Method and arrangement for defrosting vapor compression system

A compressor and vapor compression technology, applied in the direction of compressors, irreversible cycle compressors, and reversible cycle compressors, etc., can solve the problem of low refrigerant temperature, long defrosting time, and limited transfer to heat accumulators. temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

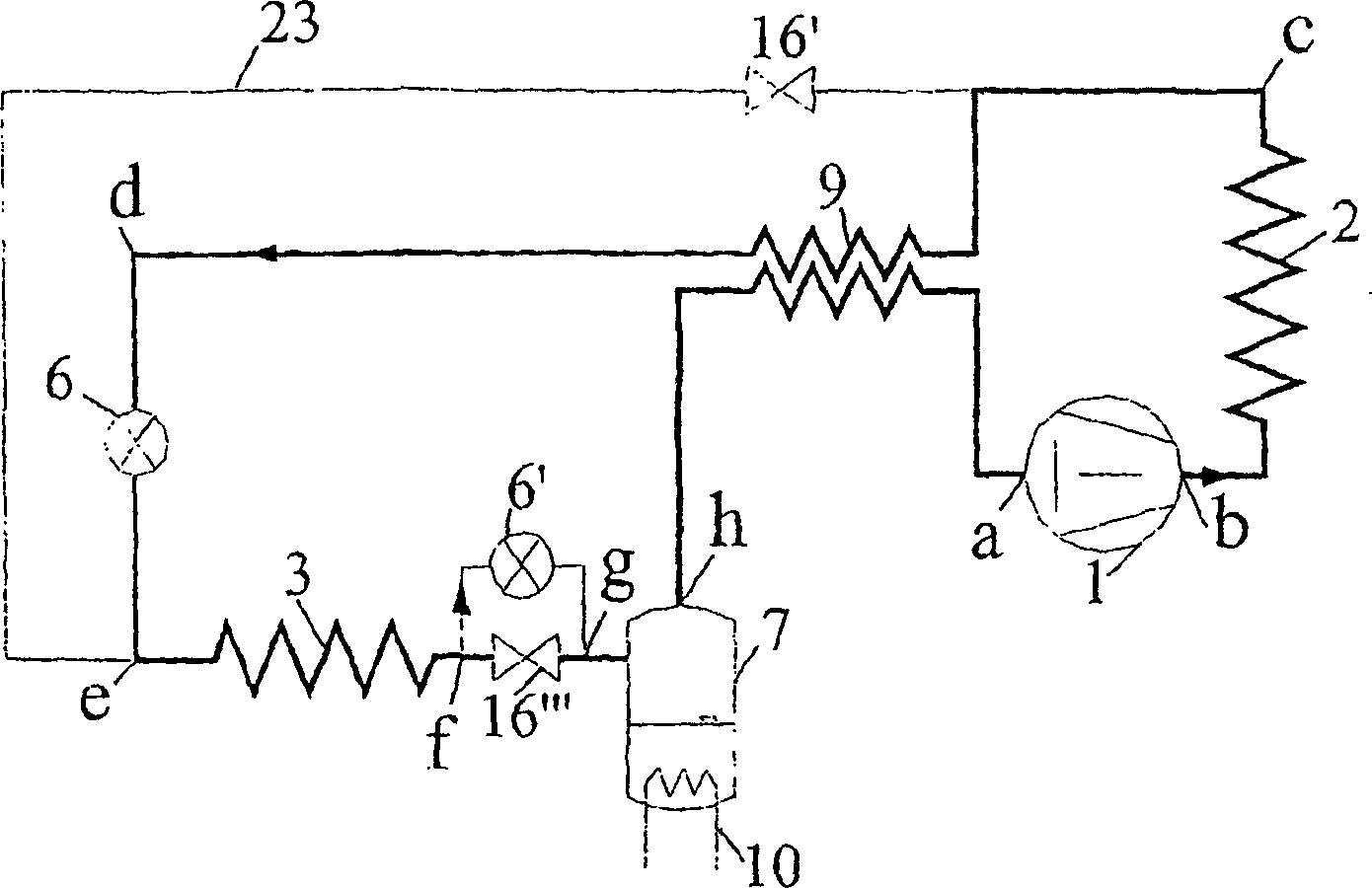

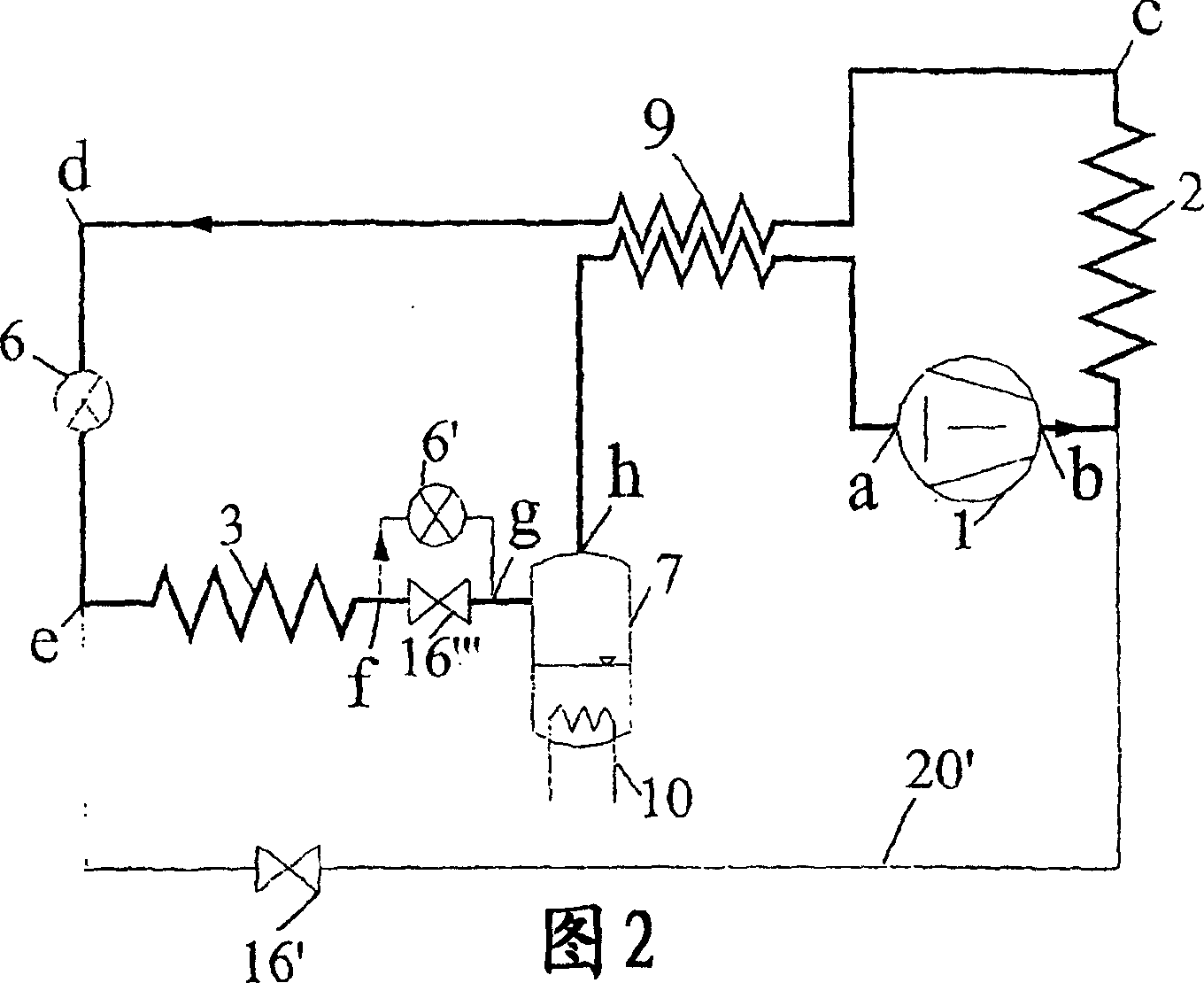

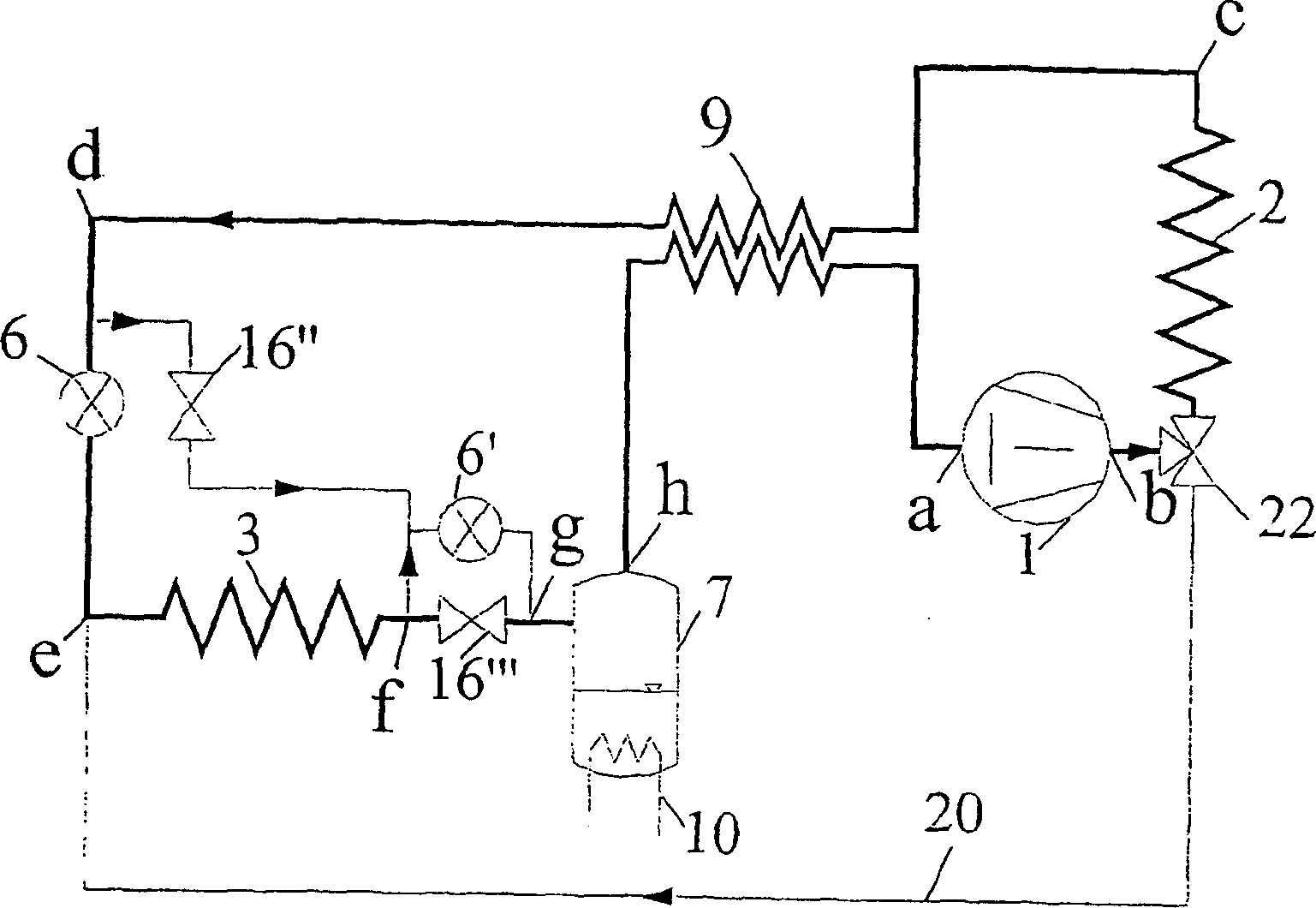

[0016] The present invention relates to refrigeration and heat pump systems, and more particularly to the defrosting of frosted heat exchangers, especially evaporators, in supercritical processes, where the refrigerant can be any fluid, especially carbon dioxide, but the present invention is not limited thereto.

[0017] The invention can be used in any refrigeration and heat pump system which preferably has a pressure receiver / reservoir. If desired, the present invention also vents the internal cooling airflow during the defrost cycle, which is the same as conventional defrost methods in heat pump systems. This can be achieved by an external heat source such as an electrical resistance or waste heat (eg from a car radiator cooling system) or any other suitable device that can be incorporated into the receiver / reservoir, or a connecting pipe along the refrigerant path in the circuit. Heat can also be provided from storage. The invention can be used in both subcritical and su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com