Patents

Literature

42results about How to "Increase the content of functional groups" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of carbon electrode material and application thereof

ActiveCN105914050AImprove wettabilityIncrease the content of functional groupsHybrid capacitor electrodesHybrid/EDL manufactureInorganic saltsSupercapacitor

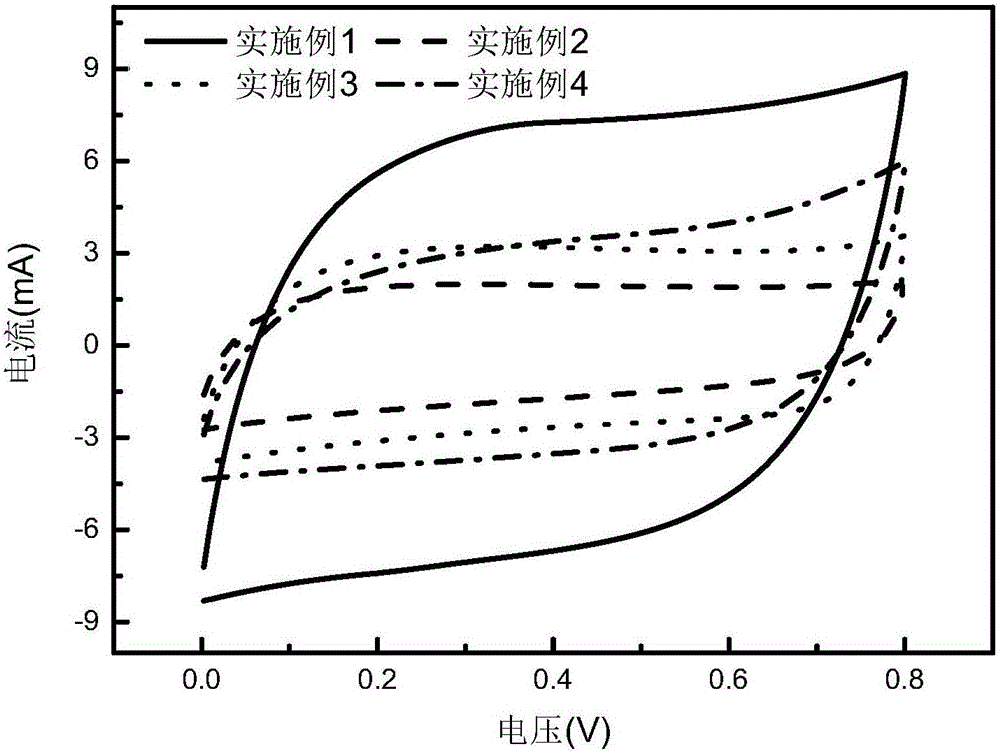

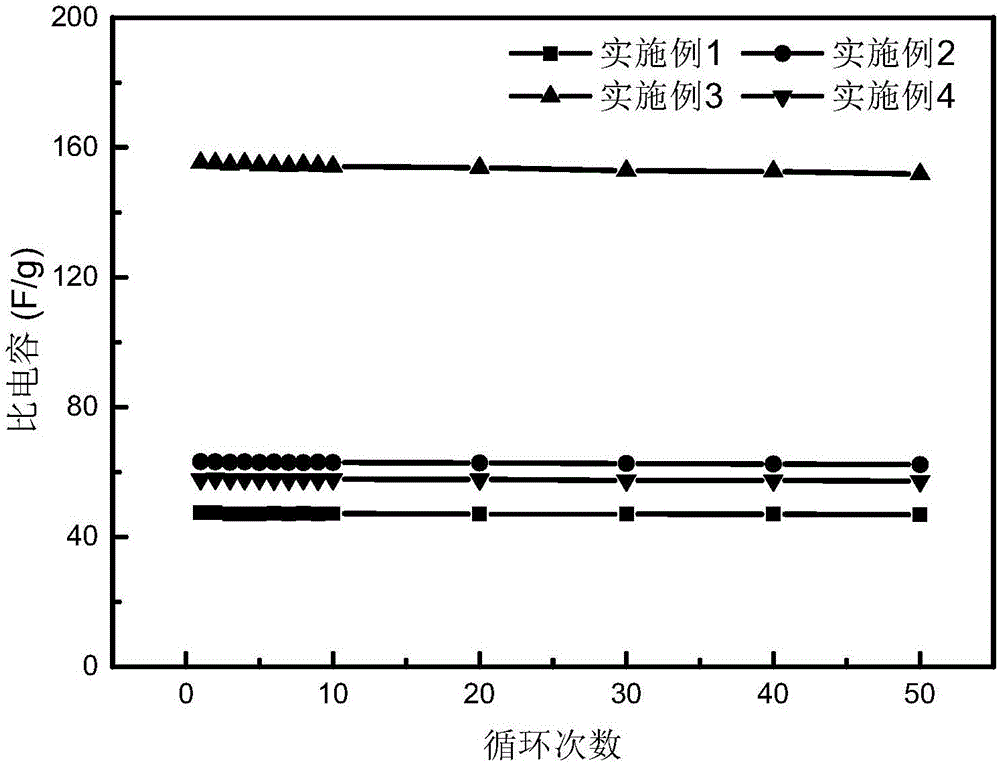

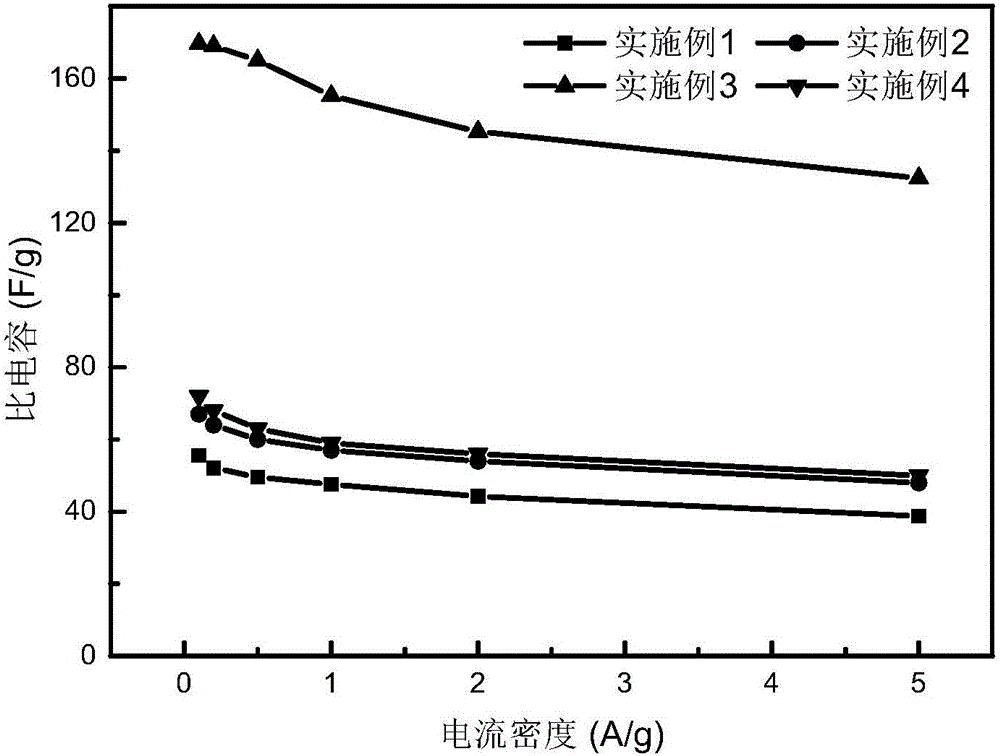

The invention discloses a preparation method of a carbon electrode material and an application thereof. The method comprises the steps of firstly uniformly mixing an activator, chestnut shells and water according to a mass ratio of 1: (0.2-1): (1-3), sufficiently drying the components, and calcining in an inert atmosphere at a temperature of 600-800 DEG C for 1-5 hours, thereby obtaining a carbon material primary product, wherein the activator is one component or multiple components selected from KOH, NaOH, ZnCl2 and Ca(NO3)2; then eliminating inorganic salts and oxide impurities in the carbon material primary product, thereby obtaining a chestnut shell based carbon material; and finally uniformly mixing the chestnut shell based carbon material, melamine and water according to a mass ratio of 1: (1-10): (2-20), and then calcining in the inert atmosphere at the temperature of 600-800 DEG C for 1-5 hours, thereby obtaining the carbon electrode material. Through the preparation method, the chestnut shell based carbon material is doped for preparing the carbon electrode material; the carbon electrode material is applied in a super-capacitor; and furthermore the carbon electrode material has high electrochemical performance and has relatively good application prospect.

