Method for burning CD ROM

A burning method and optical drive technology, which are applied in the direction of recording/reproducing by optical methods, optical recording heads, optical recording carriers, etc. efficiency issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

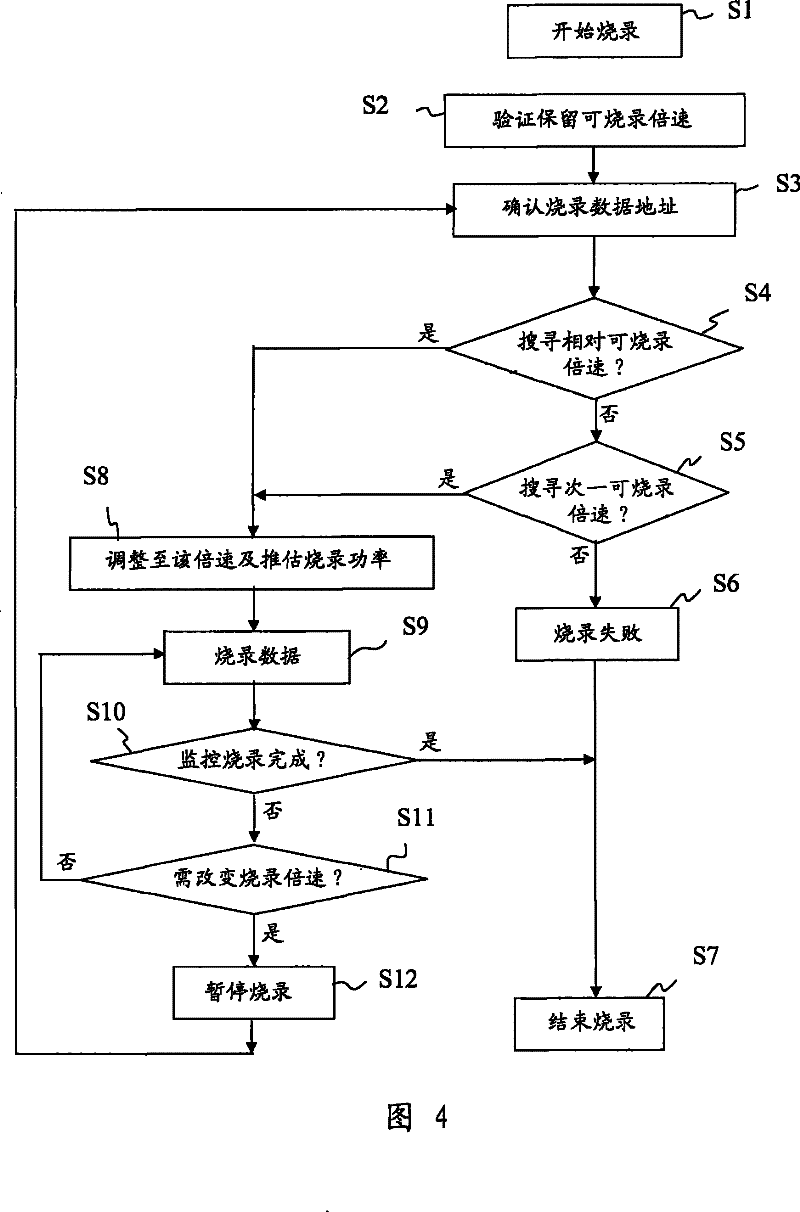

[0042] In order to achieve the above-mentioned purpose, the technical means and effects thereof adopted by the present invention are now cited as preferred embodiments, and are described as follows in conjunction with the accompanying drawings.

