Preparation method of collagen peptide grafted hydrothermal carbon microsphere absorbing agent

A collagen peptide and microsphere adsorption technology, which is applied in the field of biomass resource utilization and biomass adsorption materials, can solve the problems of limitations, restrictions on the application of collagen peptides, limited functional groups, etc., and achieve low cost and good economic benefits and the promotion and application prospect, the effect of cheap cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of collagen peptide grafted hydrothermal carbon microsphere adsorbent, comprising the following steps:

[0035] Step 1. Cut the waste leather into uniform granular leather, soak 5g of granular leather in 50mL ultrapure water, add 1g of CaO, stir and react at 75°C for 12h, filter, and adjust the pH of the filtrate to neutral with dilute hydrochloric acid. Grinding after drying to obtain collagen peptide powder;

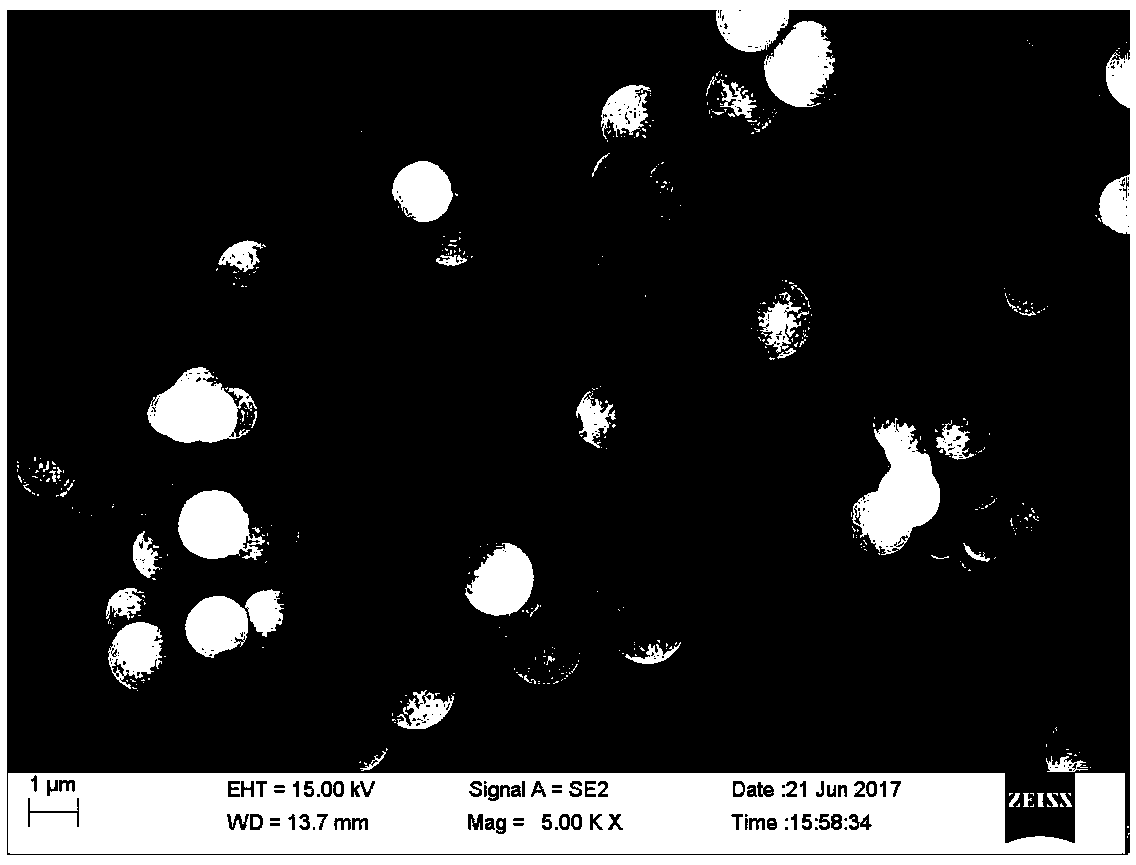

[0036] Step 2: Add an appropriate amount of 20wt% glucose solution into the reaction kettle, tighten the reaction kettle and place it at 180°C for 24 hours, cool to room temperature naturally, wash the reaction product, filter, dry, and dry it in an air atmosphere for 5 The heating rate of °C / min was raised to 300 °C for 5 hours of roasting and carbonization to obtain carboxylated hydrothermal carbon microspheres;