Owner:HUAZHONG UNIV OF SCI & TECH

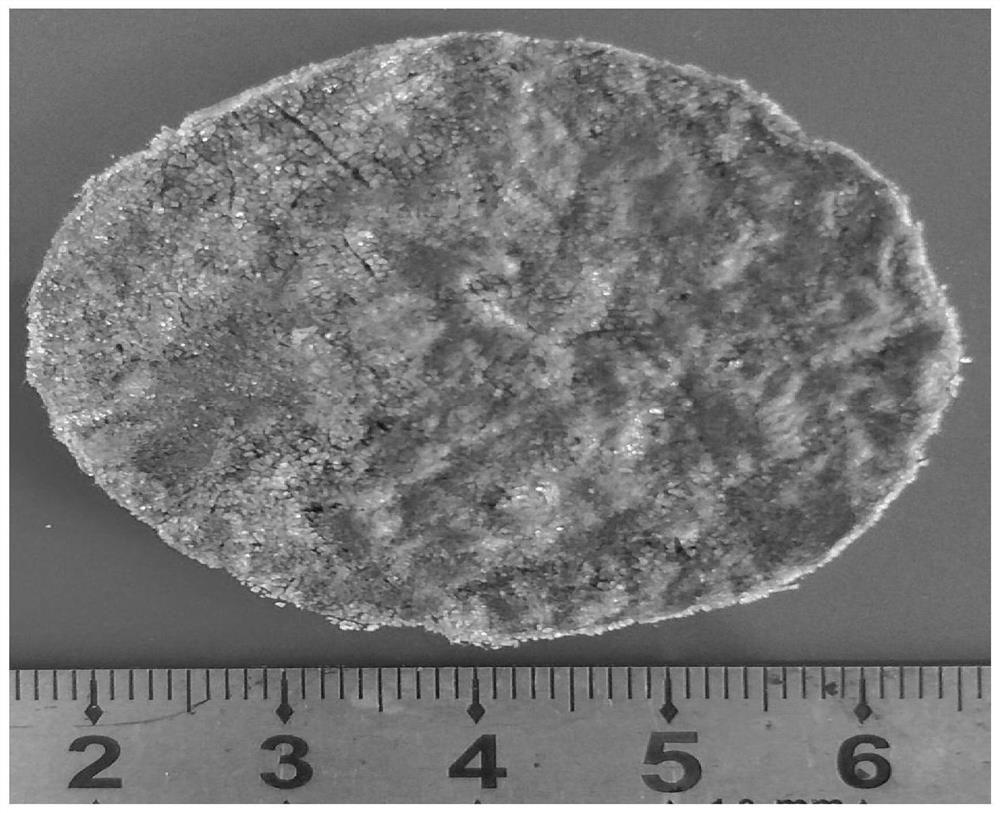

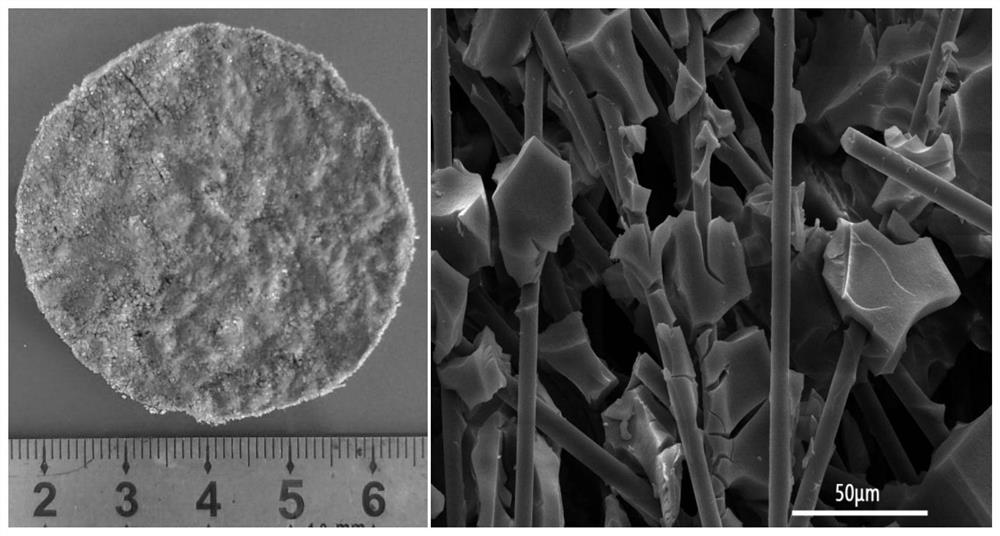

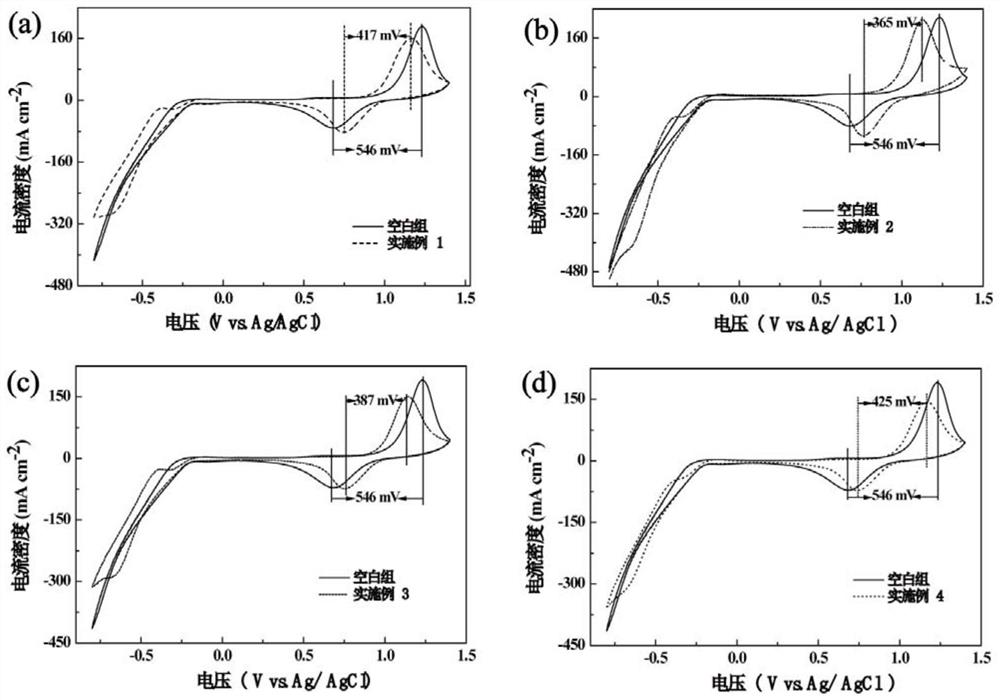

Modified carbon material and redox flow battery electrode modified by graphene-like nanosheet prepared from same

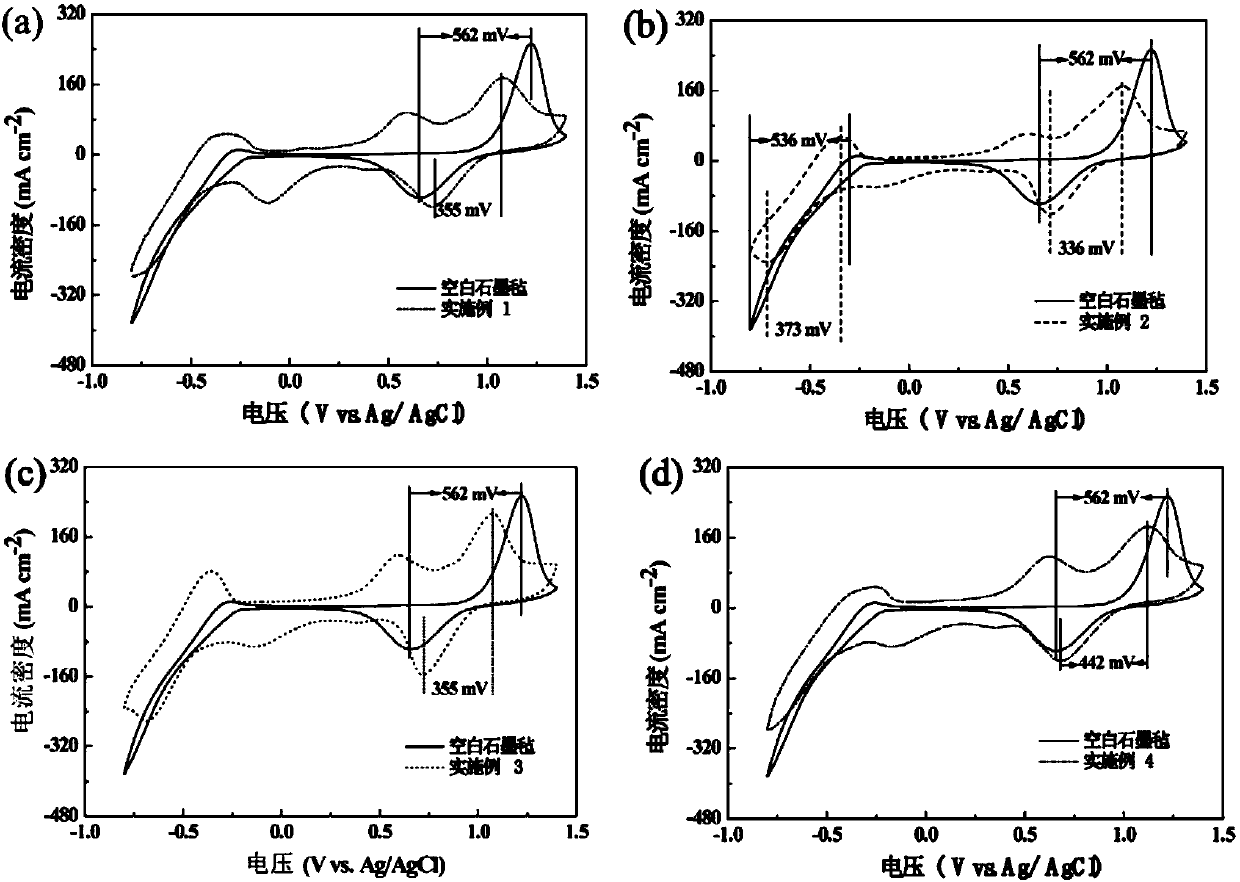

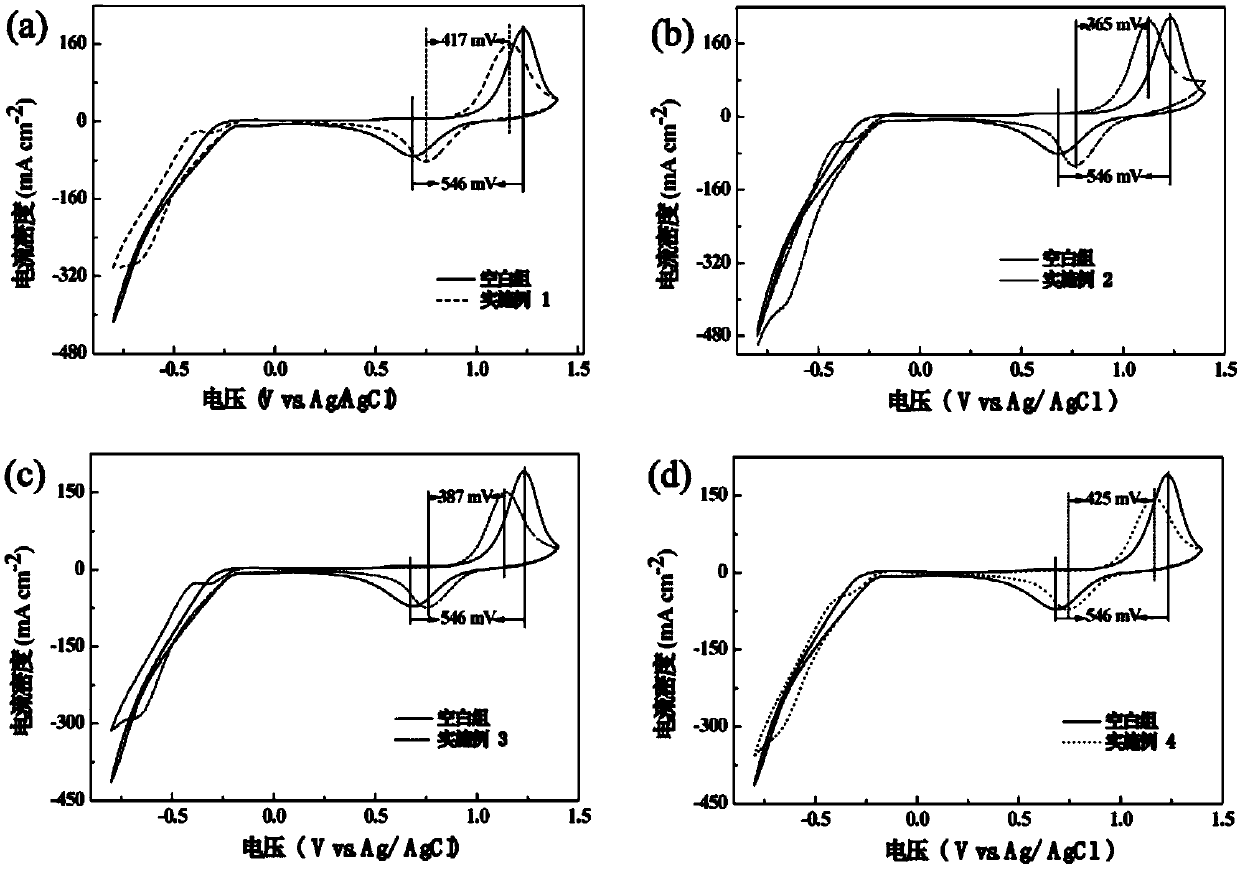

ActiveCN110197905ALarge specific surface areaIncrease the content of functional groupsCell electrodesModified carbonIn situ polymerization

The invention provides a modified carbon material, a preparation method thereof, and a redox flow battery electrode modified by a graphene-like nanosheet prepared from the same. The preparation methodcomprises the steps of: 1) subjecting phytic acid and an amino group-containing substance to in-situ polymerization on the surface of the carbon material; and 2) calcining the product at a high temperature. The carbon material treated by the method has rich oxygen-containing functional groups on its surface, and has greatly improved hydrophilic property, electrochemical activity and specific surface area. Moreover, the loading amount of hetero elements such as nitrogen and phosphorus can be controlled by adjusting the amount and molar ratio of phytic acid and urea. The electrode has high specific surface area and a high functional group content (for example, the oxygen-containing functional group), and exhibits good catalytic activity for both the positive and negative electrode pairs ofan all-vanadium redox flow battery, and the high catalytic activity of the electrode greatly reduces the polarization of the electrode.

