Spherical polytetrafluoroethylene micro-powder wax and preparation method thereof

A polytetrafluoroethylene micropowder and polytetrafluoroethylene technology are applied in the field of spherical polytetrafluoroethylene micropowder wax and its preparation to achieve the effects of improving conversion rate, reducing damage, and being beneficial to chemical modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

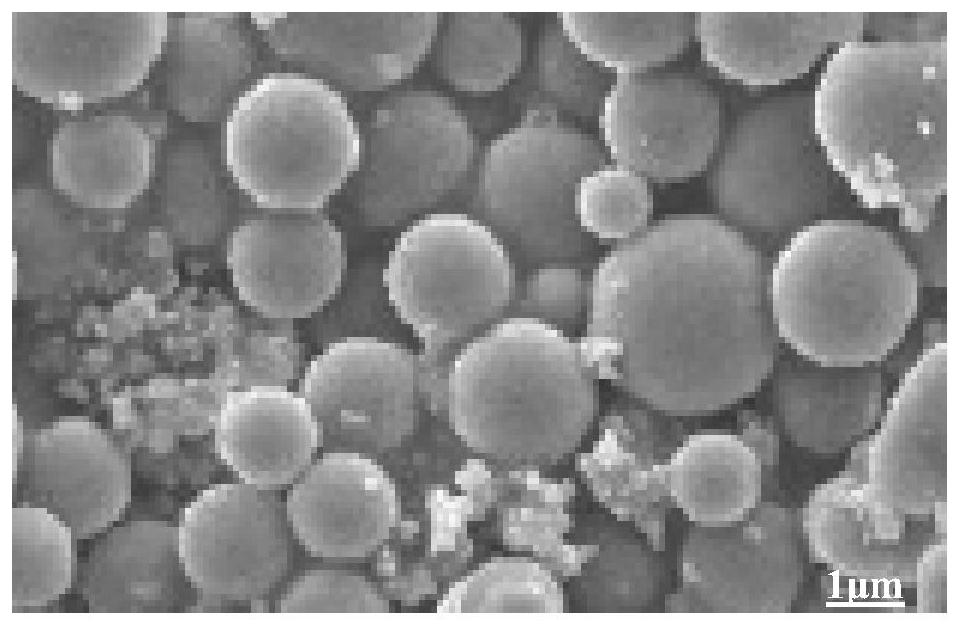

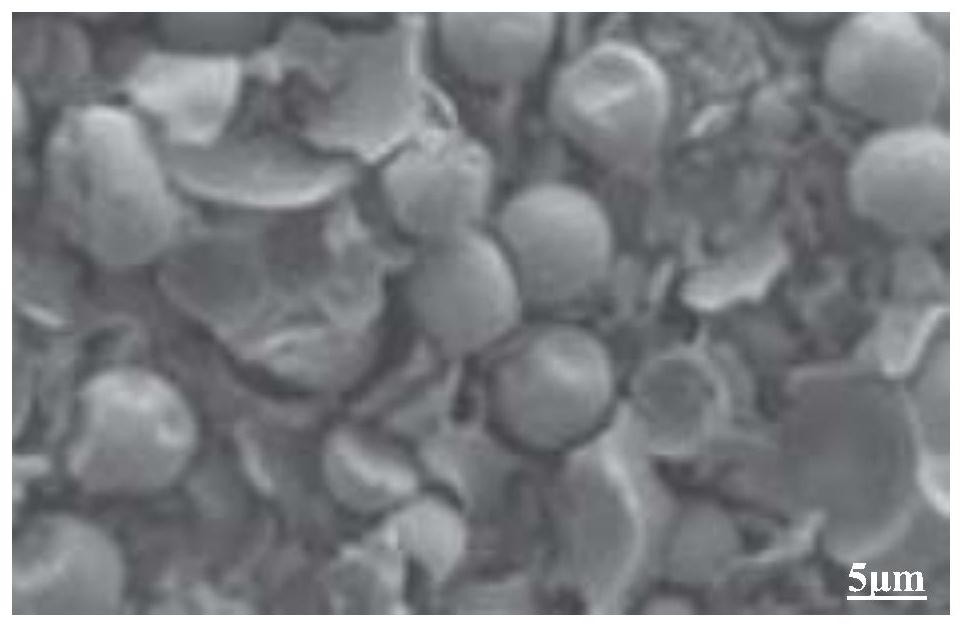

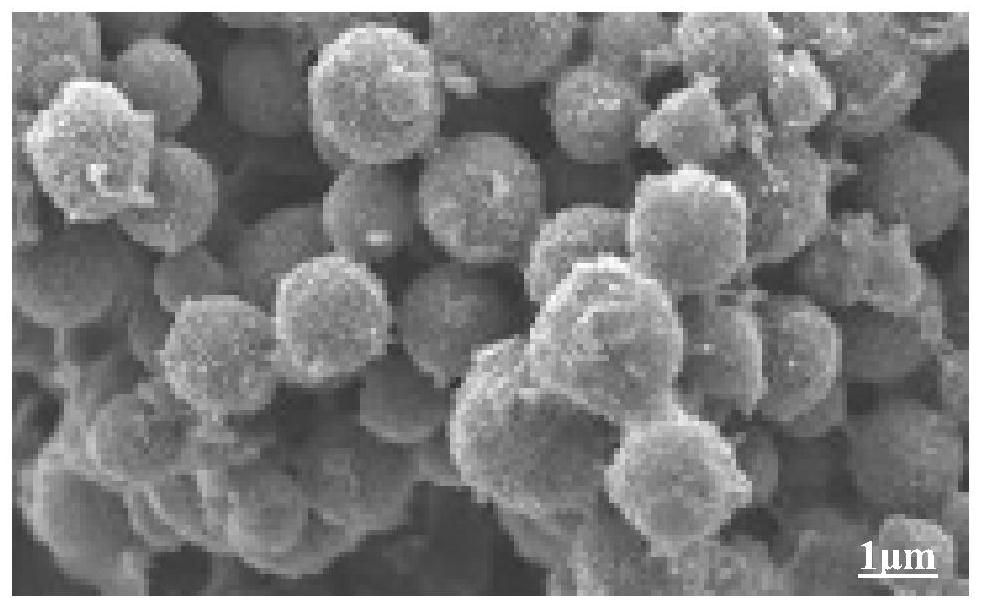

Image

Examples

Embodiment 1

[0031] 1) Stir 1000g of PTFE resin and 20g of KH560 evenly, place it in an irradiation box, and irradiate it with high-energy electron beams, and the irradiation dose is 20Mrad;

[0032] 2) Pulverize the irradiated product with a jet mill, then disperse it in acetone, add acetic acid to stir, leave it to stand for stratification, and filter to obtain polytetrafluoroethylene micropowder;

[0033] 3) Disperse 100g of the treated polytetrafluoroethylene micropowder in 500ml of ethylene glycol, add 5g of polyvinylpyrrolidone and ultrasonically disperse it evenly, react with water at 140°C for 5h, wash and dry after treatment to obtain carboxyl-terminated polytetrafluoroethylene micropowder ;

[0034] 4) Add 100g of carboxyl-terminated polytetrafluoroethylene micropowder and 10g of hydroxyethyl methacrylate into the reaction flask, add 500ml of solvent DMF, and disperse it evenly by ultrasonication, then add 2g of dimethylimidazole, and react at 150°C for 8h. Filter and dry after ...

Embodiment 2

[0037] Step 1) Stir 1000g PTFE resin with 40g KH570 evenly, place it in an irradiation box, and use high-energy electron beams to irradiate, and the irradiation dose is 50Mrad;

