Apparatus and method for controlling magnetic head loading in disk drive

A disk drive and magnetic head loading technology, which is applied in the manufacture of magnetic flux-sensitive magnetic heads, driving/moving recording heads, recording information on disks, etc., can solve problems such as data destruction and destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

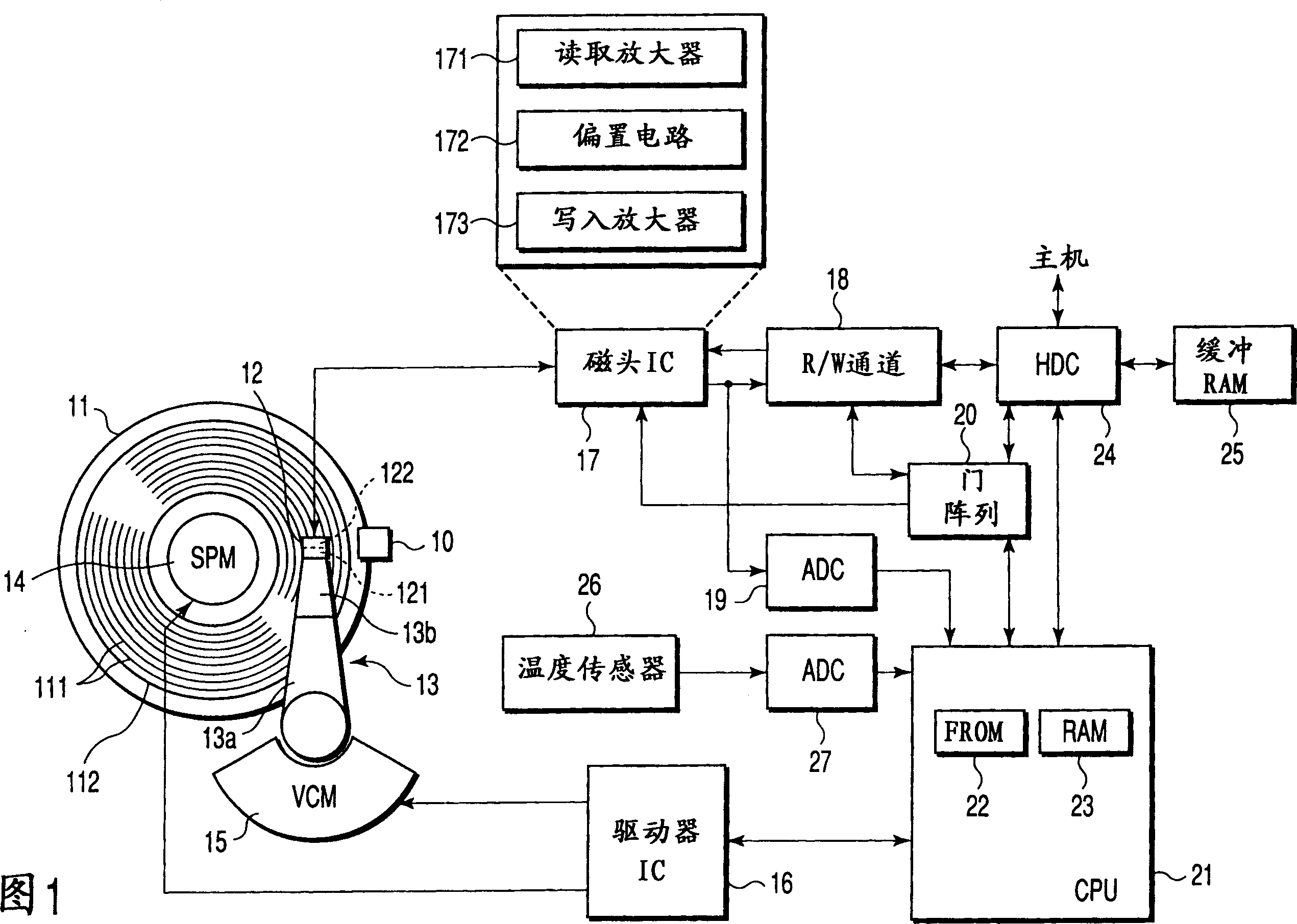

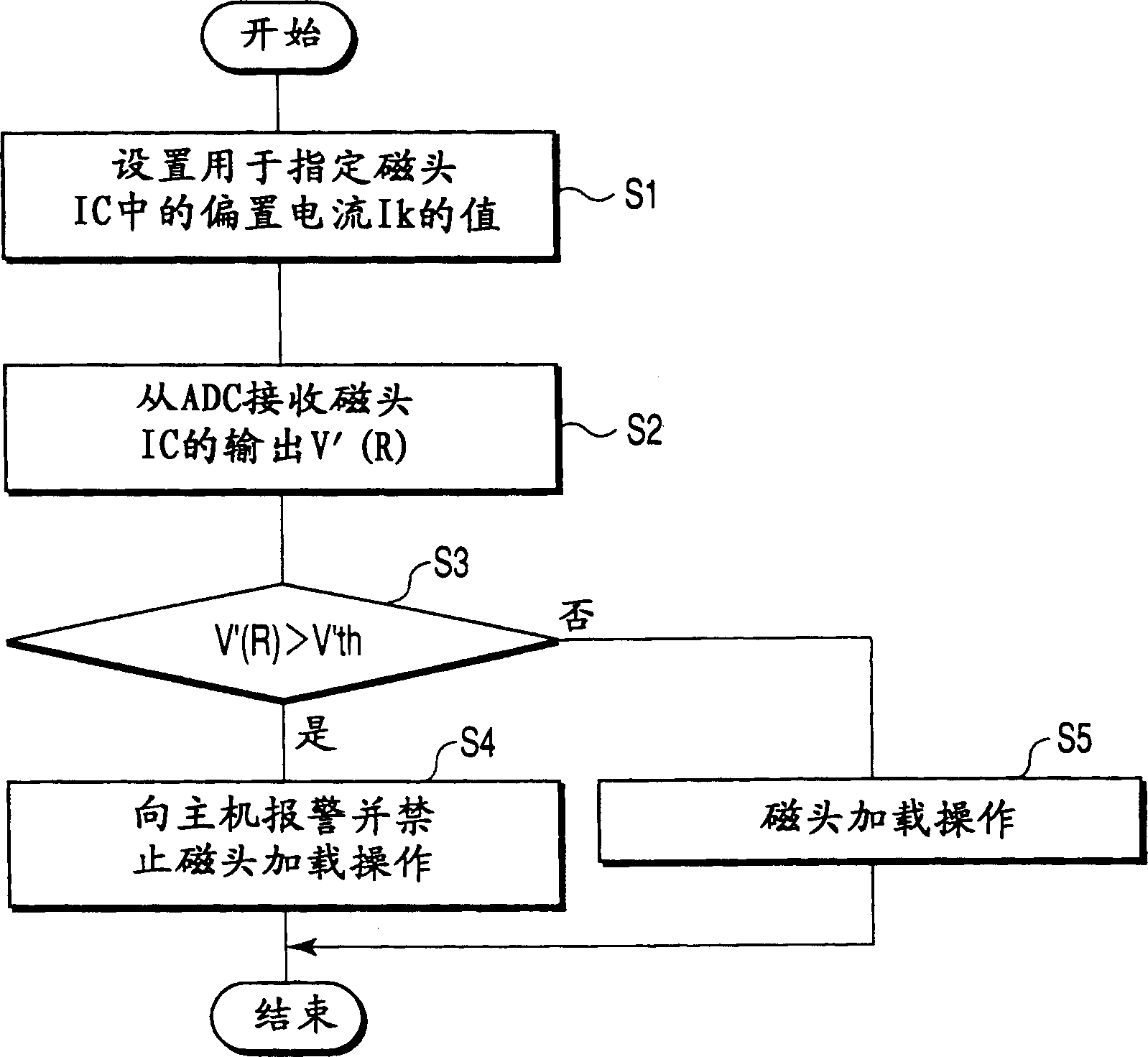

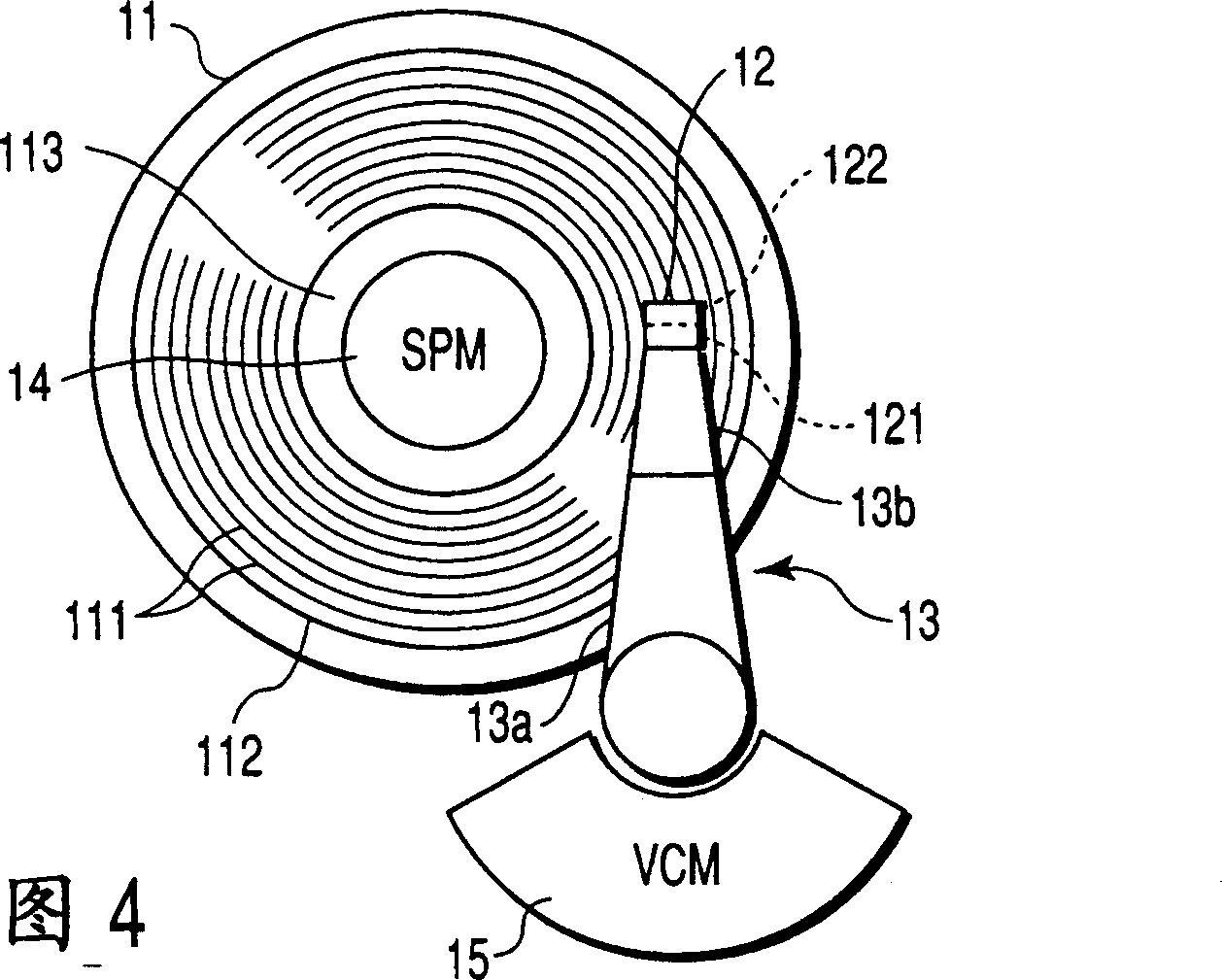

[0016] FIG. 1 is a block diagram illustrating the configuration of a hard disk drive according to a first embodiment of the present invention. In the hard disk drive (hereinafter referred to as HDD) shown in FIG. 1 , a disk medium (disk medium) 11 has two upper and lower disk surfaces. One or both disk surfaces of the magnetic disk medium 11 