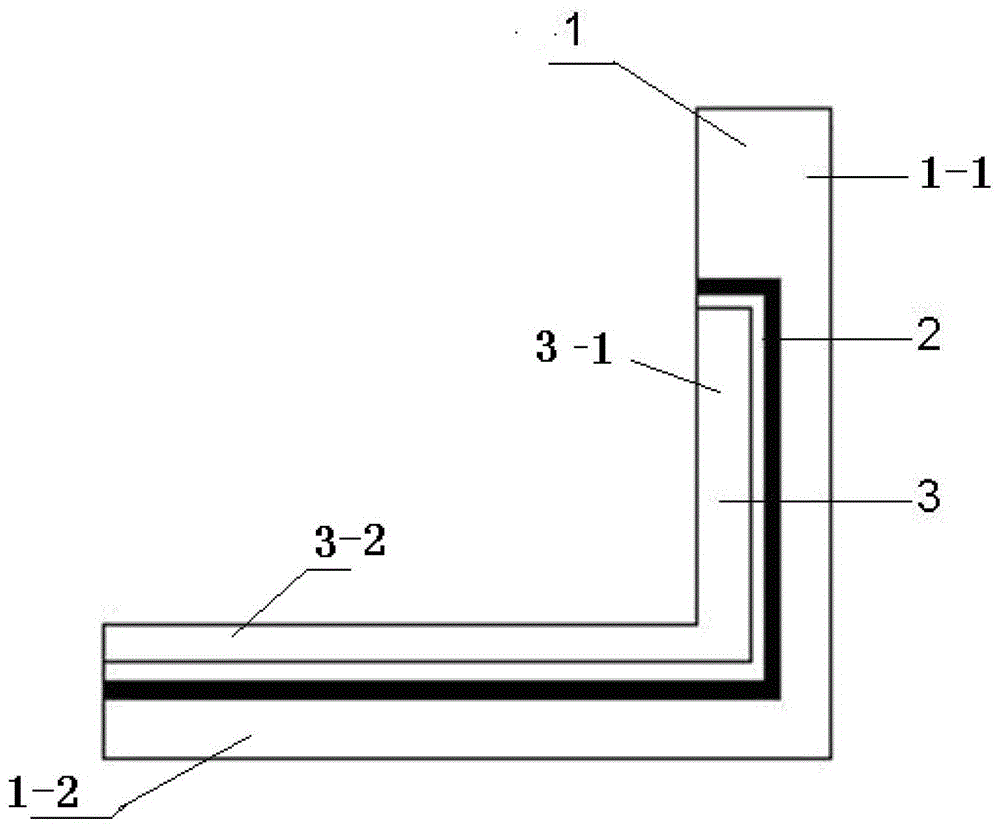

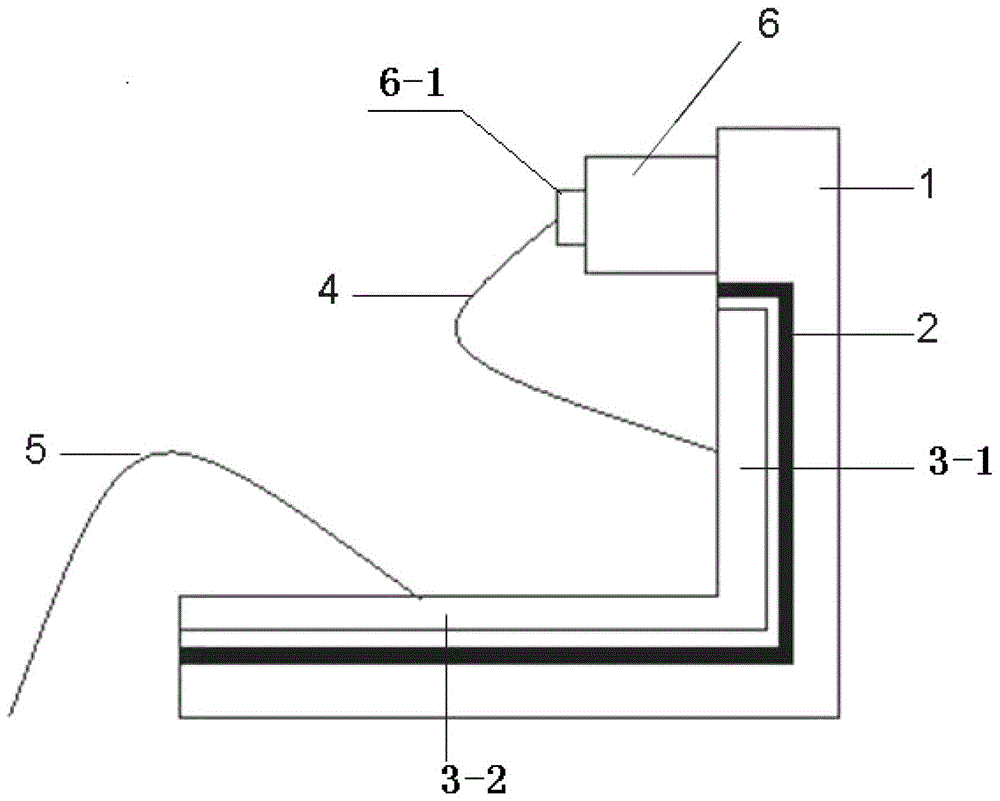

SMD laser packaging structure and packaging method in optoelectronic circuit

ActiveCN103633552BLow raw material costReduce packaging costsLaser detailsSemiconductor lasersSurface mountingEngineering

The invention discloses a surface-mounted type laser packaging structure comprising a semiconductor laser tube core and an L-shaped heat sink. The L-shaped heat sink comprises an L-shaped negative electrode layer, an L-shaped insulating layer and an L-shaped positive electrode layer. An L-shaped groove is arranged on the internal surface of the L-shaped negative electrode layer The L-shaped positive electrode layer is arranged in the L-shaped groove in an embedded way. The L-shaped insulating layer is arranged between the L-shaped negative electrode layer and the L-shaped positive electrode layer. The semiconductor laser tube core is installed on the part, which has no L-shaped groove, of the internal surface of the L-shaped negative electrode layer. The surface-mounted type laser packaging structure is small in volume, high in reliability and low in welding point defect rate. Besides, automation is easy to realize, production efficiency is enhanced and cost is lowered.

Owner:Shandong Huaguang Optoelectronics Co. Ltd.

Sensor packaging structure capable of implanting clothes, packaging method of sensor packaging structure and intelligent clothing

ActiveCN109883462AHigh signal acquisition accuracyFirmly connectedMagnetic/electric field screeningGarmentsEngineeringHot-melt adhesive