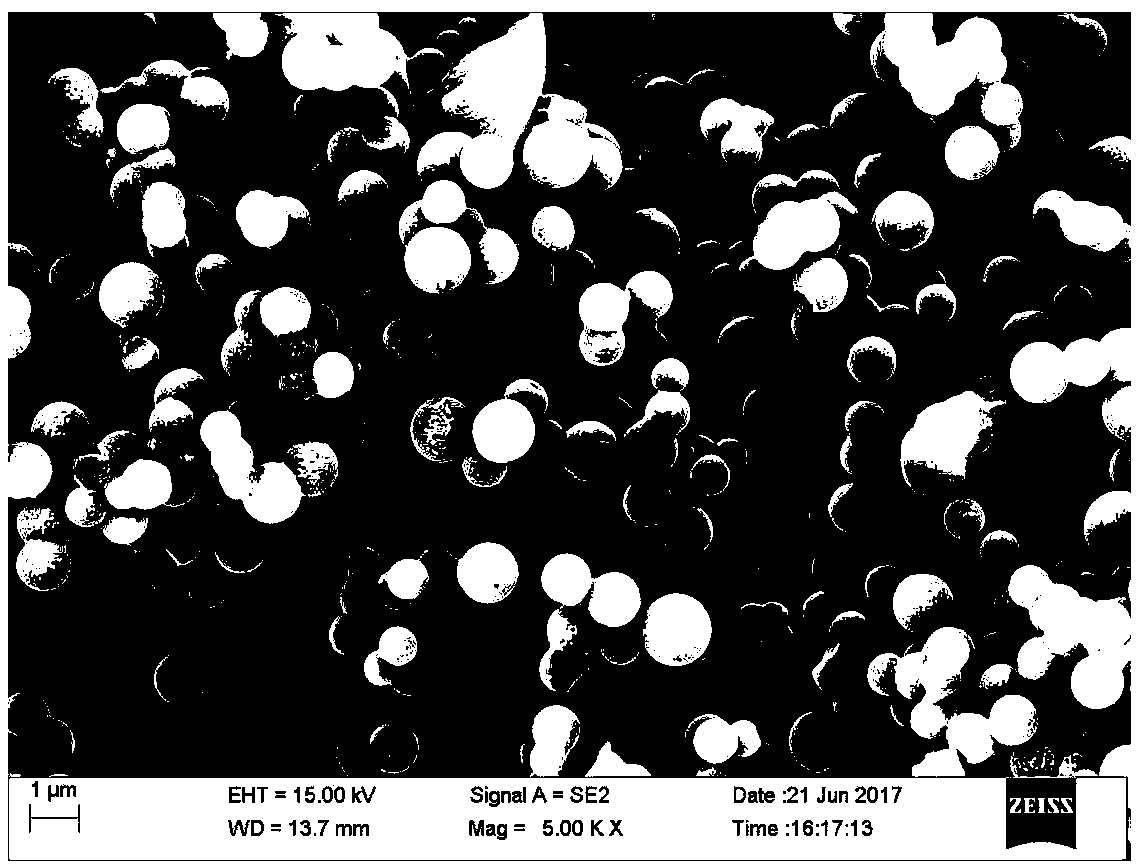

[0037]Step 3. Disperse 1 g of carboxylated hydrothermal carbon microspheres in 20 mL of ultrapure water, ultrasonicate for 3 h...

Embodiment 2

[0039] A preparation method of collagen peptide grafted hydrothermal carbon microsphere adsorbent, comprising the following steps:

[0040] Step 1. Cut the waste leather into uniform granular leather, soak 10g of granular leather in 100mL ultrapure water, add 2g of CaO, stir and react at 75°C for 16h, filter, and adjust the pH of the filtrate to neutral with dilute hydrochloric acid. Grinding after drying to obtain collagen peptide powder;

[0041] Step 2: Add an appropriate amount of 20wt% glucose solution into the reaction kettle, tighten the reaction kettle and place it at 180°C for 24 hours, cool to room temperature naturally, wash the reaction product, filter, dry, and dry it in an air atmosphere for 5 The heating rate of °C / min was raised to 300 °C for 5 hours of roasting and carbonization to obtain carboxylated hydrothermal carbon microspheres;

[0042] Step 3. Disperse 1 g of carboxylated hydrothermal carbon microspheres in 20 mL of ultrapure water, ultrasonicate for ...

Embodiment 3

[0044] A preparation method of collagen peptide grafted hydrothermal carbon microsphere adsorbent, comprising the following steps:

[0045] Step 1. Cut the waste leather into uniform granular leather, soak 10g of granular leather in 100mL ultrapure water, add 1g of CaO, stir and react at 65°C for 16h, filter, and adjust the pH of the filtrate to neutral with dilute hydrochloric acid. Grinding after drying to obtain collagen peptide powder;

[0046] Step 2: Add an appropriate amount of 20wt% glucose solution into the reaction kettle, tighten the reaction kettle and place it at 160°C for 18 hours, cool to room temperature naturally, wash the reaction product, filter, dry, and dry it in an air atmosphere for 5 The heating rate of °C / min was raised to 400 °C for 3 hours of roasting and carbonization to obtain carboxylated hydrothermal carbon microspheres;

[0047] Step 3. Disperse 1 g of carboxylated hydrothermal carbon microspheres in 20 mL of ultrapure water, ultrasonicate for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com