Water-based two-component transparent putty

A transparent putty, two-component technology, applied in the direction of filling slurry, etc., can solve the problems of poor adhesion of the upper layer of paint, loss of use value, not environmental protection, etc., to achieve excellent adhesion, good elasticity, and energy saving effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 A kind of transparent water-based two-component transparent putty

[0029] A component:

[0030] First add 25kg of water, 0.4kg of defoamer BYK094, 0.4kg of wetting and dispersing agent TEGO Dispers 760W, 0.2kg of fungicide Parmetol A 28, and 1kg of antifreeze 1,3-propylene glycol into the dispersion container in sequence, start stirring, and then Add 50kg transparent powder JH-G2, 20kg redispersible rubber powder 50E100S, 0.5kg thickener Thixol 53L and 0.4kg thickener Coapur830w under stirring state, disperse for 15 minutes, then add 0.2kg pH regulator APM-95, 2.4 kg of water, stir well.

[0031] B component:

[0032] Yantai Wanhua pure diphenylmethane diisocyanate 100kg.

[0033] During construction, the ratio of component A and component B is 100:3 and mixed evenly, and the pH is 8.5.

Embodiment 2

[0034] Embodiment 2 A kind of white water-based two-component transparent putty

[0035] A component:

[0036] First add 25kg of water, 0.4kg of defoamer BYK094, 0.4kg of wetting and dispersing agent TEGO Dispers 760W, 0.2kg of fungicide Parmetol A 28, and 1kg of antifreeze 1,3-propylene glycol into the dispersion container in sequence, start stirring, and then Add 5kg titanium dioxide TS 6200, 45kg transparent powder JH-G2, 20kg redispersible rubber powder 50E100S, 0.5kg thickener Thixol 53L and 0.4kg thickener Coapur830w under stirring state, disperse for 15 minutes, then add 0.2kg pH adjustment Agent APM-95, 2.4kg water, stir well.

[0037] B component:

[0038] Yantai Wanhua pure diphenylmethane diisocyanate 100kg.

[0039] During construction, the ratio of component A and component B is 100:4.5 and mixed evenly, and the pH is 8.0.

[0040] After testing, the performances of the inventions of above-mentioned embodiment 1 and embodiment 2 are as follows:

[0041]

Embodiment 3

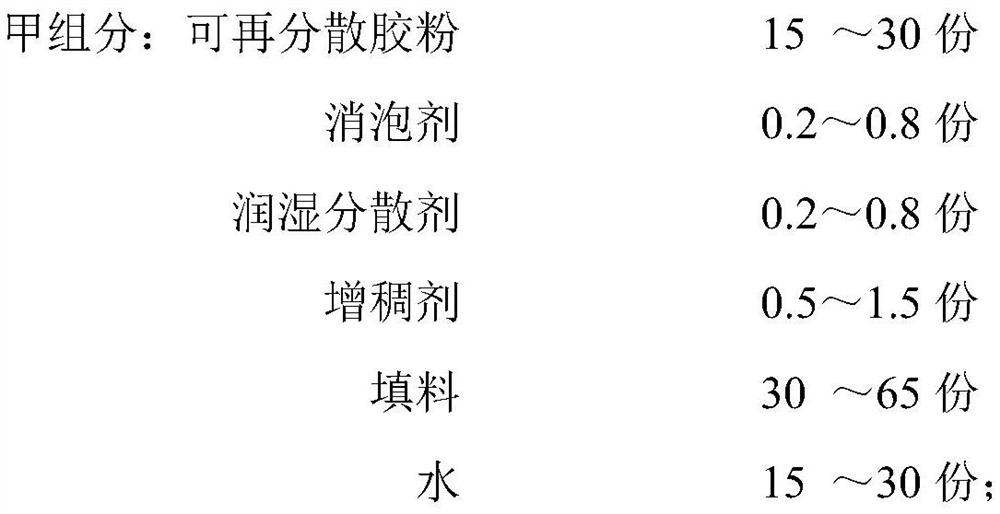

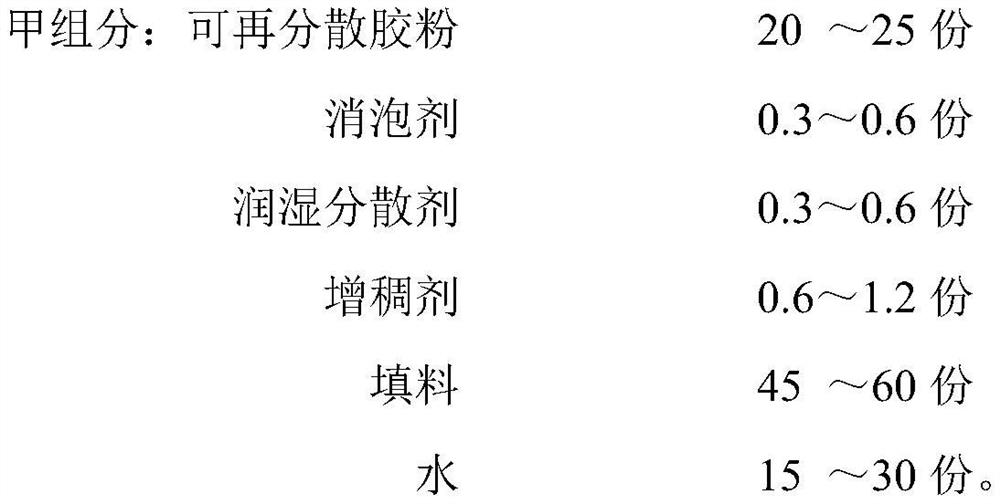

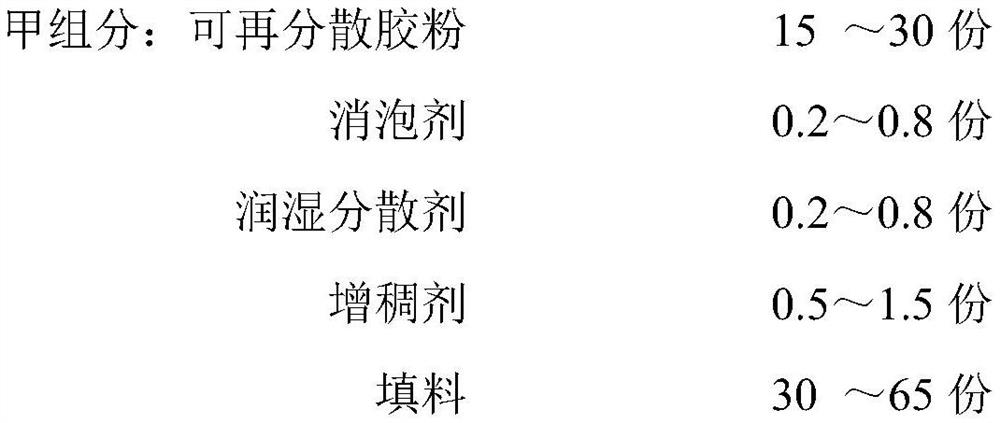

[0043] The preparation process is the same as in Example 1, except that the components of the water-based two-component transparent putty of the present embodiment are as follows:

[0044] A component:

[0045]

[0046]

[0047] The weight ratio of component A and component B is 100:1 and the pH is 7.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com