Light-emitting diode lamp

A technology of light-emitting diodes and lamps, which is applied to the semiconductor devices of light-emitting elements, light sources, electric light sources, etc., and can solve the problems of low emission angle, time-consuming and labor-intensive, and inability to project a large angle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Although the present invention will be described below in accordance with most of the embodiments shown in the drawings, the present invention is not limited to the structures of these embodiments, and it is understood that it includes various design changes described in the scope of the patent application.

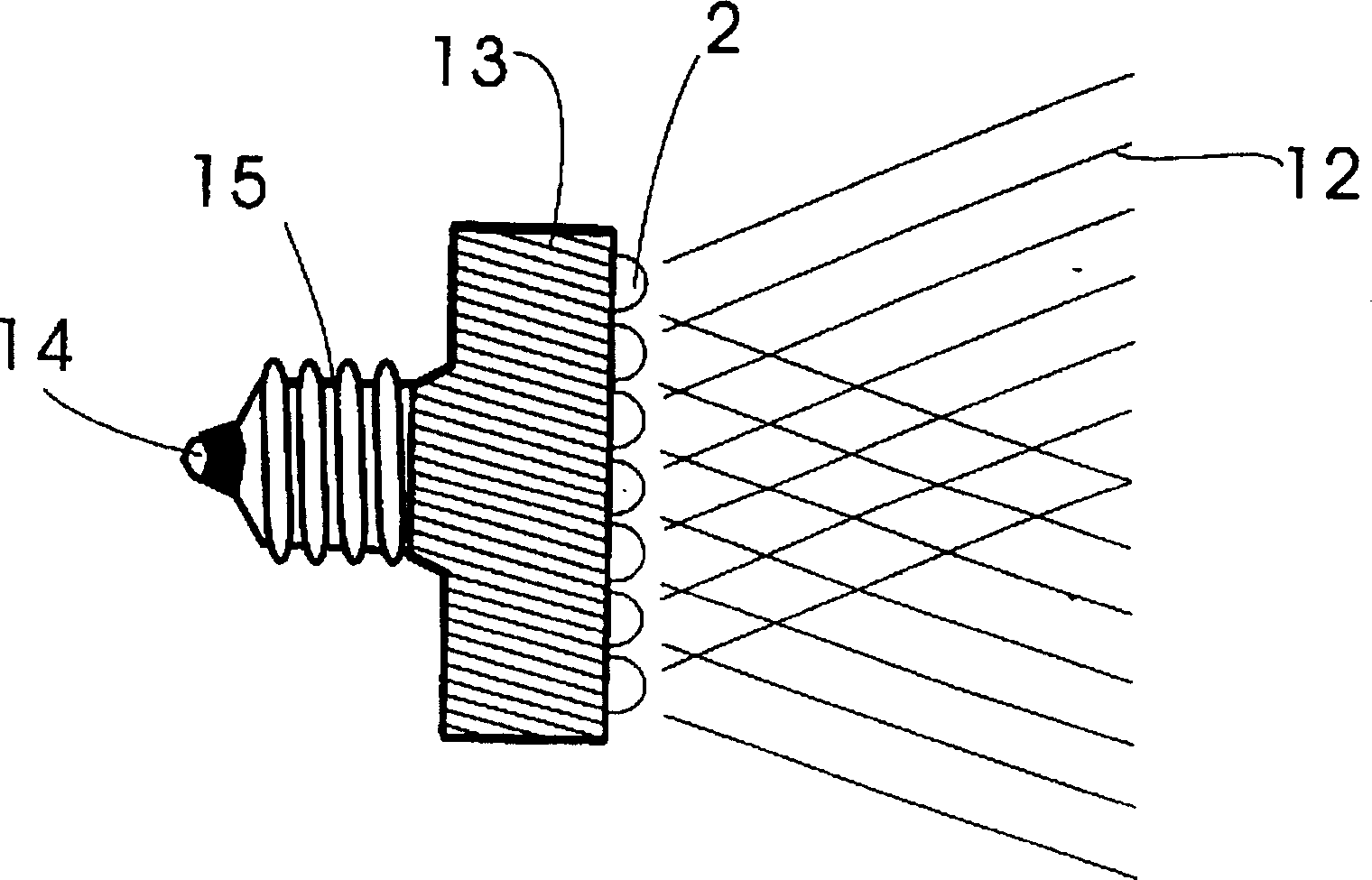

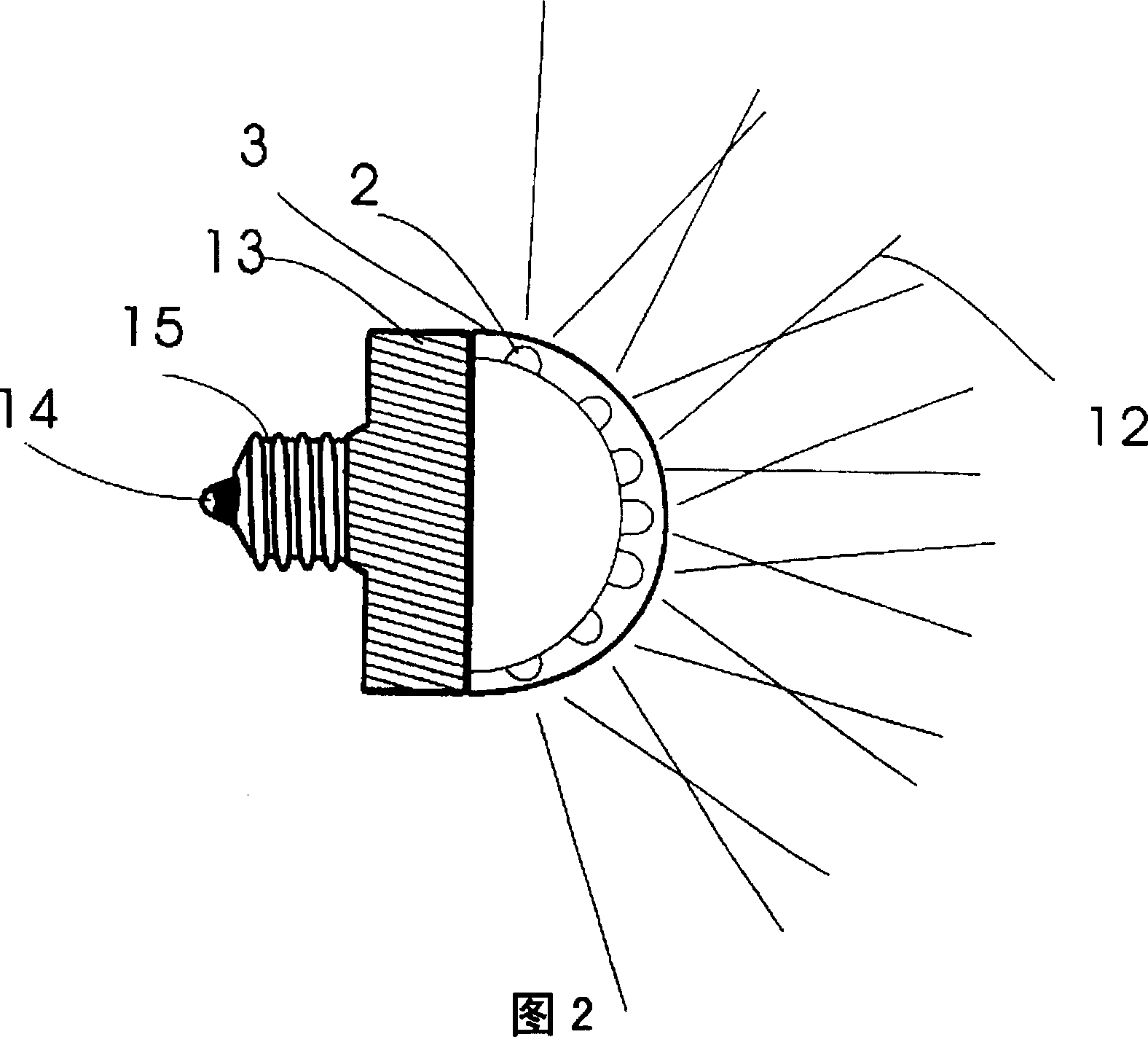

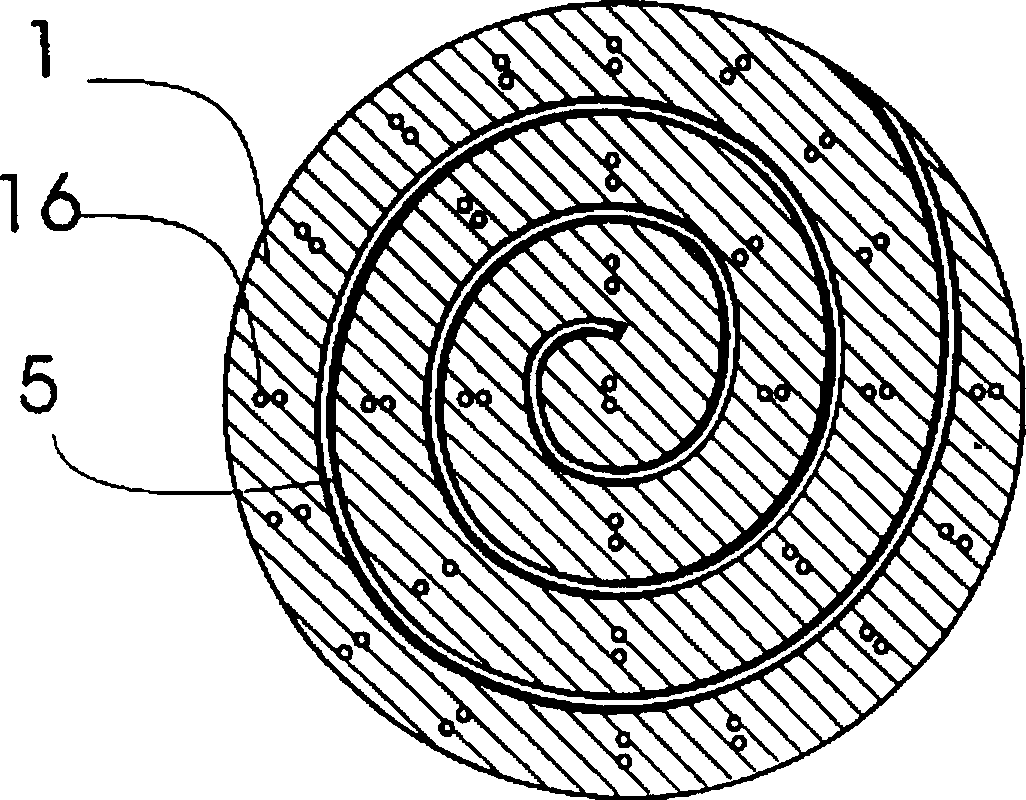

[0049] The light-emitting diode lamp of the present invention includes a plurality of LED elements, a flat circuit board 1, an LED fixing cover 3, a circuit board seating seat 4, and an LED lamp base 13 with a bulb copper head 15 (see Figure 7 ); The present invention cuts or punches a flat circuit board into a multilayer ring shape, which can be roughly divided into "spiral non-crossover manufacturing method". image 3 , Figure 4 , "Spiral jumper manufacturing method" see Figure 8 , Picture 9 , "Concentric circle connection hypotenuse production method" see Figure 13 , Figure 14 , "Concentric Circle Making Method" seeFigure 18 , Figure 19 , The three methods a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com