Chocolate flavor manipulation

A chocolate, flavor technology, applied in cocoa, food science, applications, etc., can solve problems such as significant differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation of cocoa shell gum extracts can be accomplished using standard methods for extracting gums.

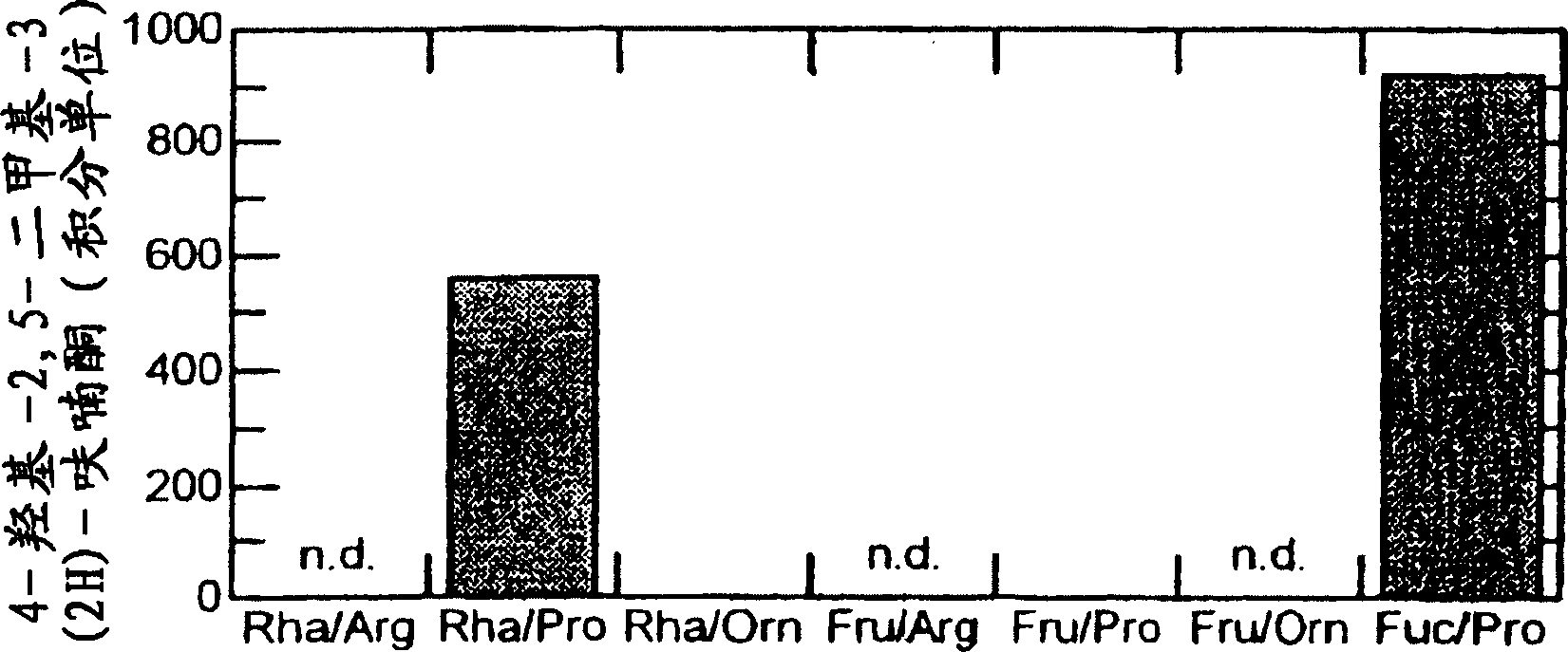

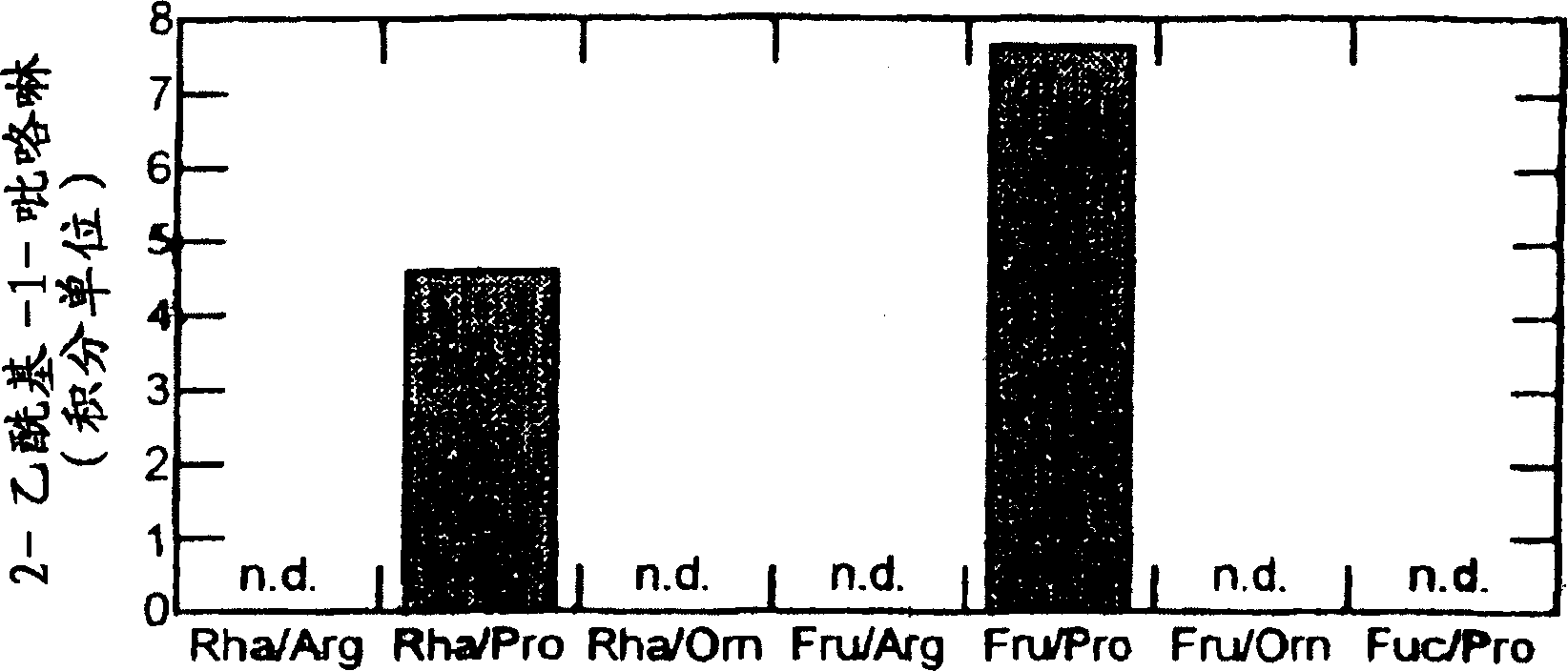

[0034] The hydrolysis of cocoa shell gum extract can be achieved by chemical degradation and / or enzymatic degradation. The following enzymes and chemicals are preferably employed: acetic acid, hydrochloric acid, pectinases (such as polygalacturonase, rhamnoglucoside, pectinase, arabinase, galactanase )) in combination with esterases such as rhamnogalactoacetylesterase or in combination with exoglycosidases such as β-galactosidase, arabinofuranosidase and fucosidase. These enzyme mixtures can be found in commercial enzyme preparations obtained by fermentation of microorganisms in suitable complex media.

