Label and RFID tag issuing apparatus

一种RFID标签、设备的技术,应用在同时进行数据标记和打印、通过打印代码标记数字方式标记、数字标记记录载体等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

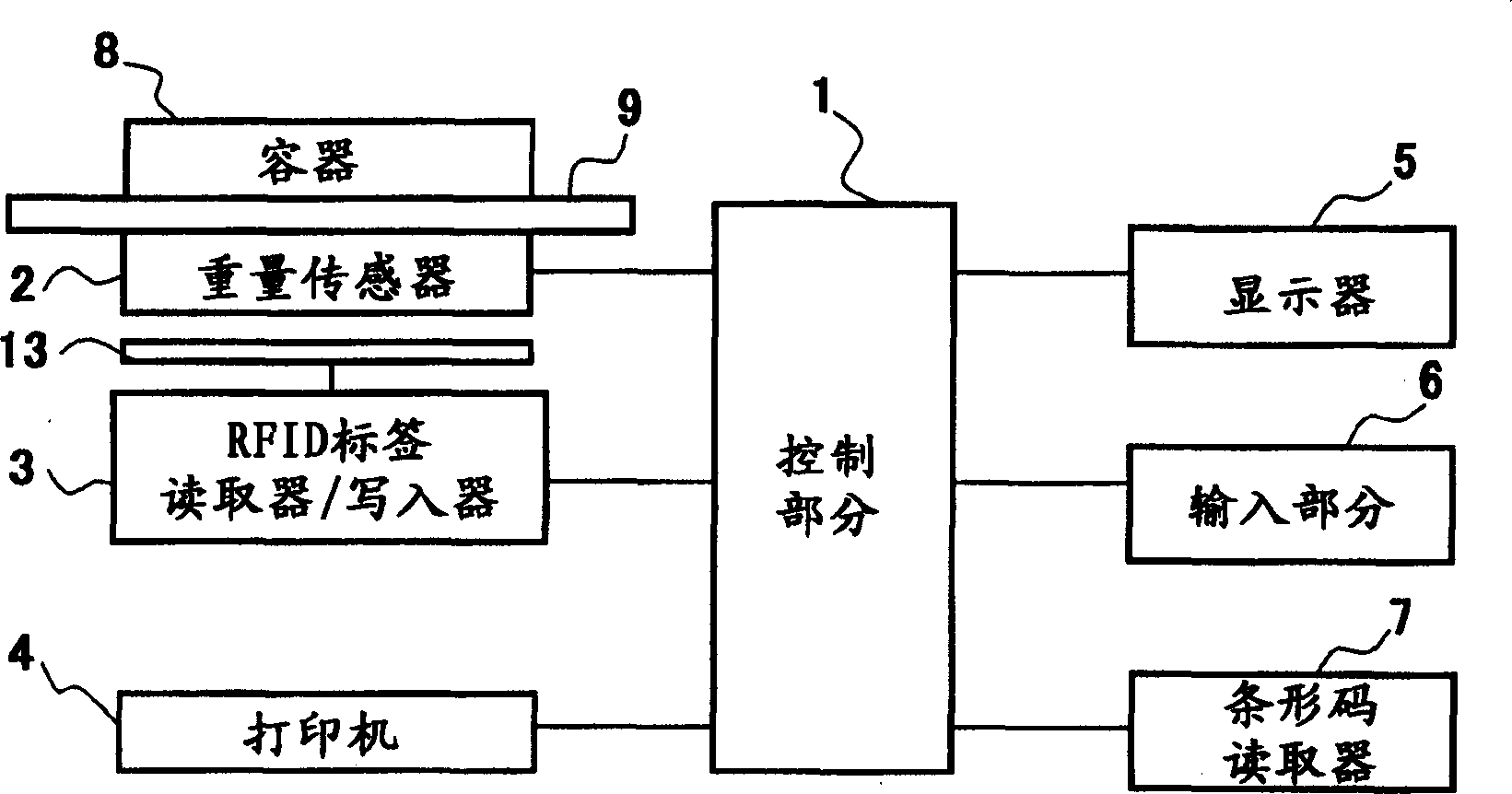

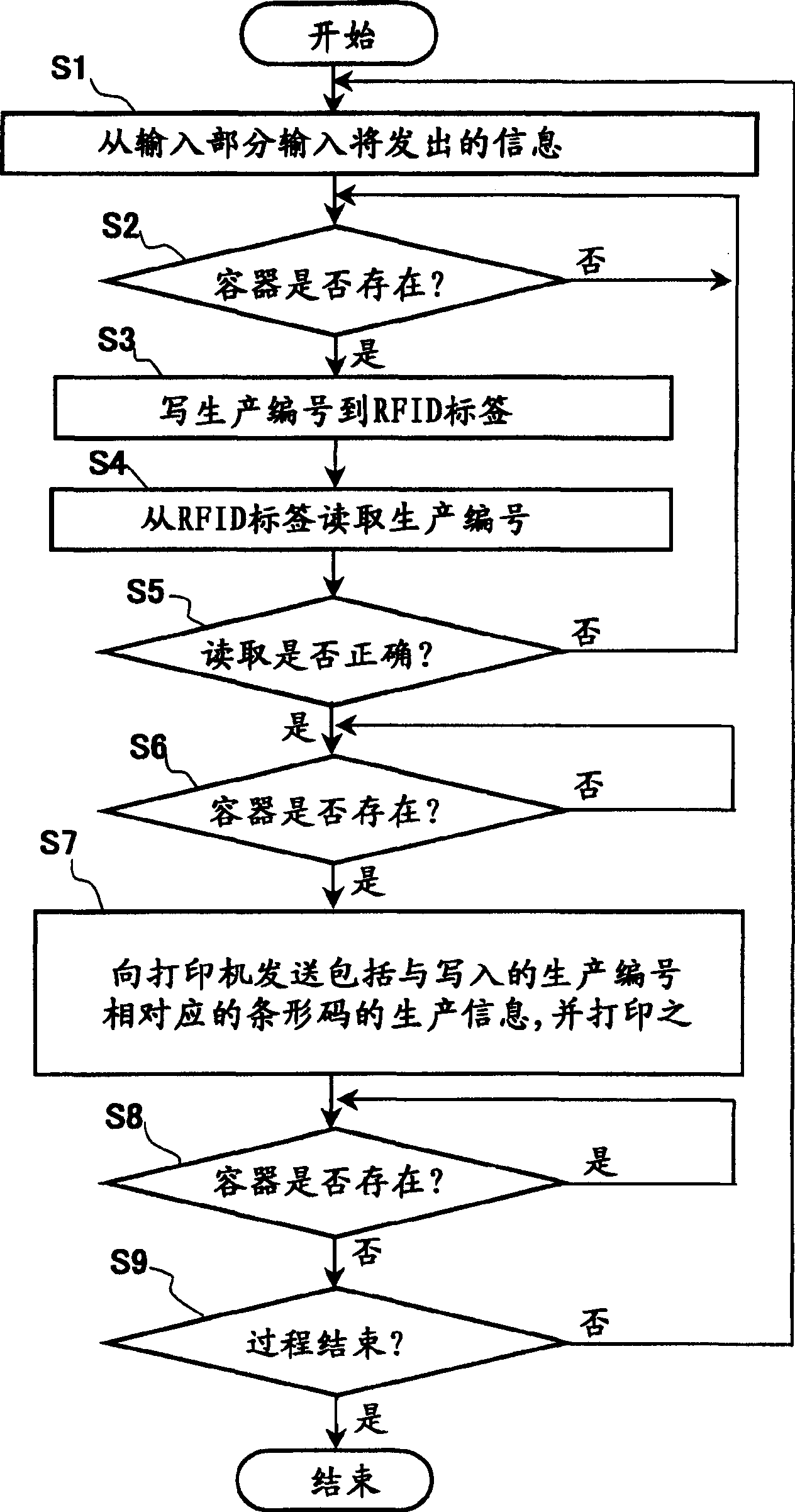

[0015] Such as figure 1 As shown, the marking and RFID label issuing apparatus according to the first embodiment includes a control section 1, a weight sensor 2 connected to the control section 1, an RFID label reader / writer 3, a printer 4, a display 5, an input section 6 and a barcode reader 7 . The weight sensor 2 detects the container 1 placed on the container stage 9 . The barcode reader 7 is of a handy type, which facilitates handling during production. The control part 1 is a control device composed of a microprocessor, memory and other devices, and outputs recording data to the printer 4 according to the program control, thereby outputting information to be displayed to the display 5, inputting input data from the input part 6, and reading from the barcode. Getter 7 inputs barcode data. The printer 4 may be any thermal printer, inkjet printer, dot matrix printer, etc.

[0016] When the marking and RFID tag issuing equipment is used in the process of manufacturing it...

no. 2 example

[0029] Figure 4 A tagging and RFID tag issuing device is shown using an optical sensor 14 as detection means. The structure of this embodiment is the same as that of the first embodiment except for the optical sensor 14 .

[0030] For the optical sensor, a reflection type sensor including a combination of a light emitting element and a photo acceptance element is used. When the container 8 is placed on the container stage 9, the optical sensor detects the presence of the container 8 on the container stage 9 through the output of the photoreceiving element, which receives the light emitted from the light emitting element and reflected from the container 8. of light. Thus, the same effect can be obtained by using an optical sensor as the detection means.