Owner:HUNAN YINFENG NEW ENERGY

Hyperbranched resin toughened PBT (polybutylene terephthalate) material with epoxy resin bonding performance and preparation method for hyperbranched resin toughened PBT material

InactiveCN105885362AImprove interfacial adhesionIncrease the content of functional groupsMicrosphereMetallic materials

The invention discloses a hyperbranched resin toughened PBT (polybutylene terephthalate) material with epoxy resin bonding performance. The hyperbranched resin toughened PBT material consists of the following raw materials in parts by weight: 60 to 80 parts of PBT, 15 to 20 parts of cardanol amine, 15 to 20 parts of polyvinyl alcohol microspheres, 5 to 8 parts of sodium dodecyl sulfate, 5 to 10 parts of gelatin, 6 to 8 parts of fiberglass, 4 to 7 parts of a toughening agent, 1 to 3 parts of polyethylene wax and 1 to 3 parts of an antioxidant 168. According to the hyperbranched resin toughened PBT material, a coated curing agent is introduced to increase the content of functional groups capable of being reacted with epoxy resin in the material, and meanwhile, a microcapsule of the microcapsule curing agent can be broken to be slowly released under a certain condition to implement curing, so that the aim of controlling a material and epoxy resin pouring sealant curing process is fulfilled, and the interface bonding performance between the material and the epoxy resin is improved; in addition, hyperbranched resin in the toughening agent has high compatibility with the PBT, and another toughening agent is matched, so that the compatibility and the processibility of the PBT material are improved, and the toughness of the composite PBT material and bonding power with a metal material are improved.

Owner:ANHUI KING AUTO ELECTRONICS TECH CO LTD

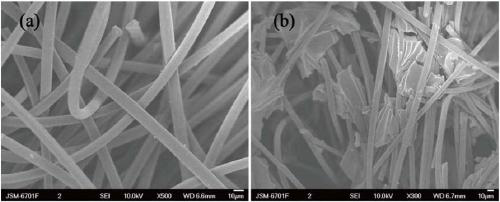

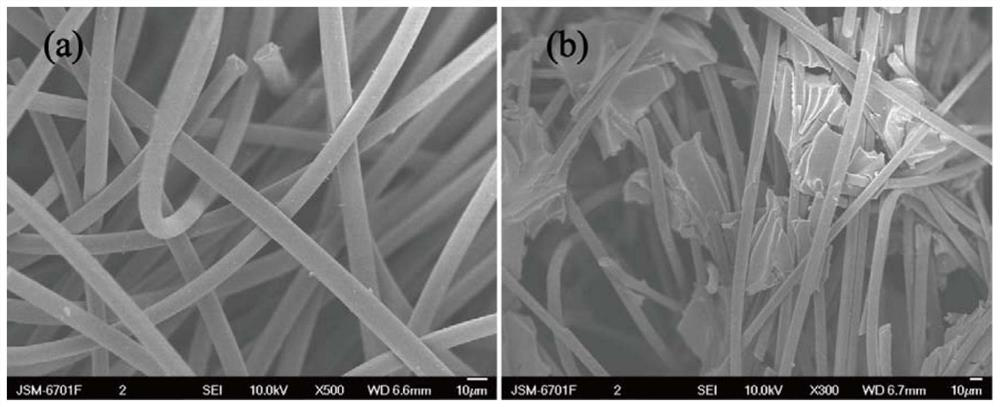

Carbon fiber electrochemical processing method for surface growth carbon nanotube

ActiveCN106319933AImprove surface roughness and functional group contentIncrease surface polarityCarbon fibresSurface reaction electrolytic coatingCarbon nanotubeElectrochemistry

The invention discloses a carbon fiber electrochemical processing method for a surface growth carbon nanotube, and belongs to the field of carbon fiber surface processing. The method includes the following steps of firstly, adding carbon fibers without surface paste agent into an electrolytic bath to be electrolyzed; secondly, removing surface residual electrolyte of the carbon fibers obtained in the first step through a rinsing bath; thirdly, drying the carbon fibers obtained in the second step through a drying box; fourthly, introducing the carbon fibers obtained in the third step into a dipping tank, wherein a catalyst precursor solution is contained in the dipping tank; fifthly, collecting the carbon fibers obtained in the fourth step through a fiber collecting machine. The tensile strength of the carbon fibers is not damaged, the surface roughness and functional group content of the carbon fibers can be effectively improved, the surface polarity of the carbon fibers is improved, and the catalyst precursor solution is evenly loaded on the surfaces of the carbon fibers.

Owner:SHANDONG UNIV

Glass bead modified PBT (polybutylene terephthalate) material with epoxy resin bonding performance and preparation method for glass bead modified PBT material

InactiveCN105885365AImprove interfacial adhesionIncrease the content of functional groupsMicrosphereSealant

The invention discloses a glass bead modified PBT (polybutylene terephthalate) material with epoxy resin bonding performance. The glass bead modified PBT material consists of the following raw materials in parts by weight: 60 to 80 parts of PBT, 15 to 20 parts of cardanol amine, 15 to 20 parts of polyvinyl alcohol microspheres, 5 to 8 parts of sodium dodecyl sulfate, 5 to 10 parts of gelatin, 6 to 12 parts of glass bead master batches, 1 to 3 parts of erucamide and 1 to 3 parts of an antioxidant 245. According to the glass bead modified PBT material, a coated curing agent is introduced to increase the content of functional groups capable of being reacted with epoxy resin in the material, and meanwhile, a microcapsule of the microcapsule curing agent can be broken to be slowly released under a certain condition to implement curing, so that the aim of controlling a material and epoxy resin pouring sealant curing process is fulfilled, and the interface bonding performance between the material and the epoxy resin is improved; in addition, the advantages of vacuum structures of hollow glass beads are fully utilized, so that the density, dielectric constant and electric conductivity of the PBT material are improved.

Owner:ANHUI KING AUTO ELECTRONICS TECH CO LTD

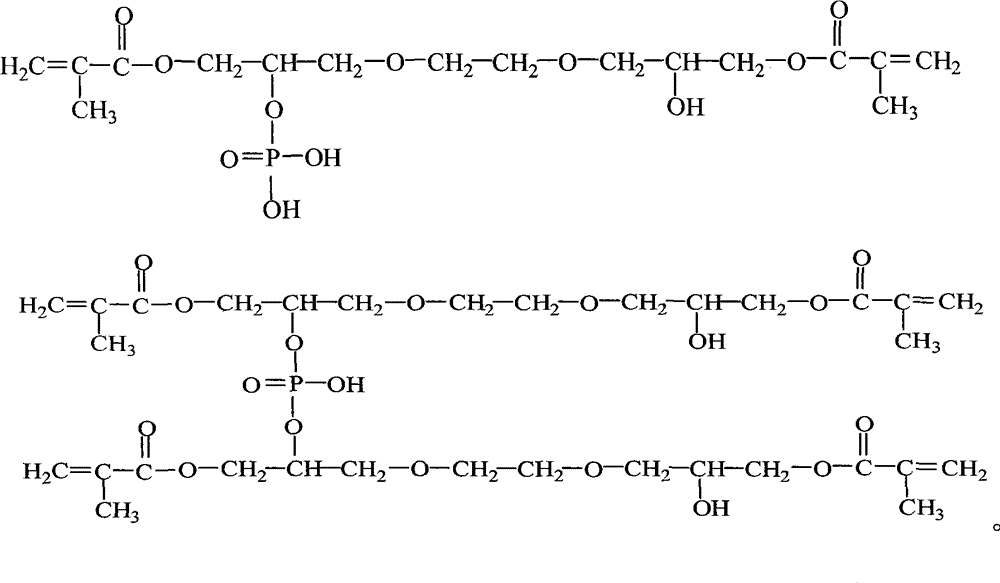

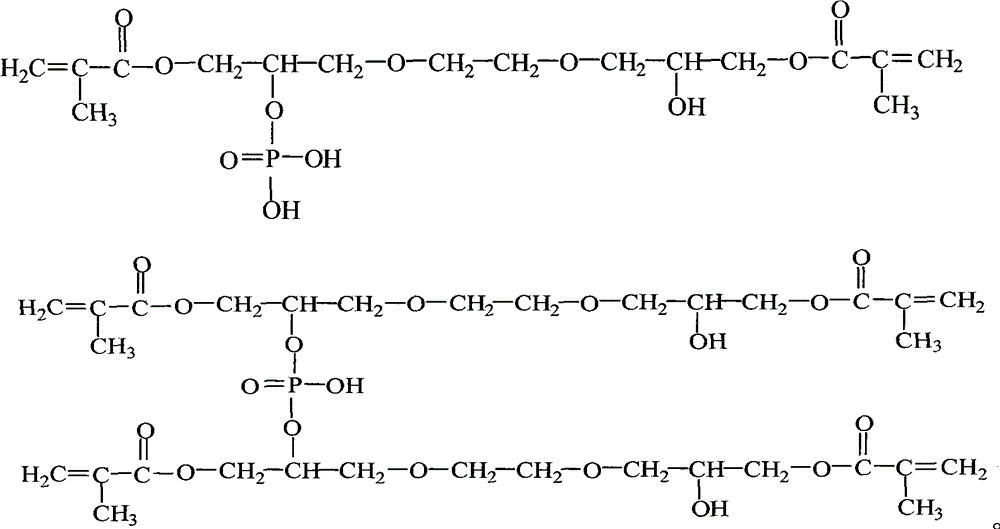

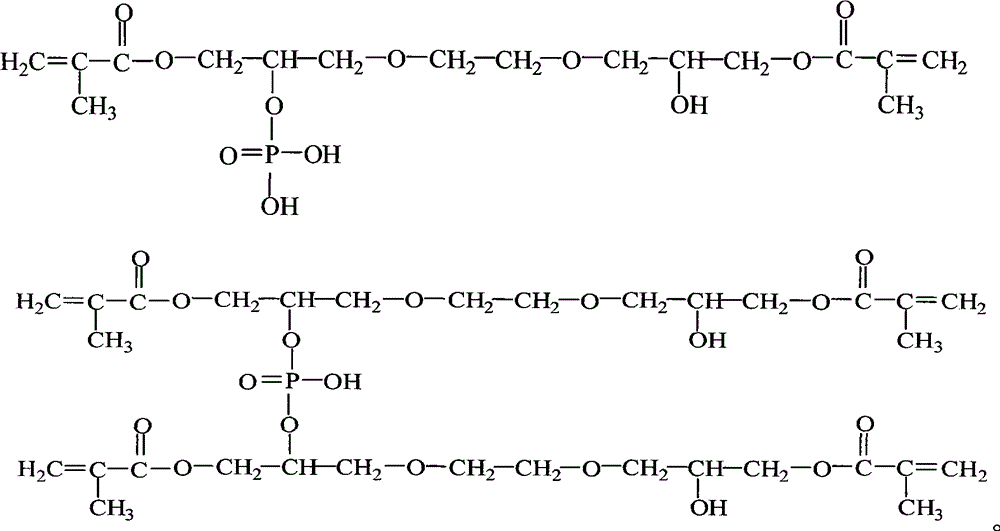

Ethylene glycol diglycidyl ether dimethacrylate organic phosphate and synthetic method thereof