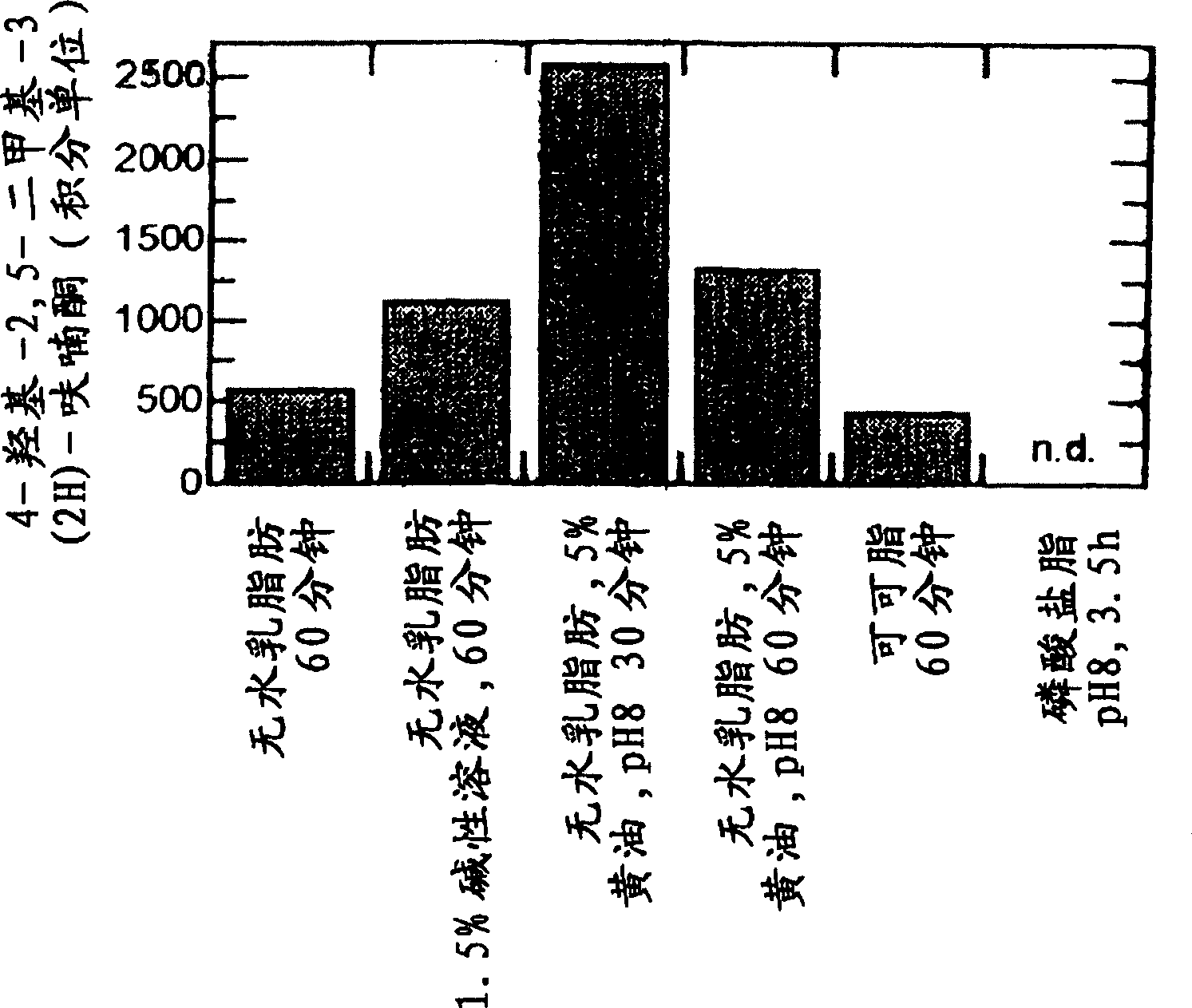

[0035] Any suitable reaction medium for the preparation of flavors may be employed including aqueous solutions, ethanol, propylene glycol, glycerol or fat based media such as anhydrous milk fat, cocoa butter, cocoa mass, complex fats, lipase hydrolyzed milk fat...

Embodiment 1

[0051] The flavor reaction is carried out in a three-neck stirred reactor with a round bottom and a temperature control device. Anhydrous milk fat (80 g) was melted and heated to 125°C in a reactor. When the temperature of the milk fat rises to 125° C., the flavor precursors rhamnose 50 mM and proline 50 mM are directly added to the reactor together with the milk fat, or the flavor precursors are added separately. Rhamnose and proline were reacted in milk fat at 125°C under reflux for 60 minutes. The reacted material was cooled to room temperature and stored at 4°C or room temperature. Flavoring was added to the mass at 0.5%.

[0052] Add to the compound:

[0053] 1 gram of reactive flavor was added to 199 grams of fully molten compound mass, they were mixed thoroughly by hand, and cast into 20 gram sticks. After cooling, the sticks were unmoulded and allowed to equilibrate to room temperature for at least 4 hours. Samples were equilibrated at 15°C for at least 1-30 days ...

Embodiment 2

[0059] The flavor reaction was carried out according to Example 1, except that 1.5% alkaline water was added together with rhamnose and proline (Stock solution: 4 drops of 50% NaOH in 20 ml of water). This approach facilitates reactions at alkaline pH conditions and enhances the solubility of the precursors. As described in Example 1, 0.5% fat-based flavors were added to chocolate to produce characteristics such as caramel, biscuit and cookie. The caramel flavor is strongest after 30 minutes of reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com