Improved apparatus and method for detecting broken pin hole and loom used together

A technology of knitting needles and hooks, applied in the field of circular knitting machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The invention will be described in more detail hereinafter with reference to the accompanying drawings, in which several preferred embodiments of the invention are shown. However, the present invention may be embodied in many different forms and should not be construed as limited to only illustrated embodiments; To those skilled in the art, these embodiments will fully convey the scope of the invention. Like reference numerals denote like elements in the various drawings.

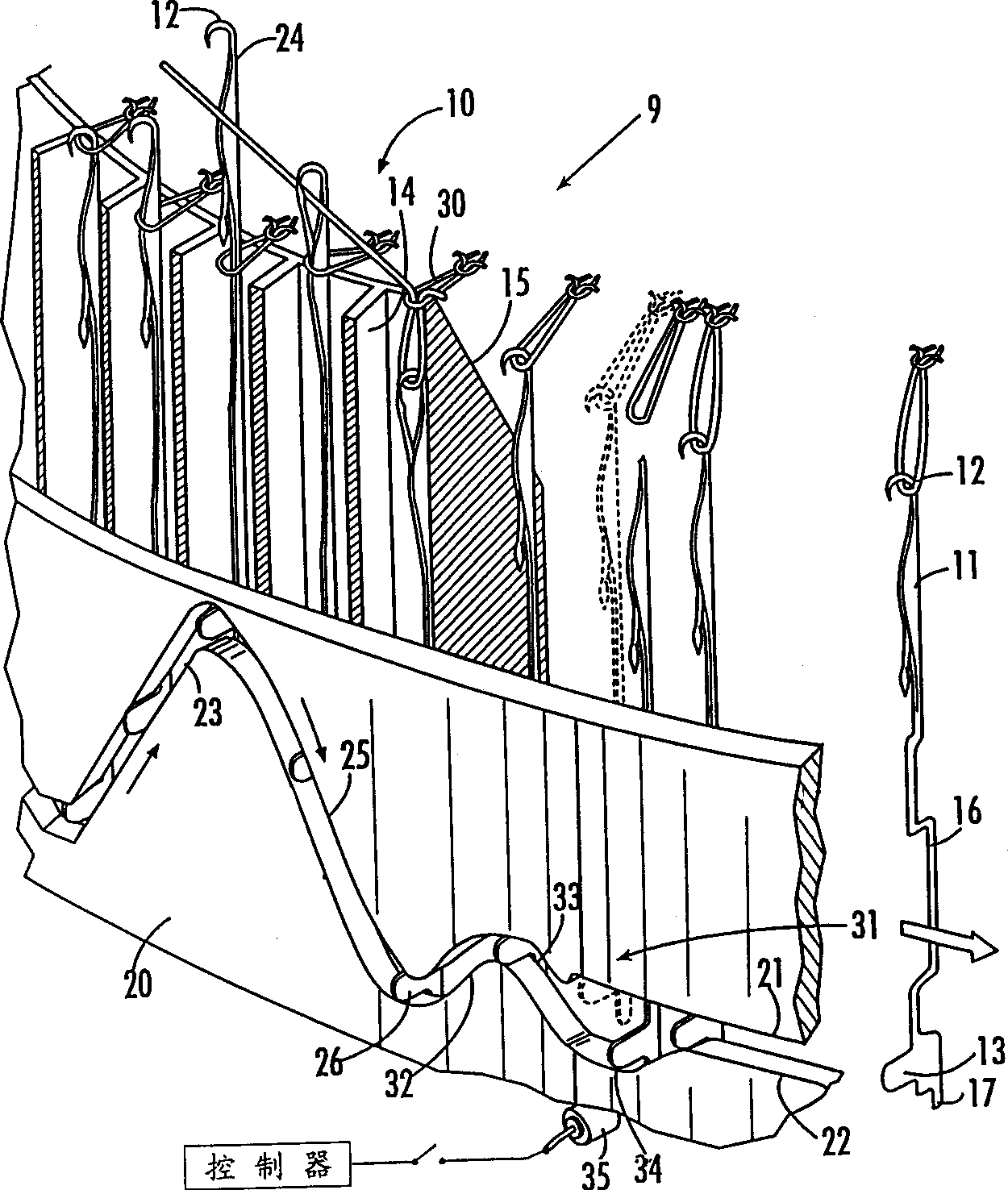

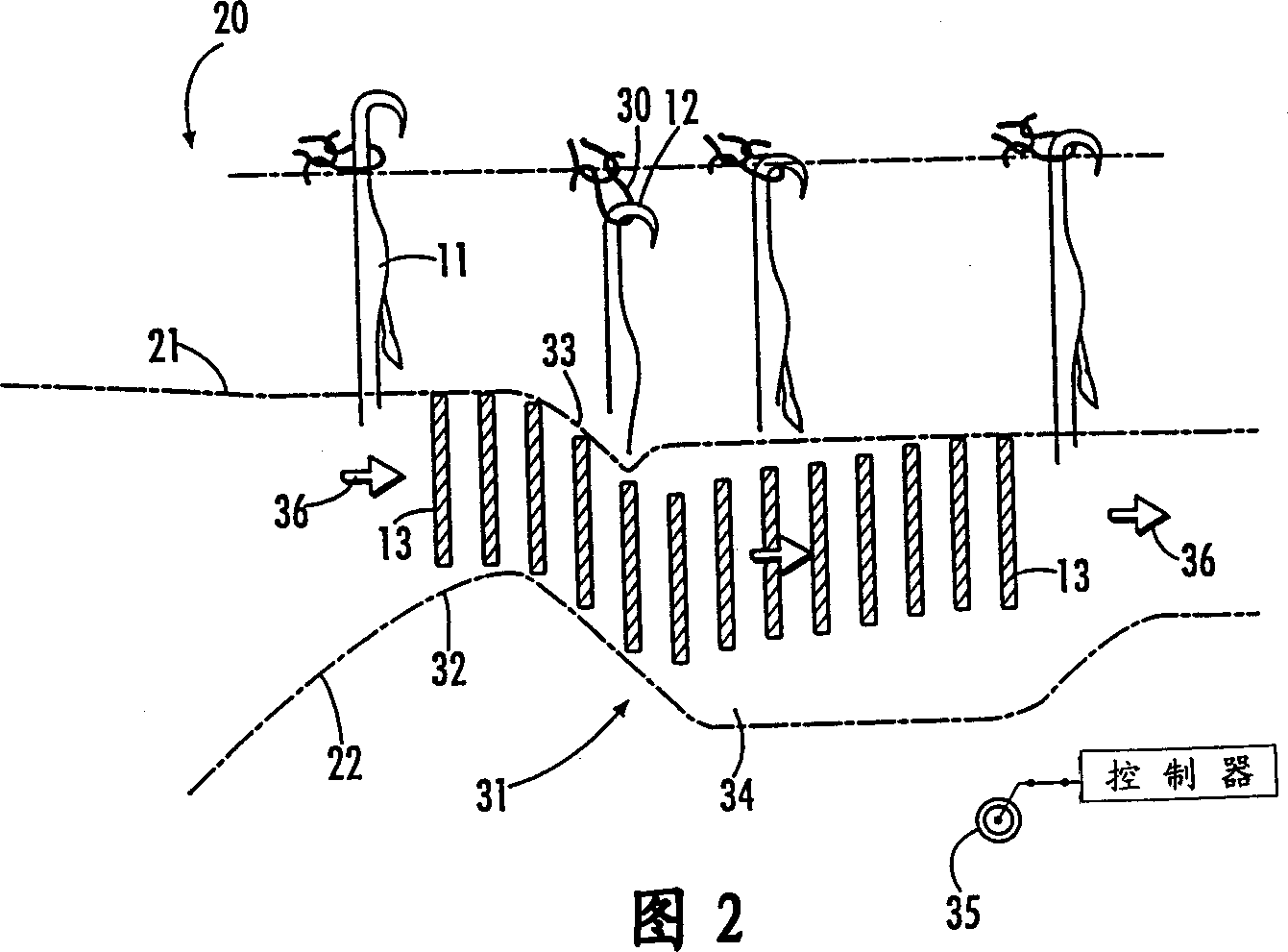

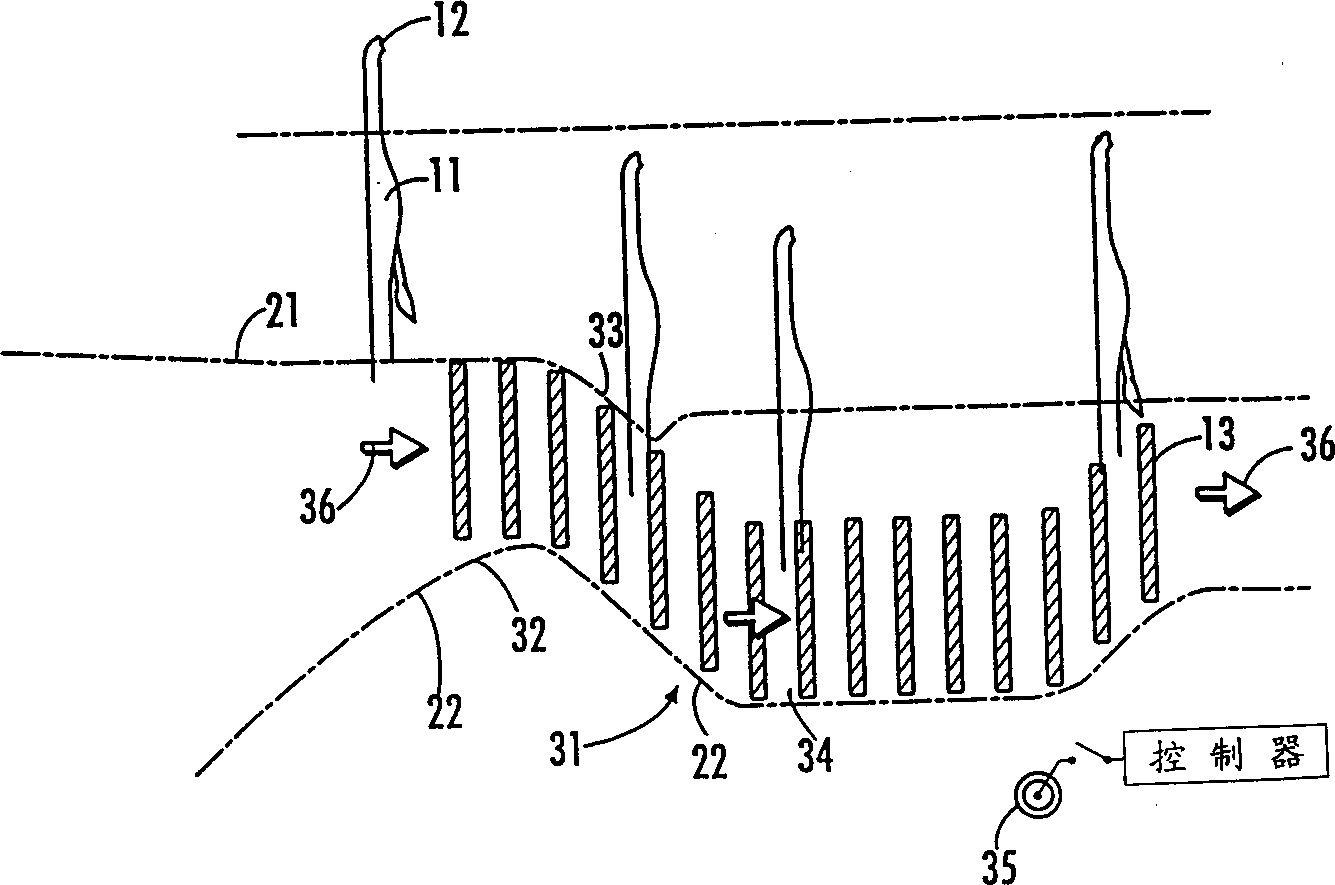

[0026] Now refer to the attached figure 1 , and reference numeral 10 shows a part of cylinder 15 and cylinder cam 20 of cylinder type circular knitting machine 9 . Knitting needles 11 with hooks 12 and butts 13 are arranged in translational movement in the direction of a needle bar 16 in a needle channel 14 of a cylinder 15 of the knitting machine. Each needle 11 also includes a terminal end 17 at the end opposite to the end of said hook 12 . According to the first embodiment, the needle hook 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com