Frame sealing glue, preparation method thereof and display panel

A frame sealing glue and glue liquid technology, applied in the direction of adhesive, epoxy resin glue, adhesive type, etc., can solve the problems of affecting display effect and stability, inconsistent thickness of frame sealing glue box, unsatisfactory packaging quality, etc. The effect of shortening curing time, improving package stability, and improving bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] Correspondingly, the embodiment of the present application provides the preparation method of the frame sealant in the above embodiment of the application. The preparation method process flow of the sealing glue of the embodiment of the present application is as follows: Figure 5 shown, including the following steps:

[0061] Step S01: pre-dispersing the conductive fibers and the components contained in the frame sealing glue solution to obtain a mixture;

[0062] Step S02: Kneading the mixture to obtain a frame sealant.

[0063] Among them, the pre-dispersion treatment of the conductive fiber and the sealing glue in step S01 is to make the components mix uniformly. Therefore, as long as the mixing method can realize the uniform mixing of the components, it is within the scope disclosed in the specification of this application, such as In the embodiment, the temperature of the pre-dispersion treatment is 20°C-30°C, and the stirring time is 2h-4h. The temperature of ...

Embodiment 1

[0073] This embodiment provides a frame sealing glue and a preparation method thereof. The sealant of this embodiment includes the following components by weight percentage:

[0074] 20% epoxy resin, 73.75% acrylic resin, 0.75% photoinitiator, 5% thermosetting agent, and 0.5% carbon nanofiber.

