Fastening system for assembling structure

A combination and joint structure technology, applied in the direction of connecting components, detachable tables, folding tables, etc., can solve the problems of instability, insufficient rigidity of stability, and waste of time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

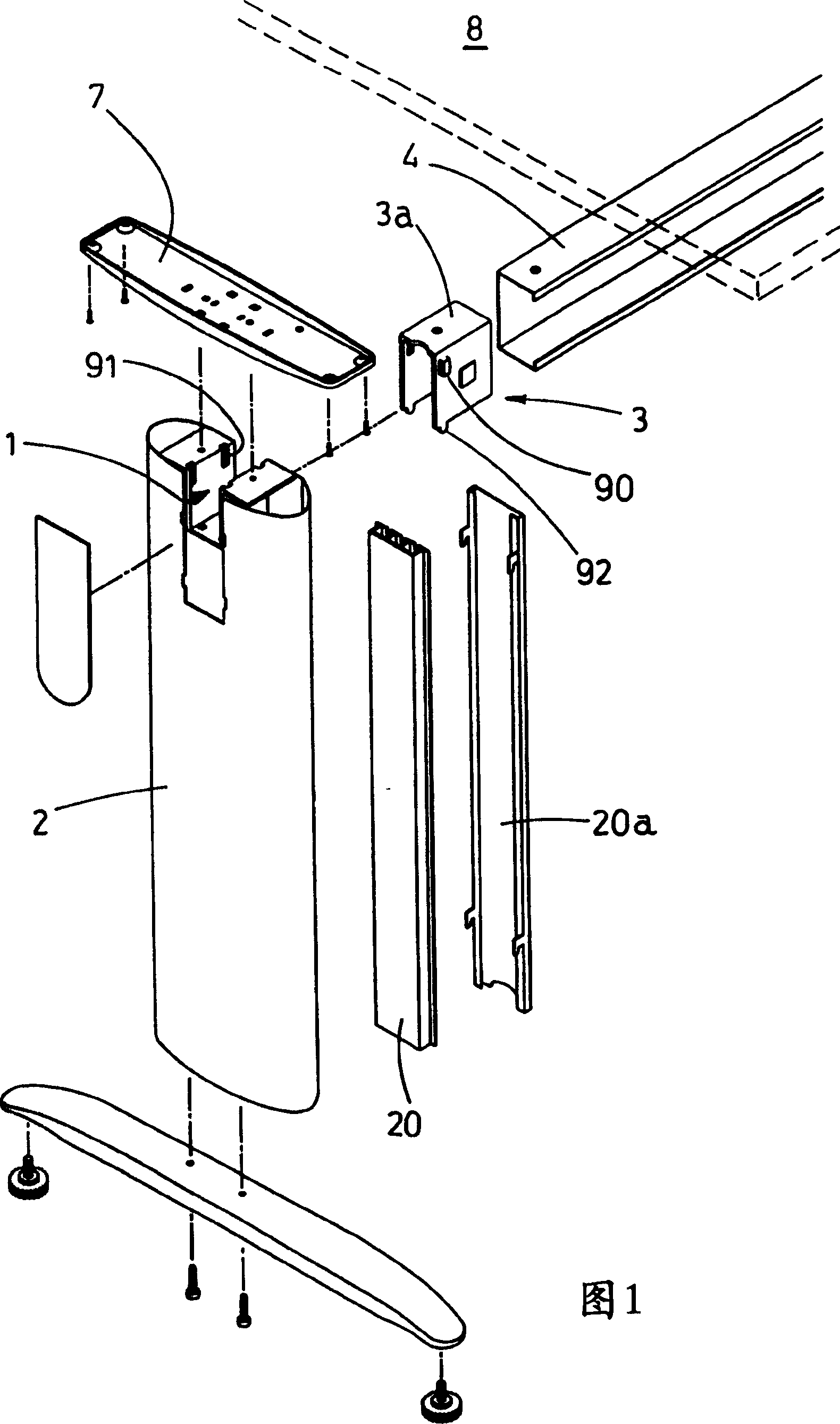

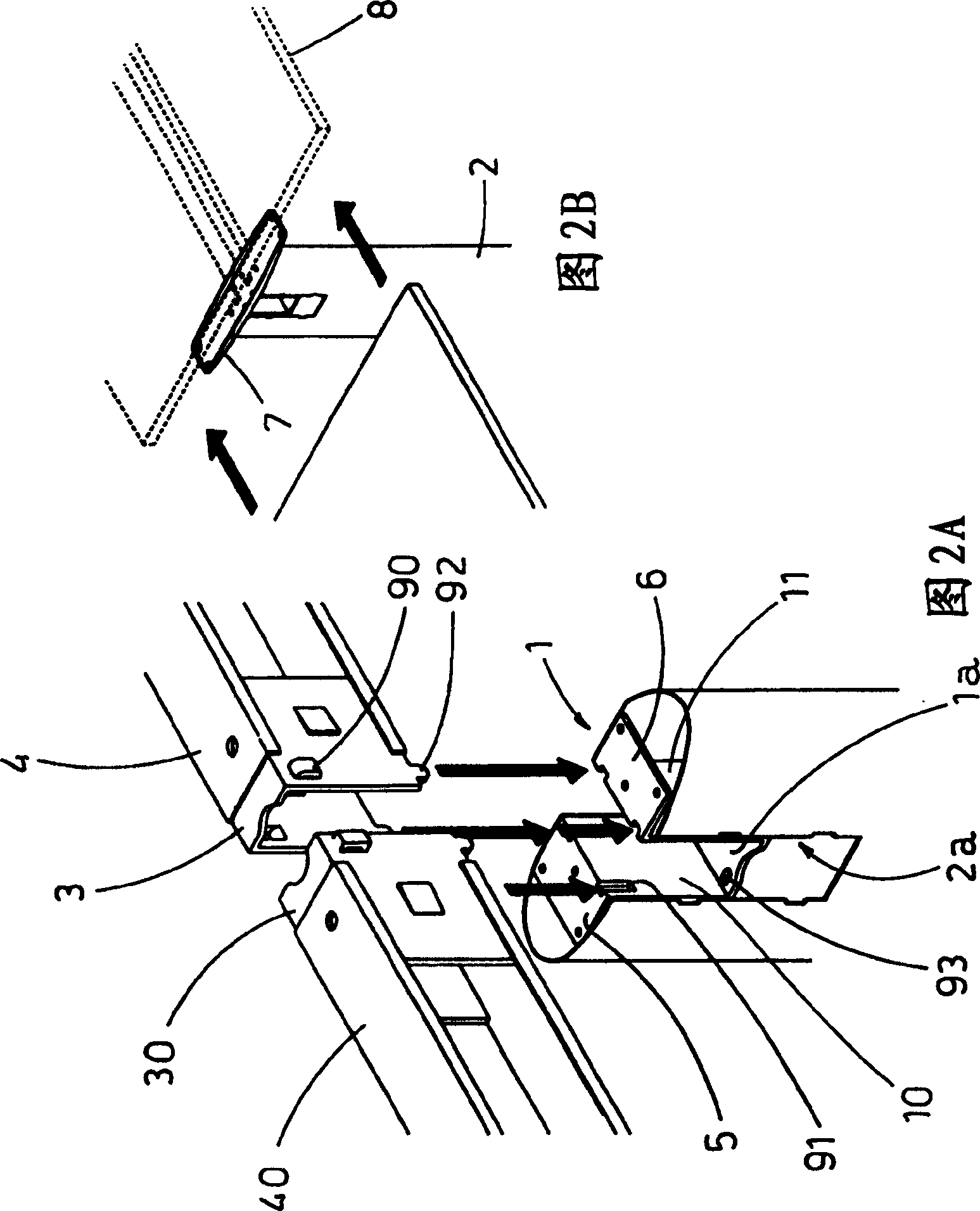

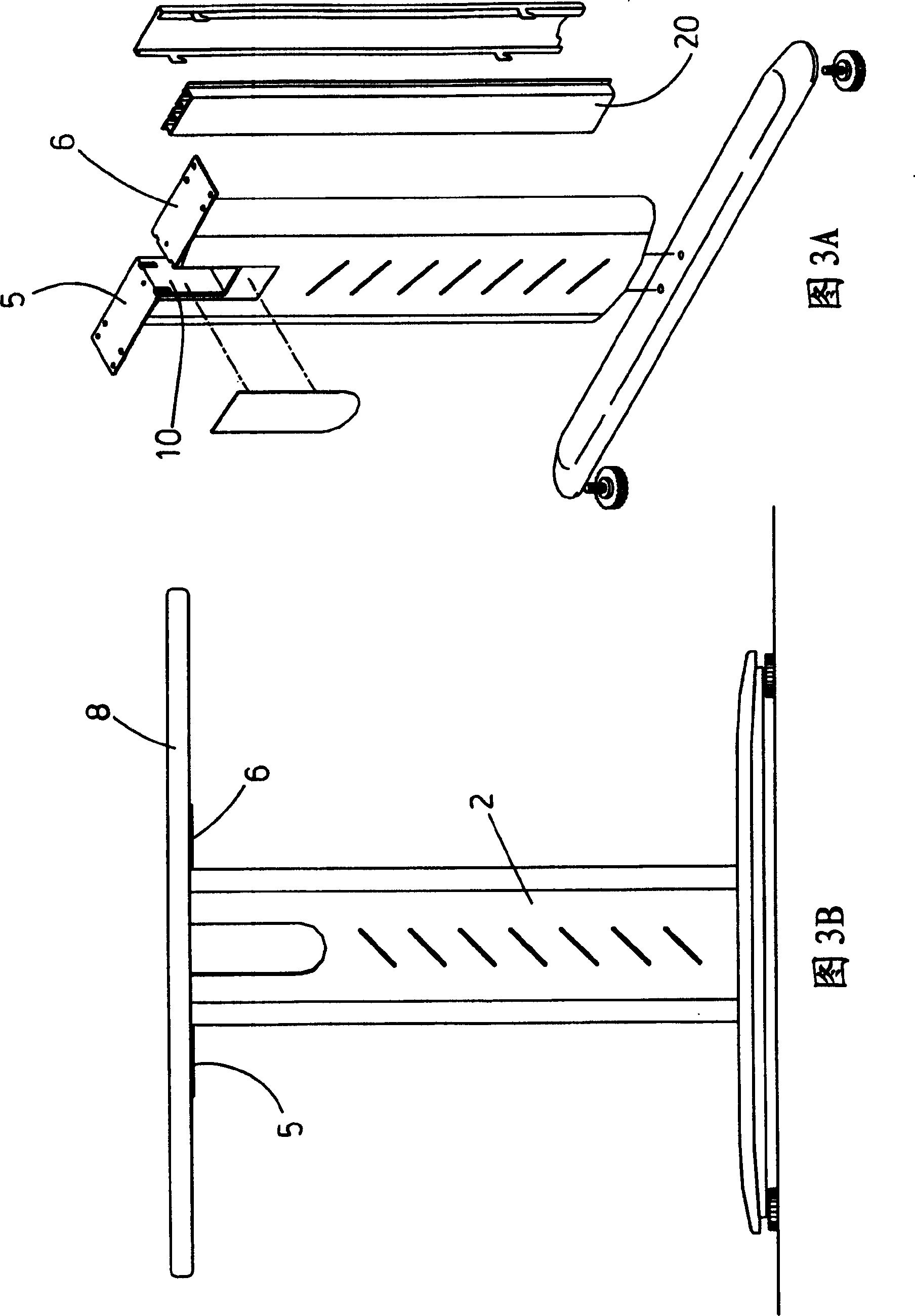

[0019] With regard to the above-mentioned figures, the general reference numeral 1 designates the proposed fastening system support element for modular structures, which cooperates with at least one first composite element 2, such as a column. The uprights 2 are formed of profiled sheet metal with vertical mating edges closed longitudinally by strips 20, which advantageously have some grooves accessible from the outside for cable channels ( figure 1 ).

[0020] A protective panel 20a is secured to the strip 20 to close the gutter.

[0021] The upper end of the upright 2 has a recess 2a which accommodates the support element 1 immovably, preferably by welding.

[0022] The support element 1 is advantageously constructed in such a way that it defines a base 1a from which extends a pair of vertical wings 10, 11, on top of which there are horizontal wings 5, 6 facing each other and carrying at least A working plane 8. It is advantageous that the vertical wings 10, 11, the horiz...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap