Carbon fiber electrochemical processing method for surface growth carbon nanotube

A carbon nanotube, surface growth technology, applied in fiber treatment, carbon fiber, surface reaction electrolytic coating, etc., can solve the problems of easy agglomeration, great damage to fiber tensile strength, increase, etc., to achieve uniform loading, improve surface Roughness and functional group content, effect of increasing surface polarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

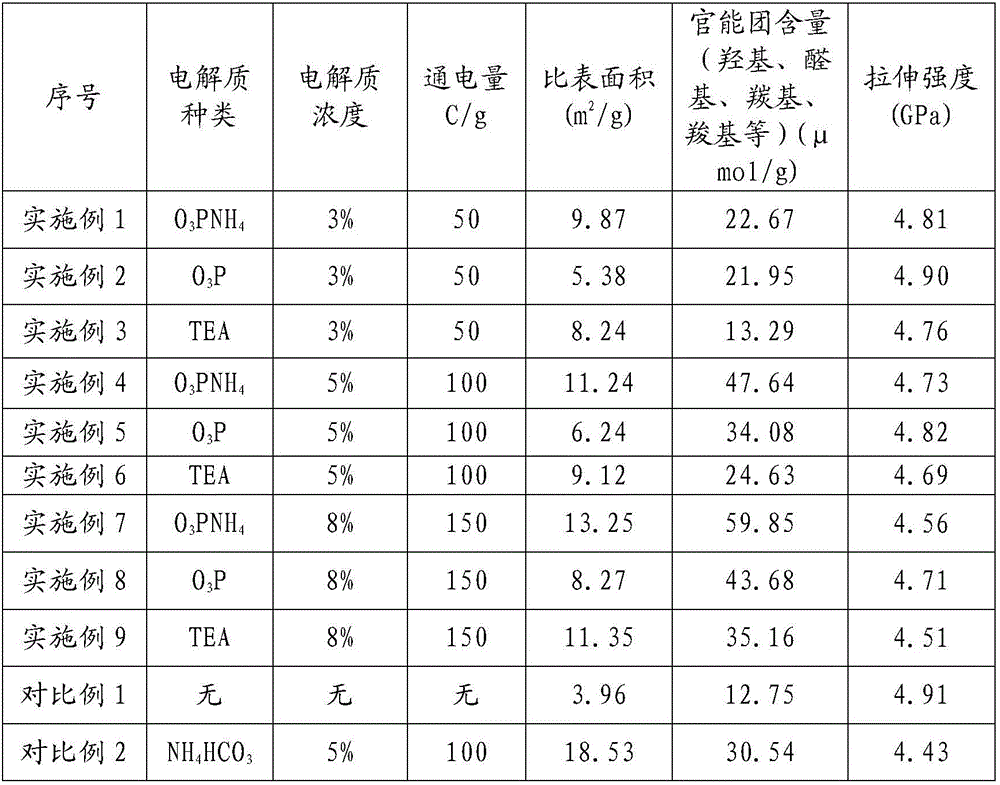

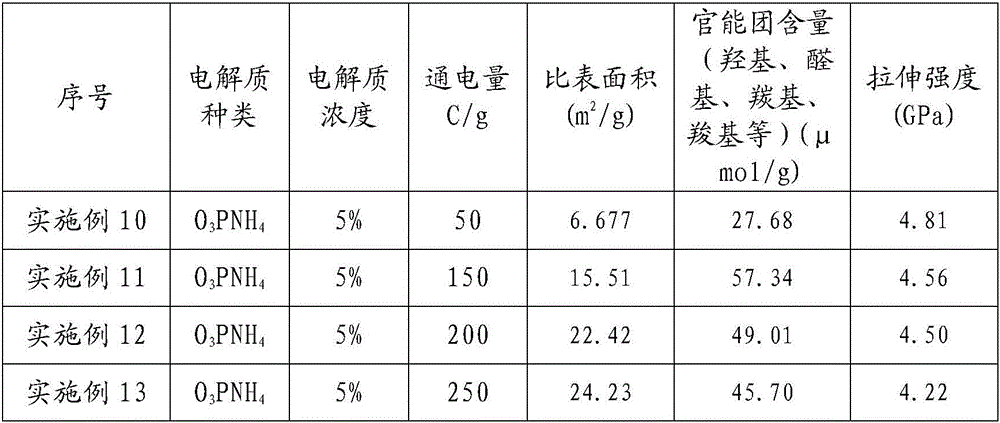

Examples

Embodiment 1

[0023] Step 1: Add the carbon fiber from which the surface sizing agent has been removed into an electrolytic cell for electrolysis. The electrolytic cell contains 3% O 3 PNH 4 Organic electrolyte solution, electrolysis time 85s, electrolysis power 50C / g;

[0024] Step 2: Pass the carbon fiber obtained in step 1 through a water washing tank to remove the residual electrolyte on the surface, the washing time is 120s, and the washing temperature is 30°C;

[0025] Step 3: drying the carbon fiber obtained in step 2 through a drying oven, the drying temperature is 115°C, and the drying time is 130s;

[0026] Step 4: Pass the carbon fiber obtained in step 3 into an impregnation tank, which contains an alcohol solution of cobalt nitrate, and the impregnation time of the catalyst solution is 150s;

[0027] Step 5: Collect the carbon fibers obtained in Step 4 by using a wire collecting machine.

Embodiment 2

[0029] Step 1: Add the carbon fiber from which the surface sizing agent has been removed into an electrolytic cell for electrolysis. The electrolytic cell contains 3% O 3 P organic electrolyte solution, electrolysis time 85s, electrolysis power 50C / g;

[0030] Step 2: Pass the carbon fiber obtained in step 1 through a water washing tank to remove the residual electrolyte on the surface, the washing time is 120s, and the washing temperature is 30°C;

[0031] Step 3: drying the carbon fiber obtained in step 2 through a drying oven, the drying temperature is 115°C, and the drying time is 130s;

[0032] Step 4: Pass the carbon fiber obtained in step 3 into an impregnation tank, which contains an alcohol solution of cobalt nitrate, and the impregnation time of the catalyst solution is 150s;

[0033] Step 5: Collect the carbon fibers obtained in Step 4 by using a wire collecting machine.

Embodiment 3

[0035] Step 1: Add the carbon fiber from which the surface sizing agent has been removed to an electrolytic cell for electrolysis. The electrolytic cell contains a TEA organic electrolyte solution with a mass fraction of 3%, the electrolysis time is 85s, and the electrolysis power is 50C / g;

[0036] Step 2: Pass the carbon fiber obtained in step 1 through a water washing tank to remove the residual electrolyte on the surface, the washing time is 120s, and the washing temperature is 30°C;

[0037] Step 3: drying the carbon fiber obtained in step 2 through a drying oven, the drying temperature is 115°C, and the drying time is 130s;

[0038] Step 4: Pass the carbon fiber obtained in step 3 into an impregnation tank, which contains an alcohol solution of cobalt nitrate, and the impregnation time of the catalyst solution is 150s;

[0039] Step 5: Collect the carbon fibers obtained in Step 4 by using a wire collecting machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com