A modified carbon fiber/sio 2 Preparation method of airgel composite material

A composite material and modified carbon technology, used in ceramic products, other household appliances, household appliances, etc., can solve the problems of weak binding ability between fibers and substrates, general mechanical properties of composite materials, etc., to achieve tight steps and good material properties. , excellent mechanical properties

Active Publication Date: 2022-06-10

GUIZHOU MATERIAL IND TECH INSTITUE

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The mechanical properties of the composite material prepared by this method are average, and the bonding ability between the fiber and the matrix is relatively weak.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0070] The pH of the mixed solution is adjusted to be 2-3 by adding an acid. The acid is hydrochloric acid.

[0071] The solution was heated to 80°C and stirred for a period of time to fully hydrolyze the TEOS.

[0072] Adding ammonia water to adjust the pH of the solution is 6 to 7, and the solution is poured into the mold to seal and leave the gel to stand.

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Login to View More

Abstract

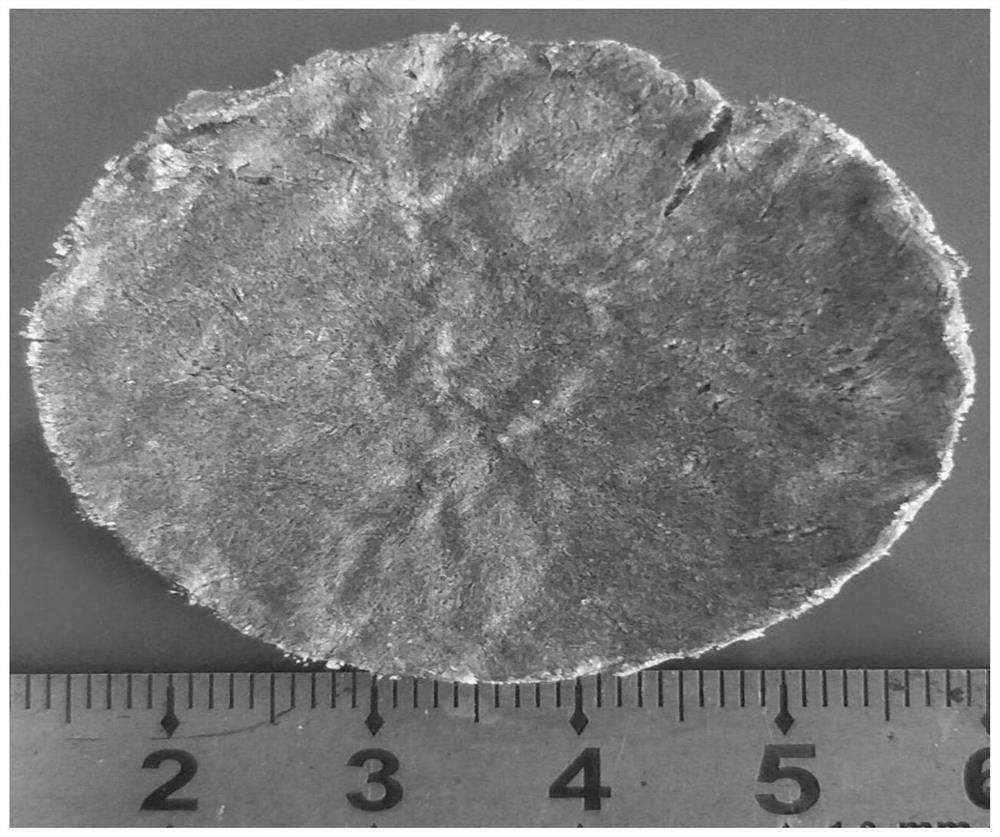

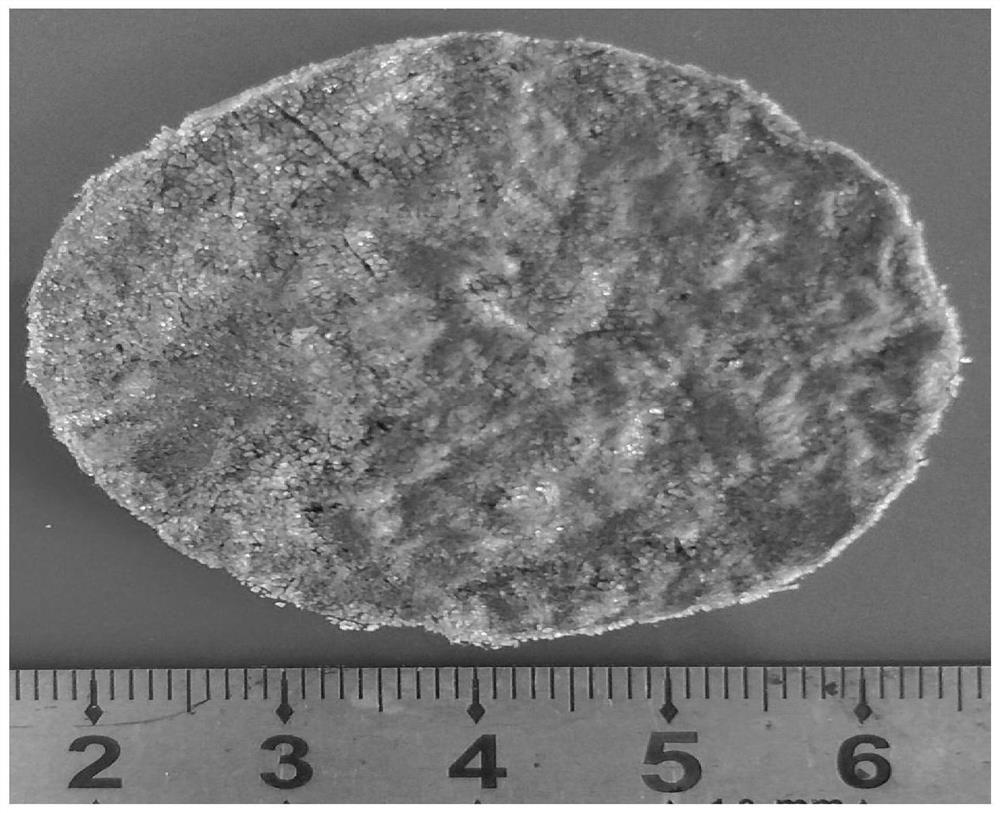

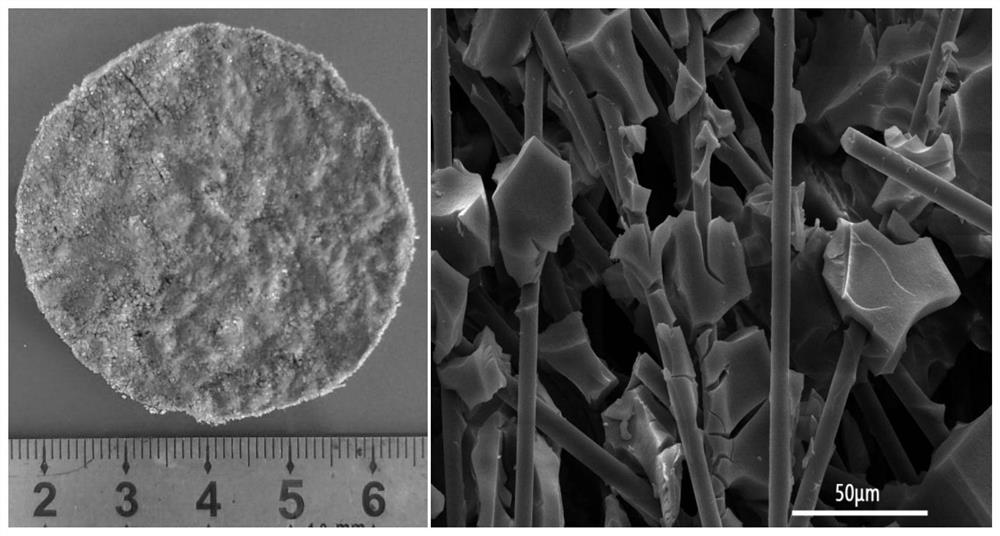

The invention provides a modified carbon fiber / SiO 2 The preparation method of the airgel composite material comprises the steps of: desizing the carbon fiber, and after nitric acid oxidation treatment, using silane coupling agents KH-550 and KH-560 to carry out surface modification and grafting treatment to obtain the modified carbon fiber; Stir and disperse the modified carbon fiber and silicon dioxide wet gel evenly, and