A kind of uniform temperature plate filling system and control method

A technology of temperature chamber and controller, applied in lighting and heating equipment, indirect heat exchangers, etc., can solve the problem of low accuracy of the target charging amount of liquid working medium in the chamber, affecting the performance and life of the chamber. , It is difficult to charge the uniform temperature plate products in batches, so as to achieve the effect of simple structure, good temperature uniformity performance and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

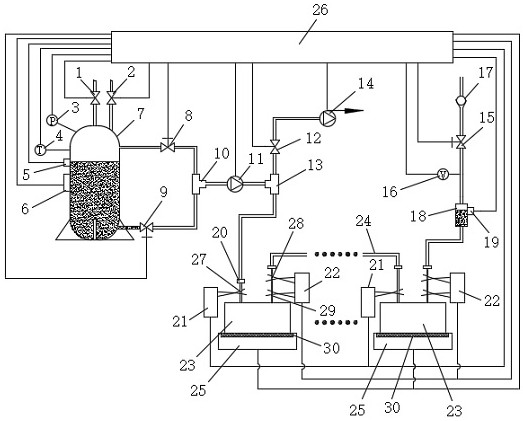

[0024] see figure 1 , the present invention provides a technical solution: a uniform temperature plate filling system, including a working medium storage tank 7, a booster pump 11, a vacuum pump 14, a liquid storage tank 18, a dynamic weighing device 25 and a controller 26, the said The top of the working medium storage tank 7 is provided with a filling pipe, and the filling pipe is provided with a filling solenoid valve 1, and the top of the working medium storage tank 7 is connected with a venting pipe, and the venting pipe is provided with a venting pipe. Solenoid valve 2, the working medium storage tank 7 is connected with a pressure sensor 3 and a temperature sensor 4, the side wall of the working medium storage tank 7 is provided with a first photoelectric liquid level gauge 5 and a first heater 6; a booster pump 11 The inlet end and the outlet end are respectively connected with the first three-way joint 10 and the second three-way joint 13 through the connecting pipe, ...

Embodiment 2

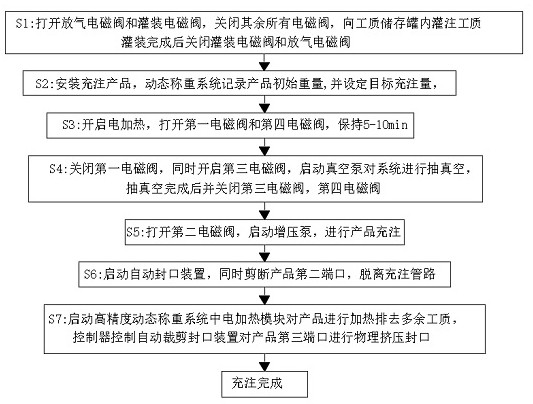

[0031] see Figure 1-2 , the present invention also provides a technical solution: a method for filling a temperature chamber, comprising the above-mentioned filling system for a chamber, including the following steps:

[0032] S1, open the air release solenoid valve 2 and the filling solenoid valve 1, close the first solenoid valve 8, the second solenoid valve 9, the third solenoid valve 12, and the fourth solenoid valve 15, and then fill the working fluid storage tank 7 Phase change working medium, when the first photoelectric liquid level meter 5 detects the liquid level of the working medium and transmits a signal to the controller 26, the controller 26 sends an instruction after receiving the signal from the first photoelectric liquid level gauge 5 to close the filling solenoid valve 1 and bleed solenoid valve 2;

[0033] S2, install the temperature equalizing plate 23, the controller 26 controls to start the dynamic weighing device 25 to record the initial weight of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com