[0031] Although the above description has been made for the structure using the weight sensor and the optical sensor, the present invention is not limited to the described manner. It is also possible to make the RFID tag ...

no. 3 example

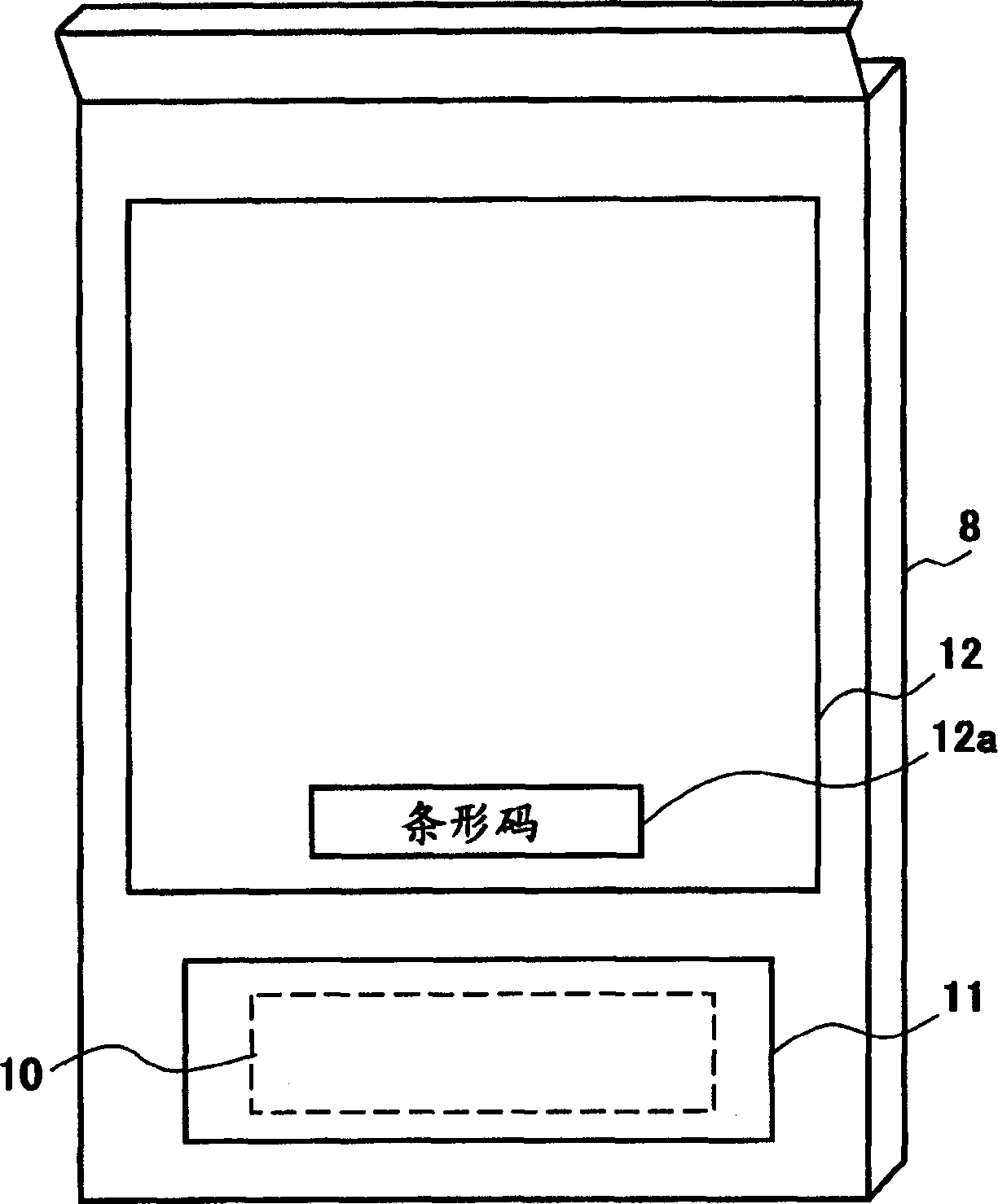

[0033] The structure of the marking and RFID tag issuing device according to the third embodiment is as follows figure 1 shown. Wherein the used container 8 carries the recording paper 12 and the RFID label 10 that have recorded the bar code, as figure 2 shown. The controller 1 executes the issuing process according to the process shown in FIG. 5 . That is, when the information to be dispensed is obtained from the input section 6 in step S11, the presence of the container 8 on the container stage 9 is judged by the output of the weight sensor in step S12.

[0034] After confirming the existence of the container 8, the controller 1 causes the printer 4 to print the production information including the barcode corresponding to the production number on the recording paper 12 at step S13. First, the recording paper 12 is issued, and then, in step S14, the barcode reader 7 reads the barcode 12a recorded on the issued recording paper 12. At this time, the controller 1 causes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com