Separable bottom stopper for zipper

A stopper, disengagement technology, applied in the direction of sliding fastener components, applications, fasteners, etc., can solve the problems of not having raised locking claws, not being able to be replaced by reverse sliding parts, and unable to hold sliding parts stably, etc. Achieve smooth opening/closing operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, preferred embodiments of the releasable bottom end stopper for a slide fastener of the present invention will be described with reference to the accompanying drawings.

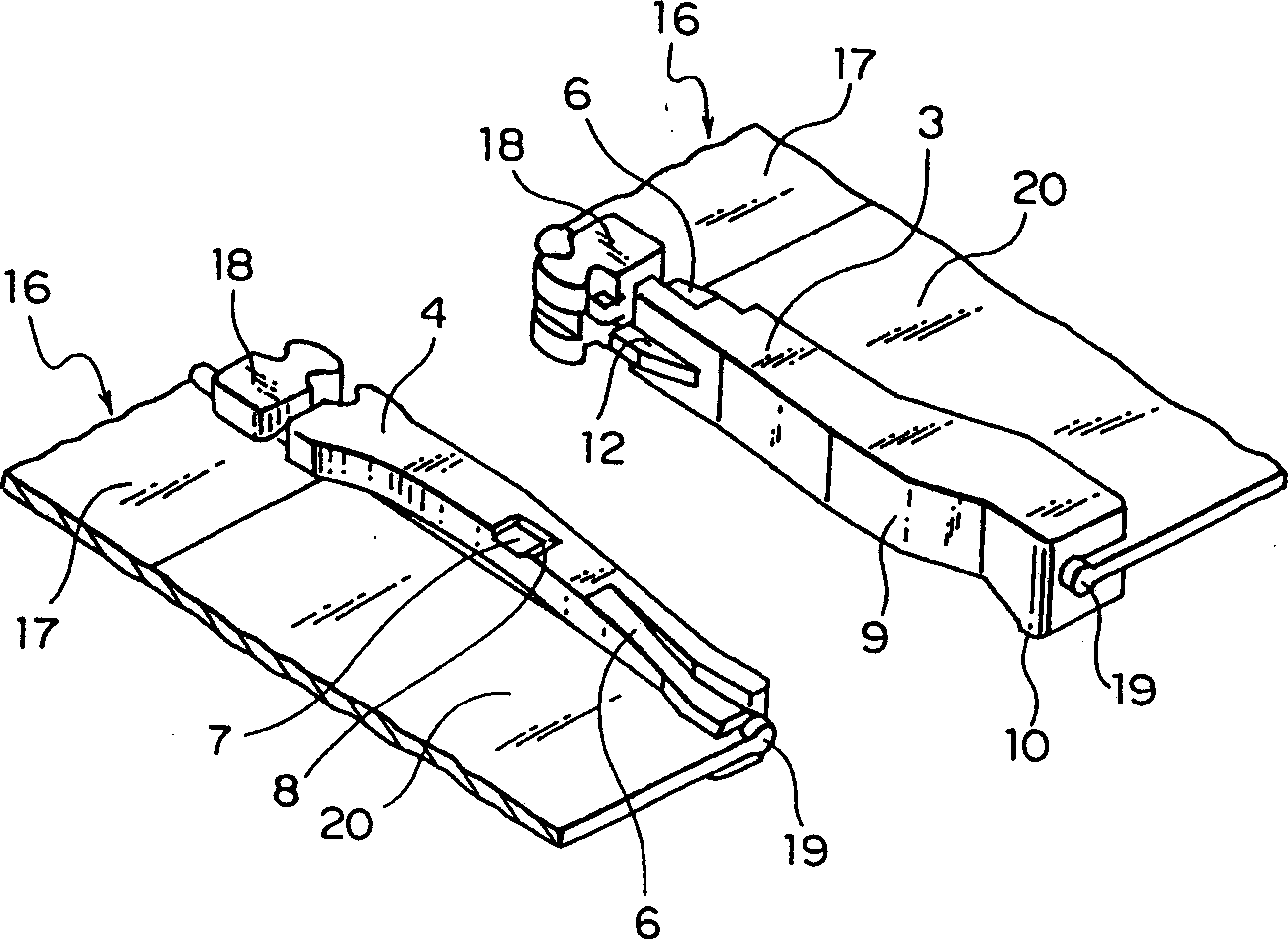

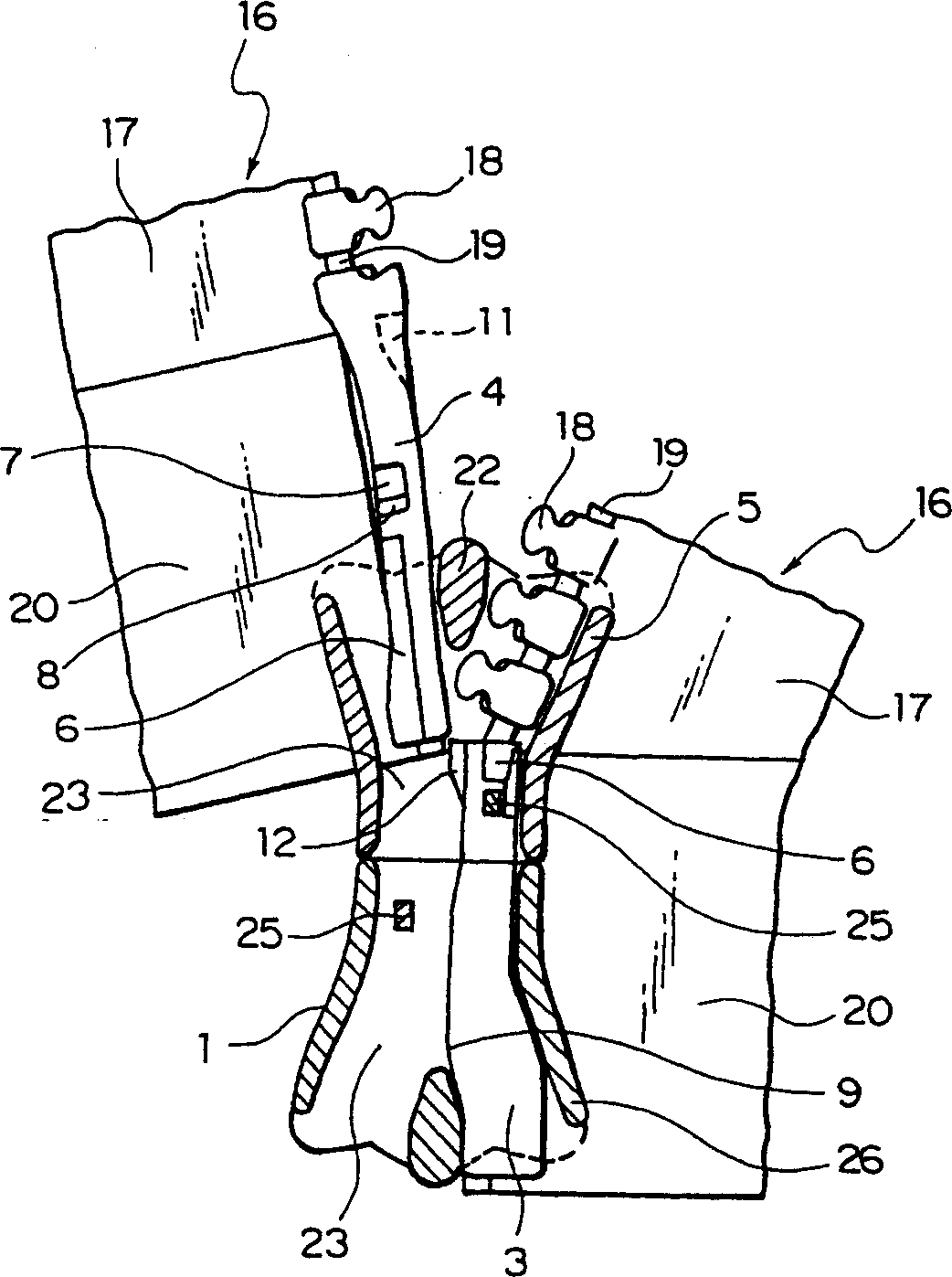

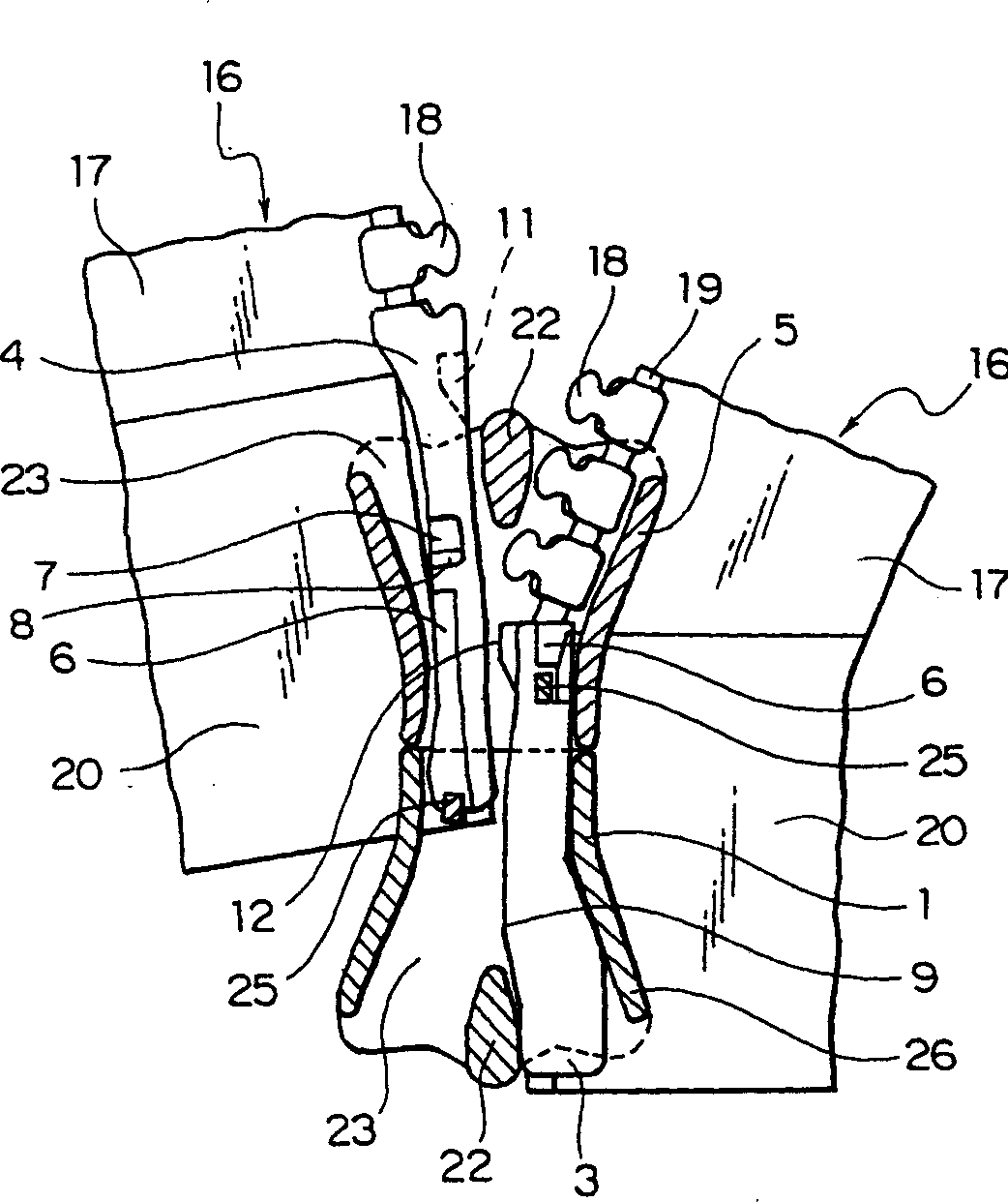

[0036] A first embodiment of the disengageable bottom end stop of the present invention is Figure 1 to Figure 4 As shown, the disengageable bottom end stopper for zippers of the present invention includes three components: a reverse opening slide 1 , a female insert 3 and a male insert 4 . The slide 5 for opening / closing the joint chain 15 is inserted into the reverse opening slide 1 through the joint chain 15 . In the reverse opening slider 1 and slider 5, such as Figure 6 As shown, the body 21 is molded by die-casting from a metal such as zinc alloy and aluminum alloy, wherein an upper plate 27 and a lower plate 28 arranged parallel to each other are connected by the ends of their rhomboids 22 . A cover 24 having a protruding locking pawl 25 at one side made by pressing a metal plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com