serve as recording surfaces on which data is magnetically recorded. A ring data area 112 is fixed on each recording surface of the magnetic disk medium 11 . The data area 112 includes a plurality of concentric tracks (data tracks) 111 . A head (magnetic head) 12 is provided for each recording surface of the magnetic disk medium 11 . The magnetic head 12 is used to write data to the magnetic disk medium 11 (data recording) and to read data from the magnetic disk medium 11 (data reproduction). The magnetic head 12 is a combined magnetic head including a read head 121 and a write head 122 integrated on a single slider. The read head 121 i...

no. 2 example

[0042]FIG. 3 is a block diagram of a configuration of a hard disk drive (HDD) according to a second embodiment of the present invention. In FIG. 3, the same parts as those in FIG. 1 are denoted by the same reference numerals. The HDD shown in FIG. 3 is characterized in that the read head 121 is not used as a magnetic field sensor for detecting a magnetic field applied to the HDD, but a special-purpose magnetic field sensor 30 for this purpose is provided. The magnetic field sensor 30 detects a magnetic field applied to the HDD and converts the magnetic field into, for example, a voltage. ADC19 converts the detection output of the magnetic field sensor 30 into a digital value. The CPU 21 receives digital values from the ADC 19 when it performs head loading. Then, like in step S3 of the first embodiment, the CPU 21 compares the digital value with a predetermined threshold. If the CPU 21 loads the magnetic head 12 on the data area 112 of the magnetic disk medium 11, it deter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com