Disk drive device

A disk drive and disk technology, applied in the direction of recording information storage, instruments, etc., can solve the problems of weakening the strength of the tray 203 and not protecting the bottom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

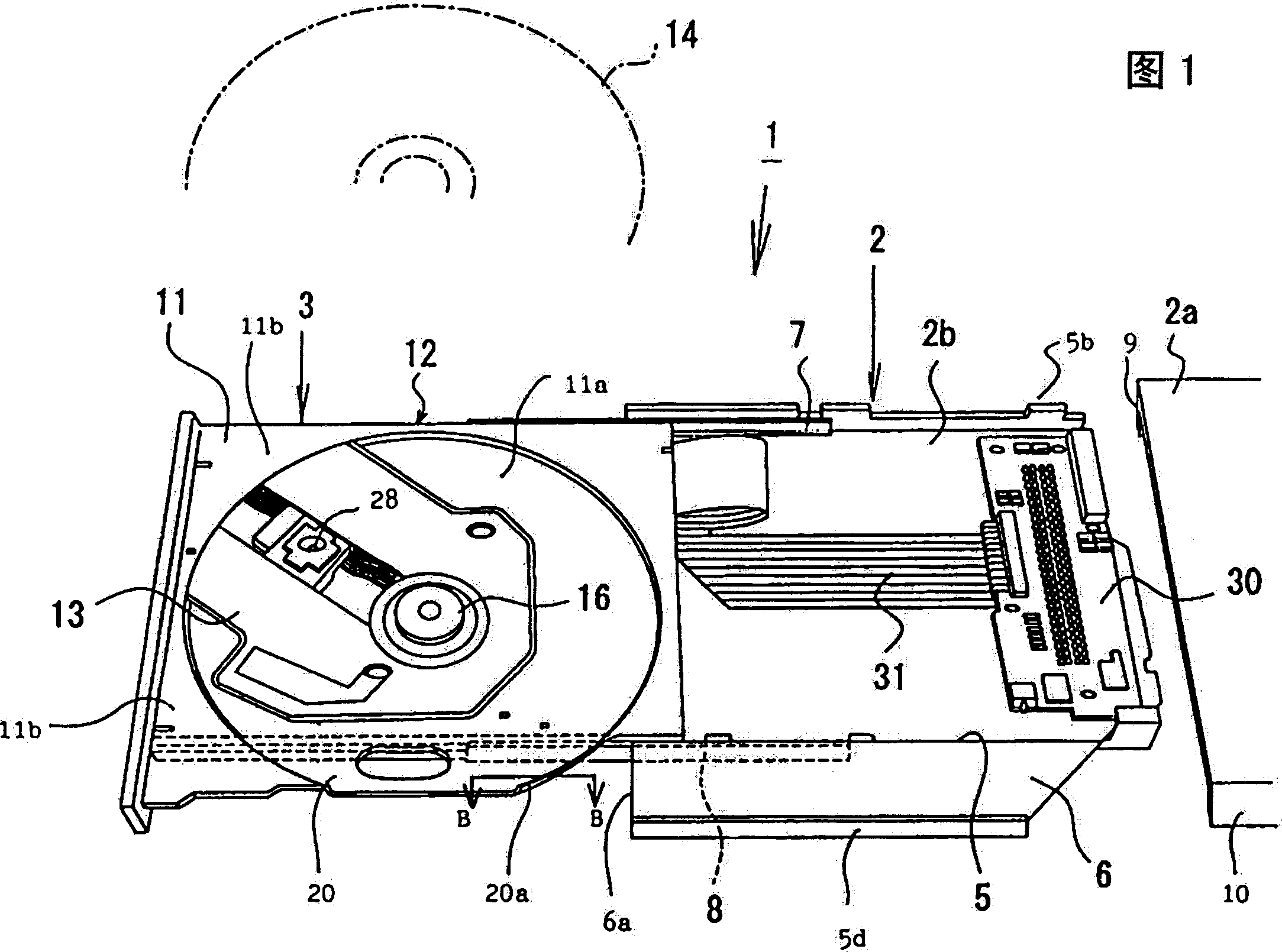

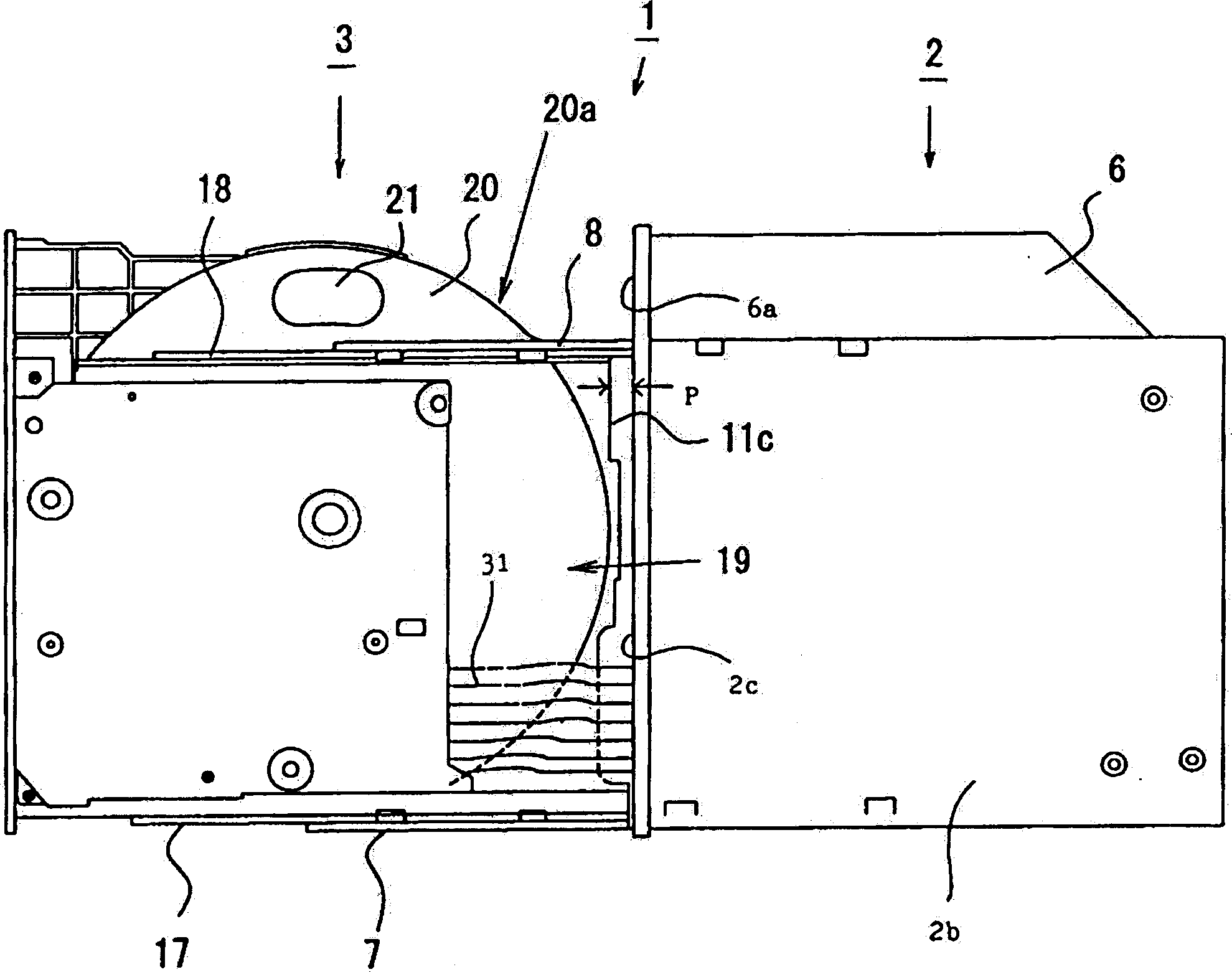

[0031] As shown in FIG. 1 , the disk drive device 1 includes a main body chassis 2 and a tray 3 . The main body chassis 2 is a stamped and formed steel plate, and consists of a top plate 2a and a bottom plate 2b.

