Preparation method of carbon electrode material and application thereof

A carbon electrode and carbon material technology, which is applied in the field of carbon electrode material preparation, can solve the problems of low specific capacitance of carbon materials, etc., and achieve the effects of improving electric double layer capacitance, good application prospect and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a kind of preparation method of carbon electrode material, comprises the following steps:

[0027] (1) Mix the activator, chestnut shell and water uniformly according to the mass ratio of 1:(0.2~1):(1~3), and fully dry, and then calcinate at 600℃~800℃ for 1h in an inert atmosphere ~5h, so that the mixture is fully carbonized and activated to obtain the primary product of carbon materials, the mass ratio of the activator to the dried chestnut shell is preferably 3:1~3:2; wherein the activator is KOH, NaOH , ZnCl 2 , Ca(NO 3 ) 2 One or more in; the inert atmosphere is one or more in nitrogen, helium or argon; Wherein, the effect of water is to make the dried chestnut shell and activator mix more uniformly, if the amount of water is too little It is easy to mix unevenly, and if the amount of water is too much, the drying time will be longer, which will affect the efficiency of the experiment. When the chestnut shells are fresh chestnut shells that...

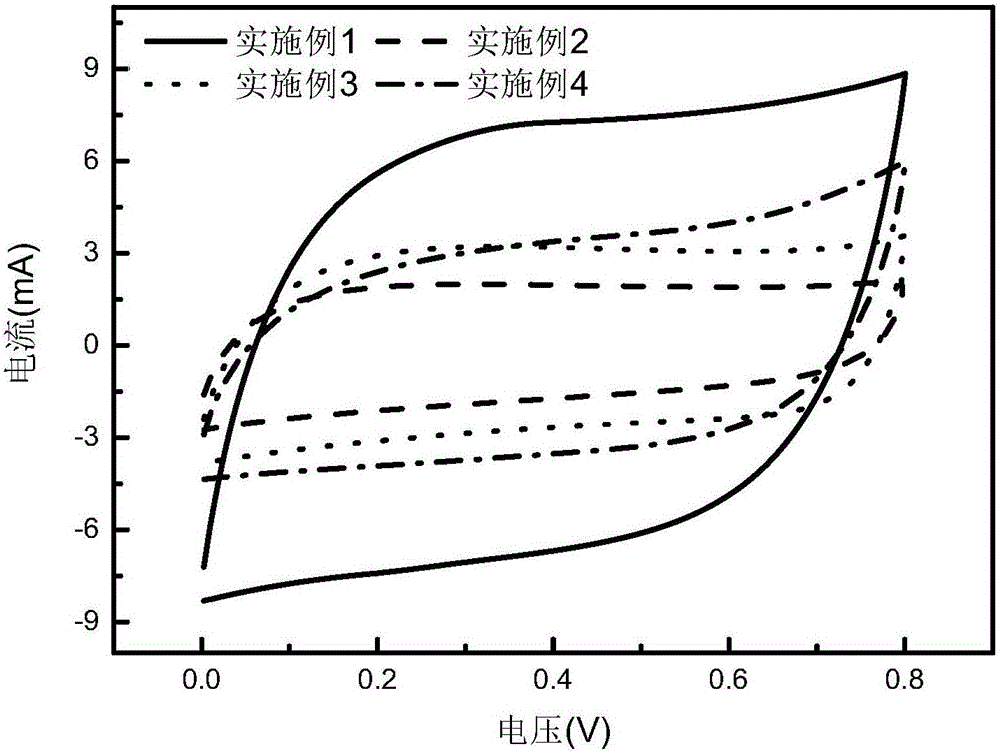

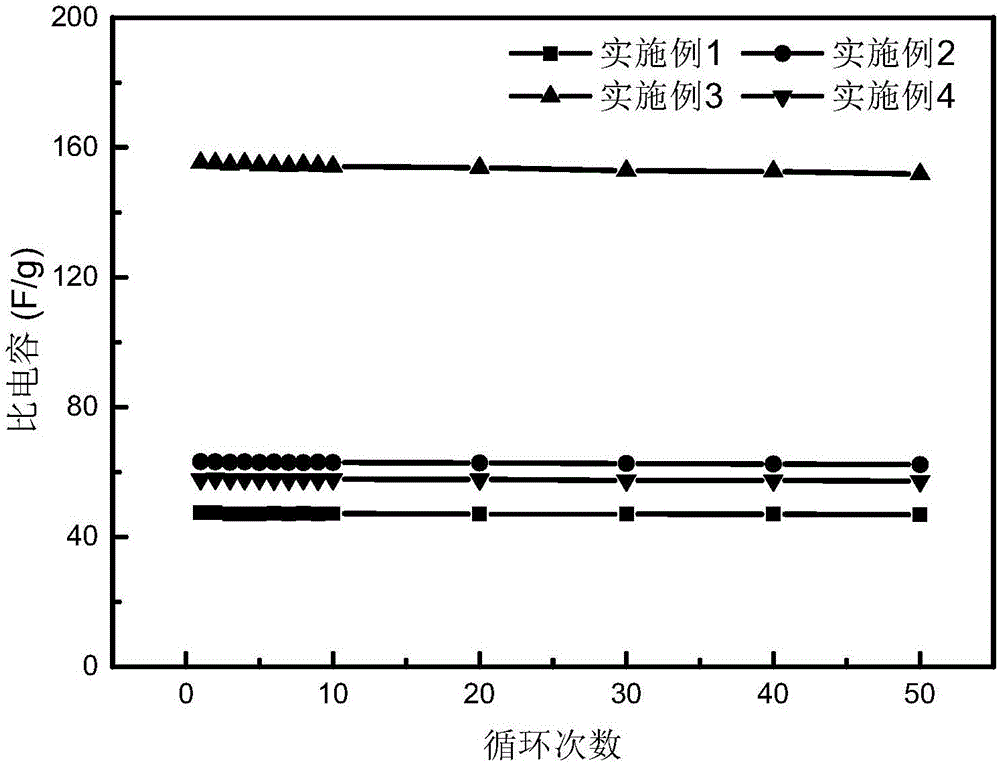

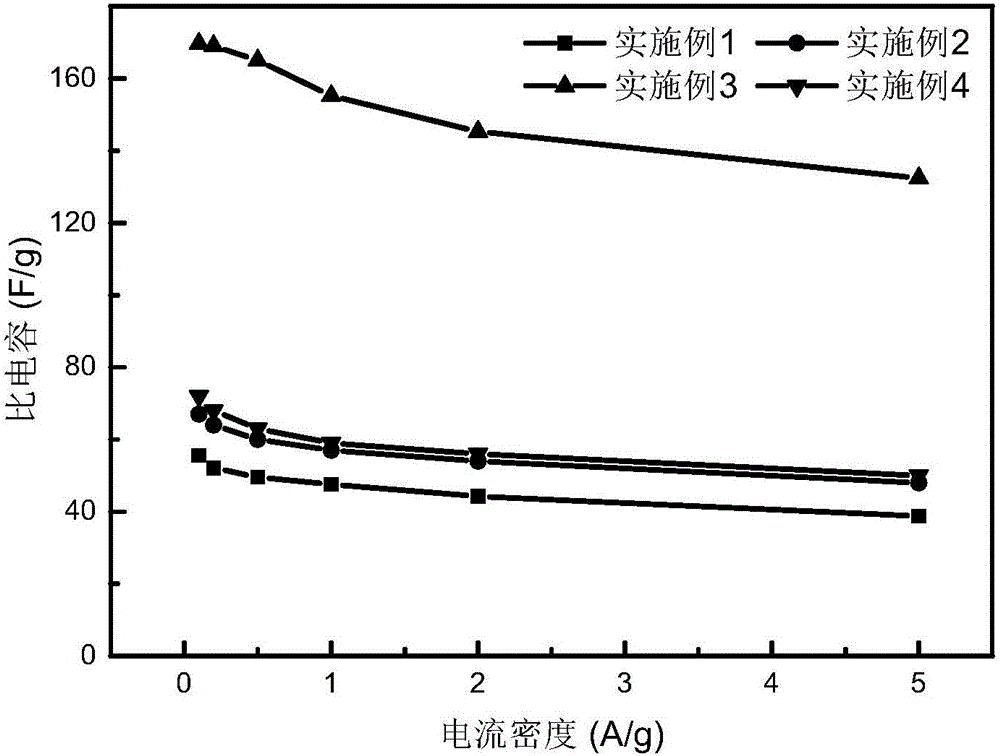

Embodiment 1

[0034] (1) Mix 5 g of dried chestnut shells, 10 g of KOH, and 20 mL of water evenly, then dry them, place them in a tube furnace, raise the temperature to 600 °C at a rate of 3 °C / min in a nitrogen atmosphere, and keep for 1.5 h;

