Service life predication method of rotation machine for apparatus for making semiconduictor and semiconductor-making apparatus thereof

A technology for manufacturing equipment and life prediction, which is used in semiconductor/solid-state device manufacturing, idle speed devices, and liquid variable-capacity machinery, etc., and can solve the problems of decreased manufacturing efficiency of semiconductor devices, defective products, and increased maintenance frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

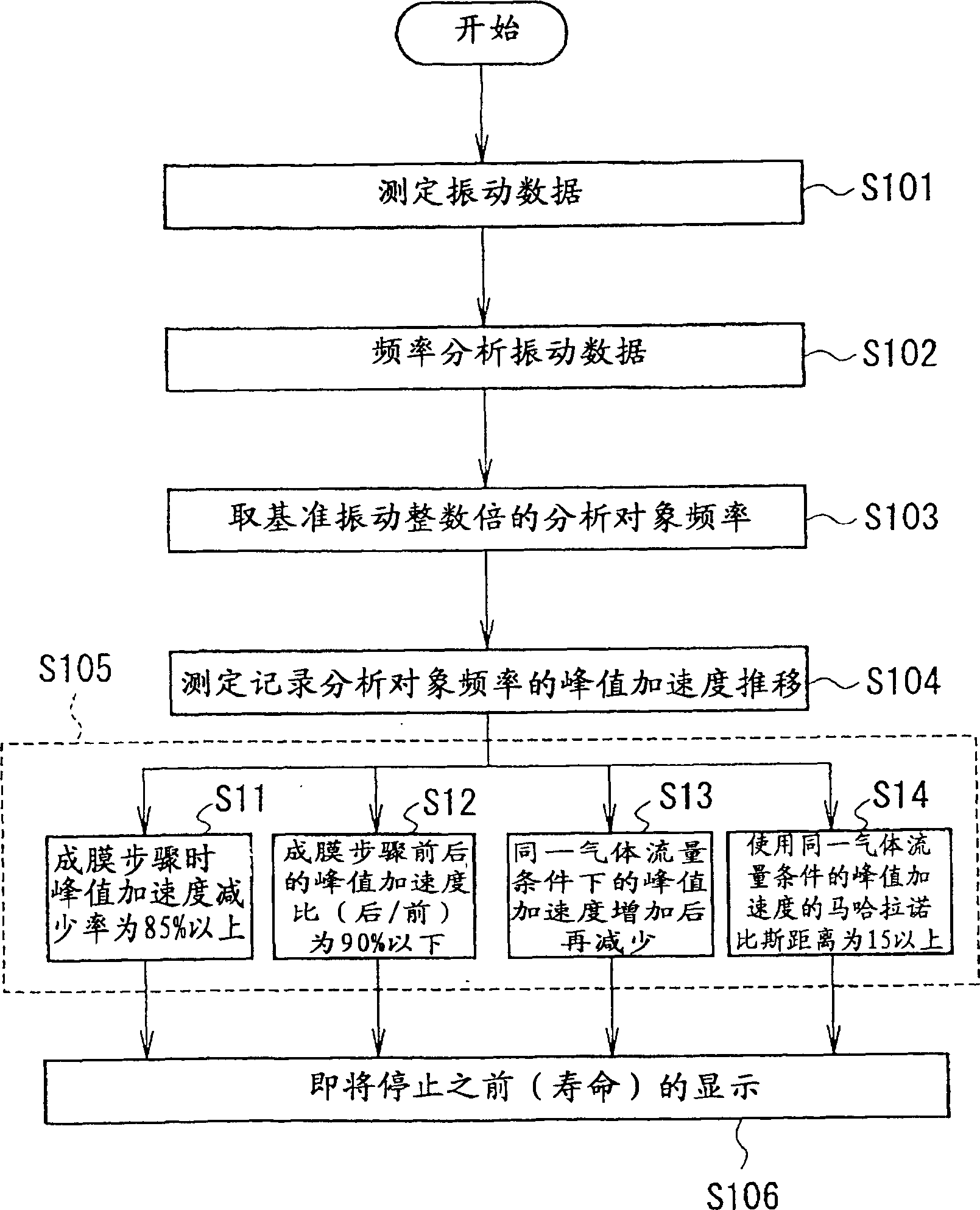

[0049] Next, first to third embodiments of the present invention will be described with reference to the drawings. In the following description of the drawings, the same or similar parts are given the same or similar symbols. However, it should be noted that the drawings are schematic diagrams.