The invention provides a sensor packaging structure capable of implanting clothes, a packaging method of the sensor packaging structure and intelligent clothing, and belongs to the technical field ofsensor packaging. The sensor packaging structure comprises a sensor packaging unit, a forming hot melt adhesive structure, a first conductive buckle an a signal outgoing line, wherein the forming thermal hot melt adhesive structure is used for covering the sensor packaging unit and sticking the sensor packaging unit to one side of a clothes cloth, and the first conductive snap joint is used for fixedly connecting the sensor packaging unit and the clothes cloth in a mechanical mode; the sensor packaging unit comprises a sensor, and a doubly-layer shielding outer shell arranged in the mode of totally covering the sensor; and one end of the signal outgoing line is connected with the a wiring pin of the sensor, the other end of the signal outgoing line is connected with the first conductive snap joint, and the first conductive snap joint is non-electrically connected with the double-layer shielding outer shell. According to the sensor packaging structure, the connecting stability between the sensor packaging structure and the clothes is great, the packaging effect is great, the signal shielding effect and signal collecting accuracy are improved, the waterproof performance is further improved, the service life is long, and the sensor packaging structure is not prone to falling off.

Owner:青岛中物云传智能科技有限公司

Display stand for disposable serving containers

InactiveUS20060231720A1Space minimizationMinimize frequencyFurniture partsStands/trestlesEngineeringPaper sheet

A display stand for disposable serving ware containers, such as paper or plastic plates, platters, deep dishes or bowls that displays the containers in a vertical position so the face of the container can be readily viewed by the consumer at the point of purchase.