InactiveCN103145755AReduce viscosityLow acid valuePhosphorus organic compoundsSolubilityMethacrylate

The invention discloses ethylene glycol diglycidyl ether dimethacrylate organic phosphate and a synthetic method thereof, wherein the ethylene glycol diglycidyl ether dimethacrylate organic phosphate is used for an ultraviolet (UV) photocureable coating adhesion promoter. Ethylene glycol diglycidyl ether is added into a reaction kettle provided with a cooling device, a heating device and a mechanical agitation device, a ring-opening addition reaction between the ethylene glycol diglycidyl ether and methacrylic acid is conducted on the conditions of methacrylic acid rapid agitation and the existence of catalyzers and polymerization inhibitors to generate ethylene glycol diglycidyl ether dimethacrylate, and an esterification reaction between the ethylene glycol diglycidyl ether dimethacrylate and phosphorus pentoxide is conducted to generate the ethylene glycol diglycidyl ether dimethacrylate organic phosphate. A generated target product is light in color, low in acid value and good in adhesive force, also has four functional groups, can be used as an addictive used for production of UV photocureable coatings, dissolves well in universal (methyl) crylic acid activated monomers and (methyl) acrylic resin, can increase adhesive force, on base materials such as metal, glass, plastics, acrylonitrile butadiene styrene(ABS), of resin and the UV photocureable speed of the resin.

Owner:HUNAN AGRICULTURAL UNIV

Glass microsphere-modified PBT (polybutylene terephthalate) material and preparation method thereof

InactiveCN107778786AImprove interfacial adhesionIncrease the content of functional groupsEpoxyPolyethylene terephthalate

The invention discloses a glass microsphere-modified PBT (polybutylene terephthalate) material. The glass microsphere-modified PBT (polybutylene terephthalate) material is prepared from the followingraw materials in parts by weight: 60 to 80 parts of PBT, 15 to 20 parts of polytetrafluoroethylene, 15 to 20 parts of polyvinyl alcohol microspheres, 5 to 8 parts of dimethylethanolamine, 5 to 10 parts of gelatin, 6 to 12 parts of glass microsphere master batch, 1 to 3 parts of alumina, and 1 to 3 parts of antioxidant 245. The glass microsphere-modified PBT material has the advantages that by introducing the coated curing agent, the content of functional groups which can react with epoxy resin in the material is increased; by adopting a microcapsule curing agent, the microcapsule can be brokento slowly release the curing agent under certain condition, and then the curing activity is completed, so that the purpose of controlling the curing process of material and epoxy resin sealant is realized, and the interface adhering property between the material and the epoxy resin is improved; the advantages of the hollow glass microsphere vacuum structure are fully played, and the density, dielectric constant and conductive coefficient of the PBT material are reduced.

Owner:徐伟权

Modified carbon material and nitrogen-rich liquid flow battery electrode prepared from modified carbon material

ActiveCN110194453ALarge specific surface areaReduce polarizationGraphiteCell electrodesIn situ polymerizationModified carbon

The invention provides a modified carbon material and a preparation method thereof as well as a nitrogen-rich liquid flow battery electrode prepared from the material. The preparation method comprisesthe following steps: 1) carrying out in-situ polymerization reaction on an amino group-containing substance and a hydroxyl group-containing substance on the surface of a carbon material; and 2) calcining to obtain the modified carbon material. The surface of the carbon material treated by the method is rich in nitrogen-containing functional groups and oxygen-containing functional groups, and thehydrophilicity, electrochemical activity and specific surface area of the carbon material are greatly improved. In addition, the loading amount of nitrogen and oxygen elements can be controlled by adjusting the dosage of formaldehyde-urea-melamine. The electrode has high specific surface area and high functional group content (such as oxygen-containing functional groups), and especially shows goodcatalytic activity to main redox pairs of vanadium ions, and the higher catalytic activity greatly reduces the polarization of the electrode.

Owner:HUNAN YINFENG NEW ENERGY

Laser-marked PBT material with epoxy resin cohesiveness and preparation technology of laser-marked PBT material

InactiveCN105907057AImprove interfacial adhesionIncrease the content of functional groupsEpoxyMicrosphere

The invention discloses a laser-marked PBT material with epoxy resin cohesiveness. The laser-marked PBT material is prepared from the following raw materials in parts by weight: 60-80 parts of PBT, 15-20 parts of cashew phenol amine, 15-20 parts of polyvinyl alcohol microspheres, 5-8 parts of sodium dodecyl sulfate, 5-10 parts of gelatin, 6-12 parts of glass fibers, 1-3 parts of silicone powder, 2-5 parts of laser marking powder and 1-3 parts of antioxidant 245. A coated curing agent is introduced to improve the content of a functional group which has reaction capacity with epoxy resin; meanwhile, a microcapsule curing agent can break a microcapsule under a certain condition to release slowly; and the curing behavior is finished, so that the target of controlling the potting adhesive curing process of the material and the epoxy resin is achieved; and the interface adhesion between the material and the epoxy resin is improved. Graphene is utilized; the laser marking powder is added; the dosage is small; the marking effect is good; and different laser-marked PBT materials can be prepared; and the laser-marked PBT material has relatively good mechanical property and meets the requirements of laser marking in the field of automotive electronics.

Owner:BENGBU ZHENGYUAN ELECTRONICS TECH

Micrometer calcium carbonate modified PBT (polybutylene terephthalate) material with epoxy resin bonding performance and preparation method for glass bead modified PBT material

InactiveCN105885363AImprove interfacial adhesionIncrease the content of functional groupsFiberSodium stearate

The invention discloses a micrometer calcium carbonate modified PBT (polybutylene terephthalate) material with epoxy resin bonding performance. The micrometer calcium carbonate modified PBT material consists of the following raw materials in parts by weight: 60 to 80 parts of PBT, 15 to 20 parts of cardanol amine, 15 to 20 parts of polyvinyl alcohol microspheres, 5 to 8 parts of sodium dodecyl sulfate, 5 to 10 parts of gelatin, 6 to 10 parts of alkali-free short fiberglass, 2 to 4 parts of micrometer calcium carbonate, 1 to 3 parts of sodium stearate and 1 to 3 parts of an antioxidant 242. According to the micrometer calcium carbonate modified PBT material, a coated curing agent is introduced to increase the content of functional groups capable of being reacted with epoxy resin in the material, and meanwhile, a microcapsule of the microcapsule curing agent can be broken to be slowly released under a certain condition to implement curing, so that the aim of controlling a material and epoxy resin pouring sealant curing process is fulfilled, and the interface bonding performance between the material and the epoxy resin is improved.

Owner:BENGBU ZHENGYUAN ELECTRONICS TECH

Production method of superfine glass microfibers

The invention discloses a production method of superfine glass microfibers. The production method comprises the following steps: weighing raw materials, preprocessing quartz sand, feldspar powder, dolomite powder, calcite powder and fluorite powder; uniformly mixing the raw materials with borax, sodium carbonate, sodium nitrate, potassium carbonate and a clarifying agent to obtain a batch, meltingthe batch to obtain molten glass, feeding the molten glass into a centrifugal fiber forming machine, throwing out the molten glass through a centrifugal head of the centrifugal fiber forming machine,and forming ultrafine glass microfibers under the action of blowing airflow. According to the invention, the tensile strength of the glass microfibers can be effectively improved, the produced microfiber glass has the advantages of less slag balls and uniform fiber diameter, and the quality of microfiber glass wool is improved.

Owner:BENGBU RONGQIANG COMPRESSOR MFG CO LTD +2

Preparation method and application method of mushroom bran immobilized microbial agent

PendingCN108823195ARealize resource utilizationReduce manufacturing costContaminated soil reclamationMicroorganism based processesMicrobial agentBran

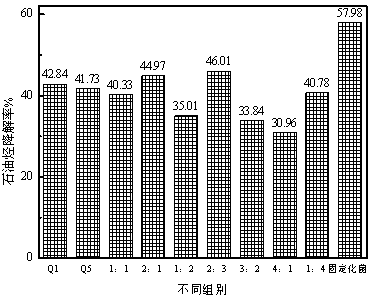

The invention discloses a preparation method of a mushroom bran immobilized microbial agent. The preparation method comprises steps as follows: (1) preparation of a bacterial suspension: hydrocarbon degradation bacteria are added to normal saline to be prepared into the bacterial suspension; (2) preparation of a carrier: air drying is performed after mushroom bran is washed clean, and a product issieved by a 20-80-mesh sieve for later use; (3) adsorption: the mushroom bran in the step (2) and the bacterial suspension in the step (1) are mixed in the proportion of 1:(15-25) (v / v), the mixtureis put in a shaking table at the temperature of 30-37 DEG C at the speed of 120-160 rpm to be adsorbed for 16-24 h, and an upper solution is discarded; (4) centrifugation: the adsorbed mushroom bran is transferred to a centrifugal tube with normal saline, and a liquid supernatant is discarded through centrifugation; the centrifugation operation is repeated multiple times, and precipitates obtainedafter centrifugation are the immobilized microbial agent. The prepared mushroom bran immobilized microbial agent can be applied to remediation of petroleum-polluted soil, has high removal efficiencyfor petroleum hydrocarbon, causes no secondary pollution and has the remediation and degradation rate substantially increased as compared with independent mushroom bran and microorganisms.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

PBT material with epoxy resin cohesiveness for ignition coil and preparation method of PBT material

InactiveCN106009546AImprove interfacial adhesionIncrease the content of functional groupsMicroballoon preparationMicrocapsule preparationIgnition coilMicrosphere

The invention discloses a PBT material with epoxy resin cohesiveness for an ignition coil. The PBT material is prepared from the following raw materials in parts by weight: 60 to 80 parts of PBT, 15 to 20 parts of cardanol amine, 15 to 20 parts of polyvinyl alcohol microsphere, 5 to 8 parts of sodium dodecyl sulfate, 5 to 10 parts of gelatin, 6 to 12 parts of carbon nanotube, 1 to 3 parts of zinc stearate and 1 to 3 parts of antioxygen 245. According to the PBT material, a coated curing agent is introduced, so that the content of functional groups with reaction capacity with epoxy resin in the material is increased, and additionally, the microcapsule curing agent can break through a microcapsule and can be slowly released under certain conditions so as to complete the curing behavior, so that the purpose of controlling the curing process of the material and an epoxy resin sealant is achieved, and the interface cohesiveness between the material and the epoxy resin is increased.