[0050] (first implementation form)

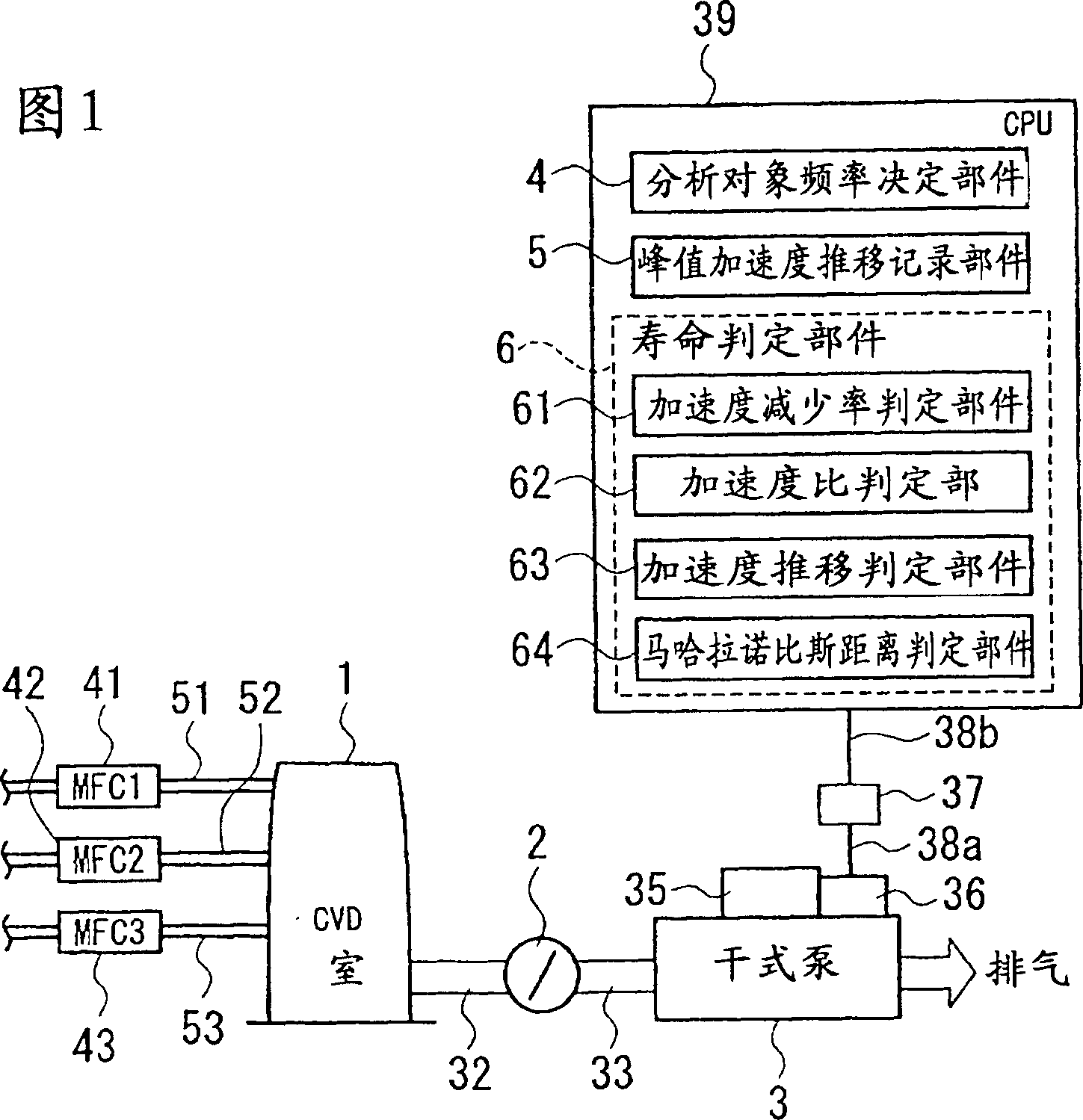

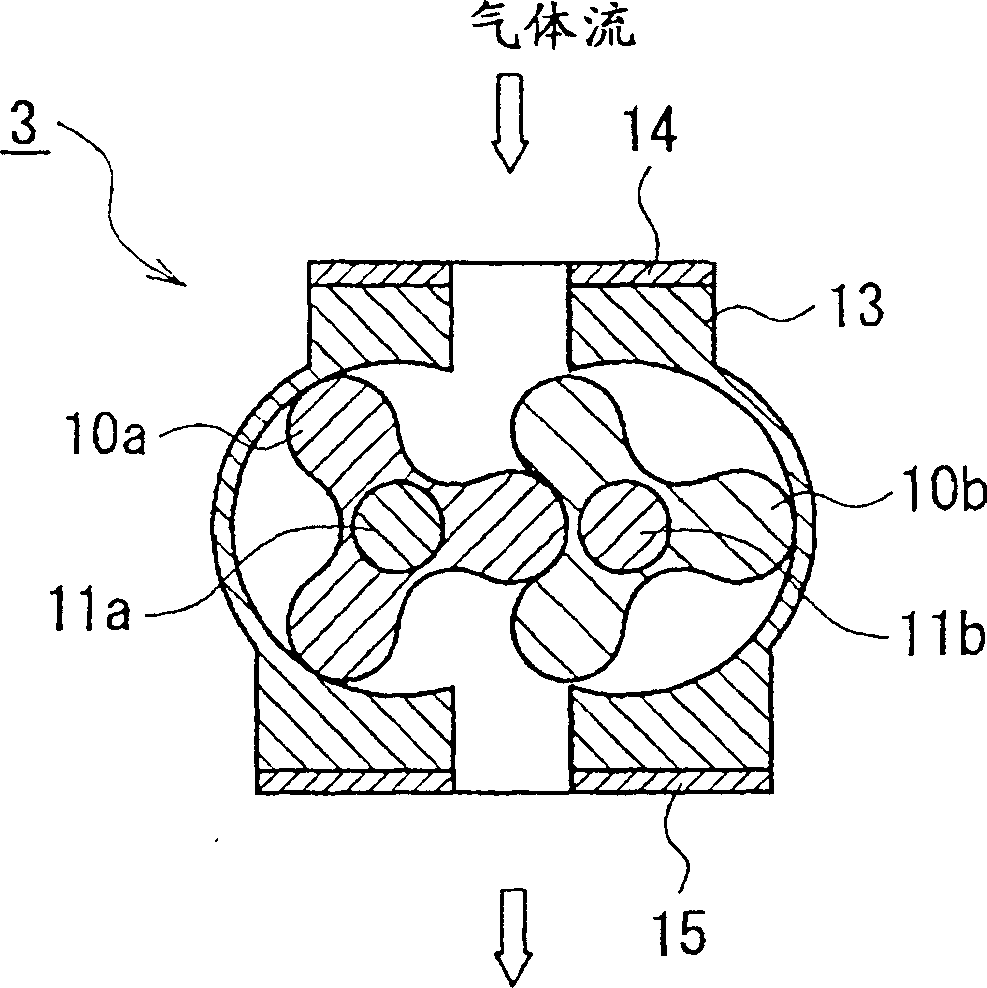

[0051] FIG. 1 is a schematic diagram of an LPCVD apparatus as a semiconductor manufacturing apparatus according to a first embodiment of the present invention. As shown in FIG. 1, this LPCVD apparatus has a CVD chamber 1 having a sealed structure capable of vacuum exhaust. The exhaust side of the CVD chamber 1 is connected to a vacuum pipe 32. The exhaust side of the vacuum pipe 32 is connected to a gate valve 2. The exhaust side of the gate valve 2 is connected to a vacuum pipe 33 , and the exhaust side of the vacuum pipe 33 is connected to a rotary machine 3 (Roots type dry pump) for exhausting the inside of the CVD chamber 1 . The gate valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com