Display stand for disposable serving containers

a technology for serving containers and display stands, which is applied in the field of display stands, can solve the problems of adversely affecting the stability of the assembled package, the aesthetic appeal of these types of decorative containers is not readily apparent to the customer, etc., and achieves the effects of minimizing the space needed for transportation, facilitating manufacturing, and minimizing the frequency of storag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

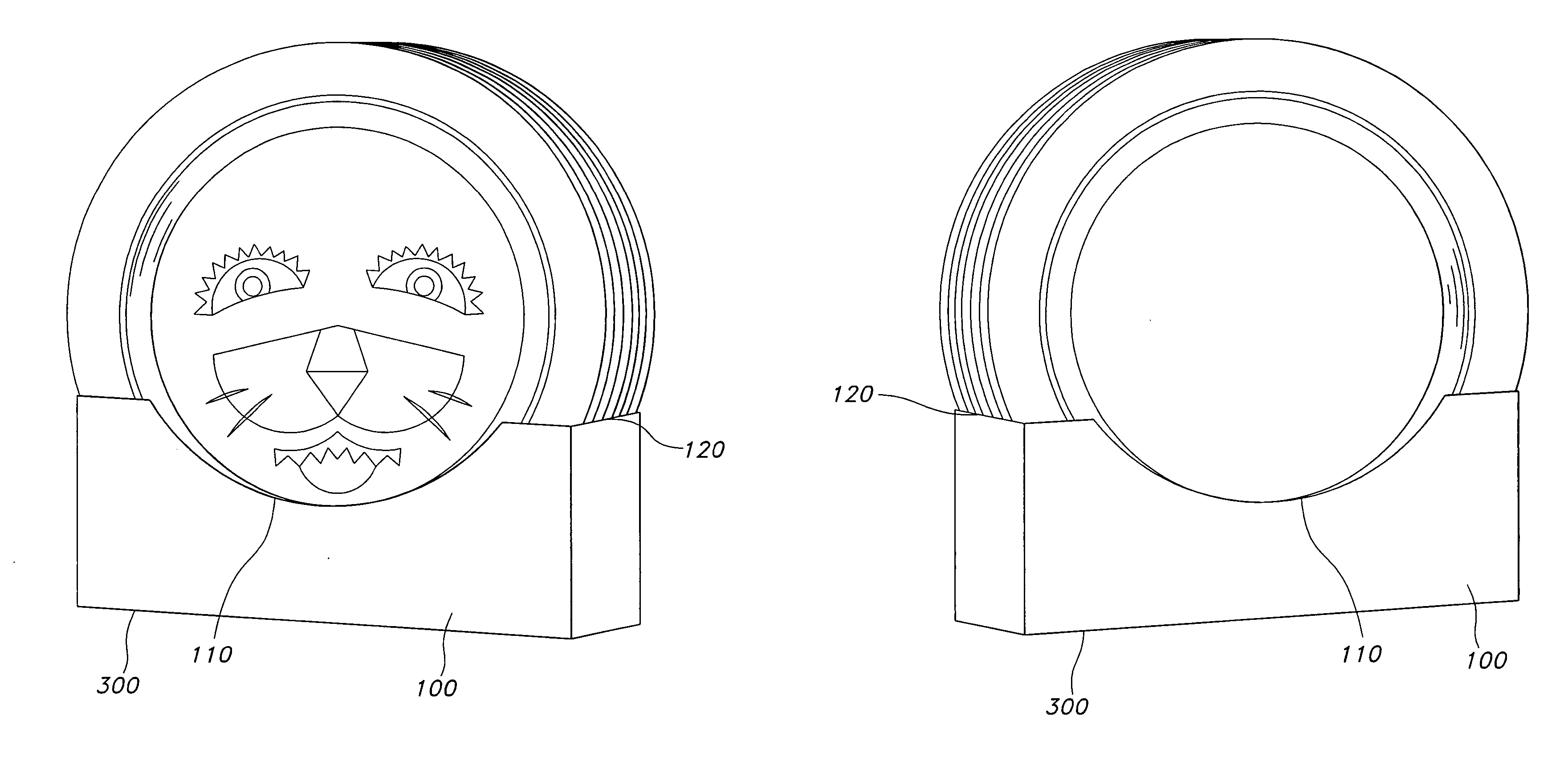

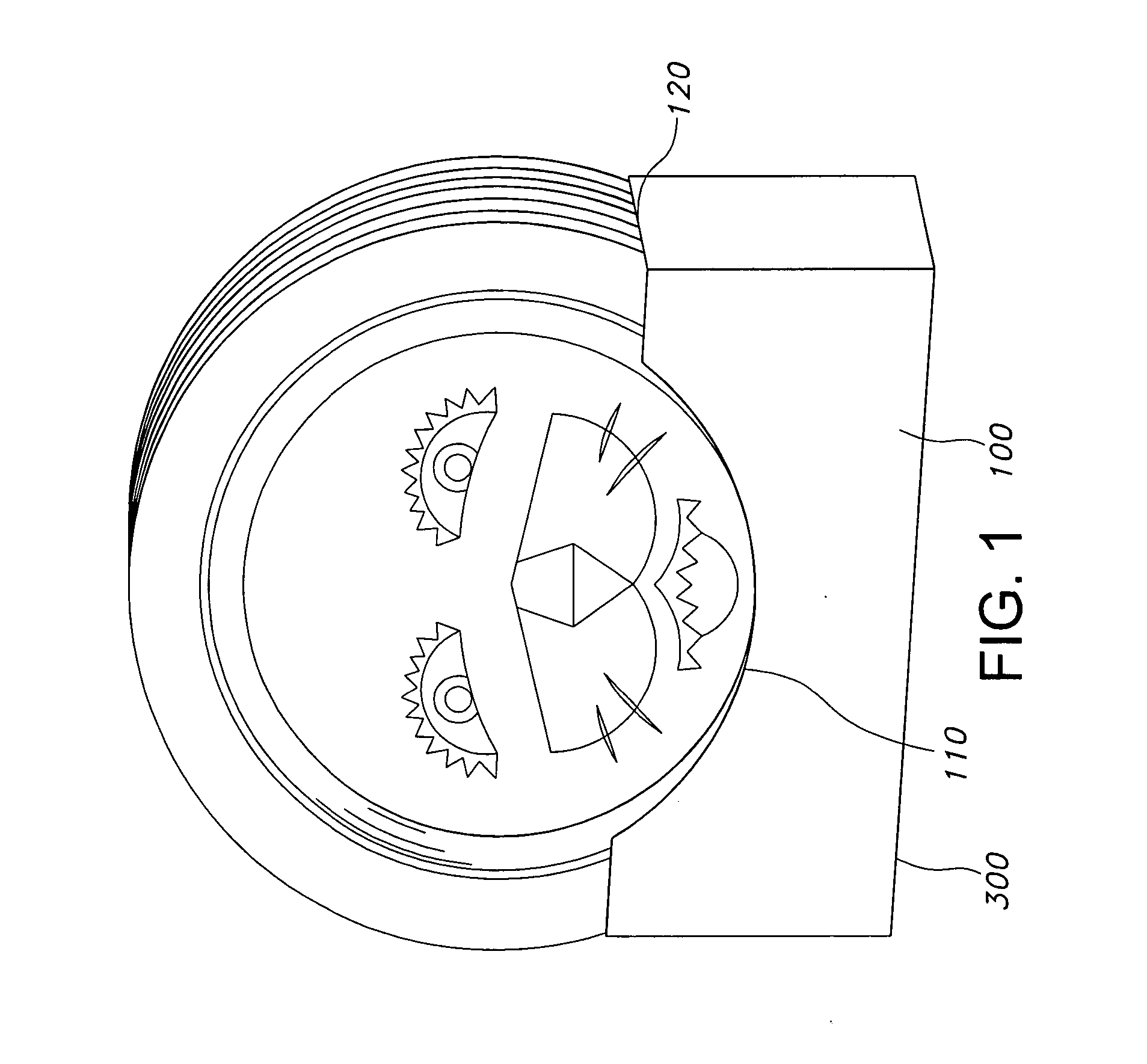

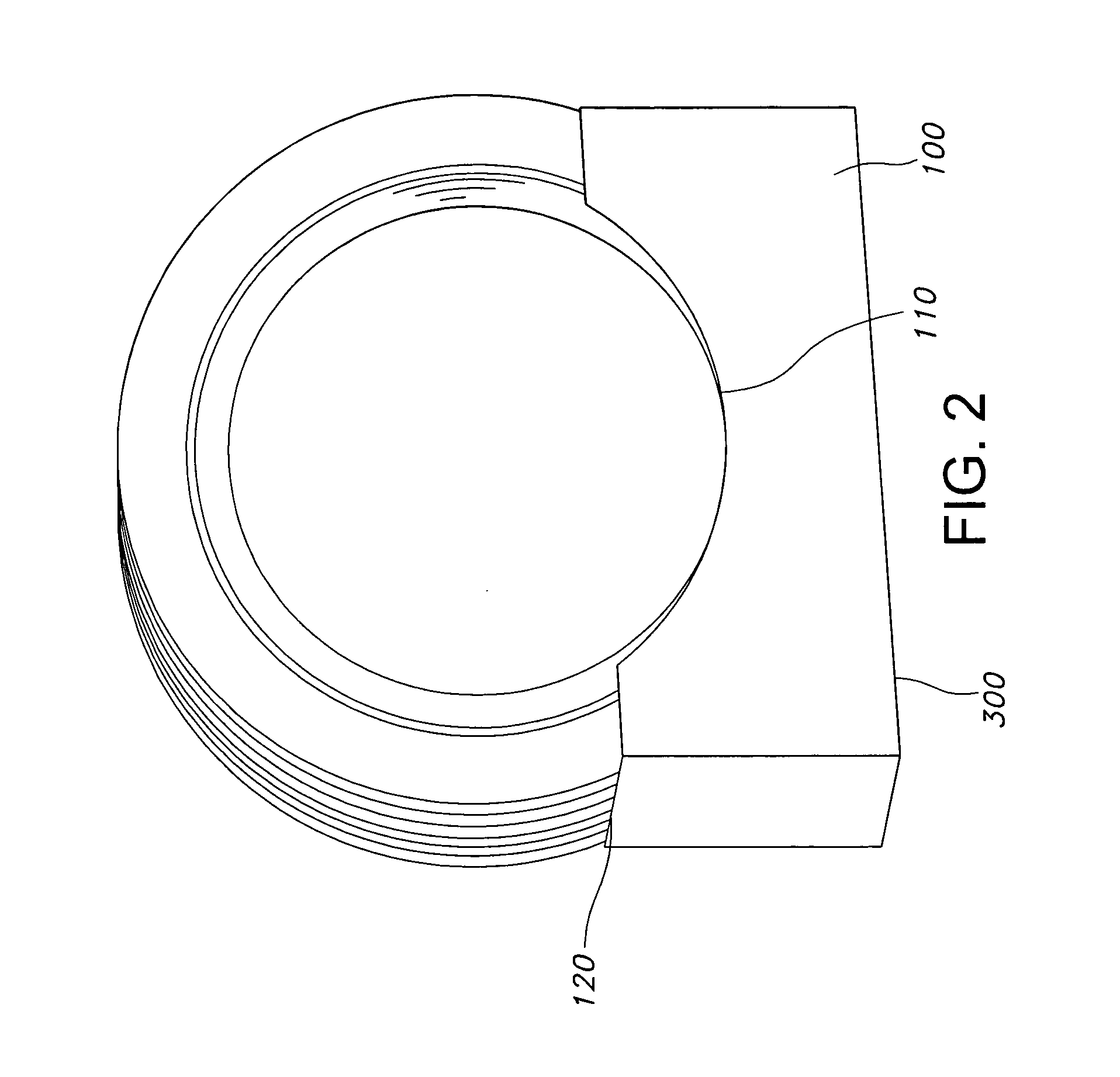

[0020] The blank for display stand 100 has a continuous straight bottom edge 300, a connection tab 410, a front flap 420, a first end flap 430, a rear flap 440 and a second end flap 450. As seen in FIG. 4, connection tab 410 is connected along