Owner:GEORGIA PACIFIC CORRUGATED

Packaging mechanism for wireless communication module

PendingCN114242625ARealize automatic liftingQuick placementSemiconductor/solid-state device manufacturingCleaning using gasesStructural engineeringControl theory

The packaging mechanism for the wireless communication module comprises a bottom box, a packaging bin is fixedly arranged on one side of the upper portion of the bottom box, a packaging mechanism is arranged in the packaging bin, a sliding plate is slidably arranged at the end, away from the packaging bin, of the upper portion of the bottom box, a driving sliding assembly is arranged on the bottom box, and a rectangular groove is formed in the upper portion of the sliding plate; a storage groove is formed in the middle of the bottom wall of the rectangular groove, a sliding column is slidably inserted in the middle of the bottom wall of the storage groove, a top plate is horizontally and fixedly connected to the upper end of the sliding column, a placement plate is placed on the top plate, a plurality of frame placement openings are formed in the upper portion of the placement plate, and a sliding recycling mechanism is arranged in the bottom box. According to the invention, the placing plate can be automatically lifted, so that people can quickly place and automatically retract after sliding, the stability during packaging operation is facilitated, the placing plate is fixed, the packaging stability is further improved, the air suction groove starts to suck air, dust collection and cleaning of a chip frame are realized, faults of a finished product module caused by smudginess of the chip frame are avoided, and the design is reasonable.

Owner:深圳百昱达科技有限公司

Potato packing device and potato excavator

PendingCN107444697AAvoid the problem of being easily damaged by falling due to gravityImprove package stabilityPackaging protectionPackaging fruits/vegetablesAgricultural scienceAgricultural engineering

The invention relates to the field of agricultural machinery, aims to solve the problem that the distance from a bag opening to a bag bottom in the prior art is long, potatoes are quite easily damaged when dropping to the bag bottom due to gravity, and provides a potato packing device and a potato excavator. According to the potato packing device, a packing bag for packing the potatoes is placed on a carrying table in an implementing process; because the carrying table is slidably arranged in accommodating space to be close to or away from a feeding opening, in a using process, the carrying table is close to the feeding opening, the potatoes enter the packing bag which is close to the feeding opening via the feeding opening, and along with increasing of the potatoes in the packing bag, the carrying table drives the packing bag to be away from the feeding opening gradually until the packing bag is filled with the potatoes. The problem that the distance from the bag opening to the bag bottom is long, the potatoes are quite easily damaged when dropping to the bag bottom due to gravity can be avoided effectively, and the potato packing stability and the potato packing efficiency are improved. The potato excavator comprises the potato packing device, and therefore, the potato excavator has the beneficial effects.