Owner:ANHUI KING AUTO ELECTRONICS TECH CO LTD

Low-temperature-resistant PBT material with epoxy resin cohesiveness and preparation method thereof

The invention discloses a low-temperature-resistant PBT material with epoxy resin cohesiveness. The low-temperature-resistant PBT material is prepared from, by weight, 60-80 parts of PBT, 8-10 parts of thermoplastic polyester elastomers, 15-20 parts of cardanol amine, 15-20 parts of polyvinyl alcohol microspheres, 5-8 parts of sodium dodecyl sulfate, 5-10 parts of gelatin, 1-3 parts of styrene butadiene acrylic ester, 6-12 parts of glass fiber and 1-3 parts of a maleic anhydride-styrene copolymer. According to the low-temperature-resistant PBT material with the epoxy resin cohesiveness, the content of functional groups which have the reaction capacity with epoxy resin in the material is increased by introducing a coated curing agent, the microcapsule curing agent can break microcapsules to be slowly released under certain conditions to complete a curing behavior, therefore, the purpose of controlling the pouring sealant curing process of the material and the epoxy resin is achieved, and the interface cohesiveness between the material and the epoxy resin is improved.

Owner:BENGBU ZHENGYUAN ELECTRONICS TECH

Branched functionalized solution polymerized styrene-butadiene rubber and preparation method thereof

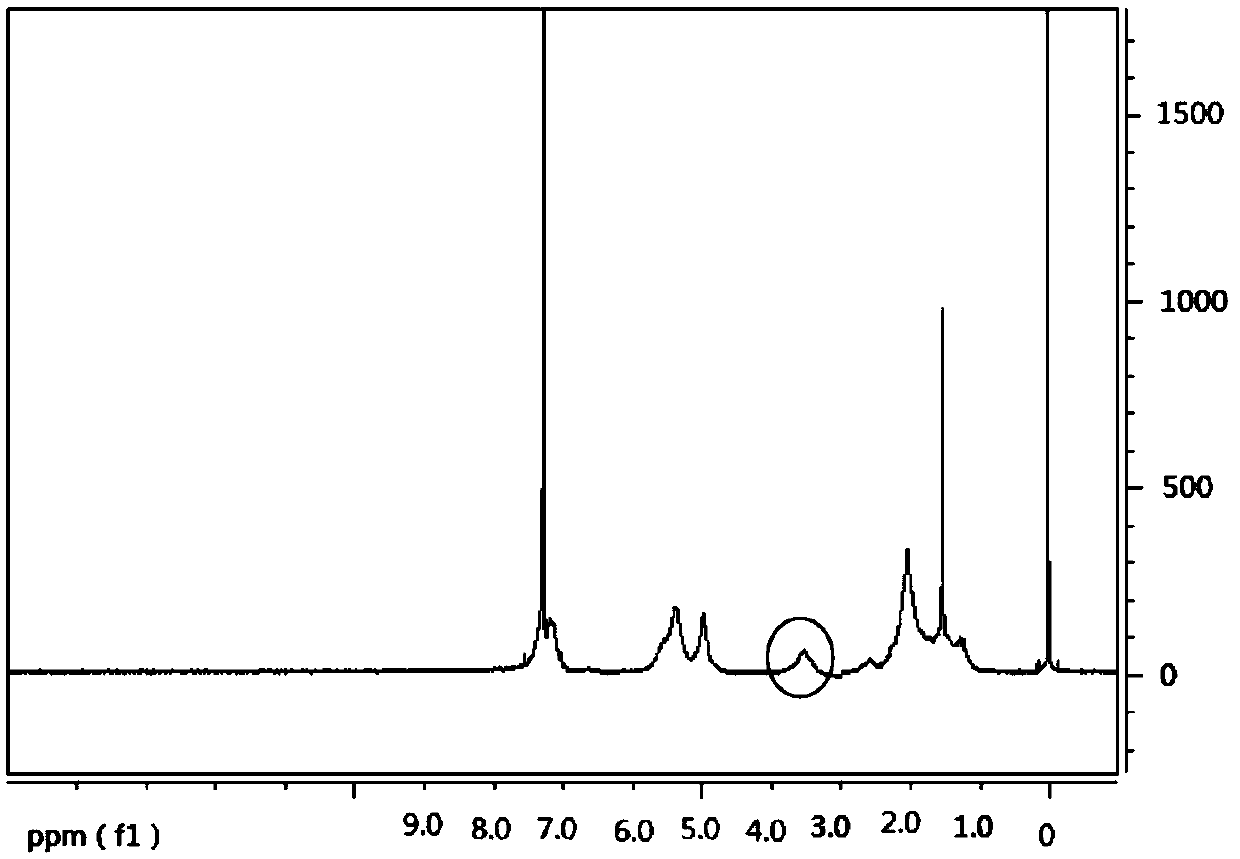

The invention discloses branched functionalized solution polymerized styrene-butadiene rubber and a preparation method thereof. A molecular chain of the prepared branched functionalized solution polymerized styrene-butadiene rubber includes a silica group with good compatibility with white carbon black, the structure of the silica group is shown in the (a) (please see the specification for the formula (a)), and the siloxane branched chain content is 0.1wt%-5wt% of the solution polymerized styrene-butadiene rubber. The preparation method of the solution polymerized styrene-butadiene rubber includes the specific following steps that organic lithium is used as an initiator, a structure regulator is added, so that butadiene copolymerizes with styrene, when the monomer conversion rate of copolymerization is close to 100%, then long chain siloxane containing hydrogen is added, an alpha-selectivity silicon and hydrogen addition reaction catalyst and addition agent are added for conducting a silicon and hydrogen addition reaction, the reaction temperature is 60-120 DEG C, the reaction time is 30-120 mins, and the branched functionalized solution polymerized styrene-butadiene rubber is obtained through termination, condensation and drying after the reaction. The branched functionalized solution polymerized styrene-butadiene rubber can improve wear resistance and wet resistance of the solution polymerized styrene-butadiene rubber and reduce rolling resistance.

Owner:PETROCHINA CO LTD

Glass bead modified PBT material and preparation method thereof

InactiveCN107793706AImprove interfacial adhesionIncrease the content of functional groupsEpoxyPhosphate

The invention discloses a glass bead modified PBT (polybutyleneterephthalate) material. The material comprises the following raw materials in parts by weight: 60-80 parts of PBT, 15-20 parts of aluminium dihydrogen phosphate, 15-20 parts of borax, 5-8 parts of sodium potassium silicate, 5-10 parts of zinc oxide, 6-12 parts of hydrogenated castor oil, 1-3 parts of cryolite, and 1-3 parts of an anti-oxidant 245. A curing agent after coating is introduced in order to increase content of function group which has reaction capability with epoxy resin in the material, and at the same time, the microcapsule curing agent can break microcapsules at a certain condition for slow release in order to complete solidification behavior, so that the purpose that the casting glue solidification process between the material and an epoxy resin is controlled is realized, and interface caking property between the material and epoxy resin is improved; further, the advantage of the hollow glass bead vacuum structure is fully performed, and density, dielectric constant and electric conductivity of the PBT material are reduced.