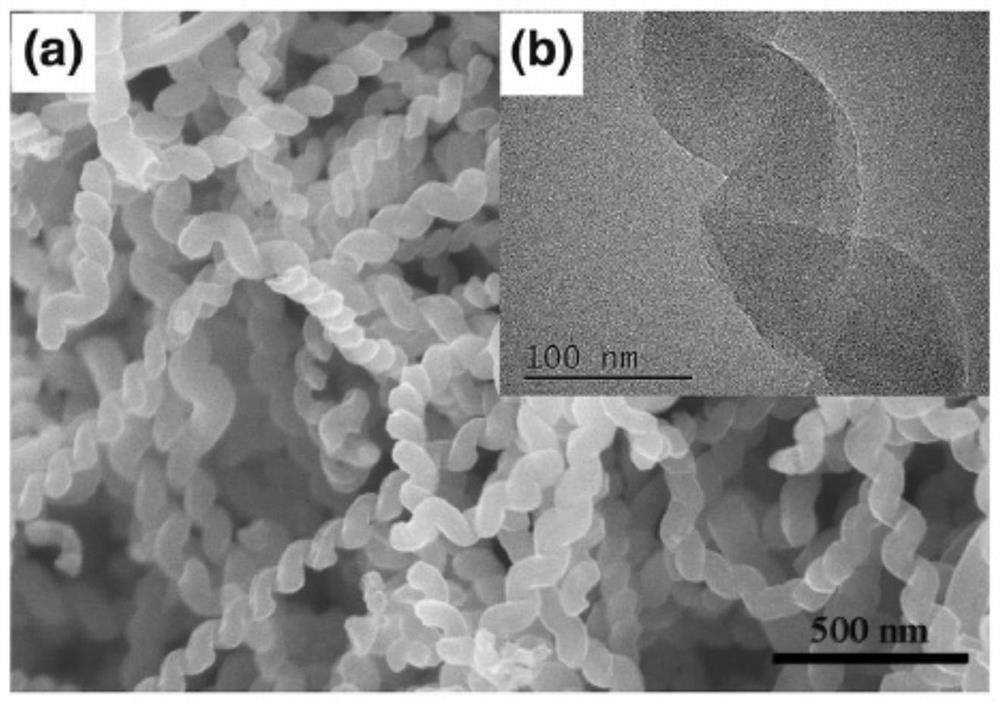

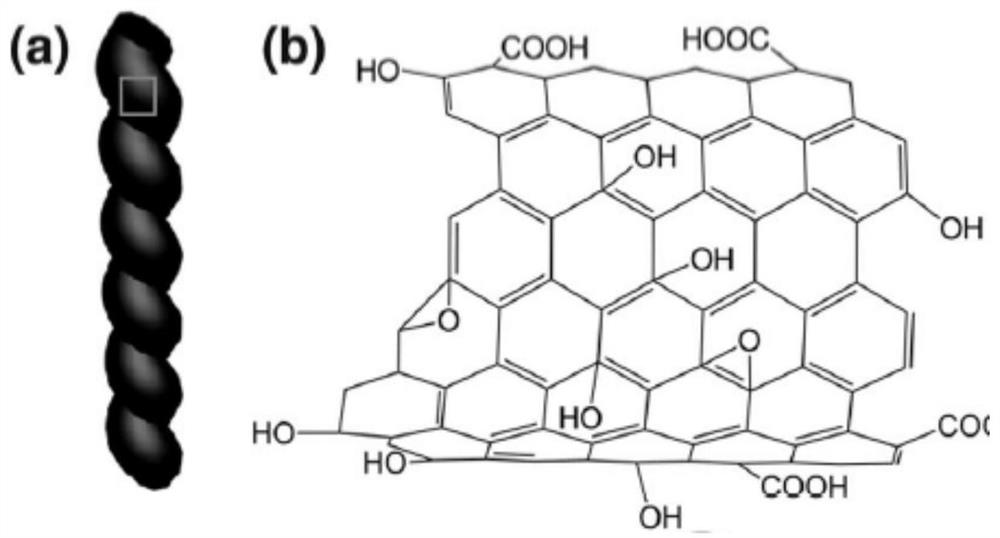

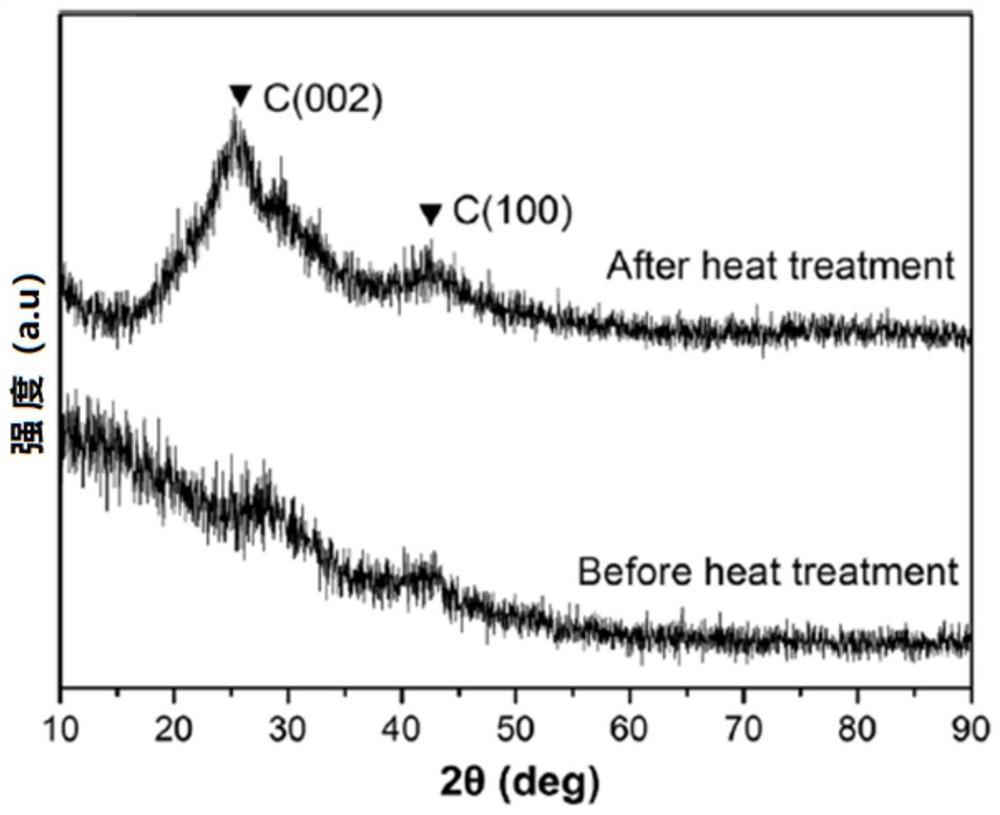

[0075] Among them, the epoxy resin is bisphenol A epoxy resin, the acrylic resin is methacrylic resin, the photoinitiator is α,α-diethoxyacetophenone, the thermal curing agent is hexamethylenediamine, and the carbon nanofibers are helical The average diameter of the three-dimensional helical structure is 380nm, the average pitch is 100nm, the diameter of the carbon nanofiber is 100nm, the carbon nanofiber is graphitized (the graphitization rate is 65%), and the surface of the carbon nanofiber is modified by KH550. Example The viscosity of the frame sealant is 240 mPa·s.

[0076] The method for preparing the frame sealant comprises the following steps:

[0077] S1. Mix the HCNFs-KH55...

Embodiment 2

[0081] This embodiment provides a frame sealing glue and a preparation method thereof. Compared with Example 1, the sealing glue of this example is different in that the surface modification treatment of HCNFs does not use KH550.

[0082] The preparation method of the frame sealant is prepared according to the preparation method of the frame sealant in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com