Engine casing and printer with locking mechanism

A technology for locking devices, printers, applied in the directions of printing devices, printing, typewriters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0104] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

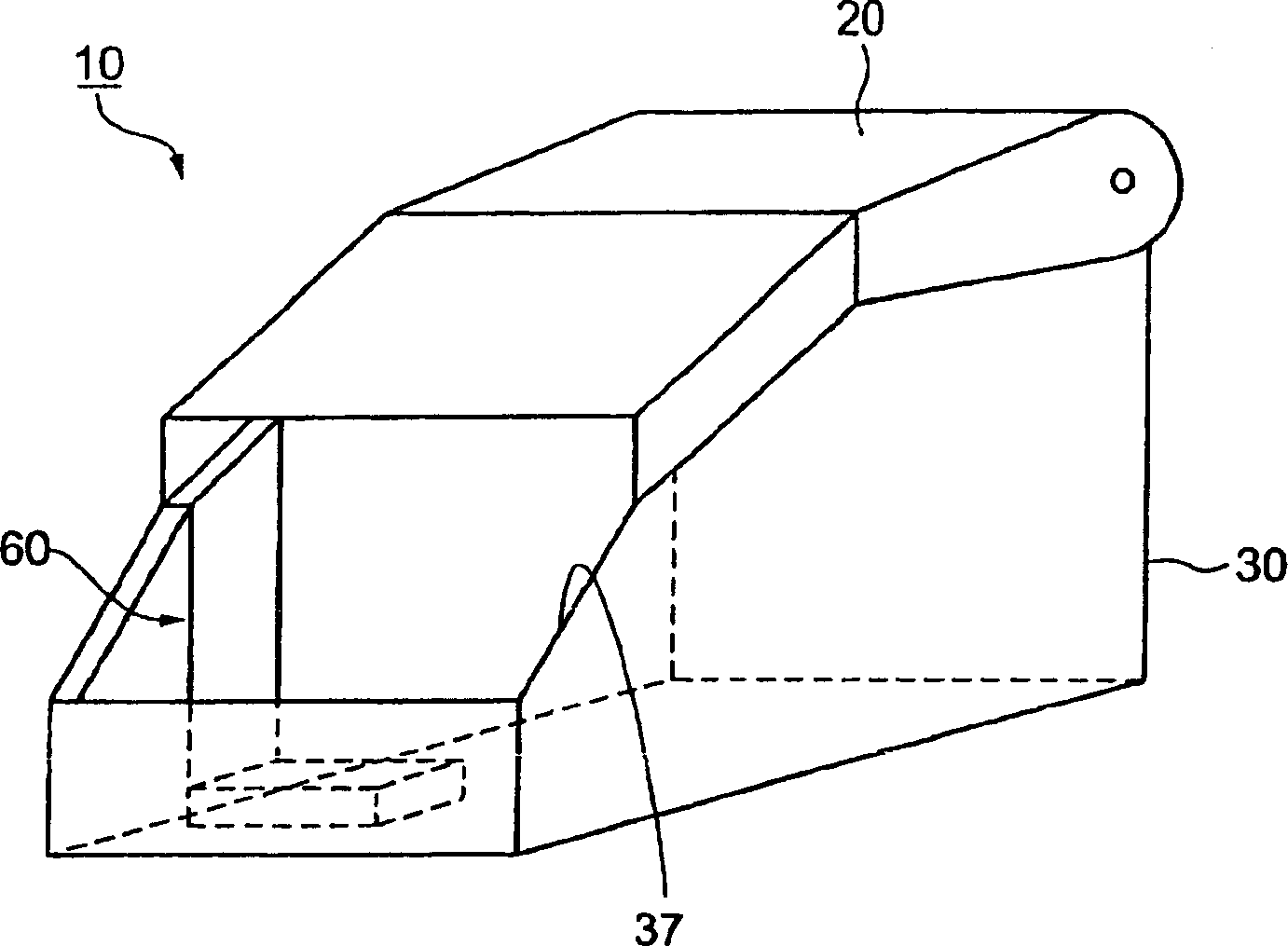

[0105] Such as figure 1 As shown, the casing 10 according to the first embodiment comprises a housing unit 30 having an opening 37 and capable of containing contents, a cover 20 connected thereto in an openable manner capable of at least partially covering the opening 37, and connecting the cover 20 and the case The body units 30 are mutually locked by the locking means 60 in the closed state. When locked after the cover 20 is closed, the locking device 60 confines the contents within the housing unit 30 . The locking device 60 is unlocked by an electric signal.

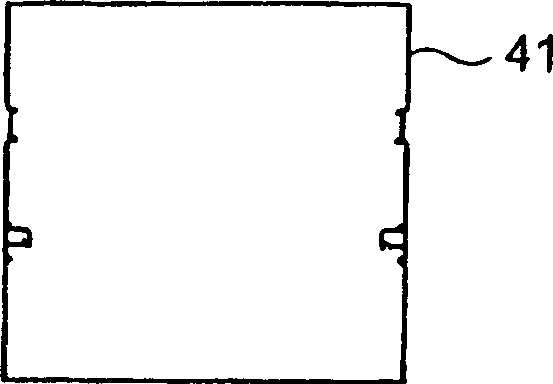

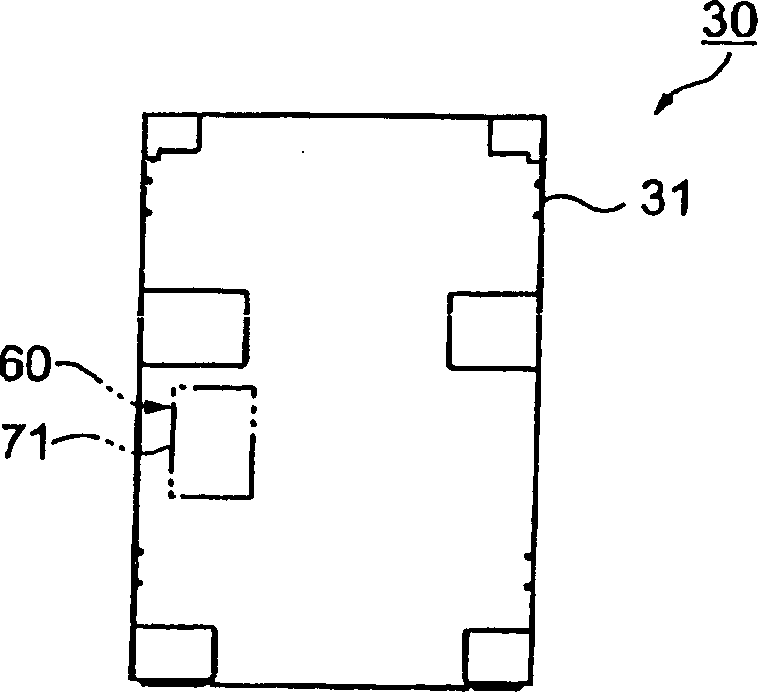

[0106] Such as Figure 2A As shown in FIG. 2C , the housing unit 30 includes a bottom panel 31 , a rear panel 41 and a side panel 51 . The locking device 60 includes a locking member 61 and an electromagnetic actuator 71 operated by an electric signal. The locking part 61 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com