Owner:GRASSLAND RES INST OF CHINESE ACAD OF AGRI SCI

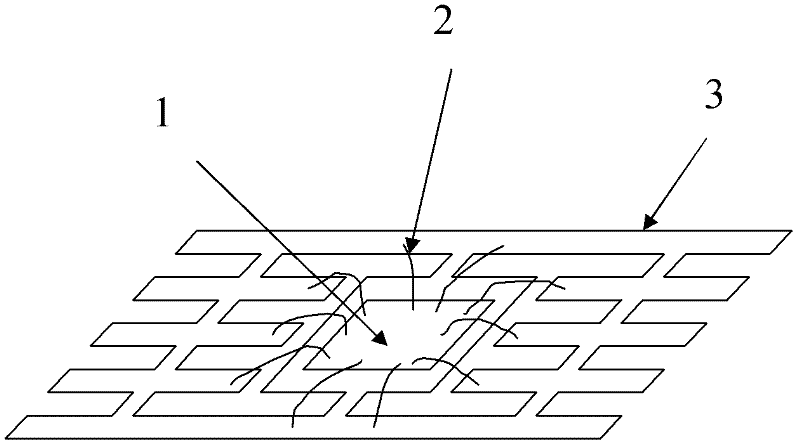

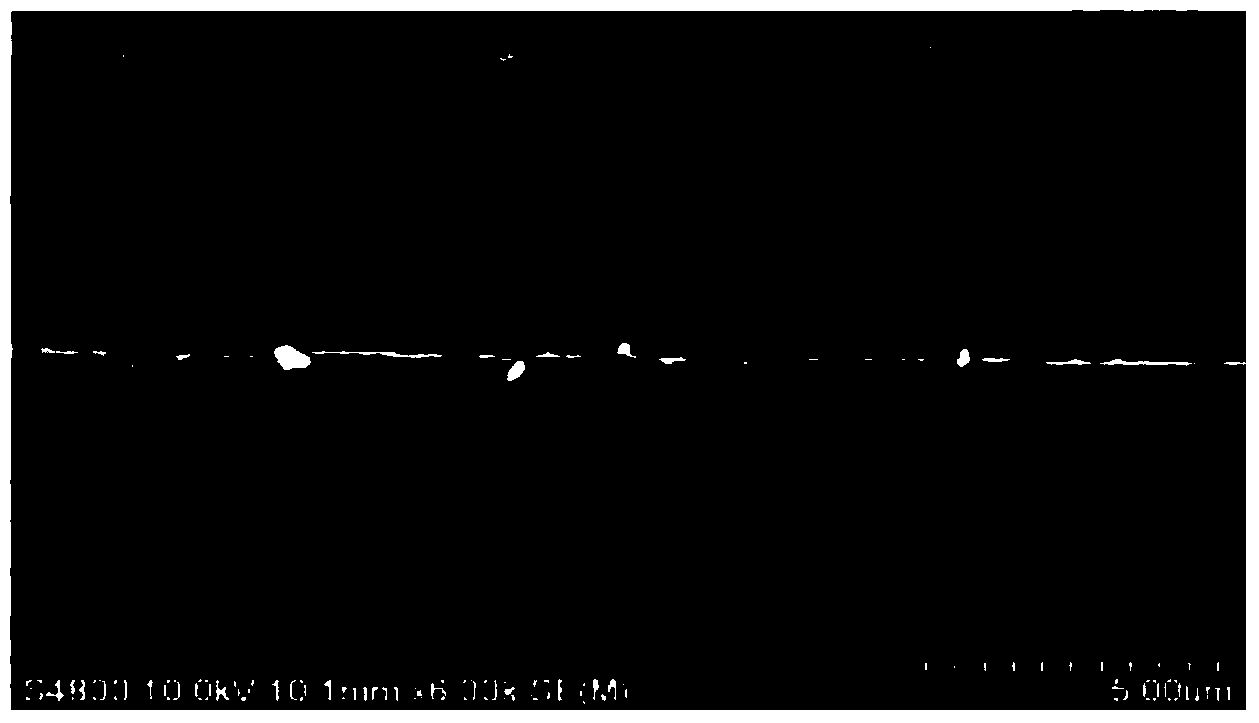

Frame sealing glue, preparation method thereof and display panel

ActiveCN113637428AGood dispersionShort curing timeNon-macromolecular adhesive additivesEster polymer adhesivesFiberMechanical engineering

The invention discloses frame sealing glue, a preparation method thereof and a display panel. The frame sealing glue comprises a frame sealing glue solution and conductive fibers dispersed in the frame sealing glue solution, and the conductive fibers are in a three-dimensional spiral shape. The frame sealing glue has excellent conductivity, high packaging quality, and excellent toughness and packaging bonding strength after being cured, and the separation resistance of two substrates of the box is improved. The preparation method of the frame sealing glue can ensure that the prepared frame sealing glue is stable in performance and high in efficiency. The display panel contains the frame sealing glue, and is stable in display and long in service life.

Owner:HKC CORP LTD

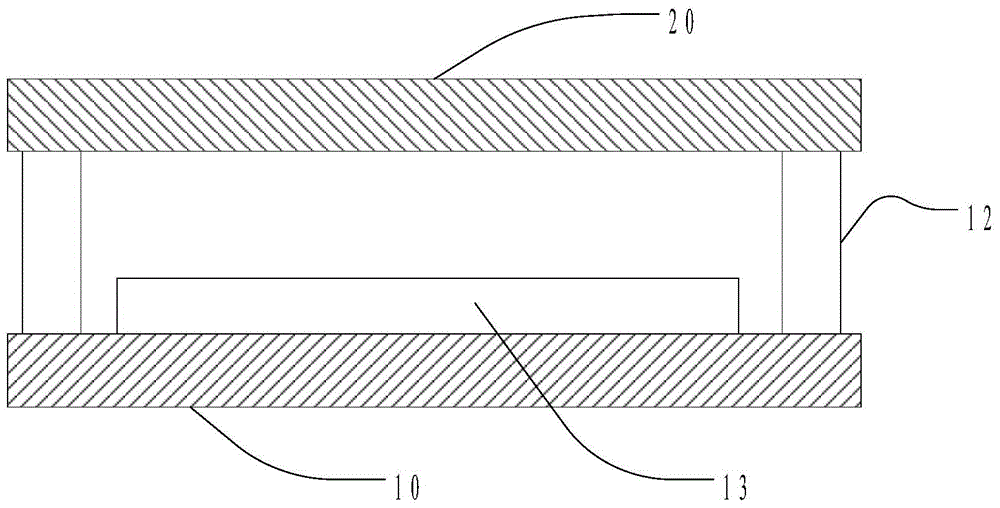

Display panel and display equipment

ActiveCN111969028AIncrease path lengthImprove package stabilitySolid-state devicesSemiconductor/solid-state device manufacturingPhysicsElectrical and Electronics engineering