[0035](2) The resulting carbonized product was then washed with 10% dilute hydrochloric acid, then washed with deionized water until neutral, and dried in an oven to obtain 0.40 g of the product;

[0036] (3) Mix the dried product, melamine, and water evenly at a mass ratio of 1:1:2, place them in a tube furnace, and raise the temperature to 600°C at a heating rate of 3°C / min under a nitrogen atmosphere. Keep for 1.5h;

[0037] (4) The obtained product was washed again with dilute hydrochloric acid (10wt%), then washed with deionized water until neutral, and dried in an oven to obtain a chestnut shell-based nitrogen-doped carbon electrode material.

Embodiment 2

[0039] (1) Mix 5 g of dried chestnut shells, 10 g of KOH, and 20 mL of water evenly, then dry them, place them in a tube furnace, raise the temperature to 600 °C at a rate of 3 °C / min in a nitrogen atmosphere, and keep it for 1.5 h;

[0040] (2) Subsequently, the obtained carbonized product was washed once with dilute hydrochloric acid (10 wt%), then washed with deionized water until neutral, and dried in an oven to obtain 0.38 g of the product;

[0041] (3) The dried product, melamine and water were mixed evenly according to the mass ratio of 1:2:4, and then placed in a tube furnace, and the temperature was raised to 600°C at a heating rate of 3°C / min under a nitrogen atmosphere. Keep for 1.5h;

[0042] (4) The obtained product was washed again with dilute hydrochloric acid, then washed with deionized water to neutrality, placed in an oven for drying, and the chestnut shell-based nitrogen-doped carbon electrode material was obtained.

[0043] Take 40mg of the prepared carbon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com