Back light module, wire fixing assembling unit and wire fixing seat

A technology of backlight components and fixing seats, which is applied in optics, nonlinear optics, instruments, etc., and can solve problems such as adhesive residue, adhesion influence, and increased rework

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

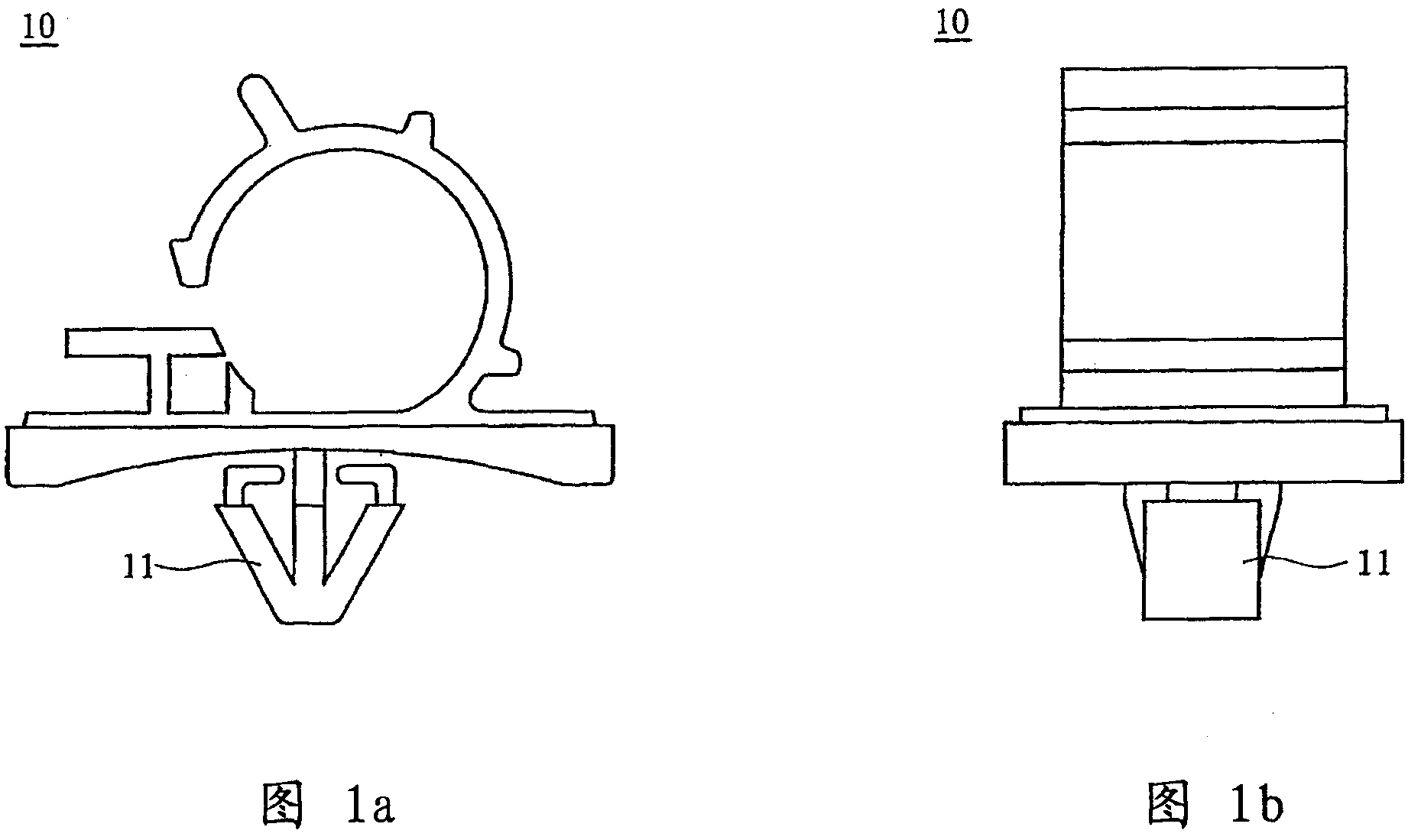

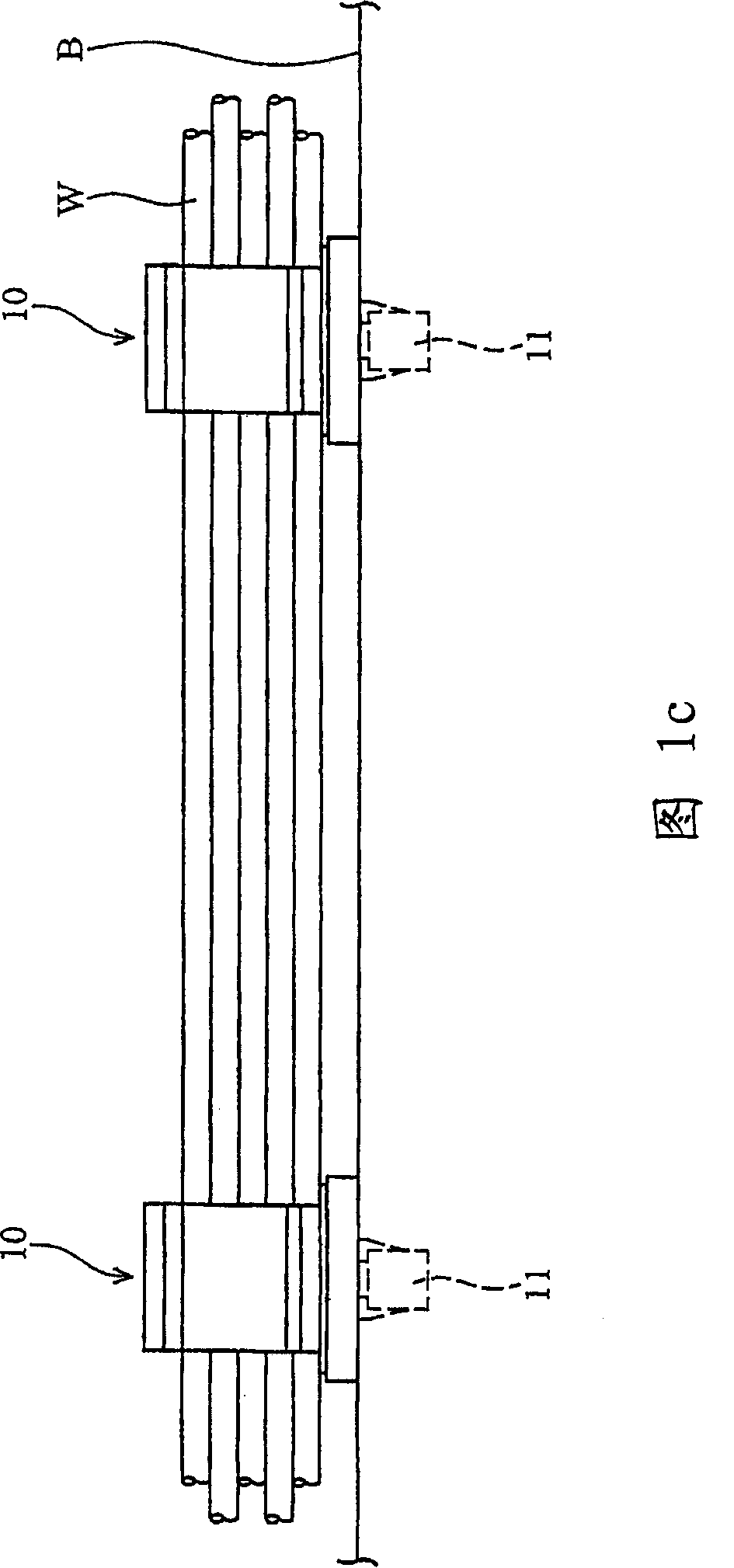

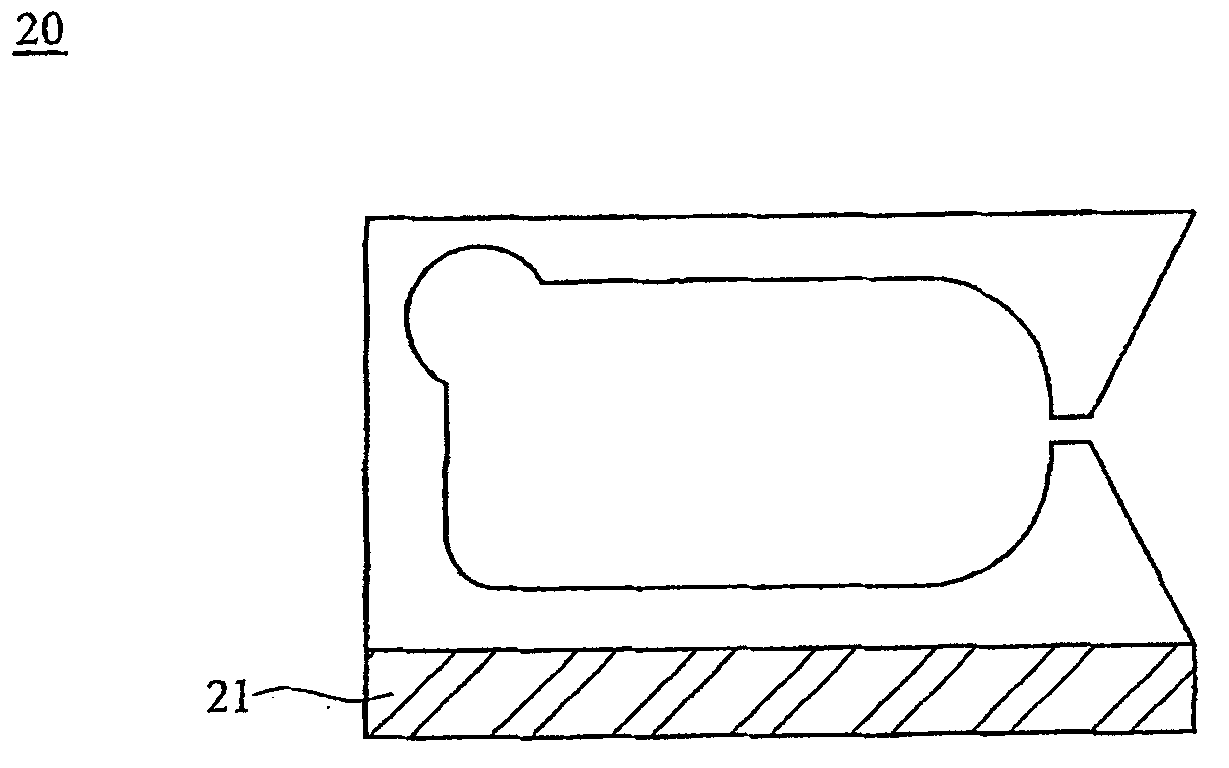

[0041] refer to image 3 , the backlight assembly 100 of the present invention includes a base 110, a plurality of wires 130, and a fixing base 120, wherein the base 110 and the fixing base 120 constitute the wire fixing assembly 200 of the present invention; in addition, it should be understood that although the In this embodiment, the backlight assembly is used for illustration, but the components such as the wire fixing assembly 200 and the fixing seat 120 can also be applied to other electronic devices that have wires that need to be fixed.

[0042] The base 110 can be a bottom plate of the backlight assembly 100, which has an outwardly facing surface 111, and a protrusion 112 is formed on the surface 111, and a perforation 113 is formed between the protrusion 112 and the surface 111; it should be understood that For the convenience of explanation, in image 3 In the figure, only one protruding portion 112 is shown, but in actual situations, the number of protruding porti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com