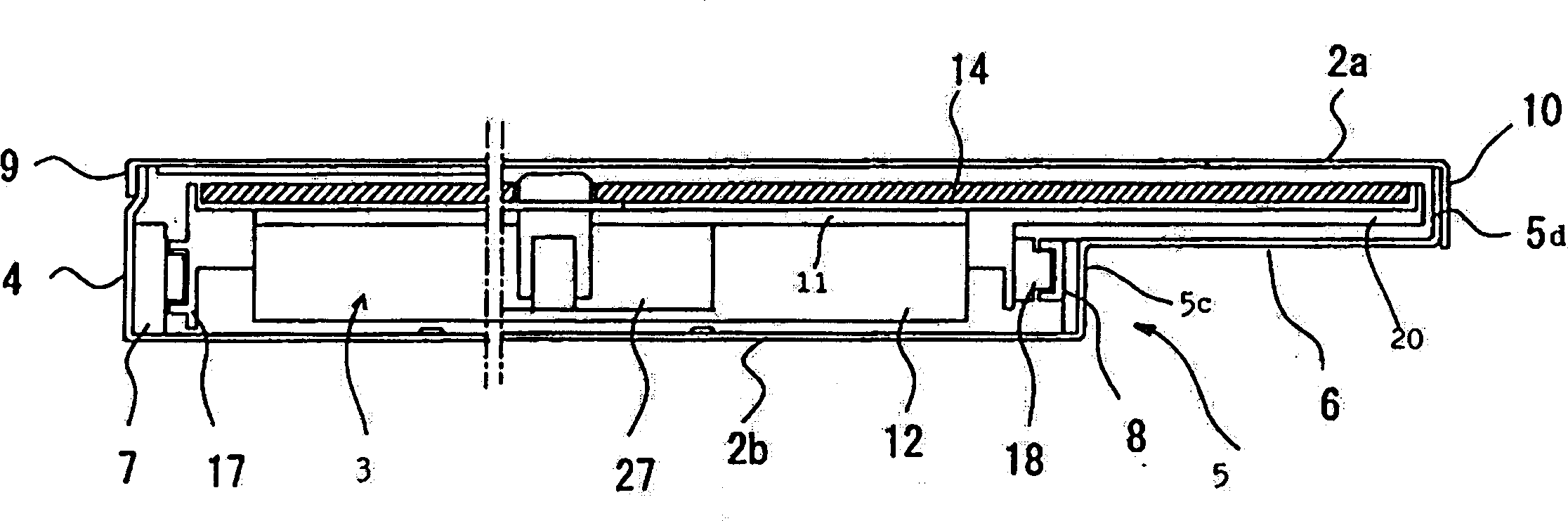

[0032] The top plate 2a is formed with side walls 9 and 10 on its left and right sides. Bottom plate 2b as figure 2 As shown in the sectional view of , side walls 4 and 5 are formed on the left and right sides thereof. The right side wall 5 is composed of a first right side wall 5c rising from the bottom end of the bottom plate 5a and a high platform portion 6 extending horizontally (to the right) from the upper end of the first right side wall 5c to the outside. The second right side wall 5d standing from the front end edge of the portion 6 is formed.

[0033] When making the top plate 2a cover the bottom plate 2b, as figure 2 As shown, the left side wall 9 of the top panel 2a is connected to the left side wall 4 of the bottom panel 2b, and the right side wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com