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT

Glass frit composition, glass frit paste composition, sealing method, and electric device

ActiveCN104045236BExpansion coefficient matchingAvoid crackingSolid-state devicesSemiconductor/solid-state device manufacturingFritVolumetric Mass Density

The invention discloses a glass frit composition, which comprises a glass frit base material and a filler. The filler includes a quasicrystal material, and the quasicrystal material accounts for 5%-45% of the total mass of the filler. The glass frit composition, the glass frit paste composition and the sealing method and device using the glass frit paste composition provided by the present invention have a negative thermal expansion coefficient, which can well reduce the thermal expansion coefficient of the glass frit, so that the glass frit It is more matched with the expansion coefficient of the substrate, and provides a channel for venting large pores, improves the density and bonding strength of the glass frit composition, thereby improving the packaging yield and improving the stability of OLED packaging.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD +1

A modified carbon material and a flow battery electrode modified by graphene-like nanosheets prepared therefrom

ActiveCN110197905BImprove hydrophilicityImprove electrochemical activityCell electrodesIn situ polymerizationModified carbon

The invention provides a modified carbon material, a preparation method thereof, and a redox flow battery electrode modified by a graphene-like nanosheet prepared from the same. The preparation methodcomprises the steps of: 1) subjecting phytic acid and an amino group-containing substance to in-situ polymerization on the surface of the carbon material; and 2) calcining the product at a high temperature. The carbon material treated by the method has rich oxygen-containing functional groups on its surface, and has greatly improved hydrophilic property, electrochemical activity and specific surface area. Moreover, the loading amount of hetero elements such as nitrogen and phosphorus can be controlled by adjusting the amount and molar ratio of phytic acid and urea. The electrode has high specific surface area and a high functional group content (for example, the oxygen-containing functional group), and exhibits good catalytic activity for both the positive and negative electrode pairs ofan all-vanadium redox flow battery, and the high catalytic activity of the electrode greatly reduces the polarization of the electrode.

Owner:HUNAN YINFENG NEW ENERGY

A modified carbon material and a nitrogen-enriched liquid flow battery electrode prepared therefrom

ActiveCN110194453BImprove conductivityImprove package stabilityGraphiteCell electrodesIn situ polymerizationModified carbon

Owner:HUNAN YINFENG NEW ENERGY

Glass frit composition, glass frit paste composition, and electrical component

ActiveCN103936284BSmall coefficient of thermal expansionCoefficient of thermal expansion adjustmentFritMaterials science

The invention provides a frit composition. The frit composition comprises a frit base material and a filler, wherein the filler is an isotropic negative thermal expansion material, and the mass of the isotropic negative thermal expansion material accounts for 5-30% of the total mass of the frit composition. The frit composition can reduce the thermal expansion coefficient of frit in order to be matched with a glass substrate, can uniformly adjust the overall thermal expansion coefficient in all directions, avoids the cracks caused by the stress between the frit and the glass substrate, and improves the yield of products.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD +1

An automatic packaging device for duck eggs

ActiveCN109250181BIncrease the feeding speedAvoid manual operationPackaging eggsWrappingMotor driveAgricultural engineering

The invention discloses an automatic duck egg packaging device which comprises a first working table and a second working table. The upper end of the second working table is provided with a protectivebox body, the upper end of the first working table is provided with a conveying belt, the upper end of the conveying belt is provided with packaging trays and packaging boxes loading duck eggs at intervals, a movable plate is slidingly connected between front and back sliding grooves, the right end of the protective box body is provided with a second servo motor, a lead screw of the output end ofthe second servo motor penetrates through the middle of a movable plate, the bottom of the movable plate is provided with a clamping box body, the upper end of a rotary shaft is connected with a turntable, and the middle of the upper end of the second working table is provided with a fixing rack for installing a preservative film roller. A third servo motor drives the turntable to rotate througha rotary shaft, so that the preservative film is wound around the packaging trays and the packaging boxes circle by circle, the working efficiency is improved, and meanwhile the overall packaging stability of the packaging trays and the packaging boxes is improved.

Owner:安徽靳氏食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com