Bending and prefabricating machining device for automobile plate parts

A processing device and plate technology, applied in the direction of manufacturing tools, metal processing equipment, forming tools, etc., to achieve the effect of eliminating the problem of bending recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following technical solution described in conjunction with the accompanying drawings is further described. It should be noted that the orientation nouns that may be involved in the following paragraphs are the visual orientations shown in the corresponding drawings of the specification, only to facilitate those skilled in the art to better understand the technical solution described in the specification. In the description of the following paragraphs, unless otherwise expressly specified and qualified, the term "installation", "connected", "connected" and other similar expressions should be understood broadly, for those of ordinary skill in the art, according to the specific circumstances of the art in conjunction with the well-known common sense in the art, design specifications, standard literature, etc. to understand the specific meaning of the above terms in the present invention.

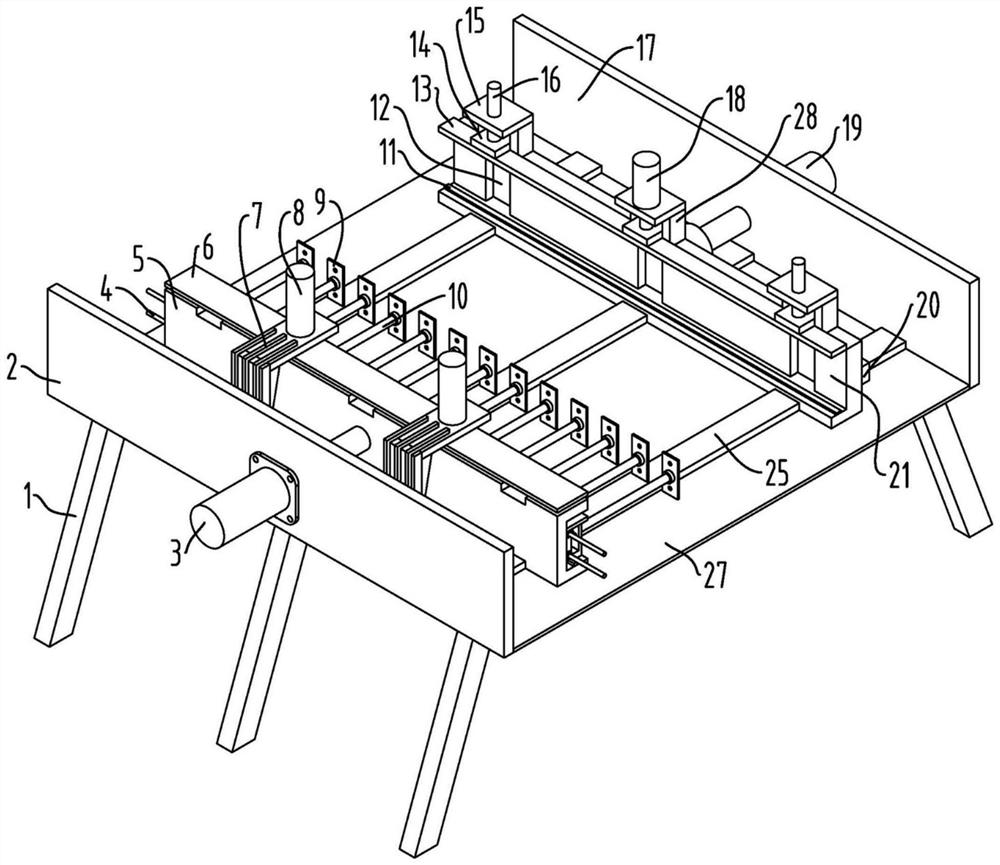

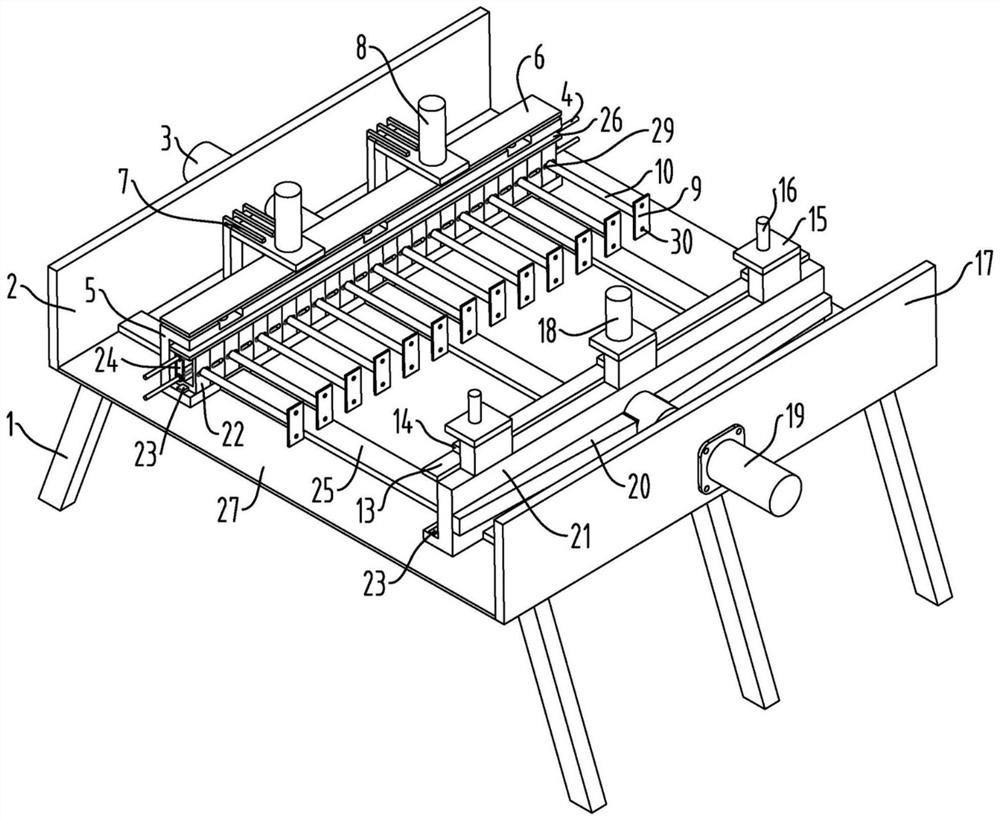

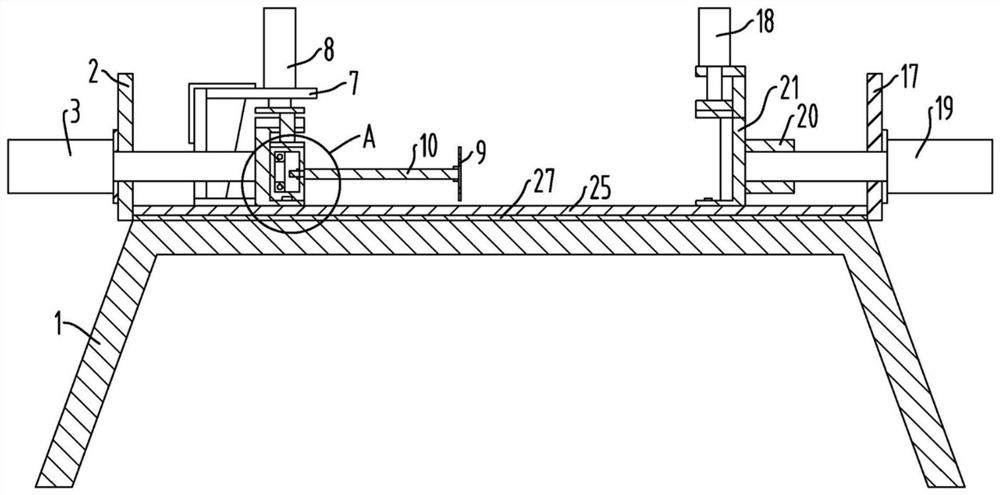

[0020] as Figures 1 through 4 As shown, an automotive sheet parts bending prefabrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com