Owner:刘健文

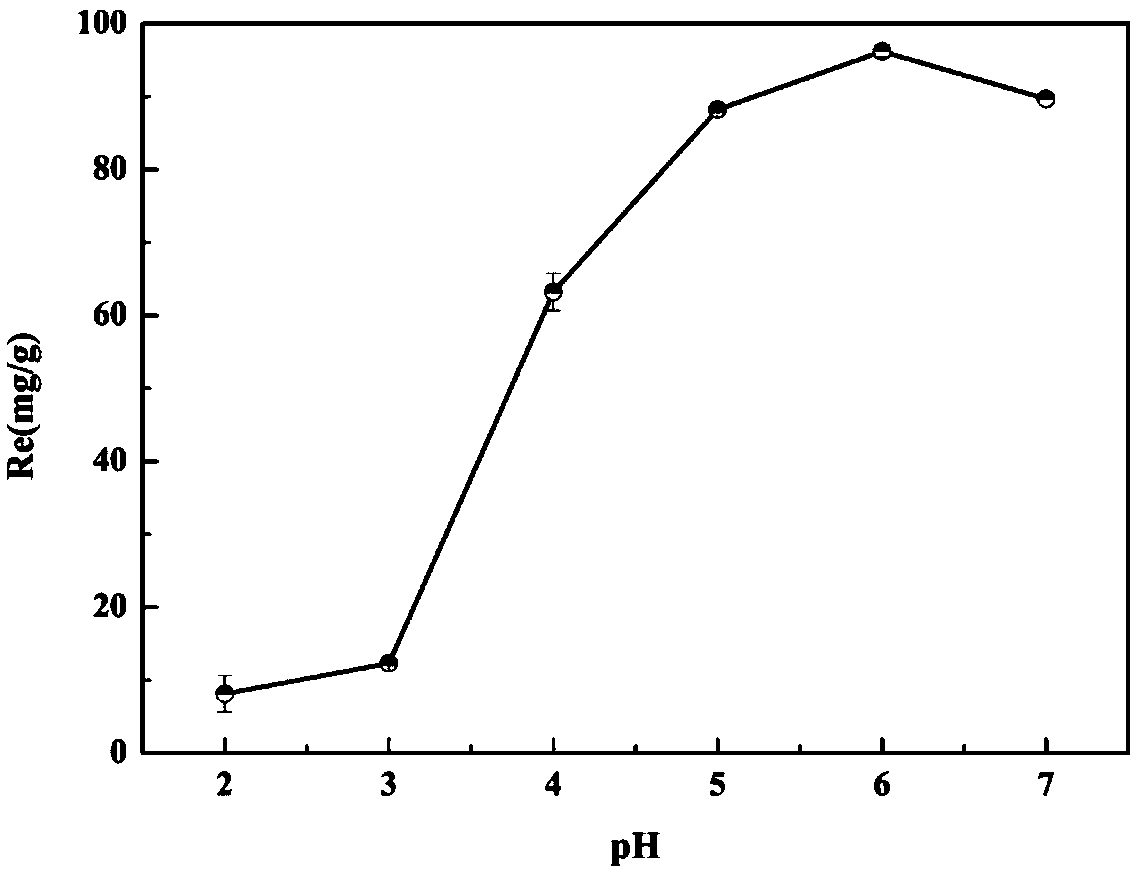

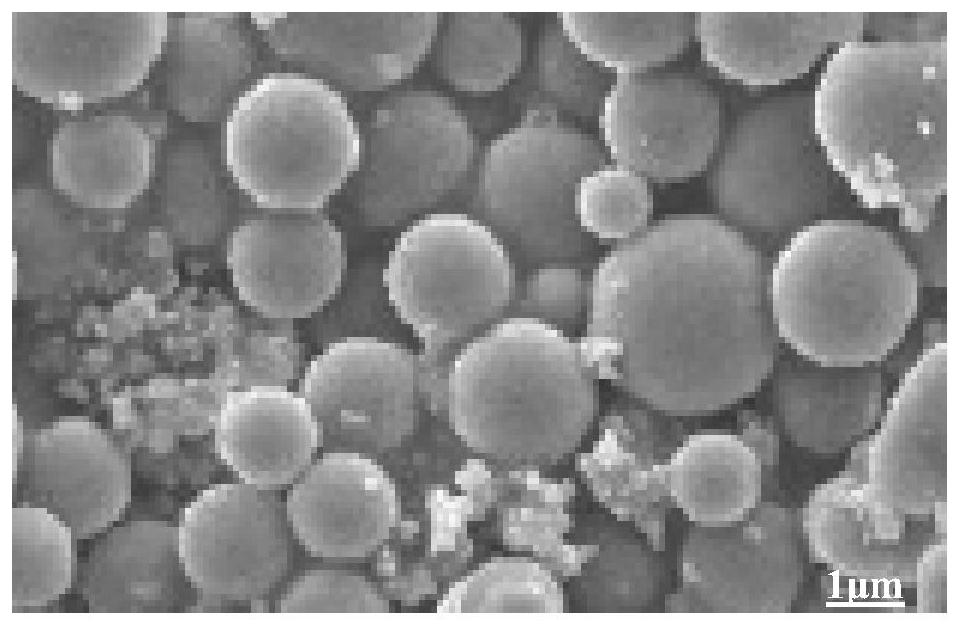

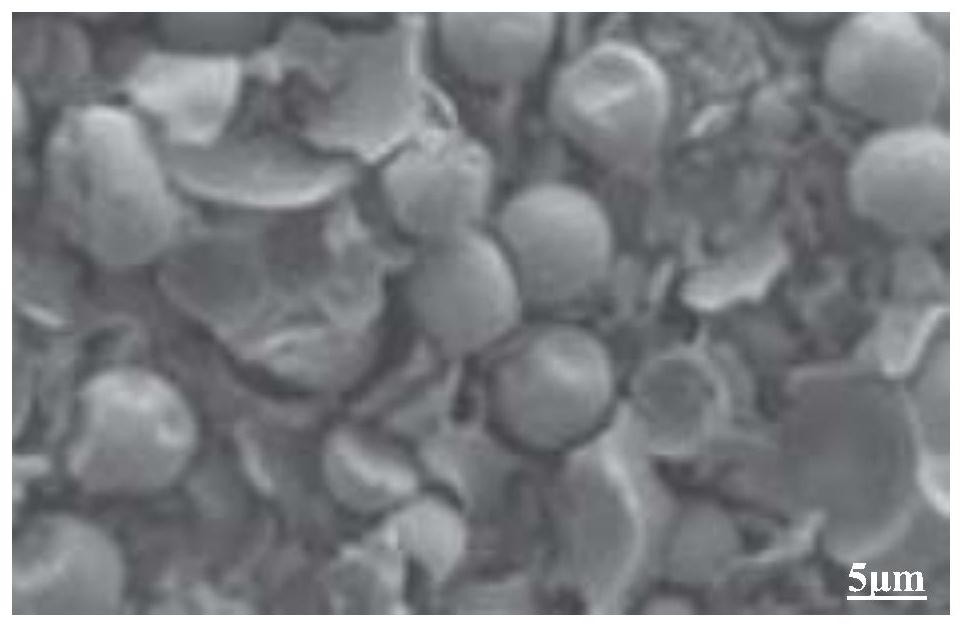

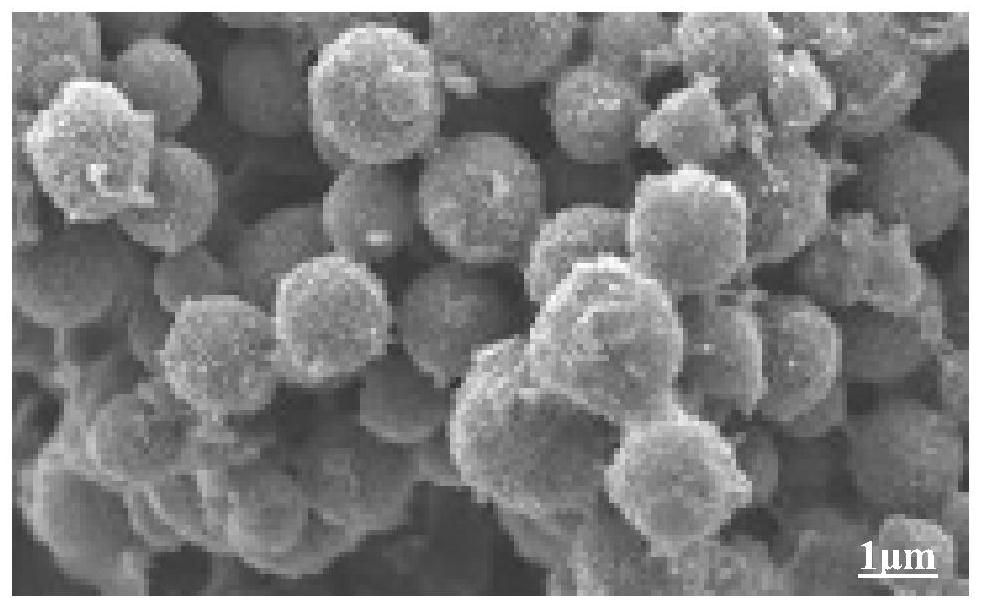

Preparation method of collagen peptide grafted hydrothermal carbon microsphere absorbing agent

ActiveCN108854970AImprove adsorption capacityHigh selectivityOther chemical processesWater contaminantsHigh absorptionMicrosphere

The invention discloses a preparation method of a collagen peptide grafted hydrothermal carbon microsphere absorbing agent. The method comprises the following steps: (1) preparing collagen peptide powder; (2) preparing carboxylated hydrothermal carbon microspheres; (3) dispersing 1-10 parts of the carboxylated water thermal carbon microspheres into 20-50 parts of ultrapure water, carrying out ultrasonic treatment for 1-3 hours, stirring, adding 1-10 parts of a mixture of 1-ethyl-(3-dimethylaminopropyl) carbodiimide (EDC) and N-hydroxysuccinimide (NHS) to enable the carboxyl group of hydrothermal carbon to be activated, carrying out an ice bath reaction for 30-90min, then adding 1-50 parts of collagen peptide powder, carrying out an ice bath reaction for 30-90min, removing the product froman ice bath, carrying out a reaction for 24h at the room temperature, then filtering, washing and drying to obtain the collagen peptide grafted hydrothermal carbon microsphere absorbing agent. The collagen peptide grafted hydrothermal carbon material has high absorption capacity and selectivity, and can be applied to treatment of wastewater containing heavy metal ions. The preparation method is simple to operate, high in efficiency, simple in preparation process, high in practicality and low in cost; the prepared absorbing agent is an environment-friendly material.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Halogen-free flame retardant PBT material with epoxy-resin cohesive performance and preparing method thereof

InactiveCN106117986AImprove interfacial adhesionIncrease the content of functional groupsAdhesiveMicrosphere

The invention discloses a halogen-free flame retardant PBT material with the epoxy-resin cohesive performance. The halogen-free flame retardant PBT material is prepared from, by weight, 60-80 parts of PBT, 15-20 parts of cardanol amine, 15-20 parts of polyvinyl alcohol microspheres, 5-8 parts of sodium dodecyl sulfate, 5-10 parts of gelatin, 3-6 parts of GWIT fire retardant, 1-3 parts of kaolin, 6-12 parts of carbon nanometer tubes and 1-3 parts of zinc stearate. According to the halogen-free flame retardant PBT material, the contents of functional groups with the reaction capacity in a coated curing-agent improving material and epoxy resin is led; meanwhile, microcapsules can be opened through a microcapsule curing agent under the certain condition, the microcapsule curing agent is slowly released, the curing behavior is completed, the aim of controlling the curing process of the material and an epoxy resin potting adhesive is achieved accordingly, and the interfacial adhesion performance between the material and the epoxy resin is improved; in addition, as the GWIT fire retardant with the high carbon forming effect is added, and treatment is carried out through a compatilizer, the glass-fiber reinforcing material has the GWIT with the value of 750 DEG C or above while the conventional flame retardant performance is met.

Owner:BENGBU ZHENGYUAN ELECTRONICS TECH

High-crystallization-rate PBT (polybutylece terephthalate) material with epoxy resin adhesion and preparation method thereof

InactiveCN106117990AImprove interfacial adhesionIncrease the content of functional groupsPolyethylene terephthalateMicrosphere

The present invention discloses a high-crystallization-rate PBT (polybutylece terephthalate) material with epoxy resin adhesion, made from the following materials according to parts by weight: 60-80 parts of PBT, 15-20 parts of cardanol amine, 15-20 parts of polyvinyl alcohol microspheres, 5-8 parts of sodium dodecyl sulfate, 5-10 parts of gelatin, 2-4 parts of fiberglass, 3-6 parts of nano talc, 2-4 parts of nano titanium nitride, 1-3 parts of acrylate and 1-3 parts of antioxidant 245. The coated curing agent is introduced to increase the content of functional groups in the material that are reactable with epoxy resin, the microcapsule curing agent can break microcapsules under certain conditions to release slowly so as to finish curing, the curing process of the material with epoxy resin potting is accordingly controlled, and interfacial adhesion between the material and the epoxy resin is improved.

Owner:ANHUI KING AUTO ELECTRONICS TECH CO LTD

Reinforced and modified PBT (polybutylene terephthalate) material with epoxy resin bonding performance and preparation method for reinforced and modified PBT material

The invention discloses a reinforced and modified PBT (polybutylene terephthalate) material with epoxy resin bonding performance. The reinforced and modified PBT material consists of the following raw materials in parts by weight: 60 to 80 parts of PBT, 15 to 20 parts of cardanol amine, 15 to 20 parts of polyvinyl alcohol microspheres, 5 to 8 parts of sodium dodecyl sulfate, 5 to 10 parts of gelatin, 5 to 10 parts of a reinforcing agent, 1 to 3 parts of calcium stearate and 1 to 3 parts of a toughening agent AX8900. According to the reinforced and modified PBT material, a coated curing agent is introduced to increase the content of functional groups capable of being reacted with epoxy resin in the material, and meanwhile, a microcapsule of the microcapsule curing agent can be broken to be slowly released under a certain condition to implement curing, so that the aim of controlling a material and epoxy resin pouring sealant curing process is fulfilled, and the interface bonding performance between the material and the epoxy resin is improved; in addition, indianite is a natural multi-walled nanometer tubular material, has a nanometer tubular structure and the property of high dispersion rate, and can be combined with nanometer zirconium carbide and aluminum titanate fibers to achieve good synergistic toughening and reinforcing effects on the PBT.