freeze-dry after drying, aging, hydrophobic modification and soaking. The preparation method of airgel composite material of the present invention strengthens SiO by adopting the modified carbon fiber 2 The performance of airgel, the chemical cross-linking combination of the two has better mechanical properties than the previous physical combination, the whole operation method is simple, the operating conditions are mild, the steps are closely connected, and the prepared material has good performance.

Description

A modified carbon fiber / SiO 2 Preparation method of aerogel composite material technical field The present invention relates to aerogel preparation field, specifically, relate to a kind of modified carbon fiber / SiO 2 Aerogel composite material preparation method. Background technique Silicon dioxide (SiO 2 ) Aerogel is made of gas as the dispersion medium, which is formed by the aggregation of colloidal particles or nanoparticles A nanoporous solid material with excellent properties such as ultra-light, ultra-low thermal conductivity, high light transmission and high specific surface area. SiO 2 gas Gels have broad application prospects in thermal insulation, adsorption, aerospace and other fields. However, SiO 2 Aerogels have low strength and toughness The disadvantages of poor performance, brittleness and easy hygroscopicity limit its application in different fields. At present, in order to enhance the SiO 2 The mechanical properties of ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C04B30/02C04B38/00C04B20/02C04B14/38

CPCC04B30/02C04B20/023C04B2201/32C04B2201/50C04B14/386C04B14/064C04B38/0045

Inventor 秦舒浩罗丹龙丽娟向宇姝单春燕张凯何敏于杰

Owner GUIZHOU MATERIAL IND TECH INSTITUE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com