its right edge to the left edge of front flap 420 along a first vertical fold line 415. Front flap 420 is connected along its right edge to the left edge of first end flap 430 along a second vertical fold line 425. First end flap 430 is connected along its right edge to the left edge of rear flap 440 along a third vertical fold line 435. Rear flap 440 is connected along its right edge to the left edge of second end flap 450 along a fourth vertical fold line 445. To assemble the blank into display stand 100, each vertical fold line is folded so that each portion of the blank is perpendicular to the adjacent portion. This allows connection tab 410 to overlap a portion of second end flap 450 and can be adhered thereto by any standard means such a...

second embodiment

[0021] The blank for display stand 100′ has a continuous straight bottom edge 300, first rear flap 510, a first end flap 520, a second end flap 530, a front flap 540, a third end flap 550, a fourth end flap 560 and a second rear flap 570. As seen in FIG. 8, first rear flap 510 is connected along its right edge to the left edge of first end flap 520 along a first vertical fold line 515. First end flap 520 is connected along its right edge to the left edge of second end flap 530 along a second vertical fold line 525. Second end flap 530 is connected along its right edge to the left edge of front flap 540 along a third vertical fold line 535. Front flap 540 is connected along its right edge to the left edge of third end flap 550 along a fourth vertical fold line 545. Third end flap 550 is connected along its right edge to the left edge of fourth end flap 560 along a fifth vertical fold line 555. Fourth end flap 560 is connected along its right edge to the left edge of second rear flap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com