Owner:BENGBU ZHENGYUAN ELECTRONICS TECH

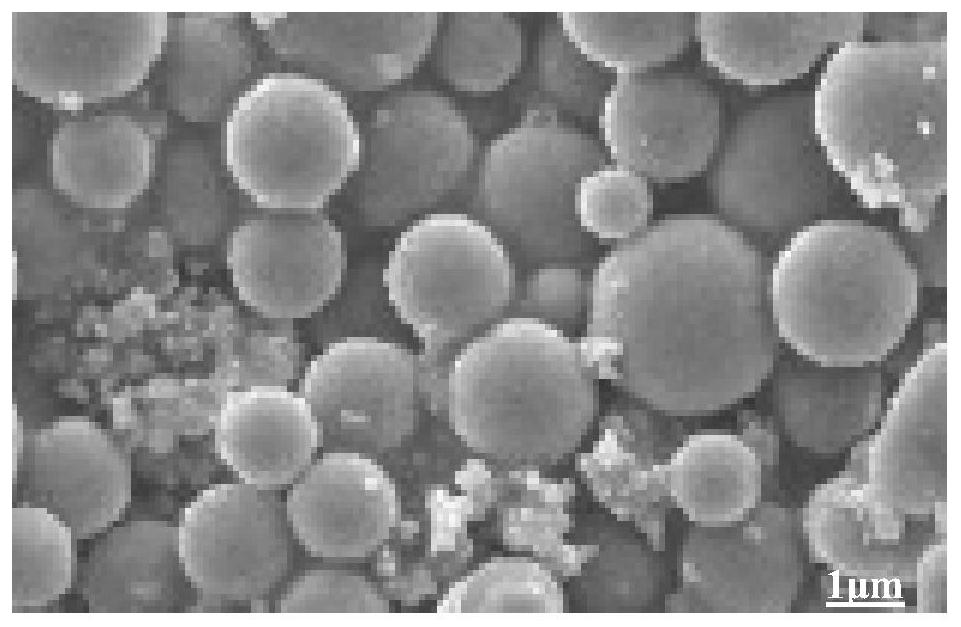

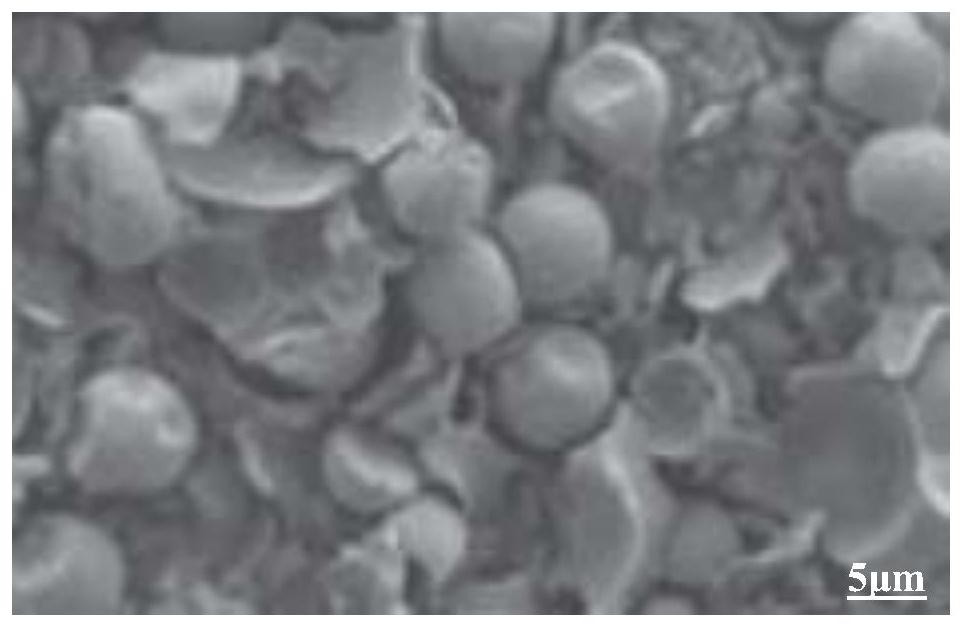

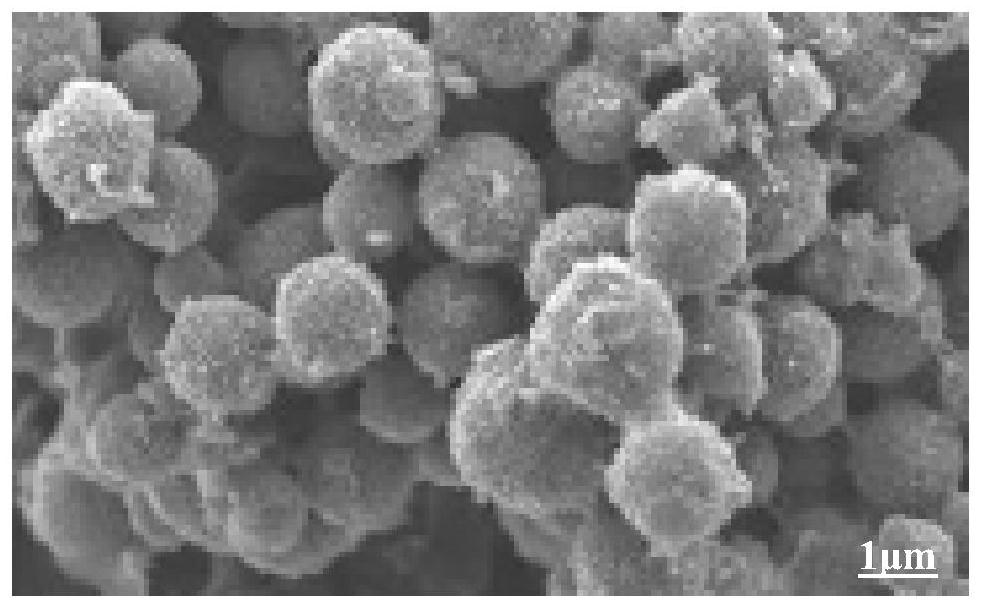

Spherical polytetrafluoroethylene micro-powder wax and preparation method thereof

The invention relates to spherical polytetrafluoroethylene micro-powder wax and a preparation method thereof, and the preparation method comprises the following steps: irradiating a polytetrafluoroethylene raw material and an organic siloxane adsorbent in an aerobic environment together, crushing to obtain polytetrafluoroethylene micro-powder, and then carrying out dispersion polymerization to obtain the spherical polytetrafluoroethylene micro-powder wax. In the preparation process, fluorine-containing gas generated in the irradiation process can be consumed, and the damage to the microstructure of the polytetrafluoroethylene micro powder is reduced; the conversion rate of carboxyl at the tail end of a polytetrafluoroethylene chain is increased, and the content of functional groups on the surface of the micro powder is increased, so that subsequent chemical modification is facilitated; the chain end of the polymer has activity and is easy to graft to obtain products with different properties, and active functional groups such as carboxyl and hydroxyl at the chain end of the polymer can be used for modification to form a comb-shaped polymer, so that the application range of the comb-shaped polymer is expanded; the shape of the polytetrafluoroethylene micro-powder is not greatly damaged, the polytetrafluoroethylene micro-powder is extremely easy to form a sphere during chemical modification, and the obtained micro powder is relatively small in particle size, uniform in size and good in dispersion performance.

Owner:江苏天问新材料科技有限公司

High-impact-resistance polybutylene terephthalate (PBT) material having epoxy resin bonding property, and preparation method of PBT material

The invention discloses a high-impact-resistance polybutylene terephthalate (PBT) material having epoxy resin bonding property. The material is prepared from the following raw materials in parts by weight: 60-80 parts of PBT, 15-20 parts of cashew phenol amine, 15-20 parts of polyvinyl alcohol micro-spheres, 5-8 parts of sodium dodecyl sulfate, 5-10 parts of gelatin, 6-10 parts of alkali-free glass fibers, 3-6 parts of an impact resistant modifier, 1-3 parts of polyethylene wax PE4221 and 1-3 parts of an antioxidant 1076. The functional group content which is in a clad curing agent lifting material and has reaction capacity with epoxy resin is introduced into the PBT material, and a microcapsule curing agent can break microcapsules under certain conditions so as to be slowly released, so that the curing behavior is completed, the aim of controlling a curing process of material and epoxy resin pouring sealant is achieved, and the interface bonding property between the material and epoxy resin is improved; furthermore, the impact resistant modifier and the alkali-free glass fibers are combined for use, so that the impact resistance, the compatibility performance and the dispersing performance of the PBT material are welled balanced; therefore, the high-impact-resistance PBT composite material is obtained.

Owner:ANHUI KING AUTO ELECTRONICS TECH CO LTD

A kind of spherical polytetrafluoroethylene micropowder wax and preparation method thereof

This case involves a spherical polytetrafluoroethylene micropowder wax and its preparation method, including: PTFE raw materials and organosiloxane adsorbents are jointly irradiated and pulverized in an aerobic environment to obtain polytetrafluoroethylene micropowder, Subsequently, spherical polytetrafluoroethylene micropowder wax was prepared by dispersion polymerization. In the preparation process of the present invention, the fluorine-containing gas produced in the irradiation process can be consumed, and the damage to the microscopic appearance of the polytetrafluoroethylene micropowder can be reduced; the conversion rate of the terminal carboxyl group of the polytetrafluoroethylene chain can be improved, and the content of functional groups on the surface of the micropowder can be increased, thereby It is more conducive to subsequent chemical modification; the end of the polymer chain is active, and it is easy to graft to obtain products with different properties. It can also be modified by using active functional groups at the end of the polymer chain, such as carboxyl and hydroxyl groups, to form a comb polymer and expand its application. Range: The morphology of PTFE micropowder is not greatly damaged, and it is also very easy to form a spherical shape during chemical modification. The obtained micropowder has a small particle size, uniform size, and good dispersion performance.