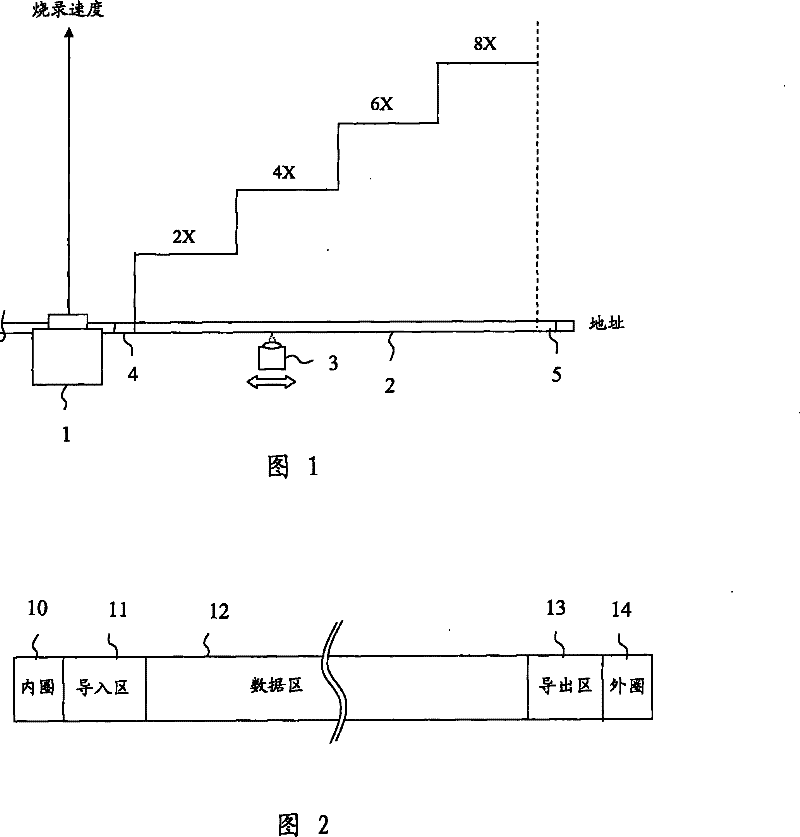

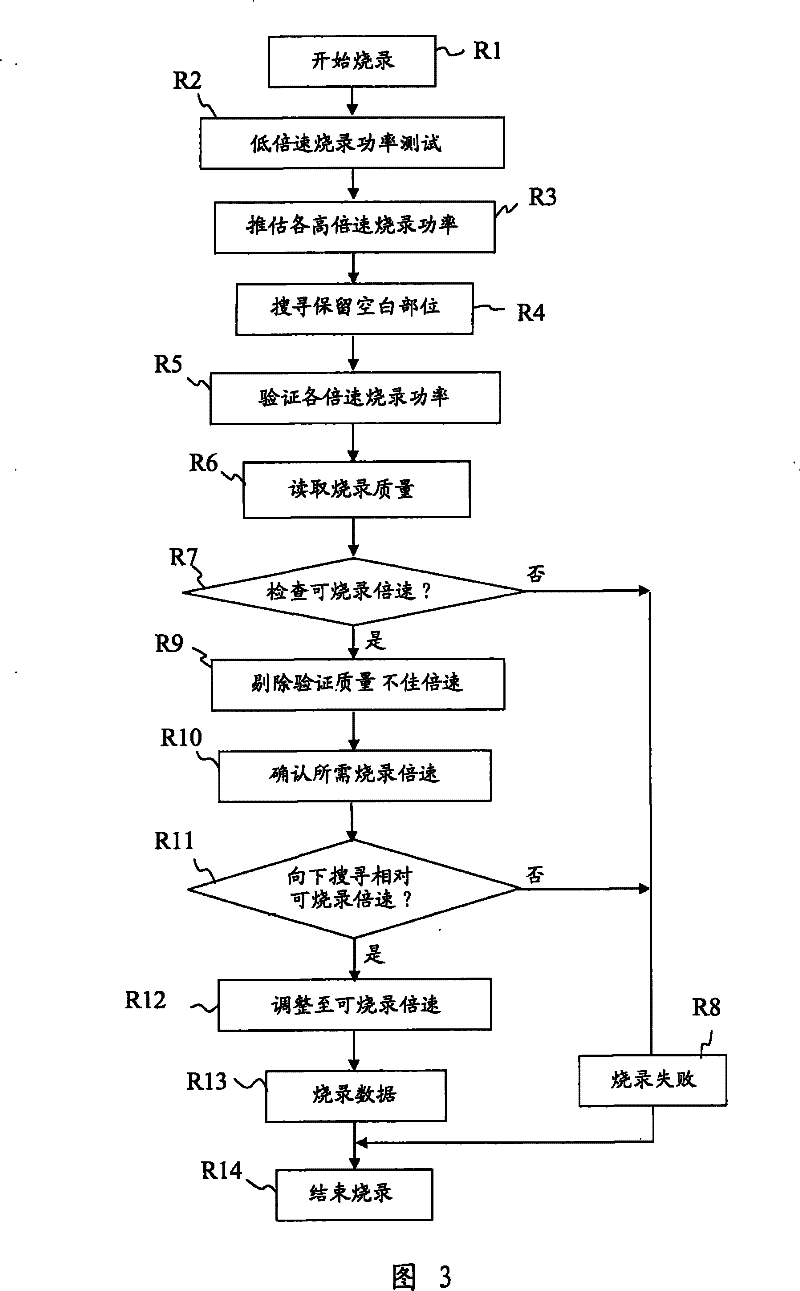

[0043] Please refer to figure 2 , which is a schematic diagram of the data structure of the optical disc. Generally, a circular optical disc has a spiral data track. The data track runs from the vicinity of the central hole of the optical disc to the vicinity of the outer edge of the optical disc. 11. Sections such as data area 12, lead-out area 13, and outer circle area 14. The inner circle area 10, together with the outer circle area 14, is used for burn-in testing the best burning power of the optical disc. The lead-in area 11 is used to record the data directory and characteristic information of the optical disc, which includes some reserved blank parts. The data area 12 is the position where the optical drive actually records ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com