Leather belt for stepless variable speed driving device

A transmission device, continuously variable speed technology, applied in the direction of belt/chain/gear, V-belt, mechanical equipment, etc., can solve the problems of increasing the manufacturing cost of components, noise, power transmission efficiency reduction, etc., and achieve the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

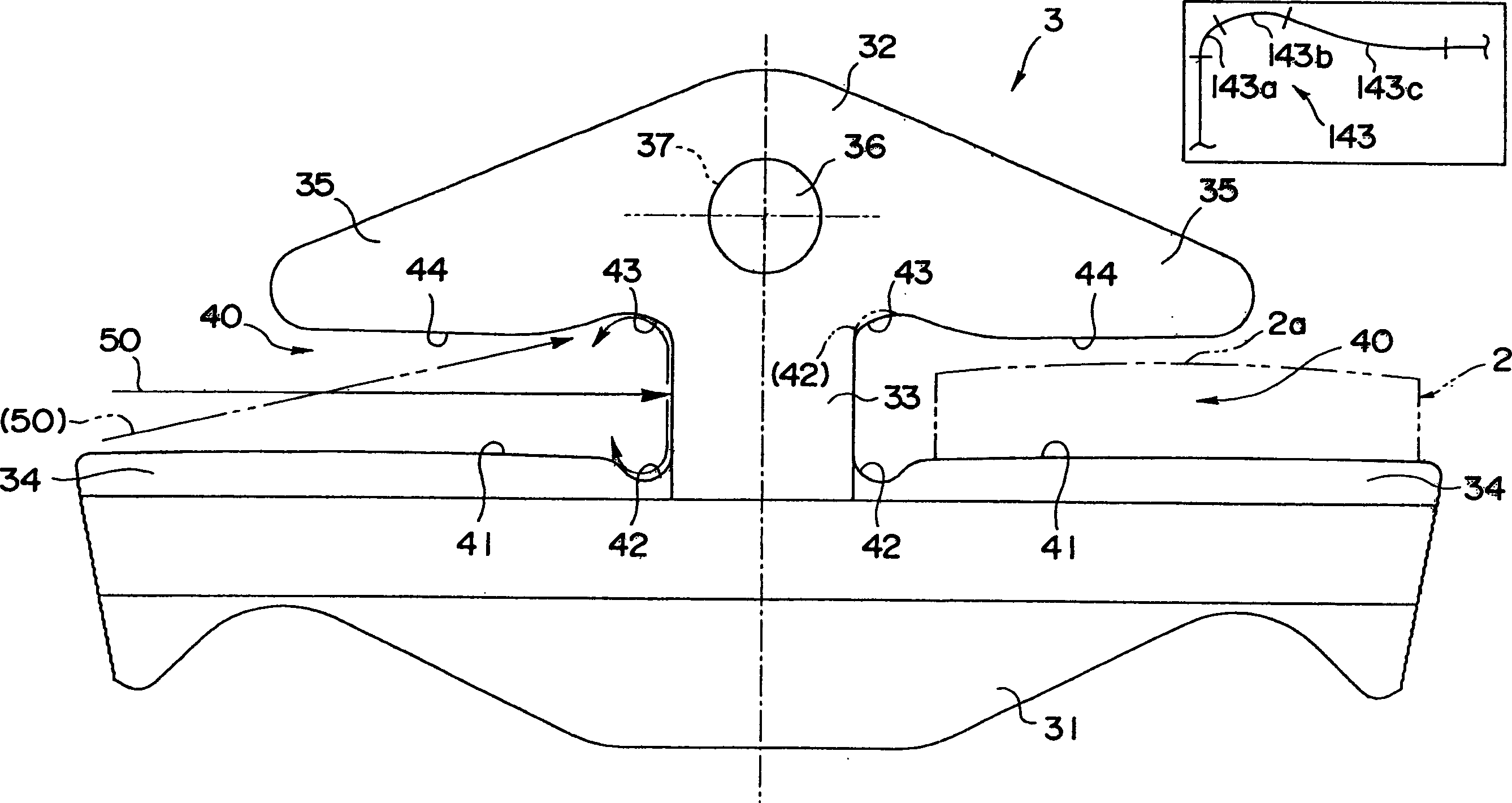

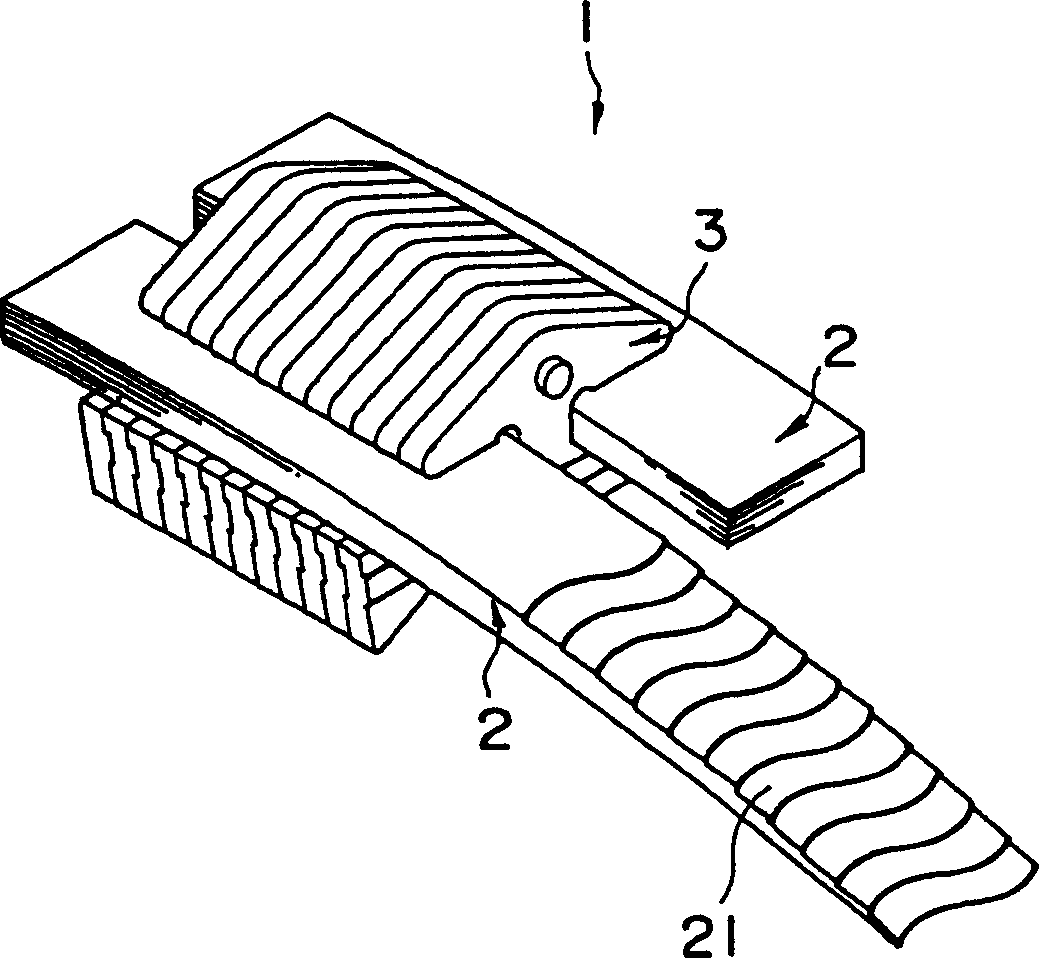

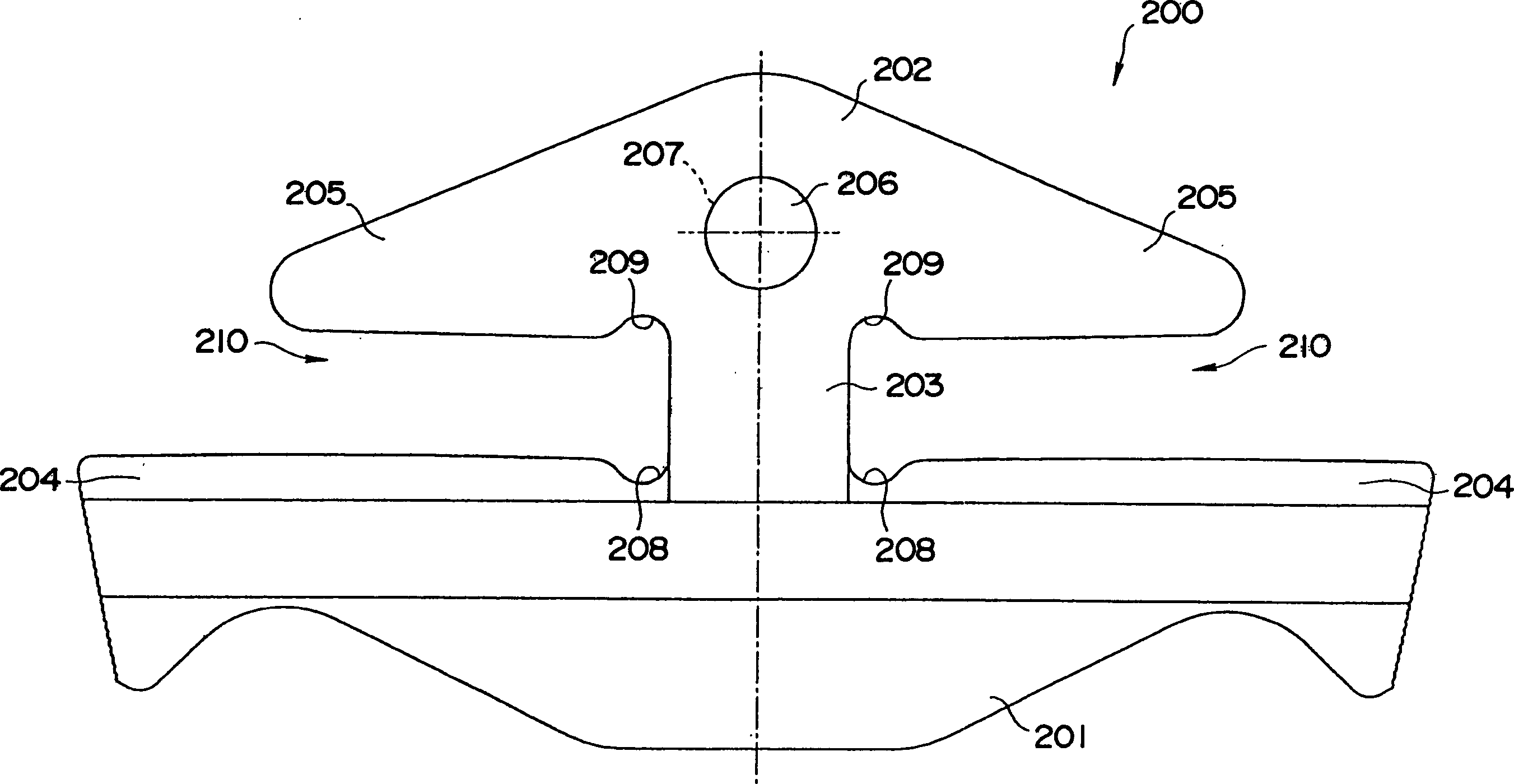

[0022] Now, preferred embodiments of the present invention will be described with reference to the accompanying drawings. figure 2 A belt constituting a continuously variable transmission according to the invention is shown. The belt 1 comprises two endless sheet-shaped endless belts 2 and a plurality of elements 3 arranged slidingly between the endless belts 2 adjacent to each other. Each endless belt 2 comprises a stacked plurality of sheet metal rings 21, which are annular and flexible.

[0023] Such as figure 1 As shown, element 3 includes an integrally formed body portion 31, head 32, and neck 33, which are punched from sheet metal (not shown). The body 31 is in contact with a pulley (not shown) of the continuously variable transmission, the head 32 is located above the body 31 , and the neck 33 connects the body 31 and the head 32 . The width of the neck 33 is smaller than the widths of the head 32 and the body 31 . In addition, a pair of saddles 34 are symmetrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com