Owner:江苏天问新材料科技有限公司

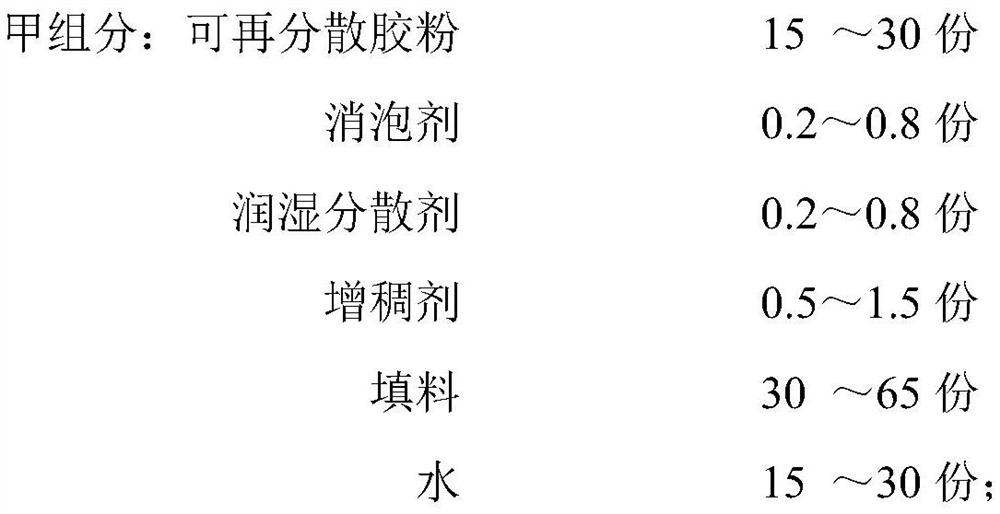

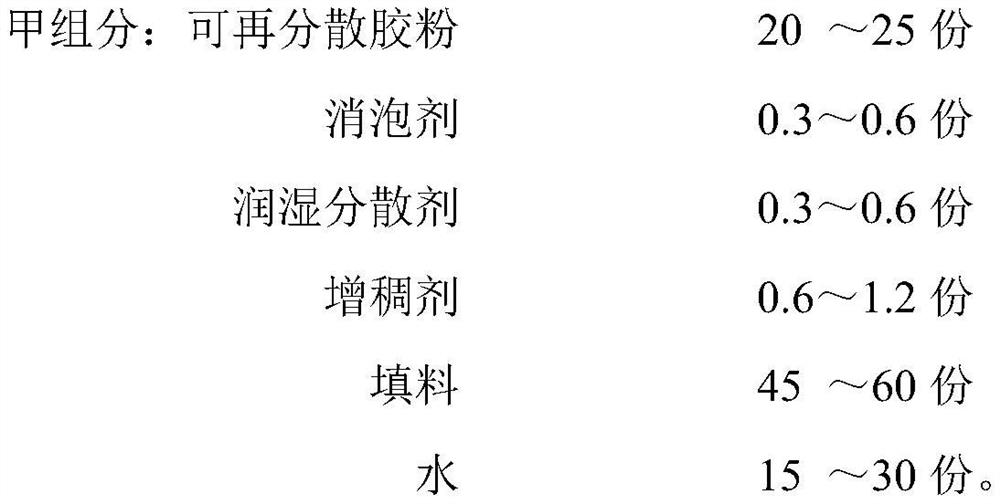

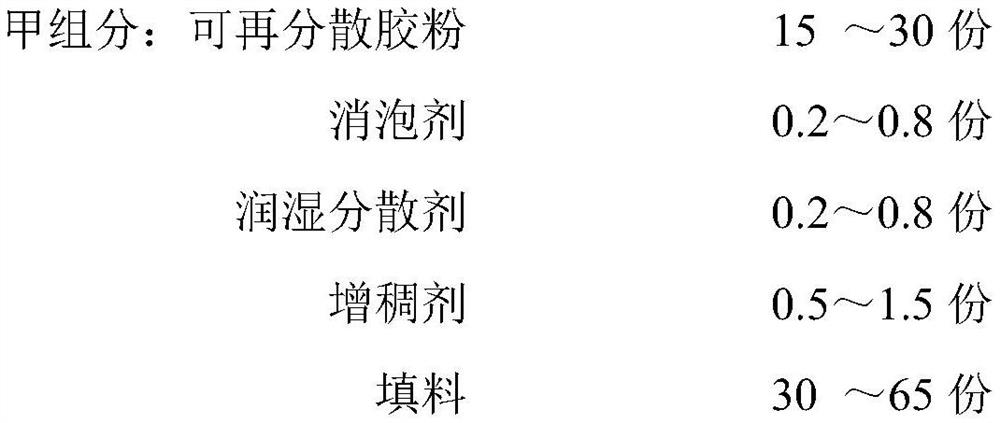

Water-based two-component transparent putty

The invention provides water-based two-component transparent putty, which is composed of a component A and a component B in a weight ratio of 100: (1-5), and the component A comprises the following components in parts by weight: 15-30 parts of redispersible rubber powder, 0.2-0.8 part of a defoaming agent, 0.2-0.8 part of a wetting dispersant, 0.5-1.5 parts of a thickening agent, 30-65 parts of filler and 15-30 parts of water; and the component B is a diphenylmethane diisocyanate monomer or a prepolymer of the diphenylmethane diisocyanate monomer. According to the water-based two-component transparent putty, the redispersible rubber powder serves as a main film forming matter, water serves as a main solvent, the diphenylmethane diisocyanate monomer or a polymer of the diphenylmethane diisocyanate monomer serves as a hardening agent, and the water-based two-component transparent putty is excellent in filling property, good in construction performance, high in adhesive force and long in construction time limit; most importantly, no harm is caused to the health of constructors, and the water-based paint is a water-based environment-friendly product.

Owner:CHENGDU ZHANCHEN PAINT

Multifunctional phosphite water-soluble fertilizer and preparation method thereof

PendingCN114853533ASmall molecular weightIncrease the content of functional groupsAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersBiotechnologyPhosphorous acid

The invention discloses a multifunctional phosphite water-soluble fertilizer and a preparation method thereof, and relates to the technical field of agricultural fertilizers. The phosphite multifunctional water-soluble fertilizer comprises phosphite, activated humic acid, phosphate and nutrient elements, the phosphate is composed of N, P2O5 and K2O, the nutrient elements are one or more of B, Mn, Cu, Zn, Mo and Fe which are mixed according to any proportion, the mass ratio of phosphorous acid phosphorus to phosphoric acid phosphorus in the phosphite (in terms of P2O5) is 1: (0.3-1.2), and the concentration of the activated humic acid is 20-80 g / L. According to the present invention, the phosphite and the activated mineral source humic acid are adopted as the basis, the antibacterial, nutritional and multifunctional water-soluble fertilizer with the macro-nutrition element and the micro-nutrition element is matched, the growth and development requirements of various crops are met, the chemical activity and the biological activity are improved by activating the mineral source humic acid, and the nutrition, the antibacterial property and the physiological regulation are integrated.

Owner:安徽悦禾生物科技有限公司

A preparation method of collagen peptide grafted hydrothermal carbon microsphere adsorbent

ActiveCN108854970BImprove adsorption capacityHigh selectivityOther chemical processesWater contaminantsMicrosphereEthyl group

The invention discloses a method for preparing a collagen peptide grafted hydrothermal carbon microsphere adsorbent, comprising: (1) preparation of collagen peptide powder; (2) preparation of carboxylated hydrothermal carbon microspheres; (3) Disperse 1-10 parts of carboxylated hydrothermal charcoal microspheres in 20-50 parts of ultrapure water, sonicate for 1-3 hours, stir, and add 1-10 parts of 1-ethyl-(3-dimethylaminopropyl) The mixture of carbodiimide EDC and N-hydroxysuccinimide NHS activates the carboxyl group of hydrothermal charcoal, and reacts in ice bath for 30-90 minutes, then adds 1-50 parts of collagen peptide powder, and reacts in ice bath for 30-90 minutes , removed from the ice bath, filtered at room temperature for 24 hours, washed, and dried to obtain the collagen peptide grafted hydrothermal carbon microsphere adsorbent. The collagen peptide grafted hydrothermal carbon material of the present invention has high adsorption capacity and Selectivity can be applied to the treatment of wastewater containing heavy metal ions; the preparation method of the invention is simple in operation, high in efficiency, simple in preparation process, strong in practicability and low in cost, and the obtained adsorbent is an environmentally friendly material.

Owner:SOUTHWEAT UNIV OF SCI & TECH

A modified carbon material and a flow battery electrode modified by graphene-like nanosheets prepared therefrom

ActiveCN110197905BImprove hydrophilicityImprove electrochemical activityCell electrodesIn situ polymerizationModified carbon

The invention provides a modified carbon material, a preparation method thereof, and a redox flow battery electrode modified by a graphene-like nanosheet prepared from the same. The preparation methodcomprises the steps of: 1) subjecting phytic acid and an amino group-containing substance to in-situ polymerization on the surface of the carbon material; and 2) calcining the product at a high temperature. The carbon material treated by the method has rich oxygen-containing functional groups on its surface, and has greatly improved hydrophilic property, electrochemical activity and specific surface area. Moreover, the loading amount of hetero elements such as nitrogen and phosphorus can be controlled by adjusting the amount and molar ratio of phytic acid and urea. The electrode has high specific surface area and a high functional group content (for example, the oxygen-containing functional group), and exhibits good catalytic activity for both the positive and negative electrode pairs ofan all-vanadium redox flow battery, and the high catalytic activity of the electrode greatly reduces the polarization of the electrode.

Owner:HUNAN YINFENG NEW ENERGY

A modified carbon fiber/sio 2 Preparation method of airgel composite material

ActiveCN113860848BIncrease the content of functional groupsIncrease the lengthCeramicwareFiberCarbon fibers

The invention provides a modified carbon fiber / SiO 2 The preparation method of the airgel composite material comprises the steps of: desizing the carbon fiber, and after nitric acid oxidation treatment, using silane coupling agents KH-550 and KH-560 to carry out surface modification and grafting treatment to obtain the modified carbon fiber; Stir and disperse the modified carbon fiber and silicon dioxide wet gel evenly, and freeze-dry after drying, aging, hydrophobic modification and soaking. The preparation method of airgel composite material of the present invention strengthens SiO by adopting the modified carbon fiber 2 The performance of airgel, the chemical cross-linking combination of the two has better mechanical properties than the previous physical combination, the whole operation method is simple, the operating conditions are mild, the steps are closely connected, and the prepared material has good performance.

Owner:GUIZHOU MATERIAL IND TECH INSTITUE

A modified carbon material and a nitrogen-enriched liquid flow battery electrode prepared therefrom

ActiveCN110194453BImprove conductivityImprove package stabilityGraphiteCell electrodesIn situ polymerizationModified carbon

Owner:HUNAN YINFENG NEW ENERGY

High-temperature-resistant PBT (polybutylene terephthalate) material with epoxy resin adhesiveness and preparation method thereof

InactiveCN105907056AImprove interfacial adhesionIncrease the content of functional groupsCardanolDodecylsulfonic acid

The invention discloses a high-temperature-resistant PBT (polybutylene terephthalate) material with epoxy resin adhesiveness. The PBT material is composed of the following raw materials in parts by weight: 60-80 parts of PBT, 15-20 parts of cardanol amine, 15-20 parts of polyvinyl alcohol microsphere, 5-8 parts of sodium dodecylsulfate, 5-10 parts of gelatin, 2-4 parts of nano calcium carbonate, 1-3 parts of ground calcium carbonate, 6-12 parts of carbon nanotube and 1-3 parts of pentaerythritol stearate. The microcapsulates of the introduced microcapsule curing agent are broken under certain conditions, so that the curing agent is slowly released, thereby achieving the goal of controlling the curing process between the material and the epoxy resin potting adhesive, and enhancing the interface binding property between the material and the epoxy resin.

Owner:BENGBU ZHENGYUAN ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com