Gantry crane cable stringing mechanism

A technology for cable racks and gantry cranes, applied in the field of gantry crane cable racking mechanisms, can solve the problems of rain and snow weather, low use efficiency, high installation cost, etc., and achieve the effects of convenient installation, low use cost, and anti-drag wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

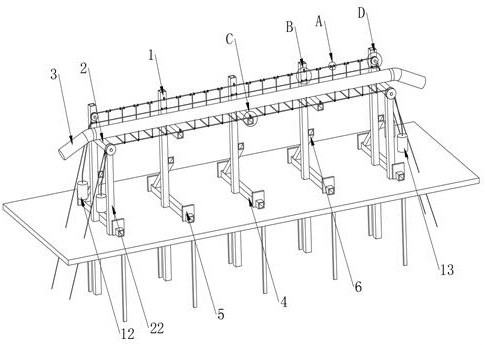

[0032] Refer to the manual attached Figure 1-Figure 7 , a kind of gantry crane cable wiring mechanism of this embodiment includes: a plurality of lateral stabilizer bars 4 and a plurality of uprights 1, cables 3, two pulley shafts one 7 and two pulleys one 8, two pulley shafts two 9 and Two pulleys two 10.

[0033] The column 1 and the stabilizer bar 4 are both made of square tubes. The column 1 is welded on the left side of the stabilizer bar 4. The upper end of the front side of each column 1 is fixedly installed with a support beam 2. 3 is arranged above the support cross bar 2, and the support cross bar 2 is used to receive the cable 3.

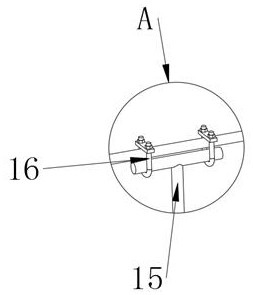

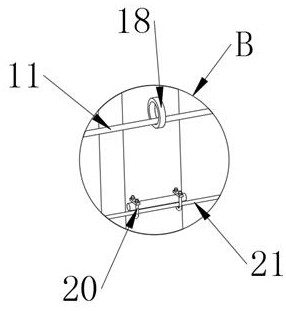

[0034] The two pulley shafts 1 7 are respectively fixed and installed on the upper ends of the front sides of the two uprights 1 on the left and right sides. There is a main suspension wire rope 11 on it, two pulleys one 8 are used to support the main suspension wire rope 11, the depth of the pulley groove in the pulley one 8 is greate...

Embodiment 2

[0044] Refer to the manual attached figure 1 , a gantry hanging cable wiring mechanism of this embodiment, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that this embodiment is provided with a supporting inclined rod 6 between the lateral stabilizer bar 4 and the upright column 1, One end of the support inclined rod 6 is fixedly connected to the rear side of the upper surface of the stabilizer bar 4 , and the other end of the support inclined rod 6 is fixedly connected to the right side of the column 1 . The support inclined rod 6 ensures that the stabilizer rod 4 The stability when connected with the upright column 1 ensures the stability of the device during use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com