[0038] 2) Pulverize the irradiated product with a jet mill, then disperse it in acetone, add acetic acid to stir, leave it to stand for stratification, and filter to obtain polytetrafluoroethylene micropowder;

[0039] 3) Disperse 100g of the treated polytetrafluoroethylene micropowder in 500ml of ethylene glycol, add 5g of polyvinylpyrrolidone and ultrasonically disperse it evenly, react with water at 140°C for 5h, wash and dry after treatment to obtain carboxyl-terminated polytetrafluoroethylene micropowder ;

[0040] 4) Add 100g of carboxyl-terminated polytetrafluoroethylene micropowder and 10g of hydroxyethyl methacrylate into the reaction flask, add 500ml of solvent DMF, and disperse it evenly by ultrasonication, then add 2g of dimethylimidazole, and react at 150°C for 8h. Filter and dry after c...

Embodiment 3

[0043] 1) Stir 1000g of PTFE resin and 60g of KH560 evenly, place it in an irradiation box, and irradiate it with high-energy electron beams, and the irradiation dose is 100Mrad;

[0044] 2) Pulverize the irradiated product with a jet mill, then disperse it in acetone, add acetic acid to stir, leave it to stand for stratification, and filter to obtain polytetrafluoroethylene micropowder;

[0045] 3) Disperse 100g of the treated polytetrafluoroethylene micropowder in 500ml of ethylene glycol, add 5g of polyvinylpyrrolidone and ultrasonically disperse it evenly, react with water at 140°C for 5h, wash and dry after treatment to obtain carboxyl-terminated polytetrafluoroethylene micropowder ;

[0046]4) Add 100g of carboxyl-terminated polytetrafluoroethylene micropowder and 10g of hydroxyethyl methacrylate into the reaction flask, add 500ml of solvent DMF, and disperse it evenly by ultrasonication, then add 2g of dimethylimidazole, and react at 150°C for 8h. Filter and dry after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com