Unitary product cushioning structure

A cushioning structure and unitized technology, which is applied in shock absorbers, packaging, springs/shock absorbers, etc., can solve the problems that cannot be recycled, it is difficult to maintain integrity, and the polystyrene foam cushioning device is fragile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

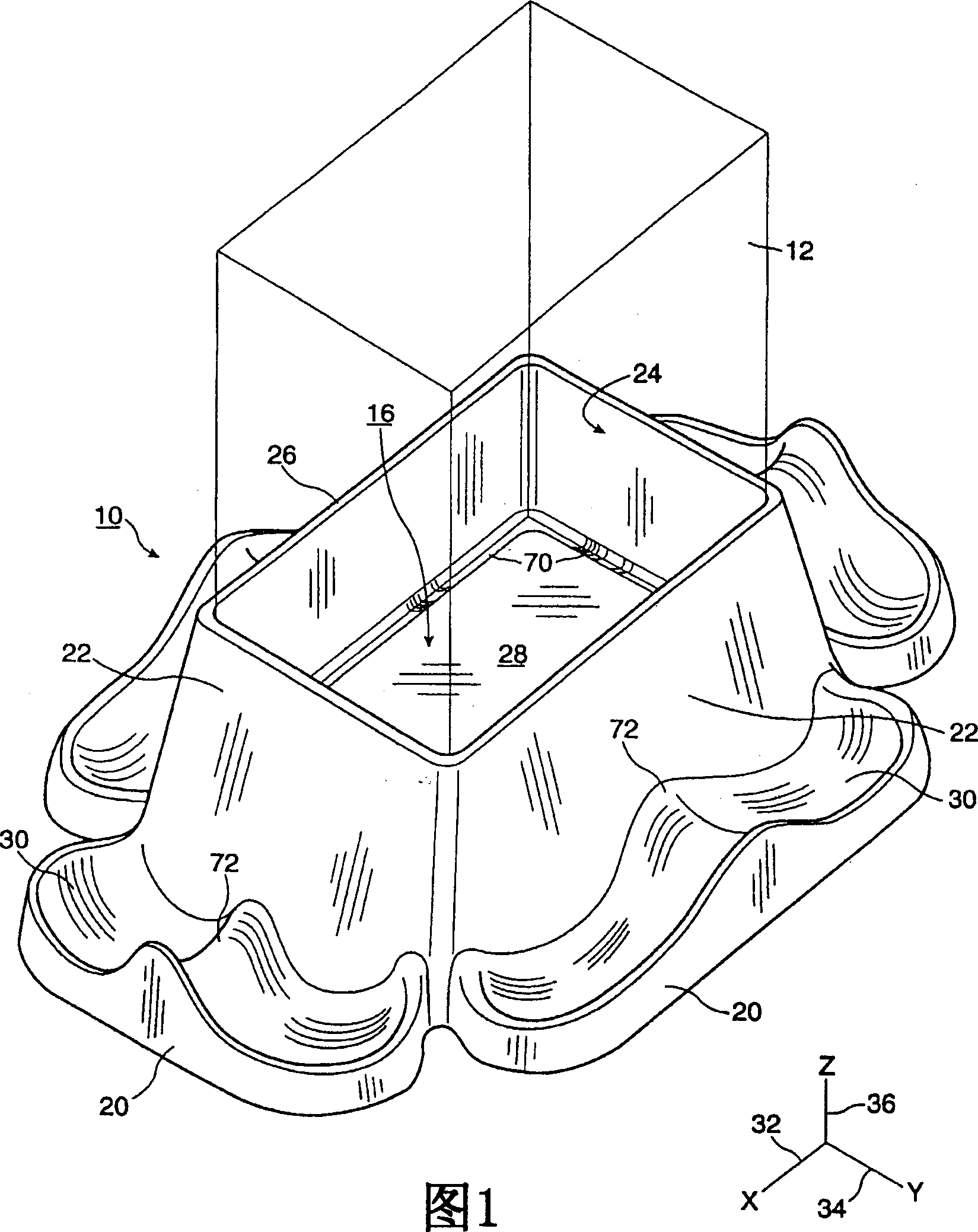

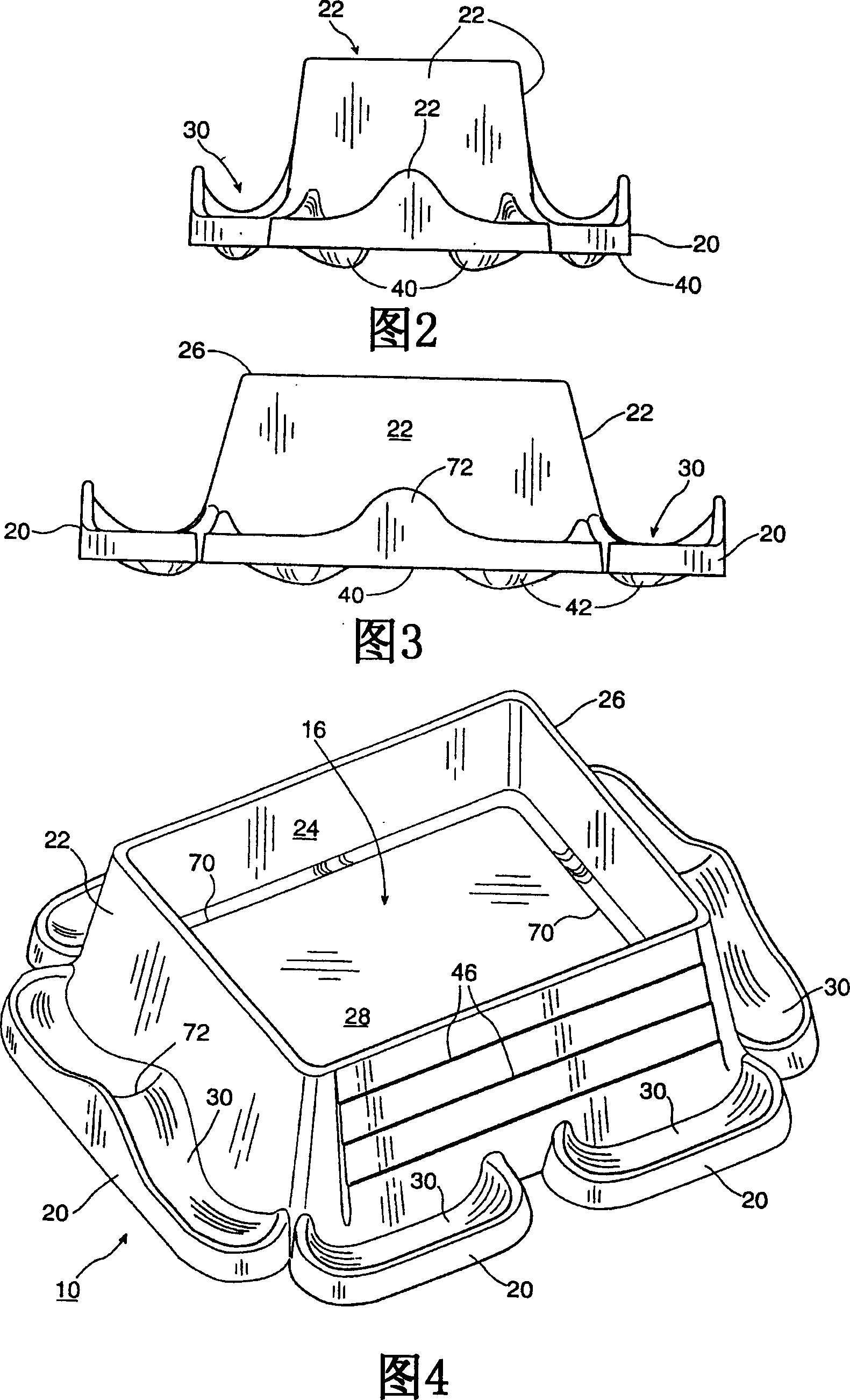

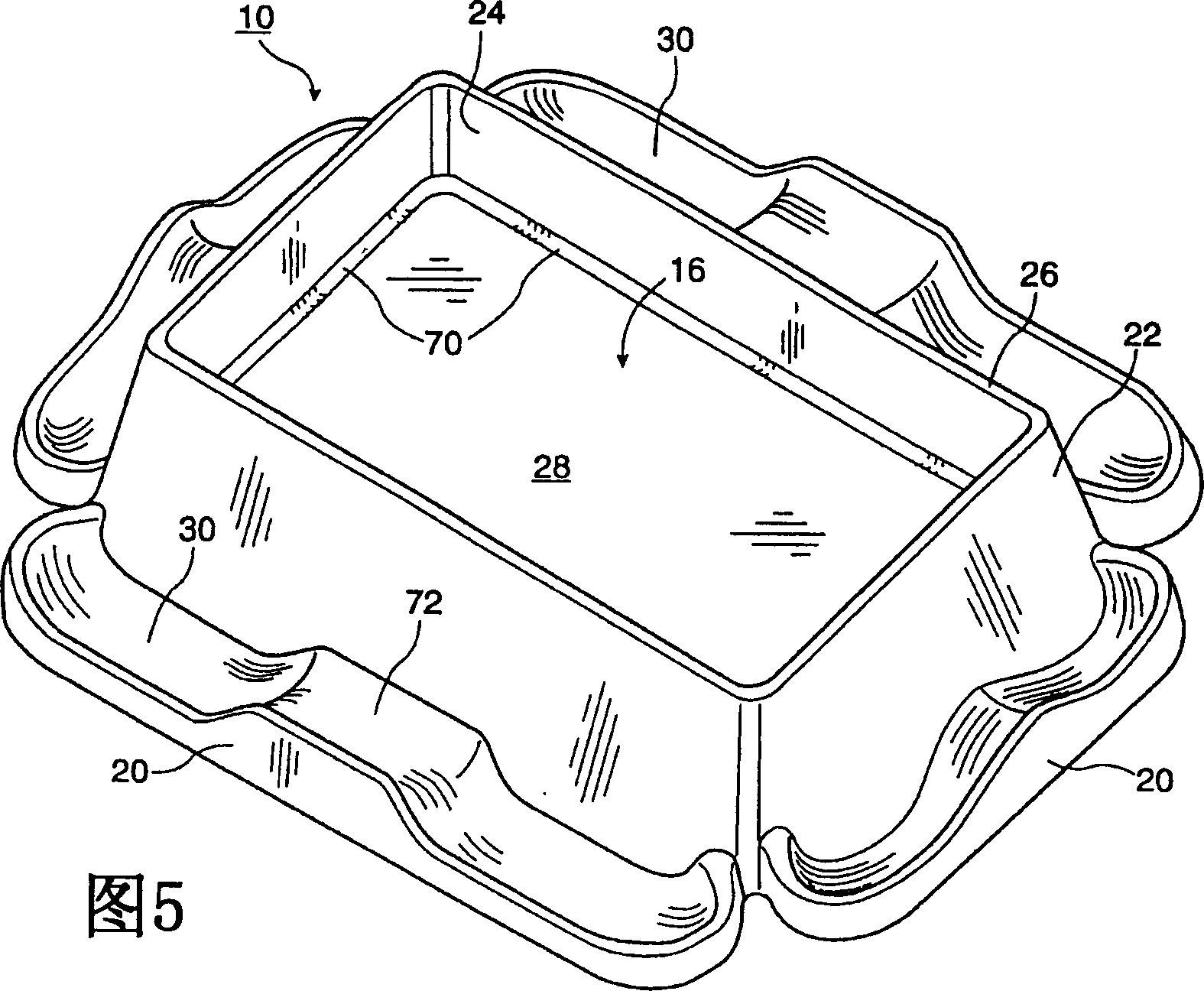

[0063] Returning to Fig. 1 first, around the design and function of the unitized product buffer structure of the present invention, we first introduce some basic concepts and assumptions to illustrate the specific terms here.

[0064] Mark 10 among Fig. 1 is a kind of typical unit type product cushioning structure of the present invention, and this cushioning structure is used together with product, and the overall outline of product is shown in mark 12, except the seismic performance that will pay attention to product, the characteristic of product It is not critical to the operation and function of the invention. Typically, such products are various electronic products such as PDAs, computer drives, tape drives, circuit boards, and the like. Other products include assembled computer cases and other various assembled electronic products, as well as other fragile products such as those made of glass or ceramics.

[0065]The main components of the unitary product cushioning st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com