Method and installation of cable mill for producing a cable at least partially untwisted

A technology for making a device and a manufacturing method, applied in the field of cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

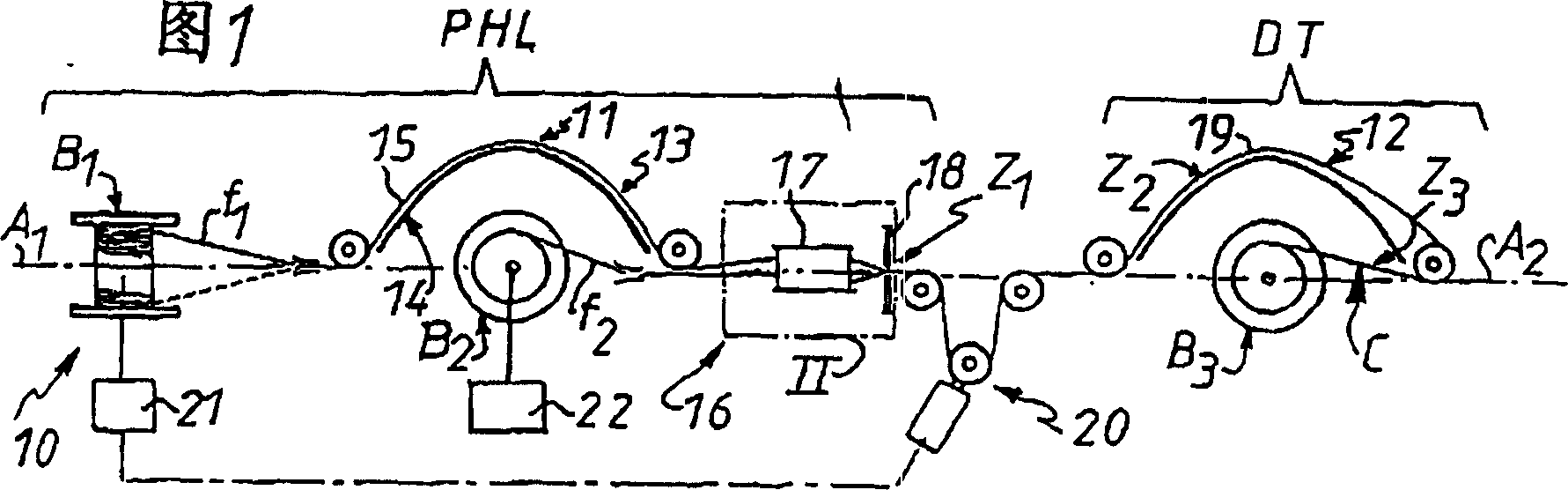

[0035] According to the invention, the cable making device 10 used for this purpose comprises in series on the same production line: first a twist-free combining station 11 suitable for joining the two wires f1, f2 without twisting them individually; The resulting combination undergoes at least one twisting station 12 of twisting.

[0036] In the embodiment shown, the twist-free assembly station 11 comprises at least one bridge 13 in addition to the first release reel B1 from which the electric wire f1 is paid out. In practice, the bridge 13 is formed by a combination device 14 in which there is a second release reel B2 from which the electric wire f2 is paid out.

[0037] Since this example only involves the production of a single twisted pair, there is only one bridge frame 13 .

[0038] As shown in FIG. 1 , for example, the combination device 14 of the bridge 13 is a bracket-shaped combination device.

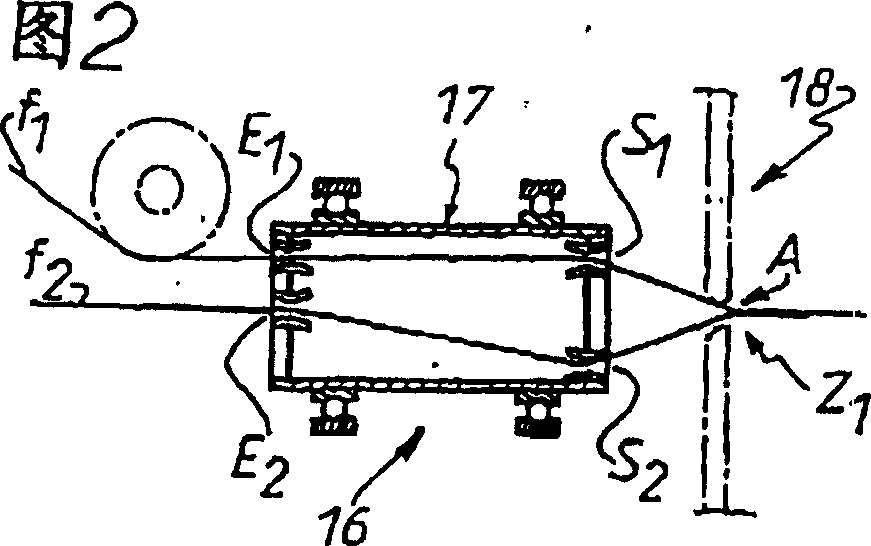

[0039] The combination device 14 comprises a bracket-shaped frame 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com