Packaging mechanism for wireless communication module

A wireless communication module and recycling mechanism technology, applied in cleaning methods and utensils, cleaning methods using gas flow, electrical components, etc., can solve problems affecting module failure, affecting quality, etc., to avoid failure, improve packaging stability, Effects for quick placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

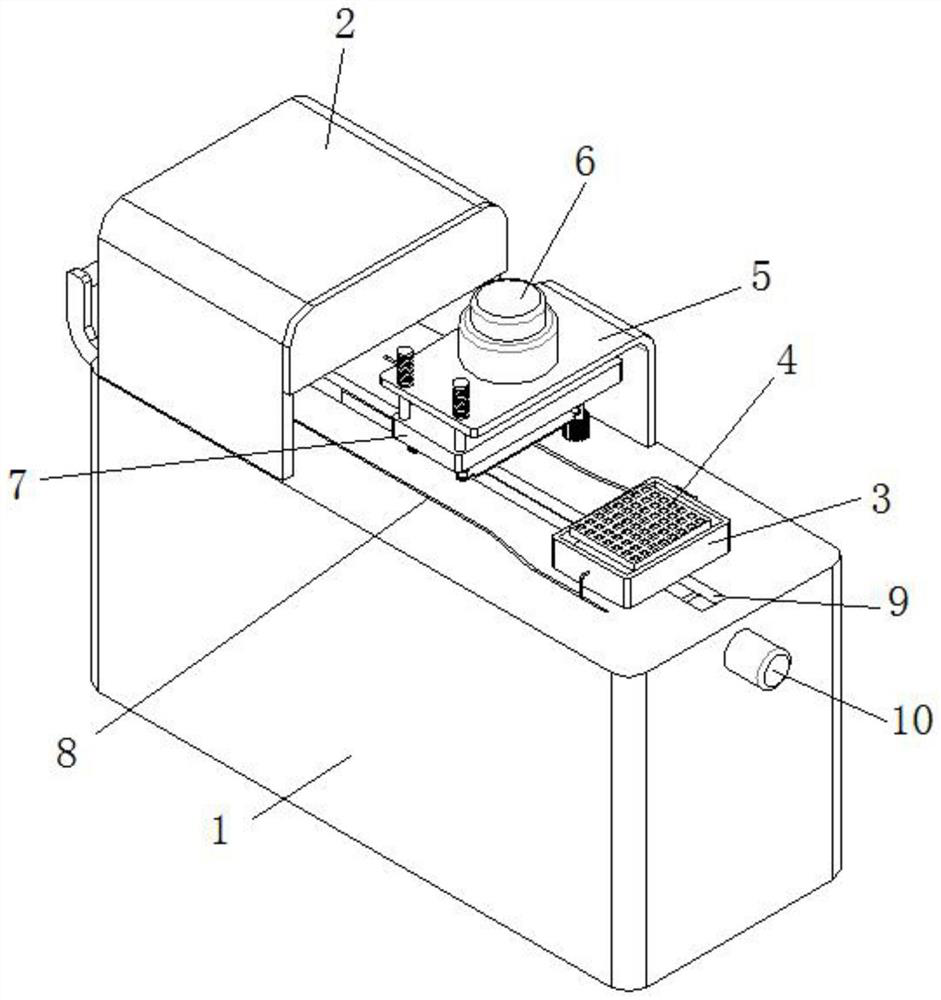

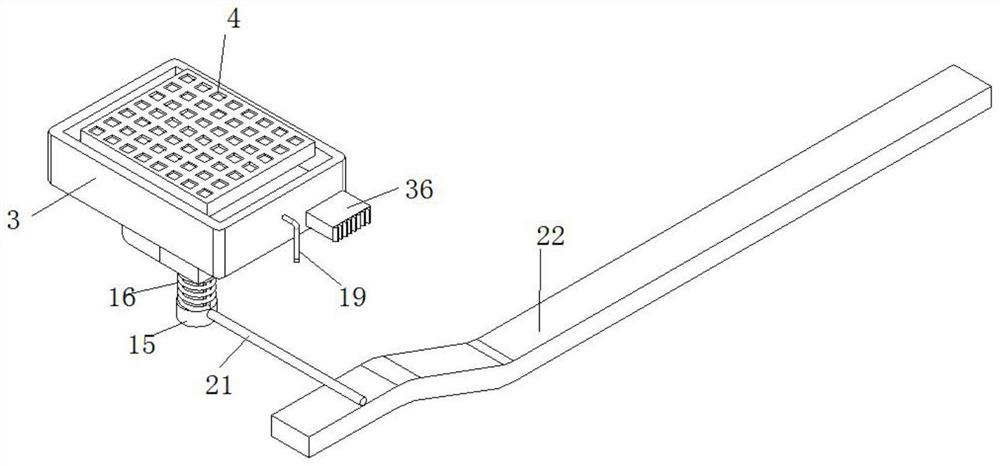

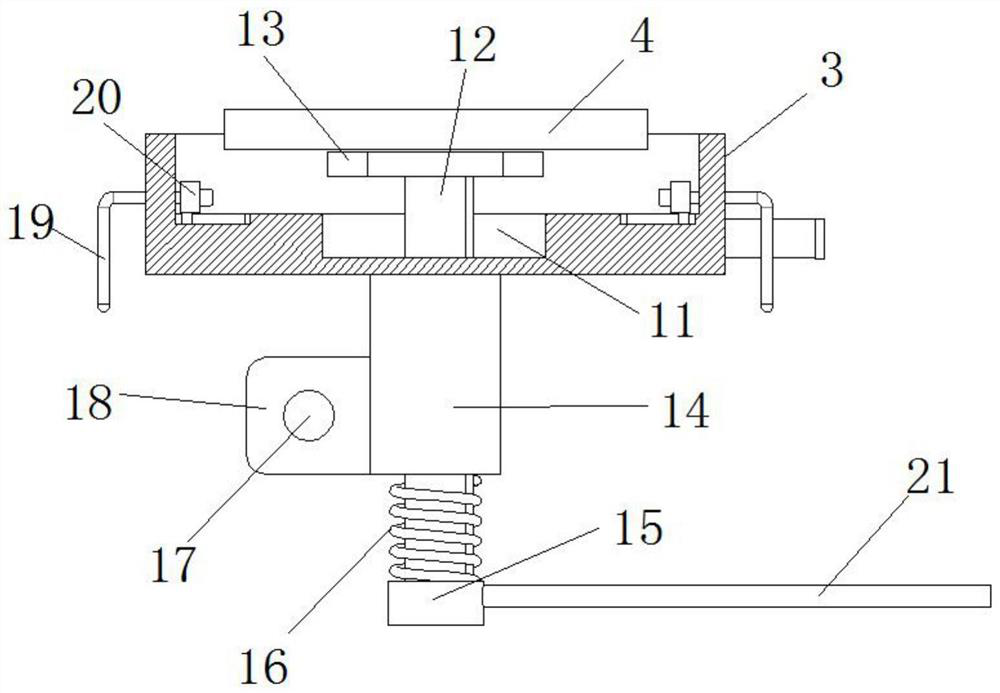

[0029] Embodiment 1, with reference to Figure 1-7 , a packaging mechanism for a wireless communication module, including a bottom box 1, a packaging warehouse 2 is fixed on one side of the upper part of the bottom box 1, and a packaging mechanism is provided in the packaging warehouse 2, and a sliding device is installed on the upper side of the bottom box 1 away from the packaging warehouse 2 Skateboard 3, bottom box 1 is provided with a driving sliding assembly, the upper part of the slideboard 3 is provided with a rectangular slot, and a storage slot 11 is opened at the middle position of the bottom wall of the rectangular slot, and a sliding post is inserted slidingly at the middle position of the bottom wall of the storage slot 11 12. The top plate 13 is horizontally and fixedly connected to the upper end of the sliding column 12, the top plate 13 is placed with a placement plate 4, and the upper part of the placement plate 4 is provided with a plurality of frame placemen...

Embodiment 2

[0037] Embodiment 2, with reference to Figure 1-2 and 4-8, compared with Embodiment 1, the only difference is that the elastic member includes two magnetic rings 35 slidingly sleeved at the lower end of the spool 12, and one of the magnetic rings 35 is fixed on one side of the limit disc 15, and the other The magnetic ring 35 is fixed on the lower part of the slider 14 , and the two magnetic rings 35 repel each other magnetically.

[0038] The above-mentioned embodiment 2 of the present invention has achieved the following technical effects: during packaging operations, only the module chip frame needs to be placed in the frame placement opening on the placement plate 4, and then the drive motor 10 drives the screw rod 17 to rotate, driving the slide plate 3 along the chute 9 Sliding, when the horizontal column 21 in the bottom box 1 is smoothed by the rising part of the guide rod 22, it will drive the sliding column 12 to move down, release the two magnetic rings 35 so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com