Packing component, packing method and packed object

A technology of packaging components and packaging methods, which is applied in the direction of transportation and packaging, internal accessories, and containers to prevent mechanical damage, etc., can solve the problems of unstable packaging, increased labor costs, and unfavorable overall packaging, and achieve simple and fast packaging methods. Highly stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

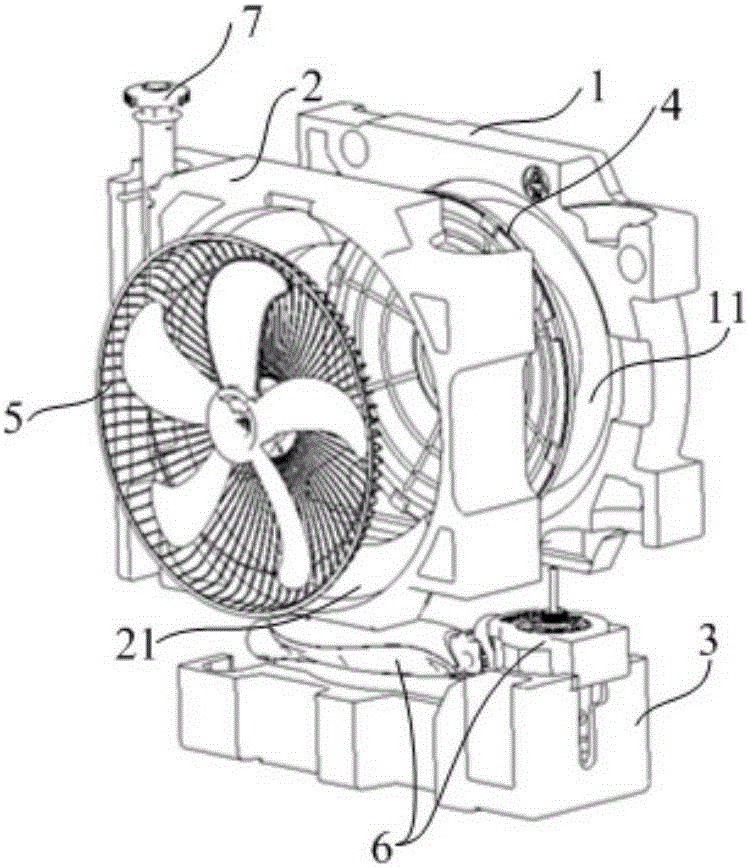

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

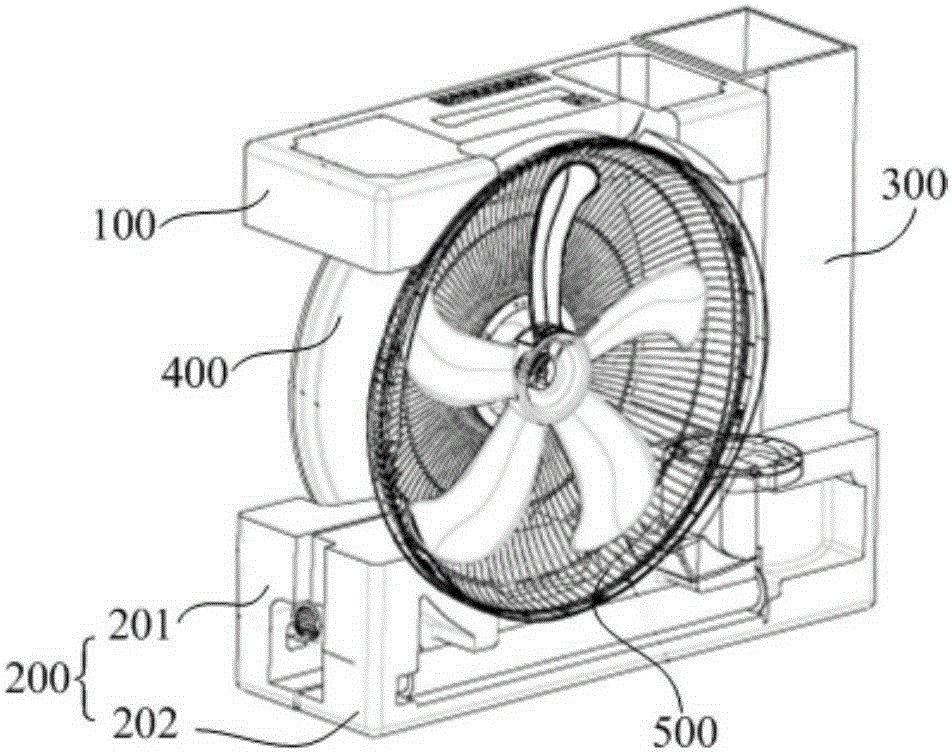

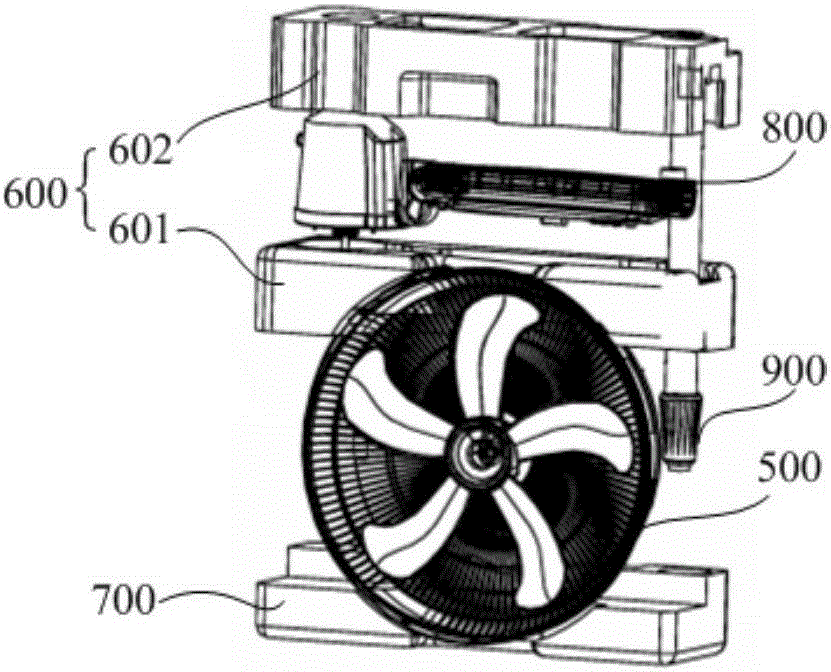

[0030] image 3 It is a structural schematic diagram of the packaging assembly provided by the embodiment of the present invention. Such as image 3 As shown, the embodiment of the present invention provides a packaging assembly suitable for the packaging of floor fans, the packaging assembly includes: a first packaging part 1 and a second packaging part 2 that are detachably connected, and the first packaging part 1 and the second packaging part 2 The first installation position 11 and the second installation position 21 that match the shape of the chassis 4 of the floor fan and the grille fan assembly 5 are set on the second package 2, respectively, for installing the chassis 4 and the grille fan assembly 5 . Because the first installation position 11 and the second installation position 21 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com